Automatic glue-pouring machine

A glue filling machine, automatic technology, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems that the glue is easy to flow downward, the quality of glue filling is unqualified, the viscosity of glue is not easy, etc., and the glue filling efficiency is high. , Good sealing effect and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

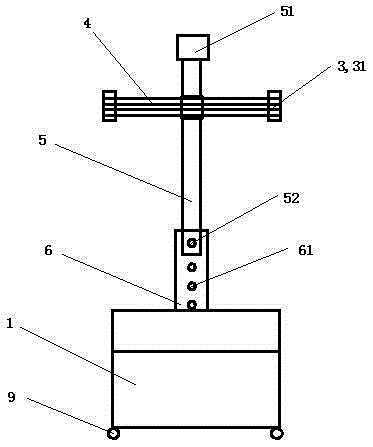

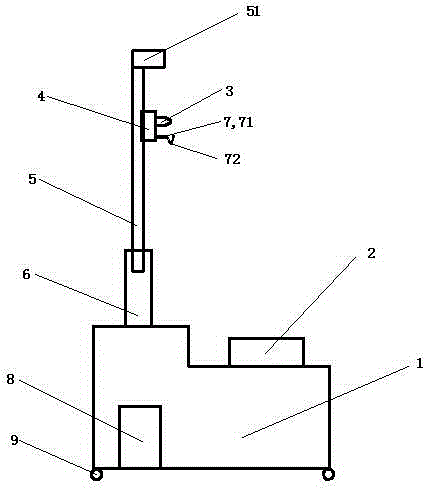

[0017] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0018] like figure 1 and 2 As shown, an automatic glue filling machine includes a fixed frame 1, a glue supply device 2 fixed on the fixed frame, a PLC control system (not shown) and a glue filling head 3, which is connected to a sliding track , the sliding track comprises a horizontal track 4 and a vertical track 5 arranged vertically to each other, the horizontal track 4 can slide up and down on the vertical track 5, the glue filling head 3 is slidably connected with the horizontal track 4 by a slide block 31, the glue filling head 3 The blowing device 7 is also provided below.

[0019] Two glue filling heads 3 are provided, one can be respectively set at both ends of the horizontal track 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com