Nano-silver-loaded microcrystal bamboo charcoal ceramic bead and preparation method thereof

A technology of microcrystalline bamboo charcoal and nano-silver, which is applied in separation methods, chemical instruments and methods, and other chemical processes, and can solve the problems that the superior performance of nano-silver has not been fully utilized, drug resistance cannot be produced, and the specific surface area is not large enough. , to achieve the effects of no environmental pollution, convenient application, and less strict temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation of microcrystalline bamboo charcoal ceramic beads

[0042] The raw materials are uniformly mixed according to the ratio, and water is added in the granulator to granulate into spherical particles of different sizes.

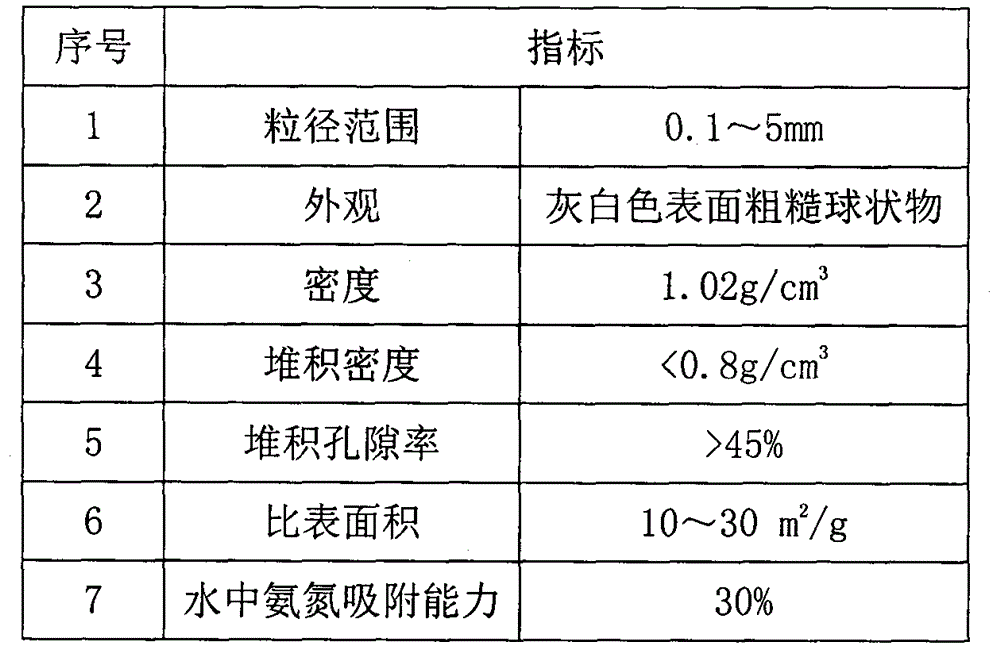

[0043] The bamboo charcoal powder, porous non-metallic mineral powder and clay have an average particle size of 1-10 μm. Zeolite is used for porous non-metallic minerals, and kaolin is used for clay. Mix the ingredients according to the ratio of bamboo charcoal 40%, porous mineral 30%, clay 25% and binder 5%. Add water and starch in the granulator to form spherical granules with a particle size of 0.5mm~5mm. The granules are then air-dried for 24 hours, and then dried in a drying oven at a temperature of 90℃ for 4 hours, and then sintered without oxygen. It is 1250°C, kept for 30 minutes, and cooled naturally to obtain ceramic pellets. The performance indexes of ceramic pellets are shown in Table 1.

[0044] Table 1

[0045]

Embodiment 2

[0047] Add nano silver to the silica sol aqueous dispersion (containing 30% silica), stir vigorously to form a suspension, and then put the microcrystalline bamboo charcoal ceramic beads obtained in Example 1 into the suspension, and stir slowly to make the microcrystalline bamboo charcoal The surface of the ceramic beads is evenly coated, and then the microcrystalline bamboo charcoal ceramic beads are taken out and dried in air for 4 hours, and then dried in vacuum at 60°C.

Embodiment 3

[0049] Add nano-silver into the silica sol water dispersion (containing 30% silica), ultrasonically form a suspension, and then put the microcrystalline bamboo charcoal ceramic beads obtained in Example 1 into the suspension, and stir slowly to make the microcrystalline bamboo charcoal ceramic The surface of the beads is evenly coated, and then the microcrystalline bamboo charcoal ceramic beads are taken out and air-dried for 4 hours, and then dried at 200°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com