Patents

Literature

47results about How to "Improve glue filling efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

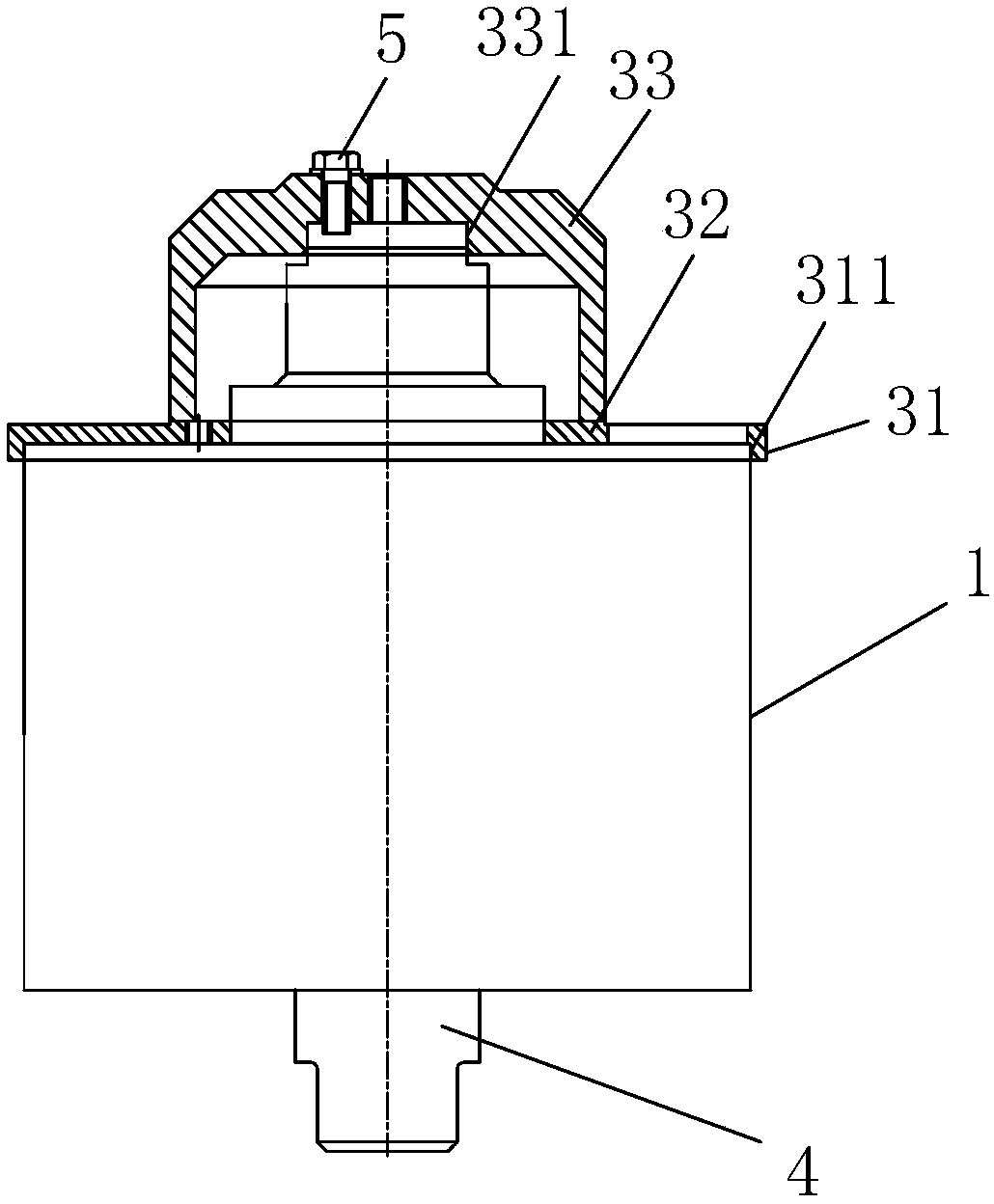

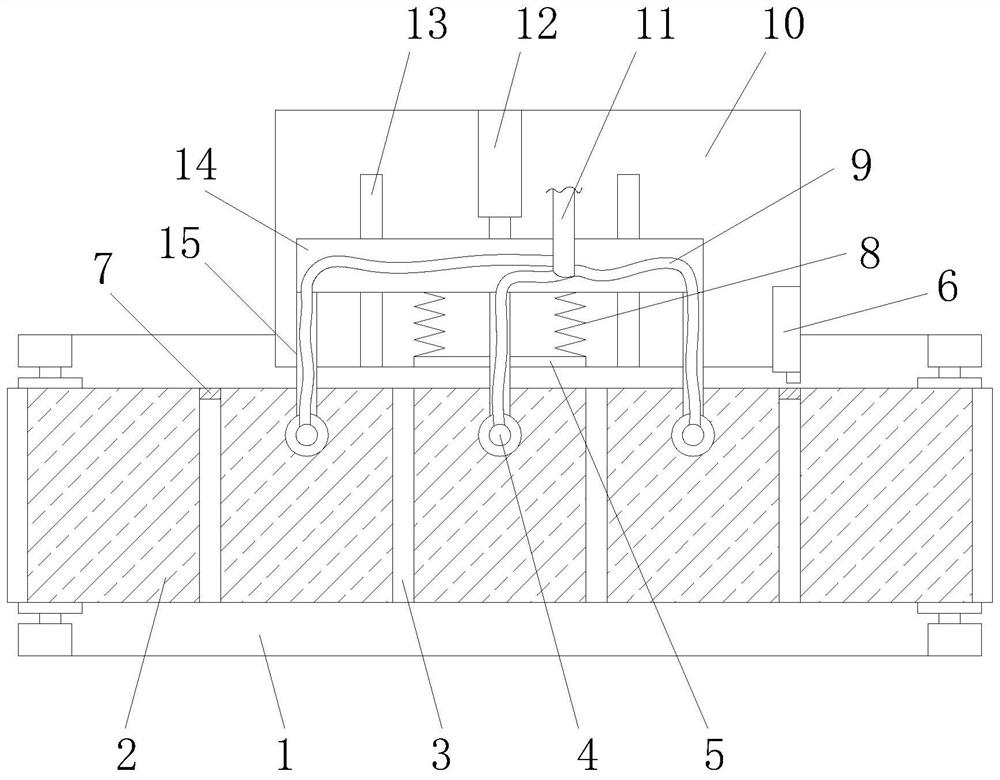

Battery module gluing device

ActiveCN105958107AImprove conductivityAvoid stickingFinal product manufactureSecondary cells manufactureEngineeringCavity wall

The invention relates to the technical field of battery module forming equipment, and in particular relates to a battery module gluing device. The battery module gluing device comprises a supporting component, a clamping component and a gluing component; the supporting component comprises a push plate and a bottom plate; a plurality of through holes are arranged on the push plate; a sealing ring is arranged in the through hole; a thimble is arranged on the bottom plate; the bottom plate is connected to a lifting component; the clamping component comprises a plurality of clamping blocks; the plurality of clamping blocks form a cavity wall for containing glue in an encircling manner; the clamping blocks are connected to a driving component; the gluing component comprises a glue container; the glue container comprises a glue groove; a glue injection hole is arranged at the bottom of the glue groove; and the glue groove is connected to a movable component. The battery module gluing device provided by the invention is used for gluing the middle part of a battery module, wherein a sealed structure is formed through the clamping blocks and the sealing ring; glue can be prevented from overflowing; therefore, glue can be prevented from being stuck on anodes and cathodes; the battery module can be ensured to have good conductivity; simultaneously, the whole process is automatic; the gluing efficiency is increased; the labour cost is saved; and time and labour are saved.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

