Protection agent applied to feeding enterococcus faecium freeze-drying preparation and preparation method of protection agent

A technology of Enterococcus faecium and protective agent, applied in the field of microorganisms, can solve the problems of strict storage conditions of freeze-dried preparations, less research and application, and few Lactococcus to develop excellent freeze-dried preparations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

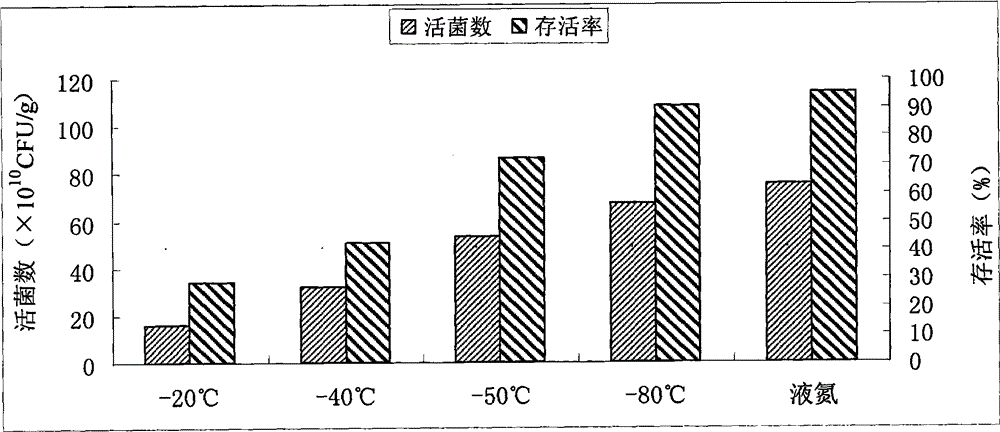

[0025] Embodiment 1, the single factor optimization experiment of protective agent composition

[0026] 1. Selection and preparation of protective agent components:

[0027] Prepare 7% skimmed milk powder solution, 1% maltodextrin, galacto-oligosaccharide, sucrose, lactose, trehalose, maltose and glycerin solution, 0.1% sodium glutamate, glycine and lysine solution , 2% sorbitol and mannitol solution, after sterilization, carry out single factor test (wherein the amino acid protective agent is sterilized by filtration, and the sterilization condition of other protective agents is 115°C, 20min).

[0028] 2. Collection of bacteria slime:

[0029] High-density fermented Enterococcus faecium (Enterococcus faecium) WEI-10 CGMCC No.7746 fermentation broth was centrifuged at 10,000-15,000 rpm to collect the sludge through a tubular centrifuge, and the centrifugation rate was controlled at 40-60 L / h.

[0030] 3. Take 30mL of the sterilized protective agent solution above and 6g of E...

