High-temperature-resistant multi-component silicide coating on surface of niobium alloy and preparation method of high-temperature-resistant multi-component silicide coating

A multi-component, high-temperature-resistant technology, applied in metal material coating process, coating, heating inorganic powder coating, etc., can solve the problems of lack of compactness of coating structure, large internal stress of coating, loss of protective effect, etc. , to achieve the effects of improving high temperature oxidation resistance, reducing internal stress, and controlling tissue composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: preparation [(Nb 0.75 Ti 0.05 Cr 0.2 ) 0.95 ,W 0.05 ] Si 2 coating

[0025] (1) Firstly, according to Mole ratio [(Nb 0.75 Ti 0.05 Cr 0.2 ) 0.95 ,W 0.05 ]:Si=1:2.03 ratio, weigh each metal elemental powder and silicon elemental powder respectively, drop into the mixing machine and fully mix for 12h;

[0026] (2) Embed the niobium alloy workpiece with the mixed multi-element metal powder and place it in a graphite crucible, and then put the graphite crucible into a spark plasma sintering furnace for sintering. The specific process parameters are: the heating rate is 100°C / s, the pressure is 30MPa, and it is sintered at 1400℃ for 5min;

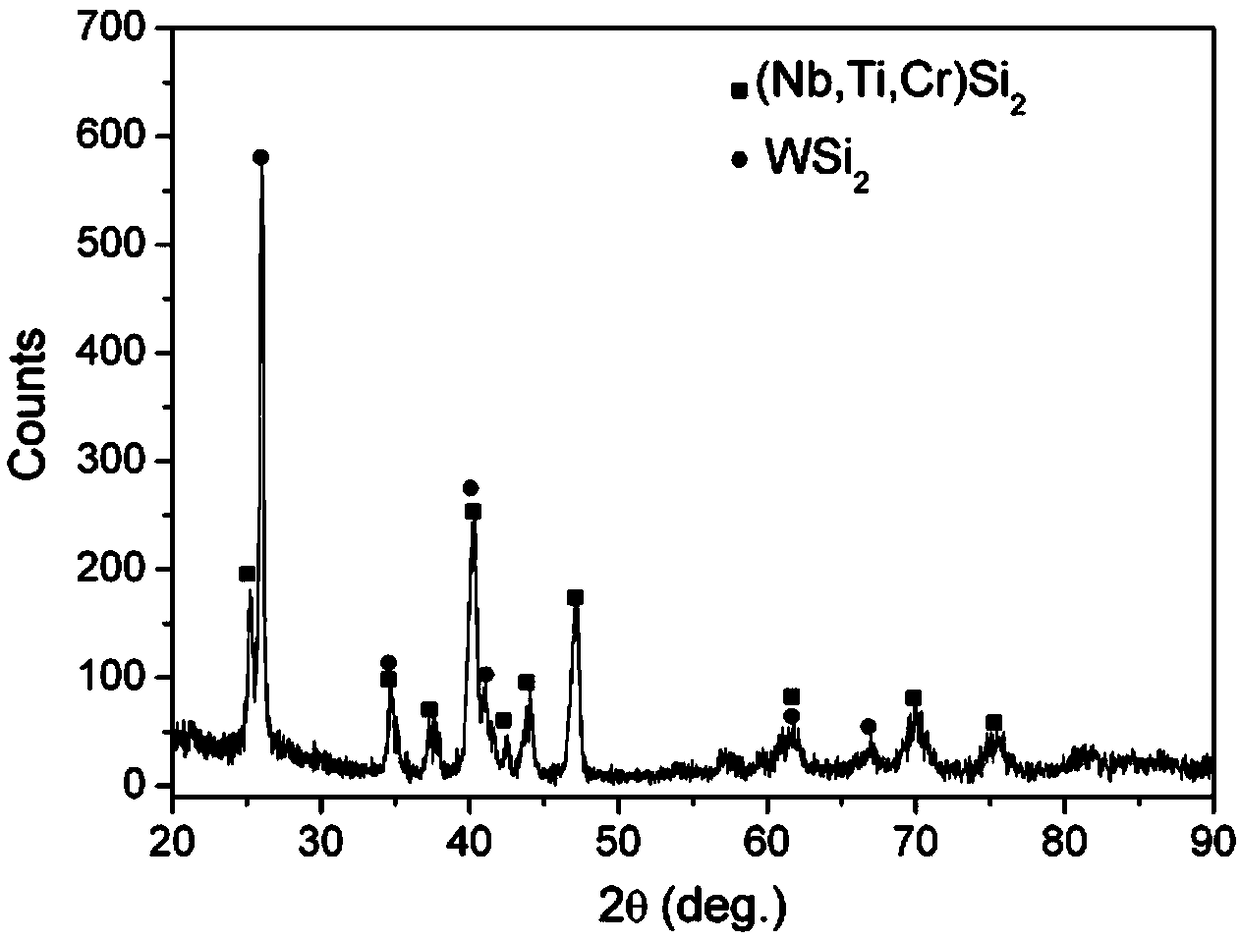

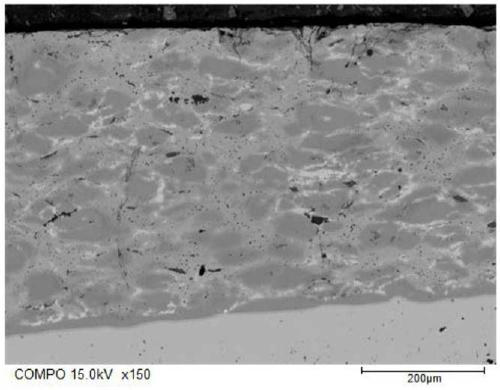

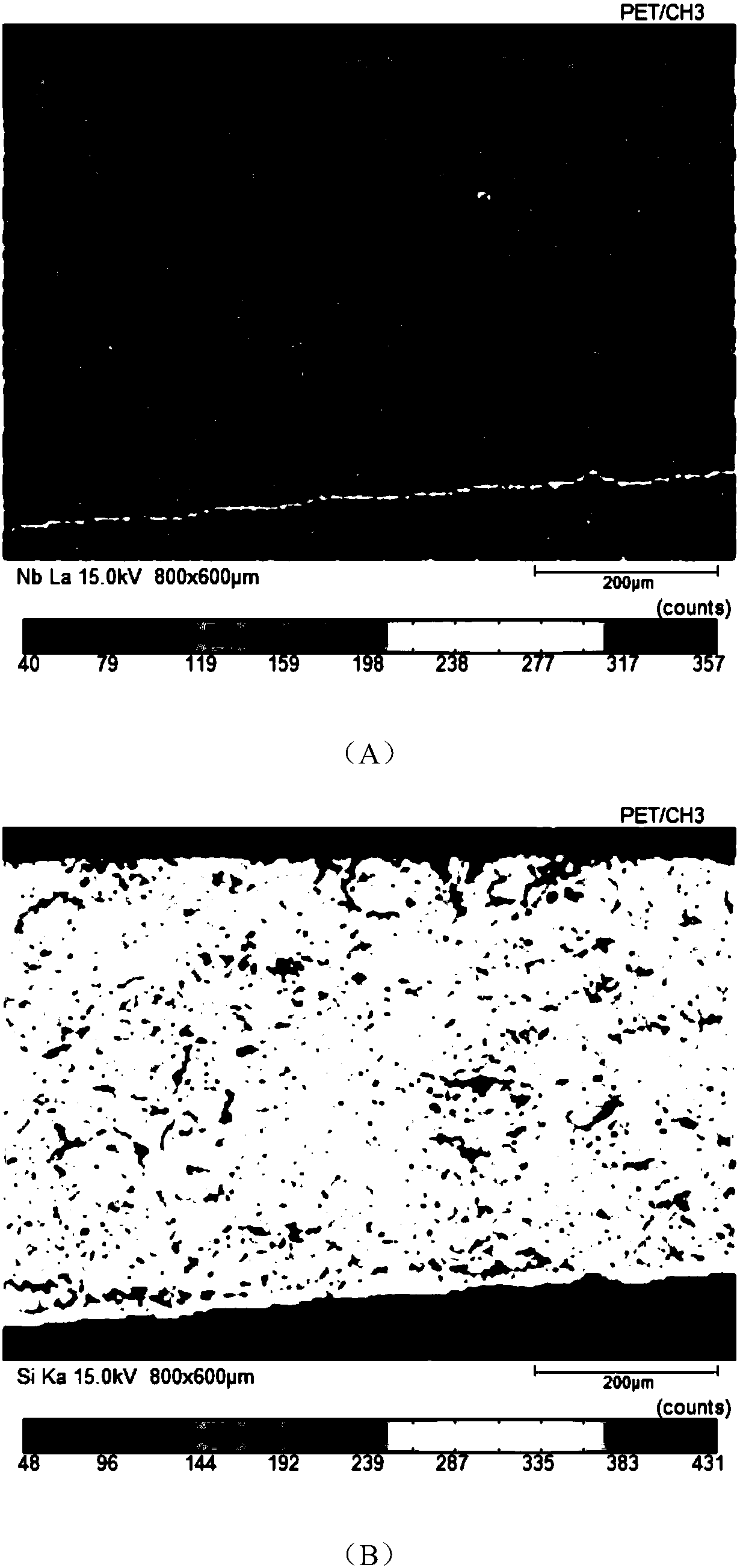

[0027] (3) Homogenize the sintered coating sample in an argon protective atmosphere at a temperature of 1100°C for 4 hours to obtain a composite material mainly composed of (Nb-Ti-Cr)Si 2 and a small amount of WSi 2 Composed of [(Nb 0.75 Ti 0.05 Cr 0.2 ) 0.95 ,W 0.05 ] Si 2 The coating has a uniform struc...

Embodiment 2

[0028] Embodiment 2: preparation [(Nb0.75 Ti 0.05 Cr 0.2 ) 0.8 ,W 0.2 ]Si 2 coating

[0029] (1) Firstly, according to Mole ratio [(Nb 0.75 Ti 0.05 Cr 0.2 ) 0.8 ,W 0.2 ]:Si=1:2.03 ratio, take each metal elemental powder respectively, drop into the mixing machine and fully mix for 18h;

[0030] (2) Embed the niobium alloy workpiece with the mixed multi-element metal powder and place it in a graphite crucible, and then put the graphite crucible into a spark plasma sintering furnace for sintering. The specific process parameters are: the heating rate is 100°C / s, the pressure is 30MPa, and it is sintered at 1450℃ for 5min;