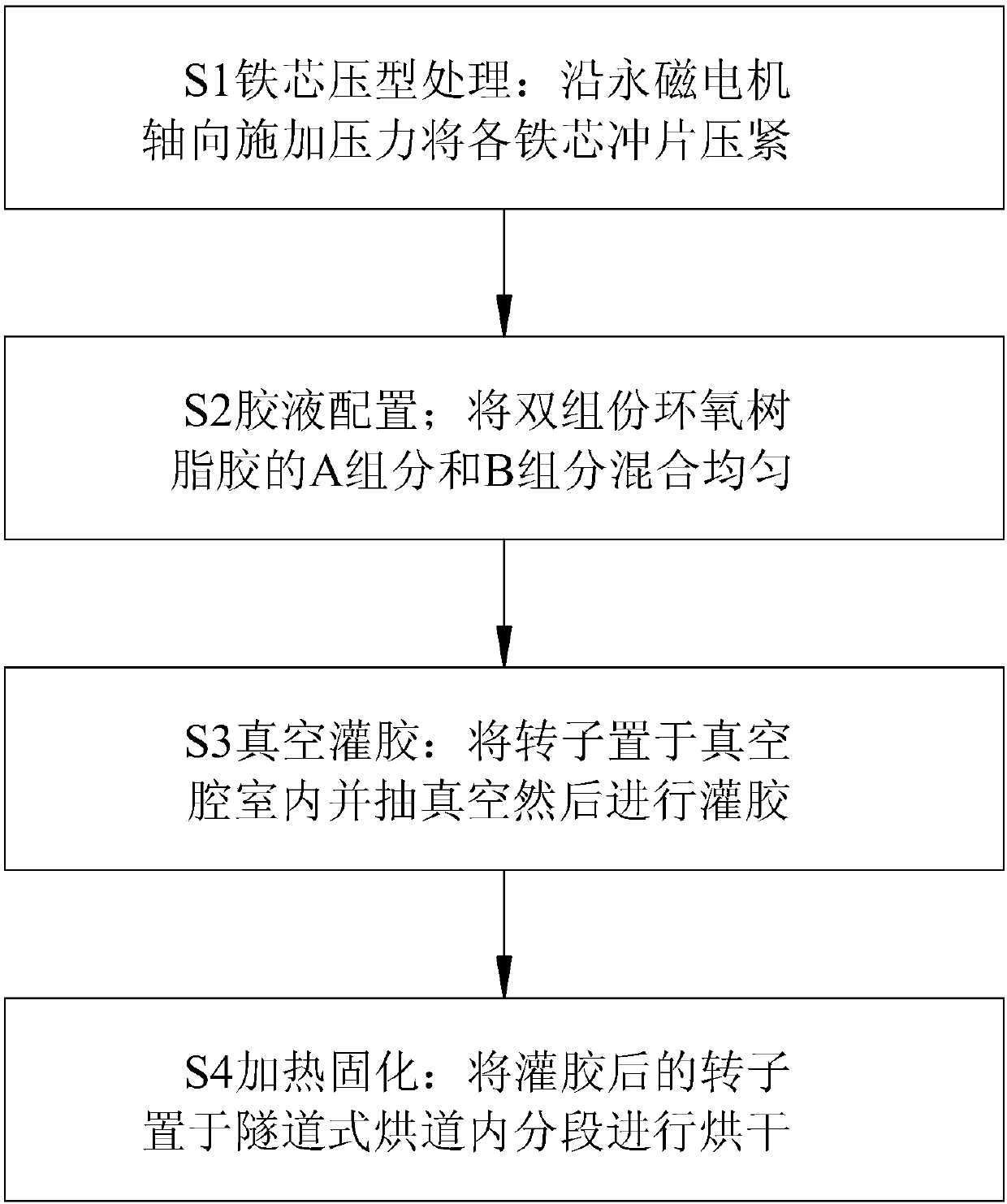

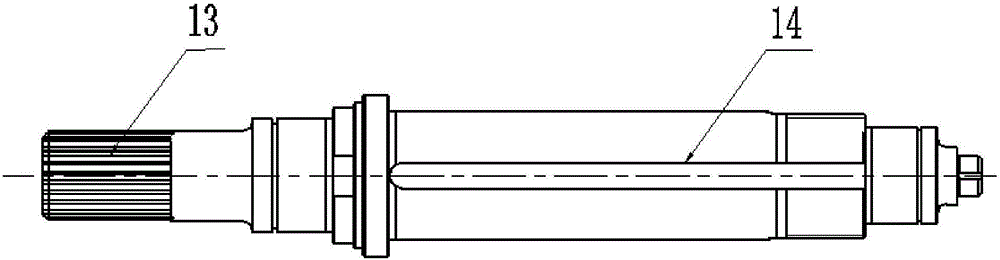

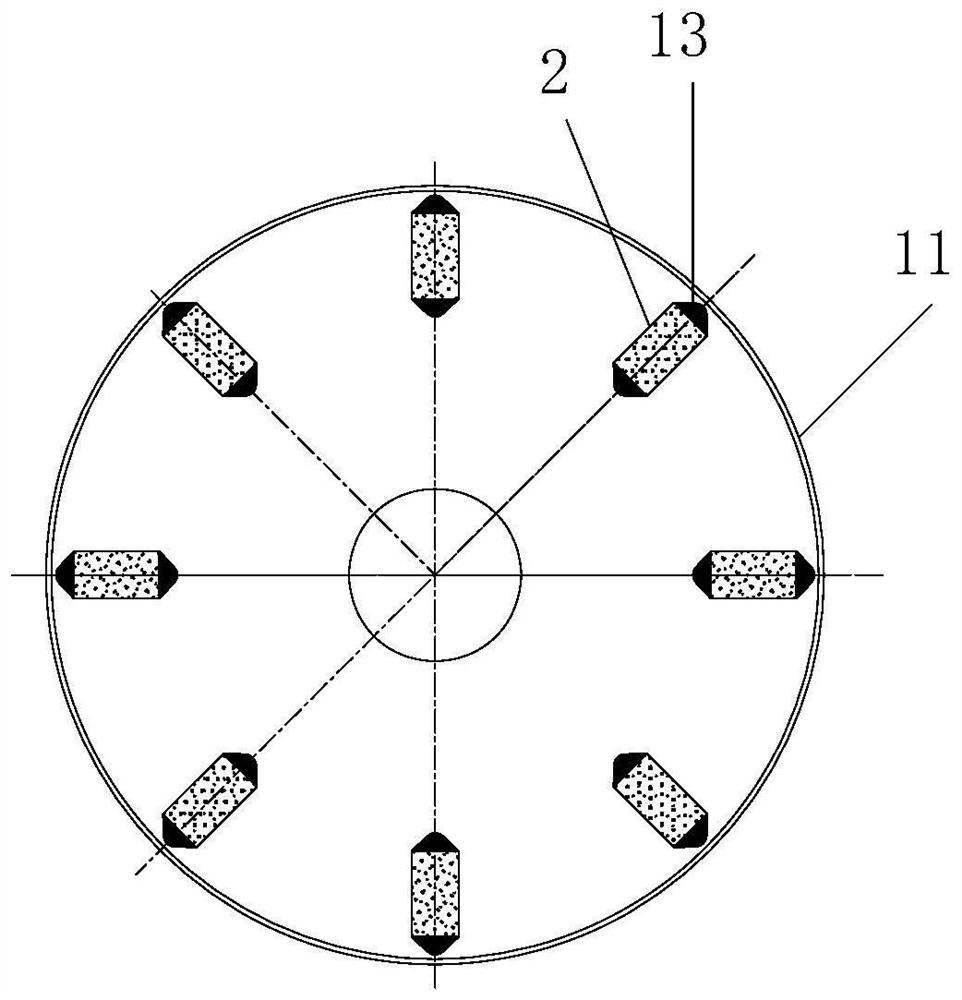

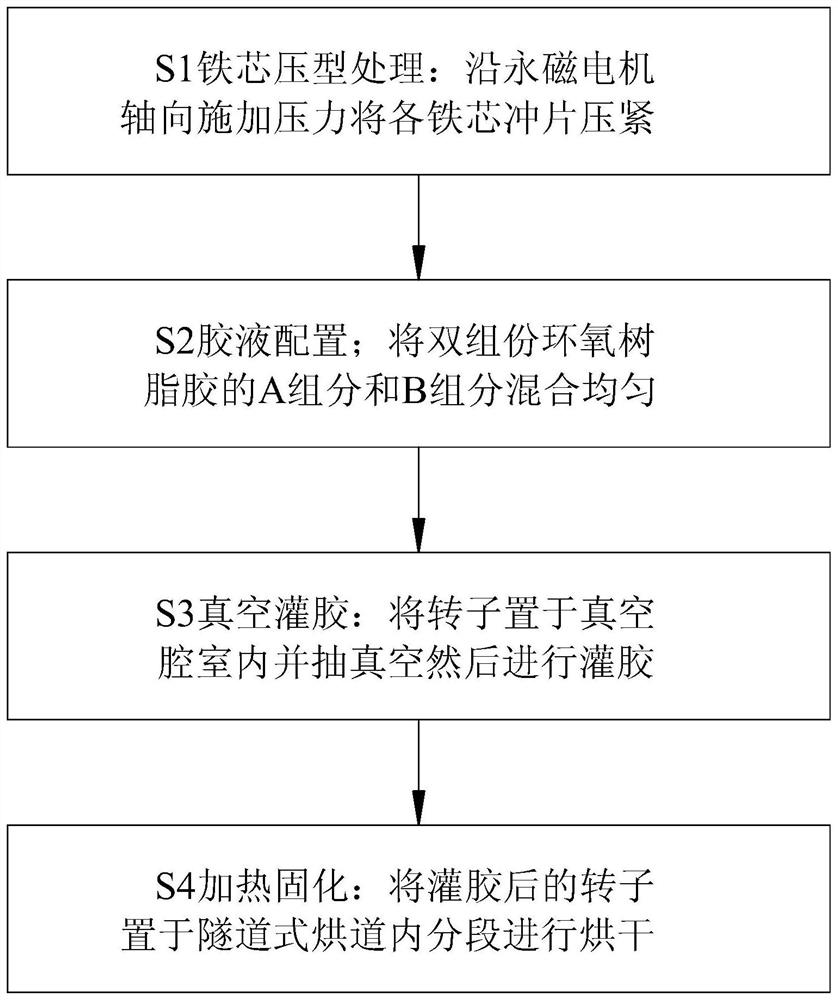

Vacuum glue pouring method for permanent magnetism motor rotors

ActiveCN109698590AReduce gapAvoid churnPretreated surfacesManufacturing stator/rotor bodiesEpoxyVacuum pumping

The invention discloses a vacuum glue pouring method for permanent magnetism motor rotors. The method includes the following steps: S1, a step of iron core profiling processing, namely the step of applying pressure to compress iron core punching sheets in an axial direction of a permanent magnetism motor; S2, a step of glue solution configuration, namely the step of uniformly mixing an A componentand B component of a two-component epoxy resin adhesive; S3, a step of vacuum glue pouring, namely the step of placing a rotor into a vacuum cavity to perform vacuum pumping, and then performing gluepouring; and S4, a step of heating and curing, namely the step of placing the rotor after glue pouring into a tunnel type baking channel to perform segment drying. The method has high glue pouring efficiency, tooth tension and glue loss phenomenon is not easy to occur, and the quality of products can meet the filling technical requirements of the permanent magnetism motor rotor.