Embodiment 2

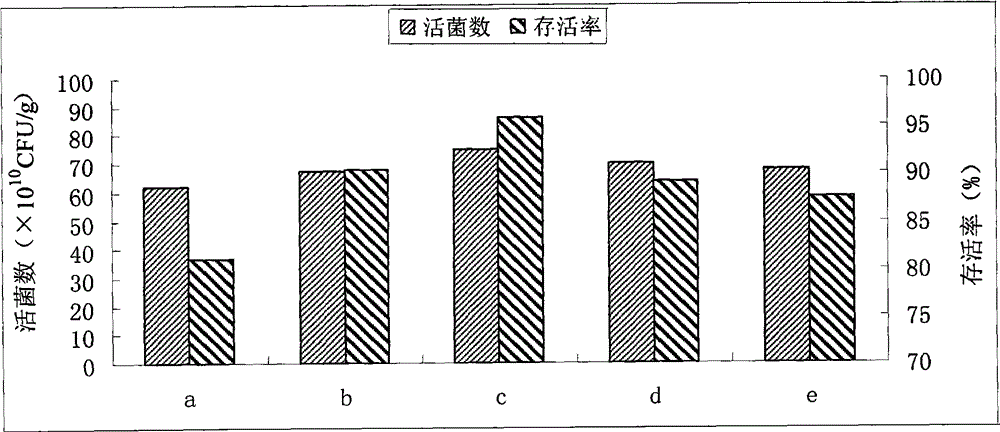

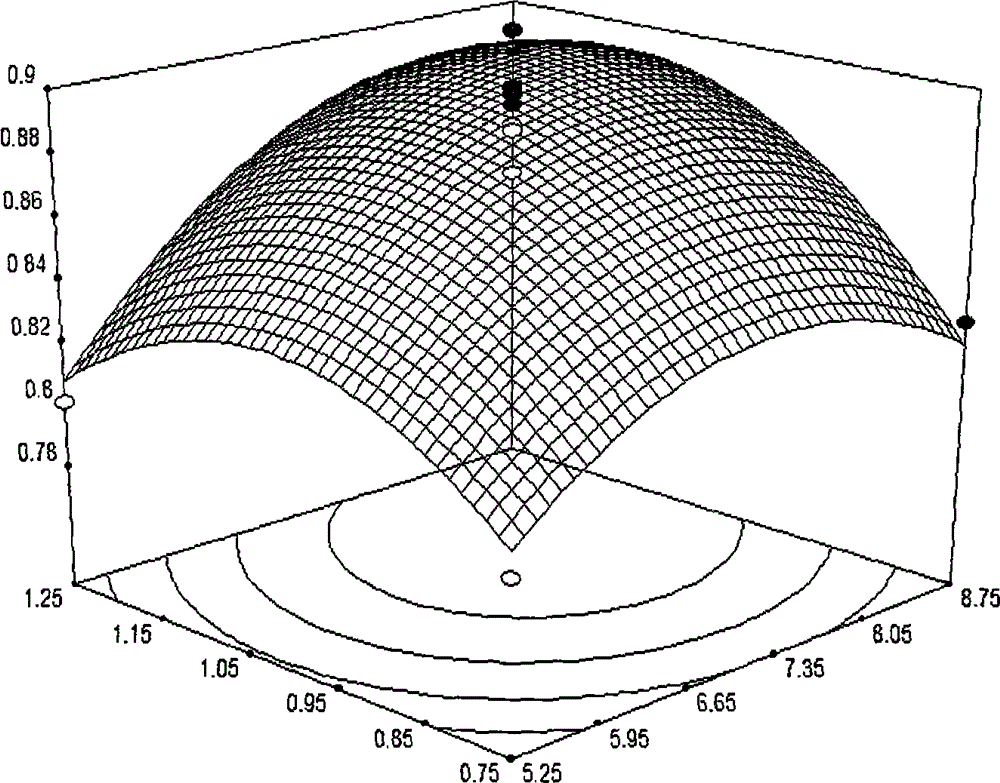

[0038] Example 2. Response Surface Optimization Experiment of Protective Agent Components

[0039] Response surface test design can integrate the interaction between multiple factors in the test results, and use statistical software to fit the quadratic function model equation to find the best optimization plan. 46 groups of experiments with 5 factors and 3 levels were designed by Box-Behnken design method, with concentration of 5 significant influencing factors as independent variable and survival rate as response value. According to the single factor test results, the coding levels of the 5 factors are shown in Table 2. The Box-Behnken test design and results of 46 groups of 5 factors and 3 levels are shown in Table 3, among which 40 groups of tests are factorial points, and the remaining 6 groups of tests are zero points. The independent variable takes the center point, which is used to estimate the experimental error. The collection of bacteria slime, mixing with differen...

Embodiment 3

[0057] Embodiment 3, the influence of different mixing ratios of protective agent and bacteria slime on freeze-drying effect

[0058] 1. According to the optimal protective agent formula, mix the bacteria sludge collected after fermentation and the protective agent according to the ratio (W / V) of 1:1, 1:3, 1:5, 1:10, and 1:20, respectively. Homogenize for 5 minutes at 2800rpm in a homogenizer.

[0059] 2. Take 36g of bacterial suspension and place them on stainless steel trays, pre-freeze at -80°C for 5 hours, then put them into a freeze dryer at -40°C for vacuum freeze-drying, and the freeze-drying time is 44 hours.

[0060] 3. After the freeze-dried solid was pulverized, the viable bacteria were counted, and the survival rate was calculated according to the method in Example 1.

[0061] 4. Analysis of results: by image 3 The results showed that when the ratio of the sludge to the protective agent was 1:3 and 1:5, the survival rate of about 90% could be obtained, which was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Survival rate | aaaaa | aaaaa |

| Survival rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com