Bracket-free packaged LED light source and preparation method thereof

An LED light source, no bracket technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of increased bracket cost, poor sealing, poor glue bonding, etc., to save costs, improve sealing, and reduce machine labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention is further described below in conjunction with accompanying drawing and embodiment:

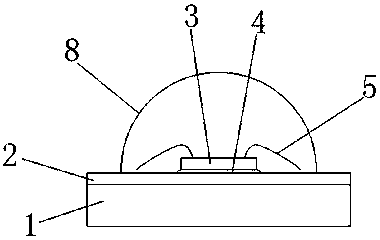

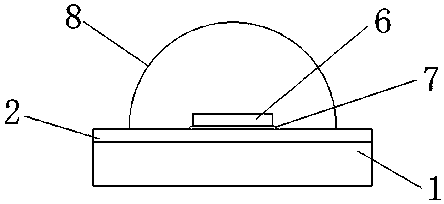

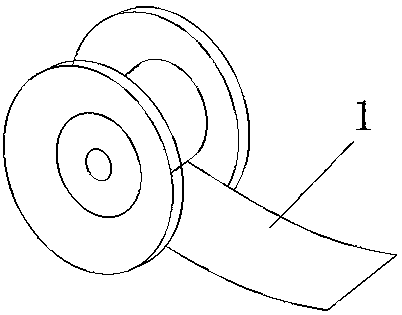

[0066] Such as Figure 1 to Figure 5 As shown, a packaged LED light source without a support includes a silver-plated copper sheet 1, a first mold top glue 2, a chip 3 and a second mold top glue 4, and the silver-plated copper sheet 1 is provided with a first mold top glue 2 and connected with the first mold top glue 2, the chip is located on the first mold top glue 2 and connected with the first mold top glue 2, the second mold top glue seal 8 is installed on the first mold top glue 2 and The chip is encapsulated in the second top mold compound 4 .

[0067] The beneficial effects of the bracketless packaged LED light source provided in this embodiment are as follows: the bracketless packaged LED light source provided by the present invention is packaged with mold top glue after the silver-plated copper sheet 1 is solid-welded, which improves the sealing performa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com