Owner:湖南中车商用车动力科技有限公司

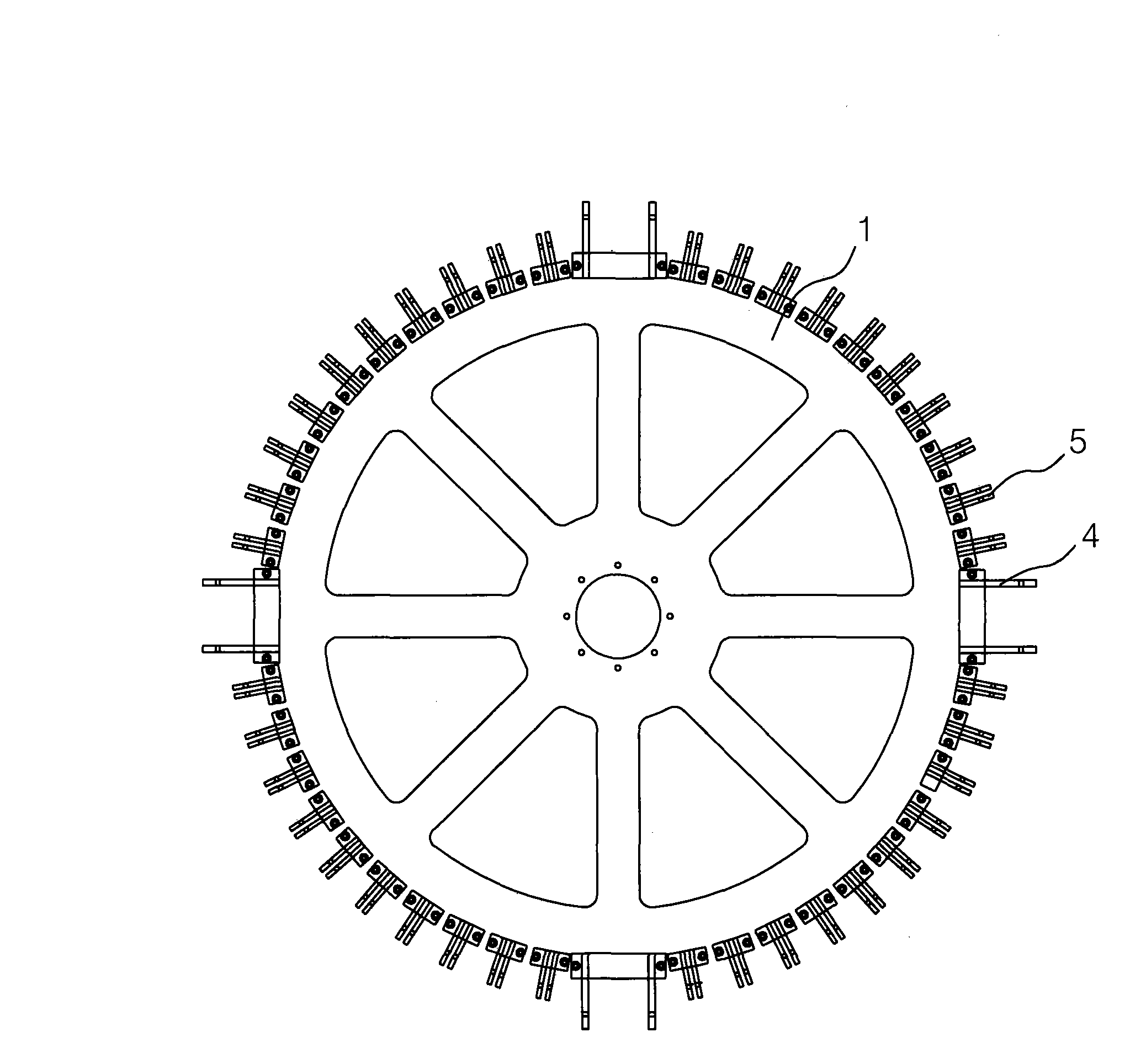

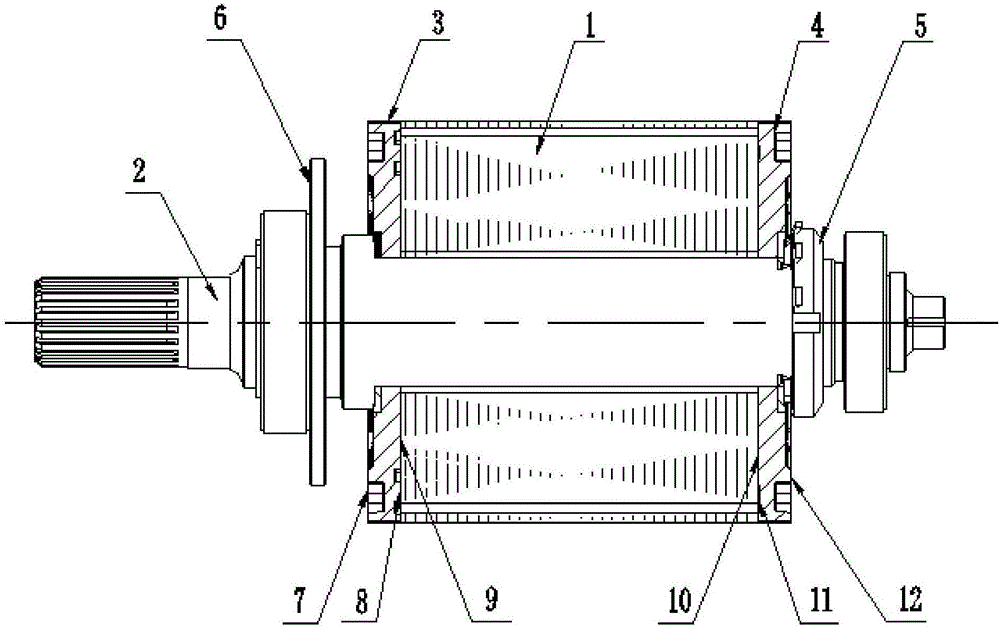

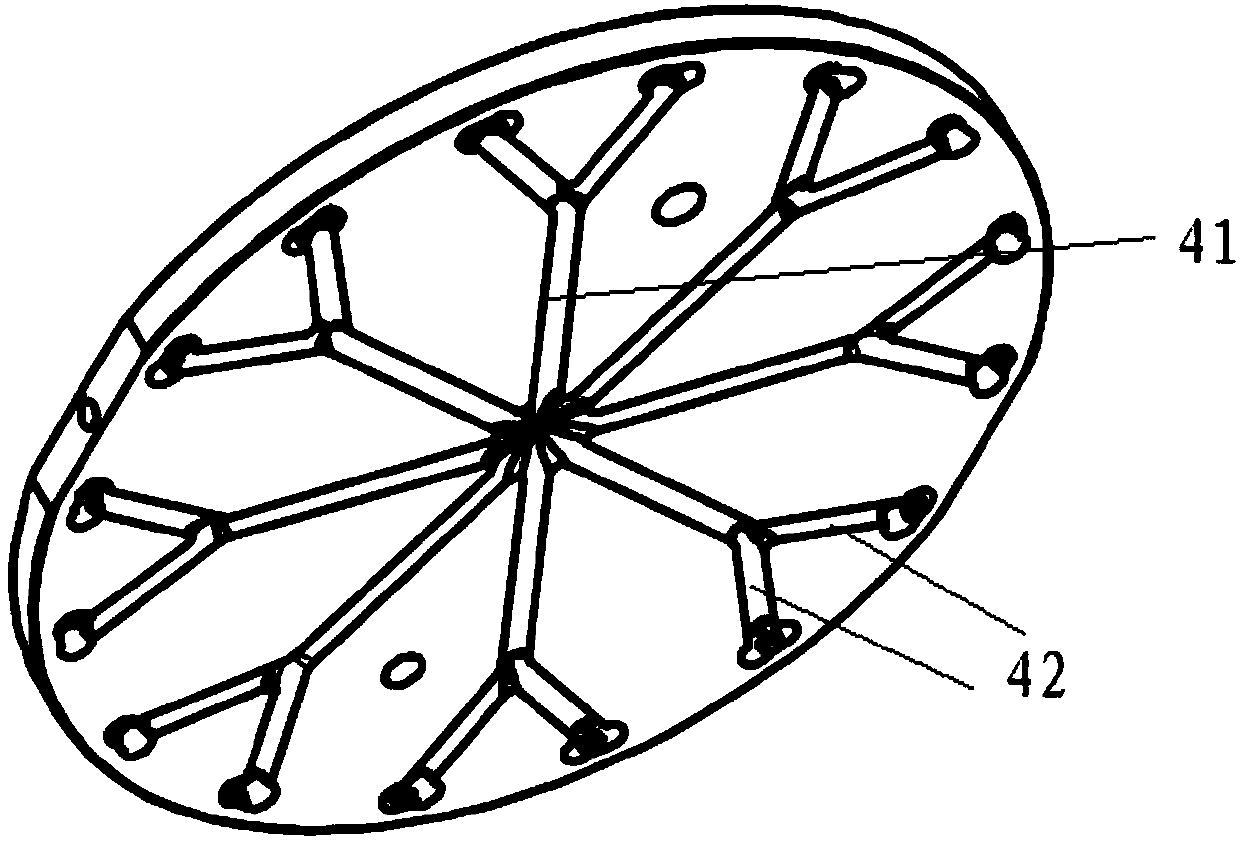

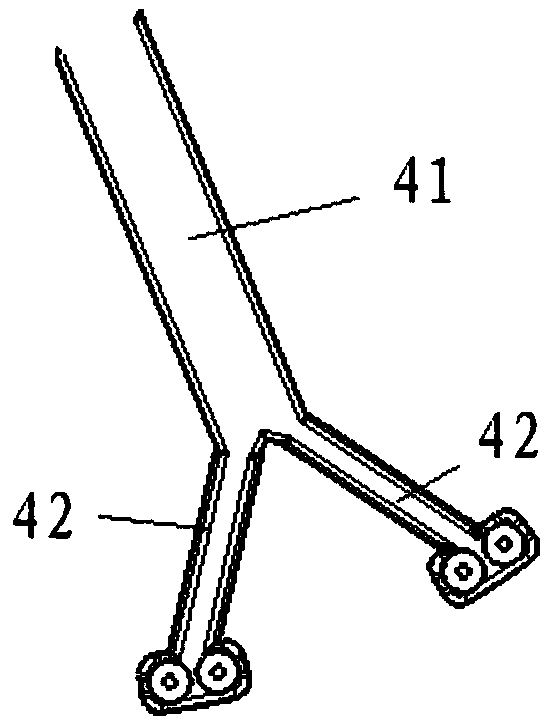

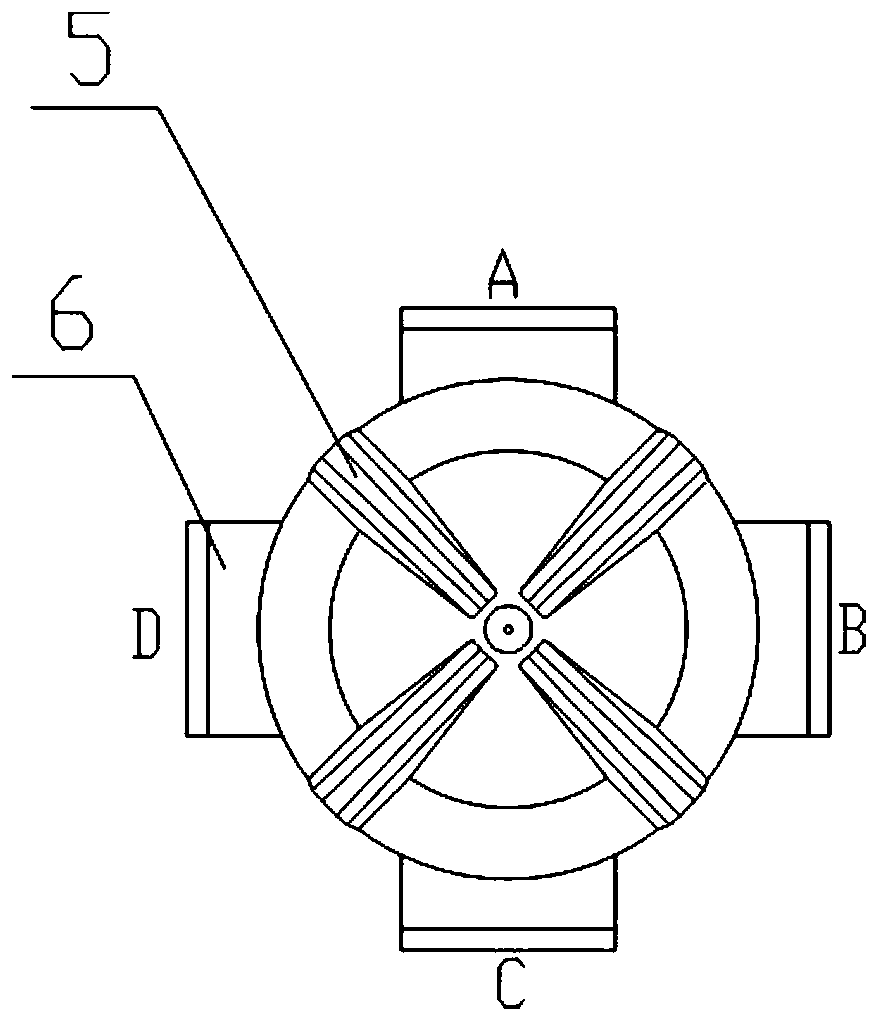

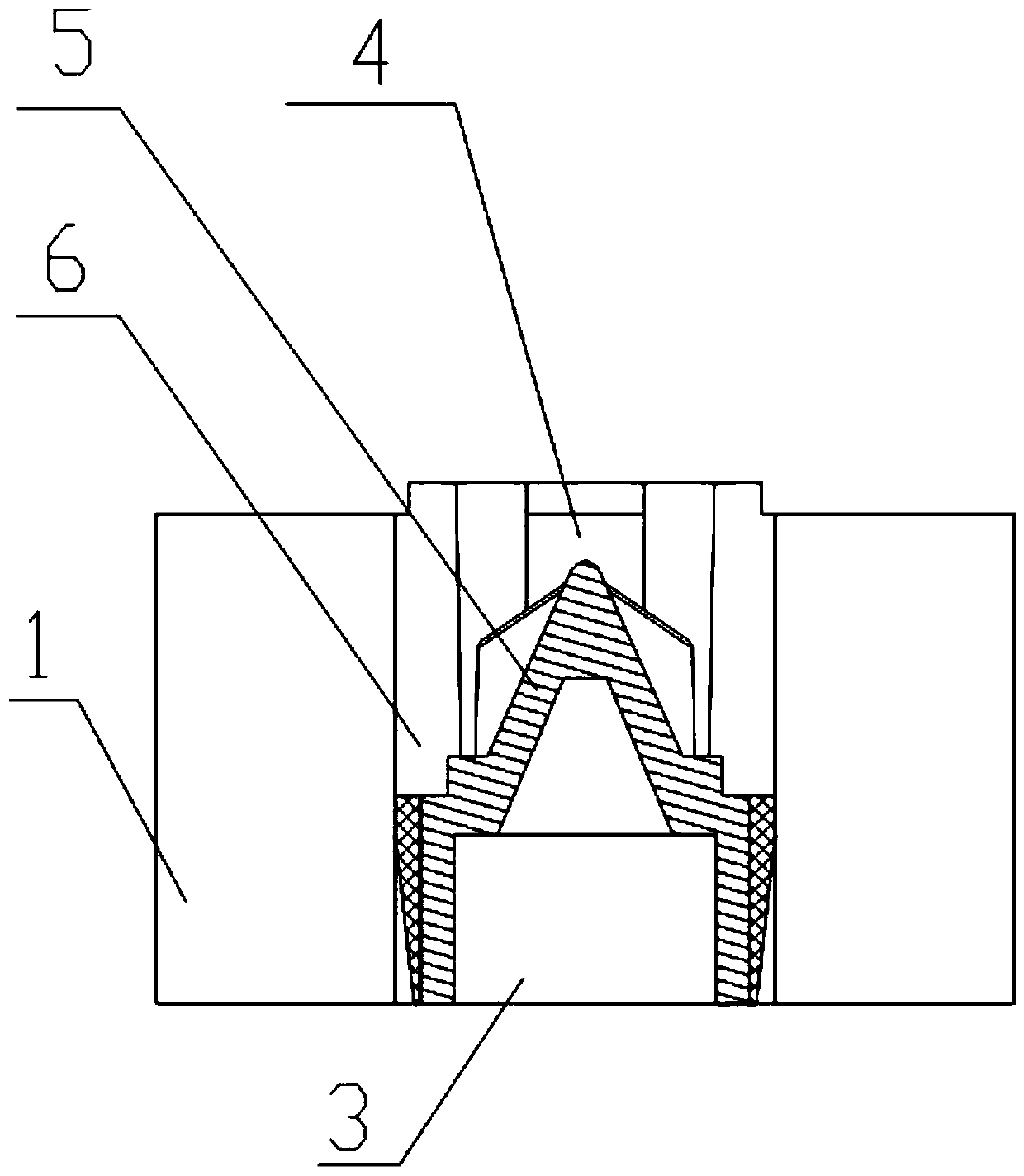

Centrifuge and hanging rack thereof

InactiveCN101579658APrevent leakageImprove glue filling efficiencyRotary centrifugesRotary stageFiber

The invention relates to a centrifuge and a hanging rack thereof which are used for the manufacture process of a hollow fiber film and the assembly process of a filter. The technical proposal is as follows: a centrifuge comprises a base, a supporting platform arranged on the base, and a rotation platform rotatablely arranged on the supporting platform; the rotation platform is driven by a motor through a transmission mechanism; the centrifuge also comprises a first hanging rack group and a second hanging rack group that are arranged on the external edge of the rotation platform; the first hanging rack group comprises a plurality of first hanging racks with one end capable of being articulated on the rotation platform in a dismountable way; and the second hanging rack group comprises a plurality of second hanging racks with the middle parts capable of being articulated with the rotation platform in a dismountable way. The centrifuge and the hanging rack thereof have the advantages that the rotation platform is provided with the plurality of the first hanging racks and the second hanging racks, the efficiency for glue-pouring is improved, the first hanging racks and the second hanging racks are arranged vertically when the rotation platform is not in a rotation state and the glue is not easy to leak.