[0031] (3) Homogenize the sintered coating sample in an argon protective atmosphere at a temperature of 1150°C for 4 hours to obtain a composite material mainly composed of (Nb-Ti-Cr)Si 2 and WSi 2 Composed of [(Nb 0.75 Ti 0.05 Cr 0.2 ) 0.8 , W 0.2 ] Si 2 The coating has a uniform structure and is combined with the substrate in a metallurgic...

Embodiment 3

[0032] Embodiment 3: preparation [(Nb 0.75 Ti 0.05 Cr 0.2 ) 0.6 ,W 0.4 ]Si 2 coating

[0033] (1) Firstly, according to Mole ratio [(Nb 0.75 Ti 0.05 Cr 0.2 ) 0.6 ,W 0.4 ]:Si=1:2.03 ratio, take each metal elemental powder respectively, drop into the mixing machine and fully mix 24h;

[0034] (2) Embed the niobium alloy workpiece with the mixed multi-element metal powder and place it in a graphite crucible, and then put the graphite crucible into a spark plasma sintering furnace for sintering. The specific process parameters are: the heating rate is 100°C / s, the pressure is 30MPa, and it is sintered at 1450℃ for 5min;

[0035] (3) Homogenize the sintered coating sample in an argon protective atmosphere at a temperature of 1200°C for 4 hours to form a high temperature resistant multi-component silicide coating.

[0036] [(Nb 0.75 Ti 0.05 Cr 0.2 ) 0.6 ,W 0.4 ]Si 2 The surface of the coating is tested and analyzed, the results are as follows figure 1 shown.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com