Magnetic flux guide component

A guide, flux technology, applied in the direction of magnets, magnetic objects, electrical components, etc., can solve the problems of high permeability materials brittle, vulnerable to cracking and fracture, etc., to reduce heat generation, high repeatability, The effect of reducing eddy currents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

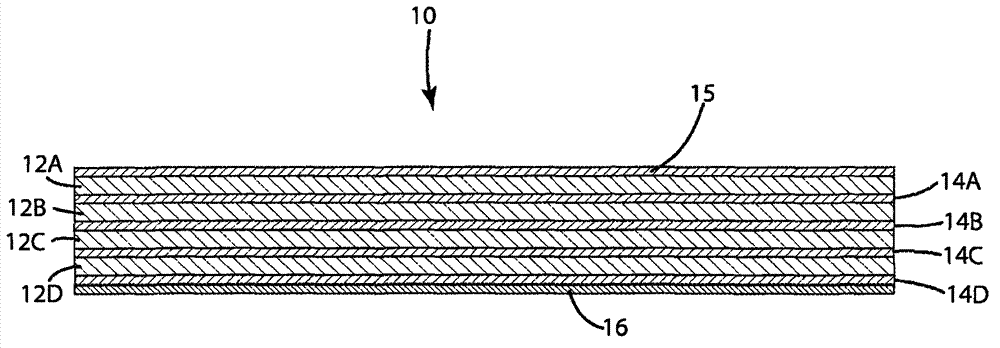

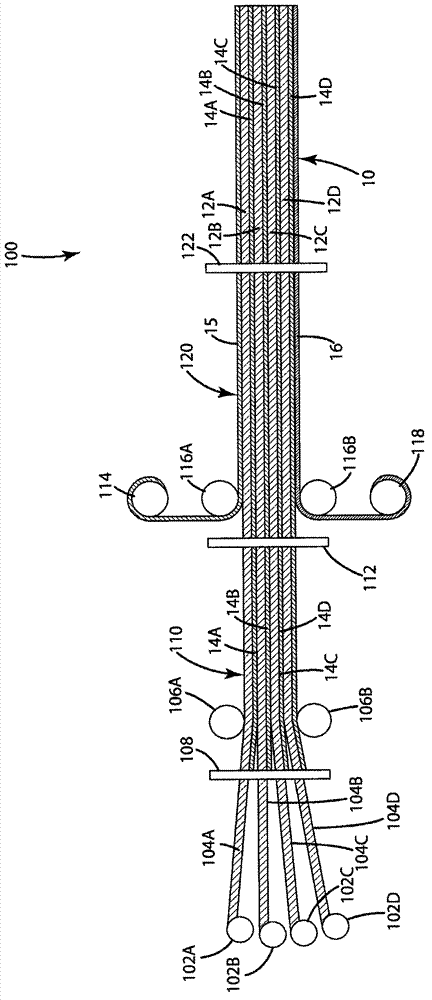

[0026] exist figure 2 A laminated flux guide according to one embodiment of the invention is shown in . The laminated flux guide 10 generally includes a cover layer 15 and a thermally conductive outer layer 16 disposed on opposite sides of the arrangement of alternating layers of high magnetic permeability material 12a-d and electrically insulating material 14a-c. The number of alternating layers can vary. The cover layer 15 may be a thin layer of material capable of holding the laminated flux guide together and providing a vapor barrier protecting the underlying high permeability material layer. The thermally conductive layer 16 can be a metal or metal that can also hold the laminated flux guide together and provide a vapor barrier that protects the overlying layer of high permeability material, as well as provide a heat flow path for removing thermal energy from the flux guide. Thin layers of other thermally conductive materials. For example, the thermally conductive laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com