Owner:苏州优水纳滤膜技术有限公司

Electric connector cable outlet vulcanization sealing method

ActiveCN106058599AAchieve sealingImprove sealingDustproof/splashproof/drip-proof/waterproof/flameproof connectionVulcanizationEngineering

The invention relates to an electric connector cable outlet vulcanization sealing method which successively includes the following steps: vulcanization surface pre-treating, surface conditioning agent processing, die installation, glue pouring and vulcanization, and solidification and demoulding. According to the invention, the method is advantaged in that the method includes a step 1 of vulcanization surface pre-treating, a step 2 of surface conditioning agent processing, a step 3 of die installation, a step 4 of glue pouring and vulcanization, and a step 5 of solidification and demoulding so as to realize vulcanization sealing processing on an electric connector cable outlet; the method is safe and reliable, has simple structure and high practicality, and increases sealing property of the entire electric connector; products that undergo vulcanization moulding can meet all kinds of environments; each step of the method can be operated at normal temperature and under normal pressure, and the method avoids operation difficulty of traditional heat vulcanization moulding.

Owner:杭州航天电子技术有限公司

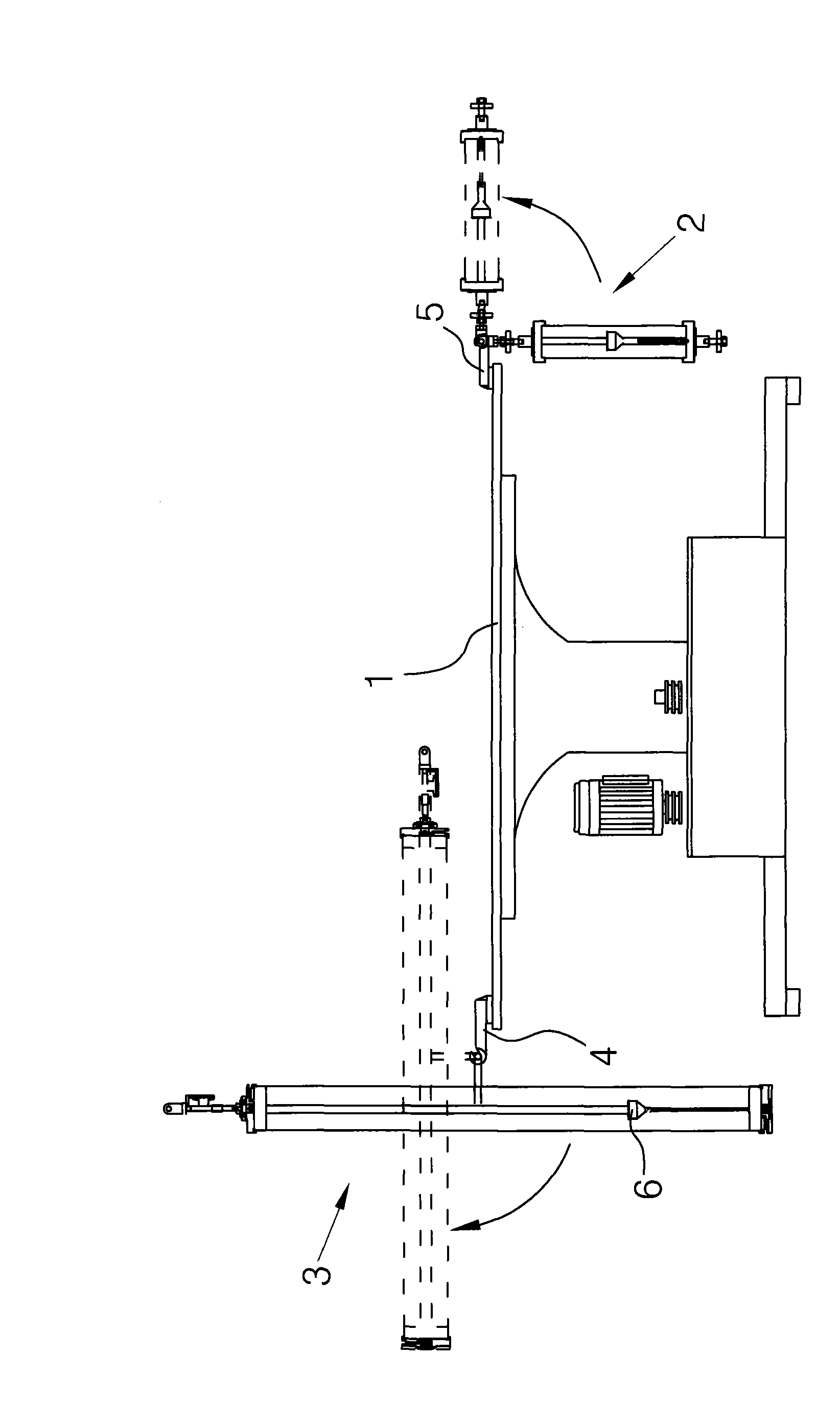

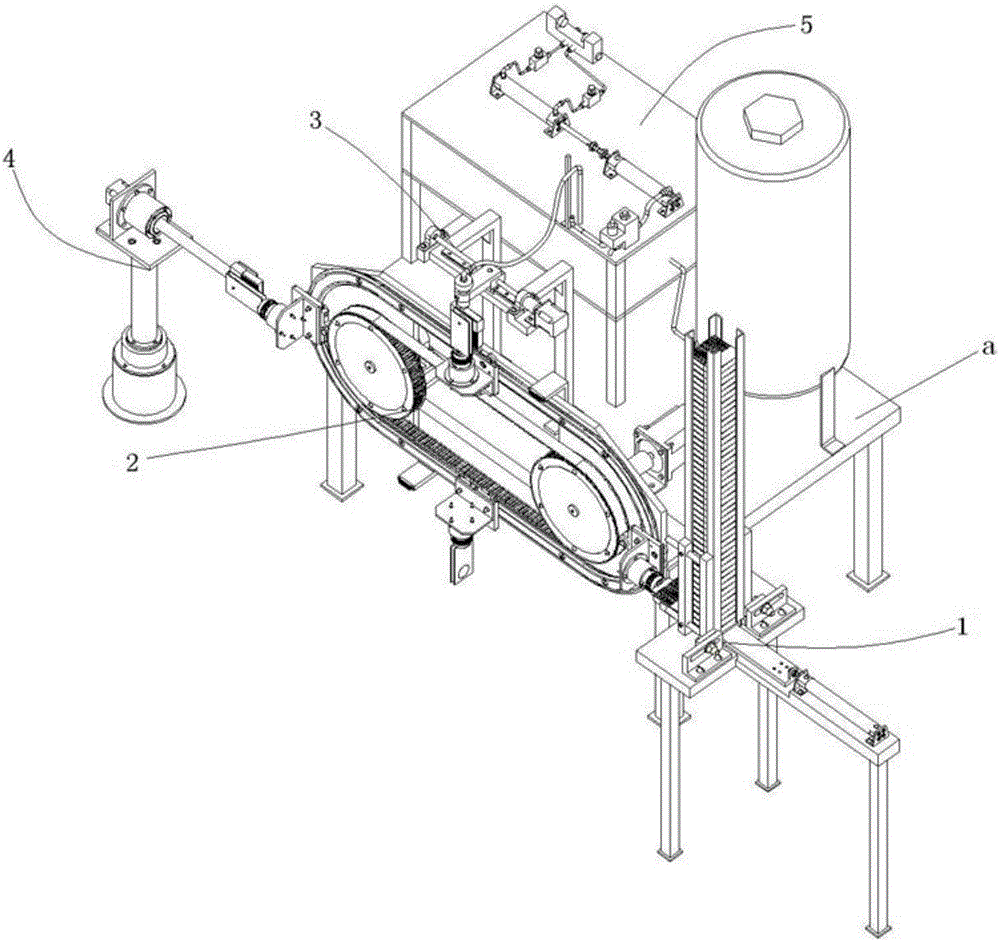

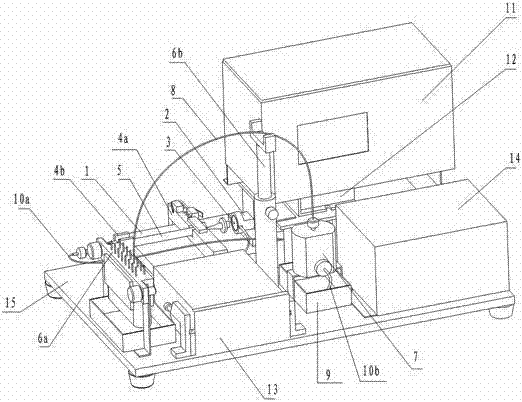

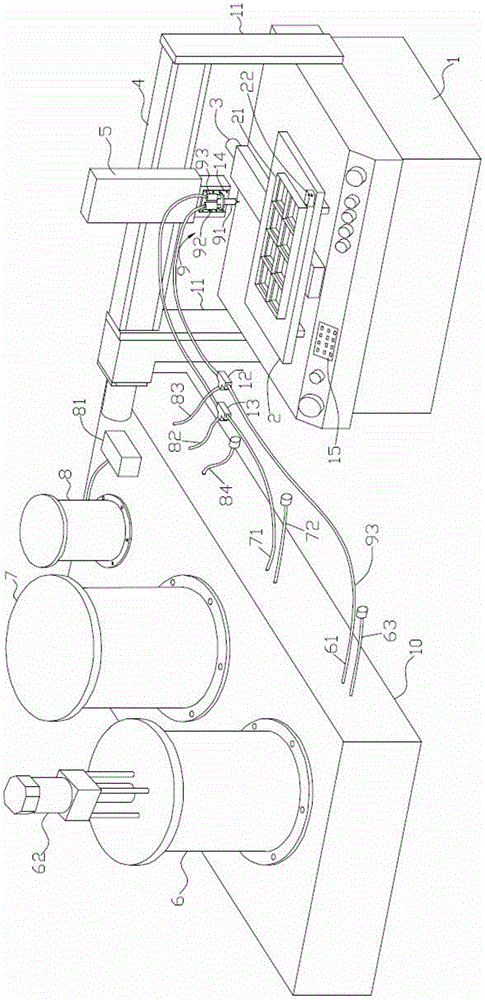

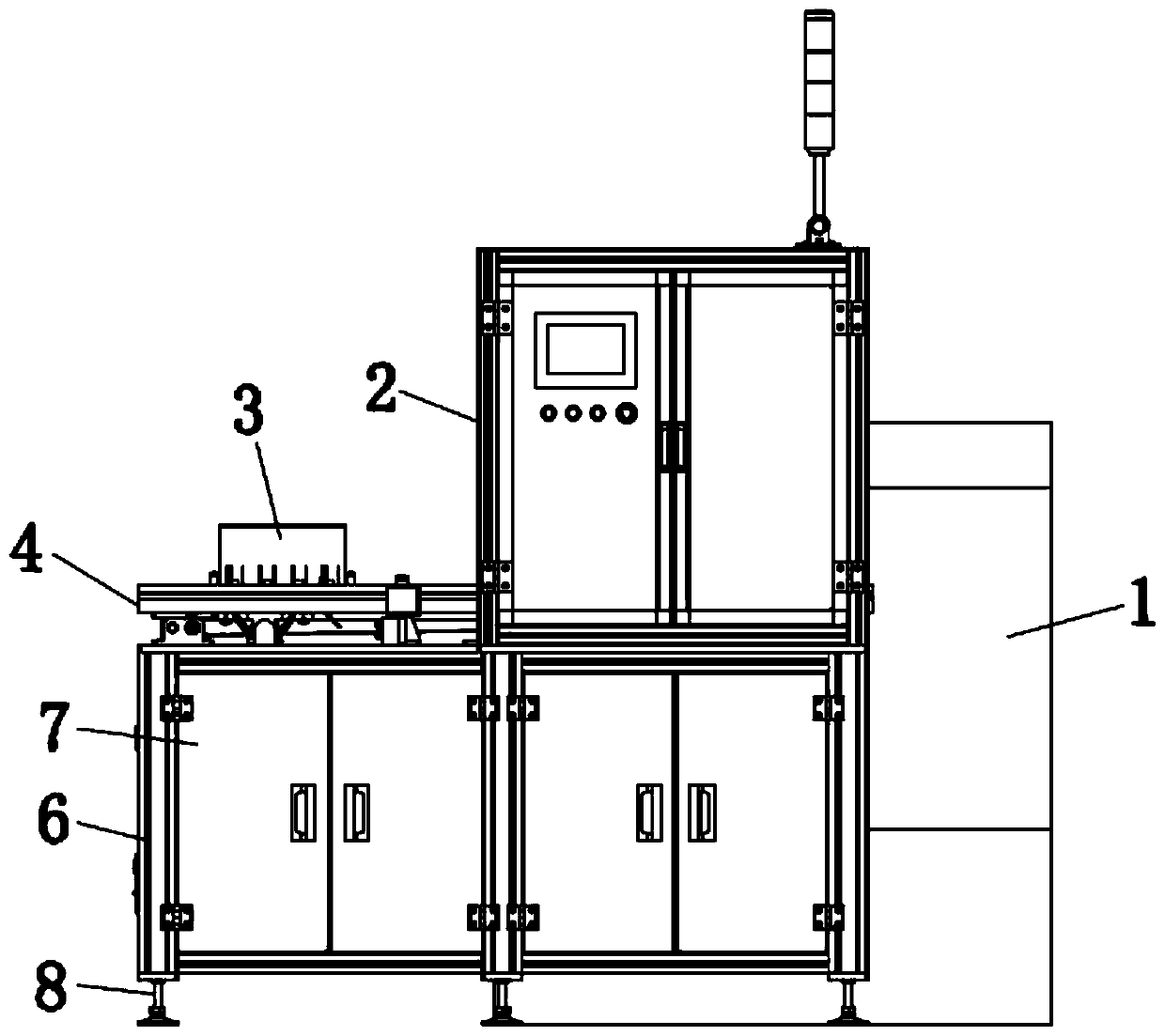

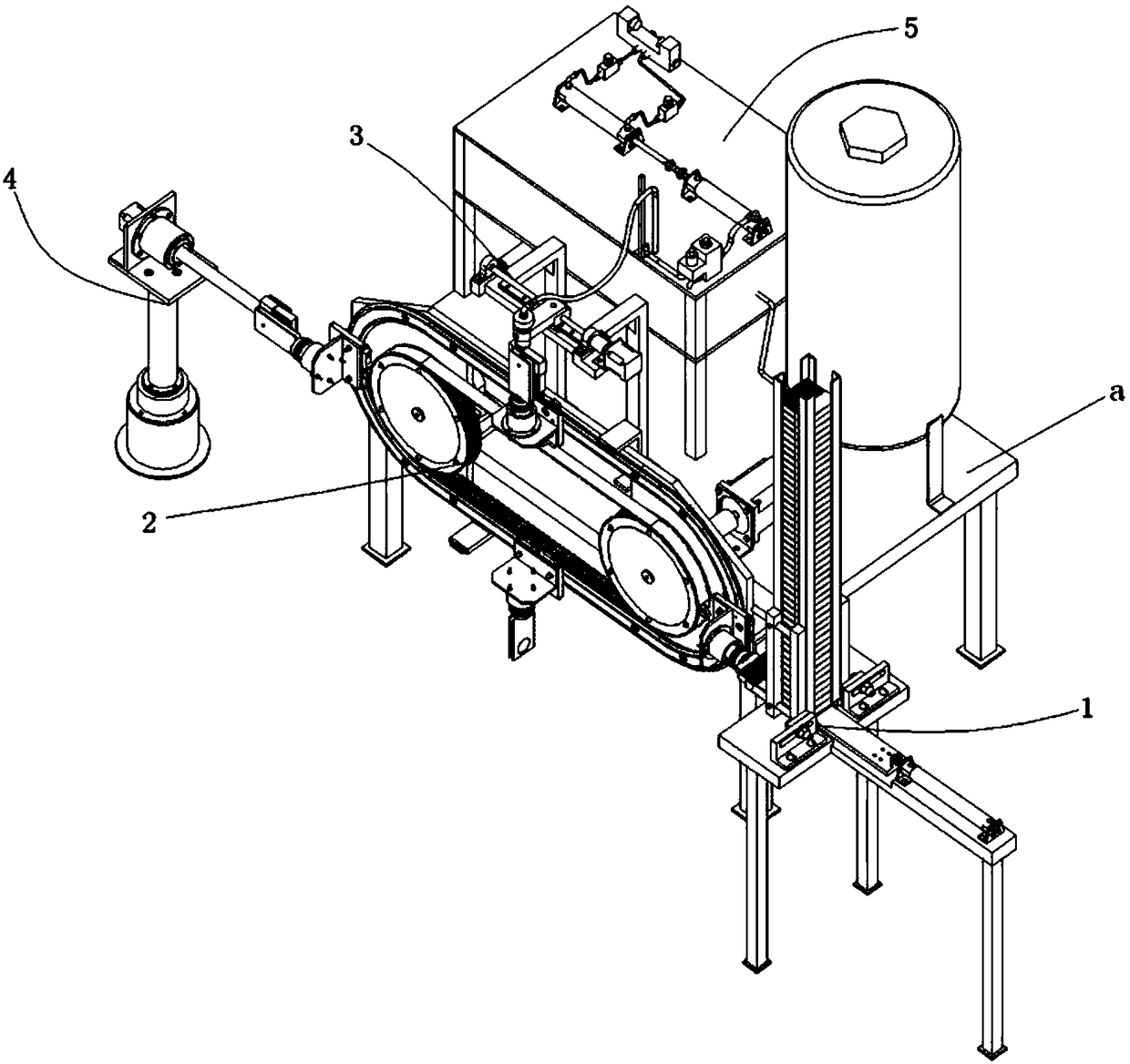

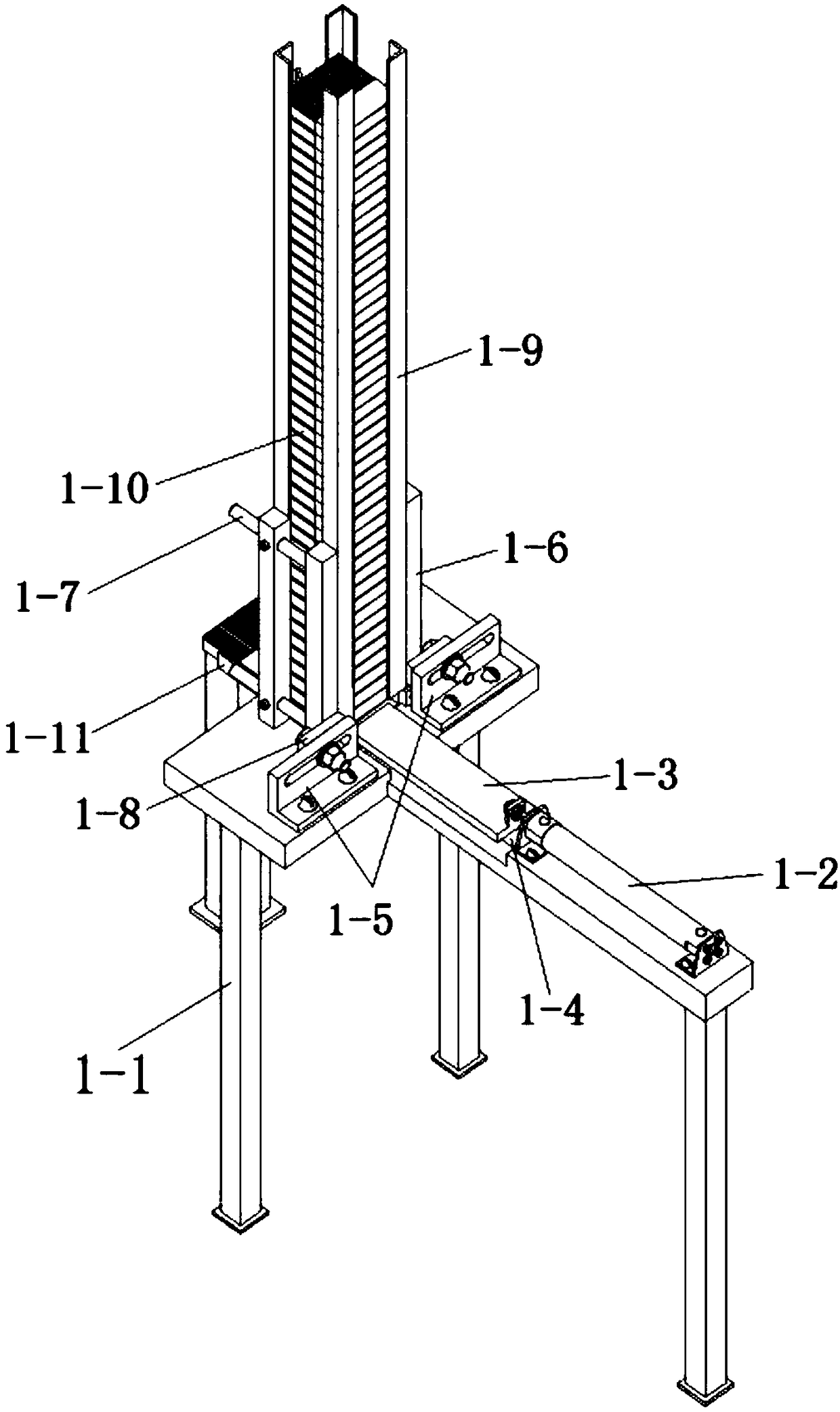

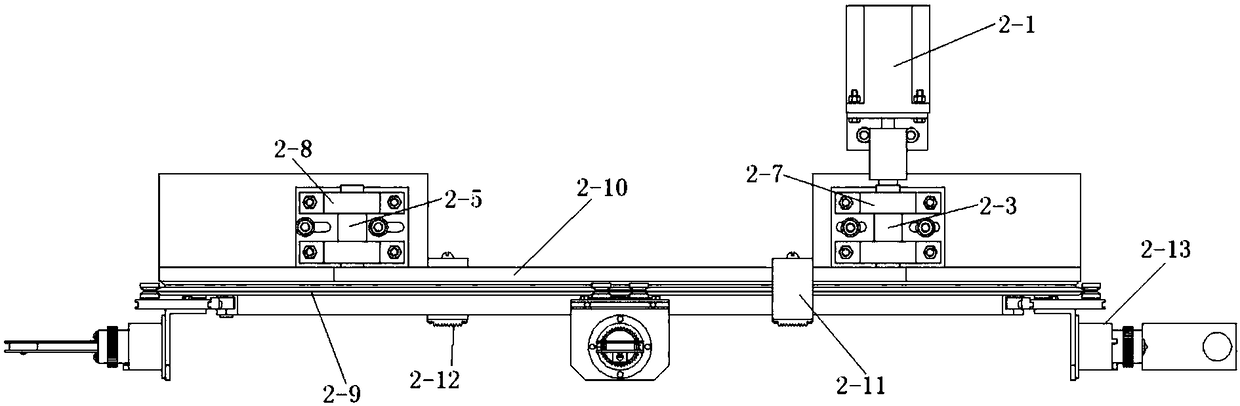

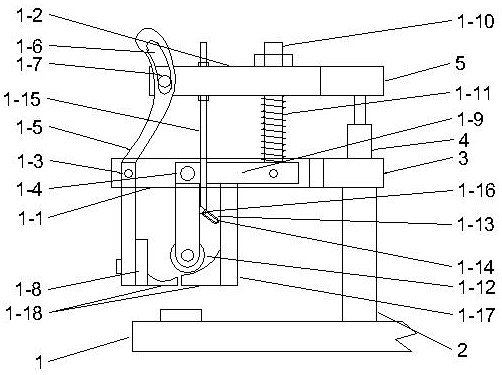

Automatic glue pouring system and method for paint brush

ActiveCN106423733AEasy to unloadImprove working environmentLiquid surface applicatorsCoatingsABSORPTION BASEControl system

The invention discloses an automatic glue pouring system and method for a paint brush. The system comprises a device fixing platform, a feed assembly, a transfer assembly, a glue pouring assembly, a discharge assembly, a pneumatic system and a control system. The feed assembly, the transfer assembly, the glue pouring assembly and the discharge assembly are connected with the pneumatic system and the control system; the feed assembly drives a push plate through a push cylinder to push a brush head in a storage tank to a material inlet of the transfer assembly, the transfer assembly drives a movable absorption base through a transmission belt to slide along a rolling guide rail, and therefore transfer and glue pouring of the brush head are achieved; the glue pouring assembly drives a glue pouring head through a stepping motor to achieve uniform glue pouring of the brush head; and receiving and discharge of the brush head are achieved through a receiving iron piece, a transverse cylinder and a longitudinal cylinder. The automatic glue pouring system and method can be suitable for glue pouring of paint brushes of various models, the automation degree is high, operation is convenient, the glue pouring efficiency and quality can be improved through the paint brush while labor is saved, and therefore the production cost is lowered.

Owner:XUZHOU NORMAL UNIVERSITY

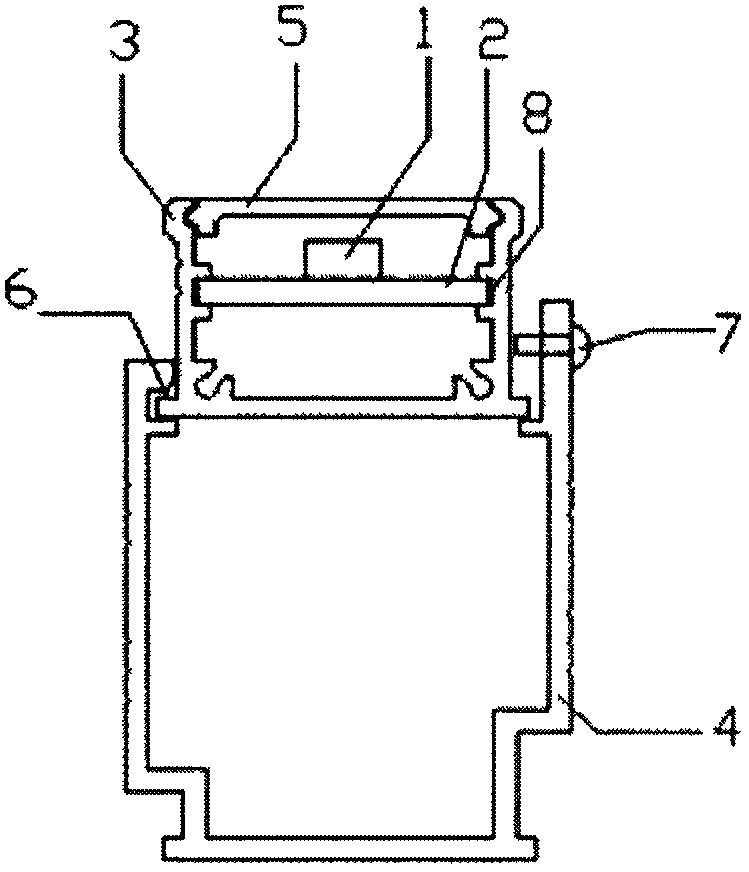

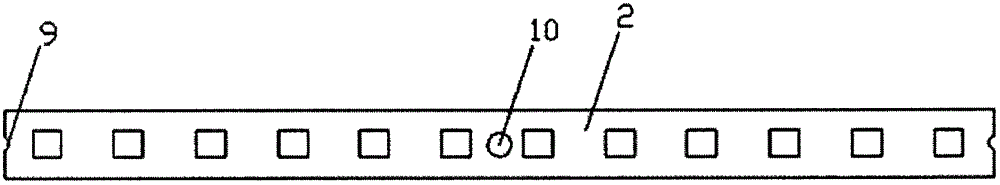

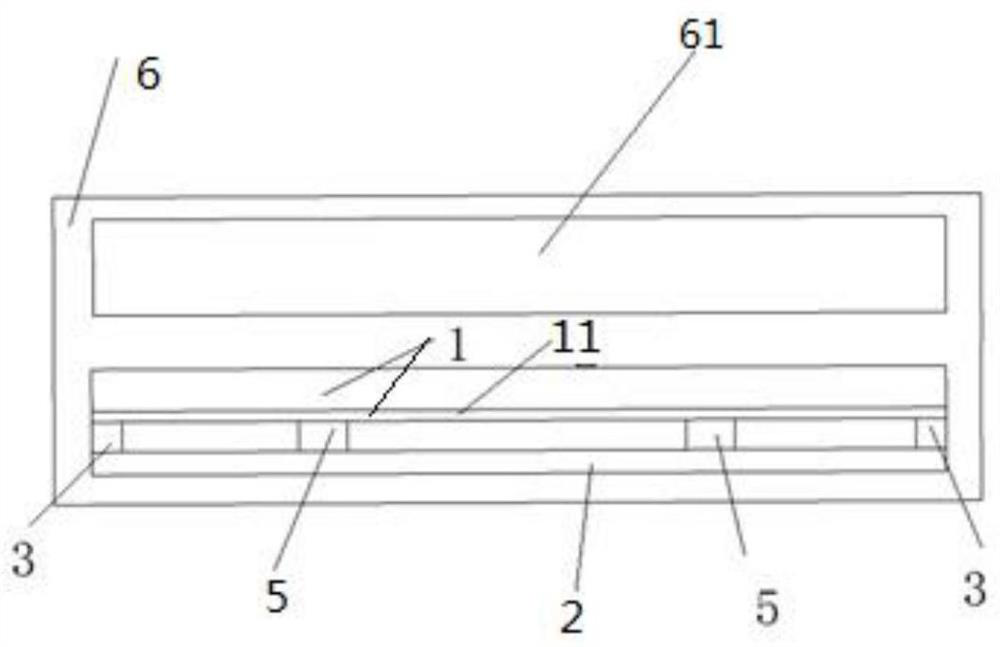

LED line light

InactiveCN102720975AImprove waterproof performanceExtended service lifePoint-like light sourceElectric circuit arrangementsTrunkingEffect light

The invention relates to a LED line light, comprising a trunking bracket and a LED lighting fixture, wherein the trunking bracket is of a frame structure with an open upper end to which the LED lighting fixture is connected, and the LED lighting fixture includes a light source, a PCB circuit board and a lamp frame, with the lamp frame connected to the PCB circuit board and the PCB circuit board arranged inside the lamp frame. The invention has the beneficial effects that: power lines and signal lines are hidden in a card slot and joints are hidden, which makes the lighting fixture meet the requirements of aesthetics in high standard installation environment; safety is improved; the installation is convenient; the lamp frame has good heat radiating effect; and holes on the circuit board can help improve efficiency and quality of glue filling. With full waterproofing encapsulation adopted, the lighting fixture is waterproof and thus has a long service life.

Owner:HANGZHOU OUCAI OPTOELECTRONICS TECH

Modified epoxy acrylic resin and preparation method thereof

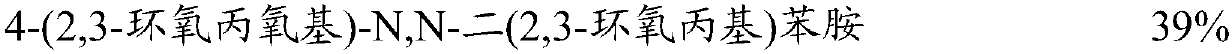

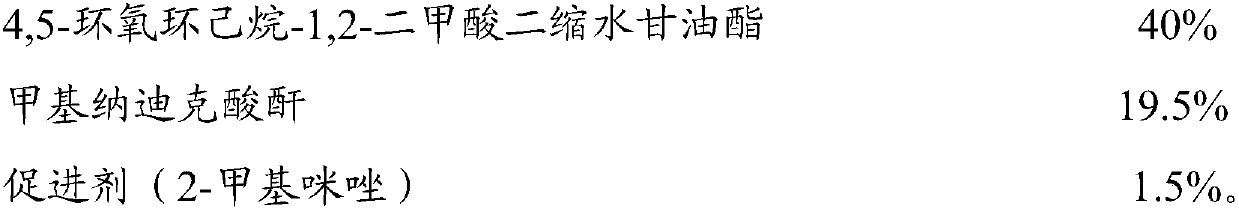

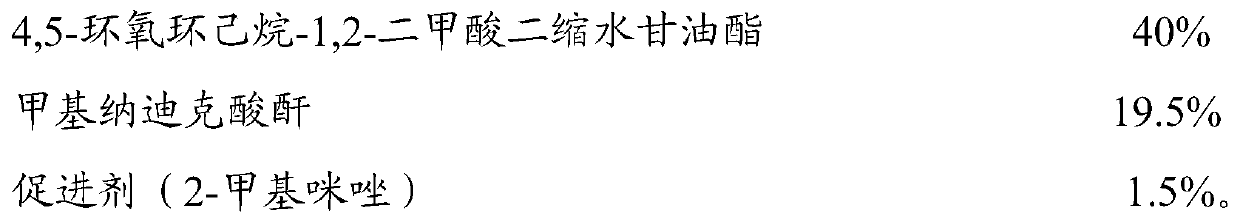

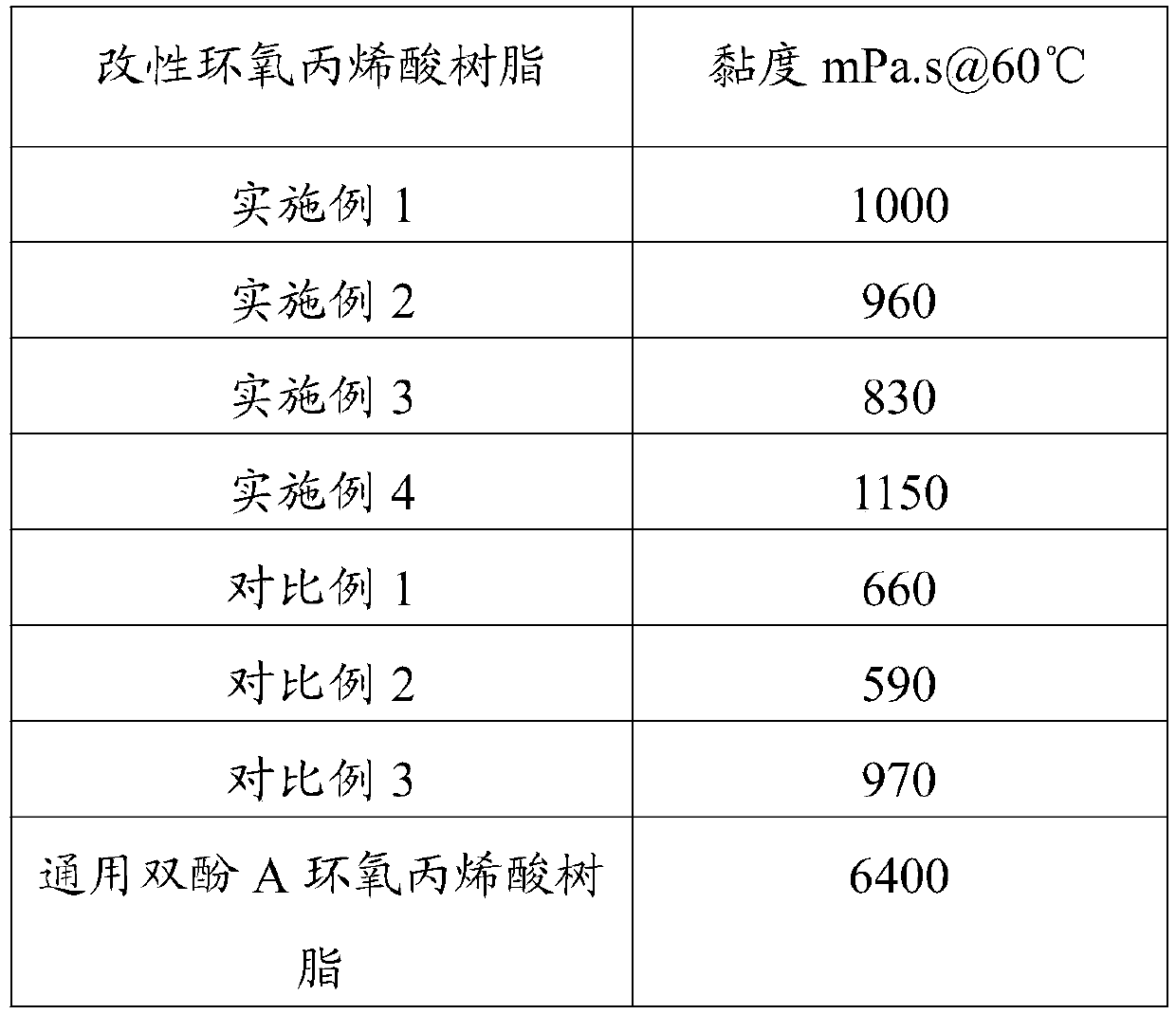

The invention relates to modified epoxy acrylic resin and a preparation method thereof. The modified epoxy acrylic resin is mainly prepared from modified cycloaliphatic epoxy resin, acrylic monomers,a catalyst and a polymerization inhibitor, wherein the modified cycloaliphatic epoxy resin is prepared from raw materials in percentage by weight as follows: 65%-85% of polyfunctional cycloaliphatic epoxy resin, 14%-34% of methyl nadic anhydride and 0.1%-3% of a promoter, wherein the mole ratio of epoxy groups to acrylic monomers in the modified cycloaliphatic epoxy resin is 1:(0.7-1.5). The modified epoxy acrylic resin has good heat resistance, can reduce curing shrinkage and has lower viscosity. With addition of the modified epoxy acrylic resin, the Tg value of a UV curing product can be greatly increased, and the modified epoxy acrylic resin has better market prospects.

Owner:广州日高新材料科技有限公司

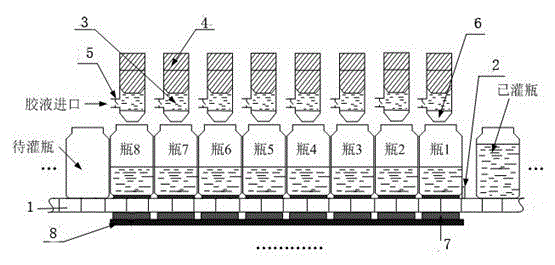

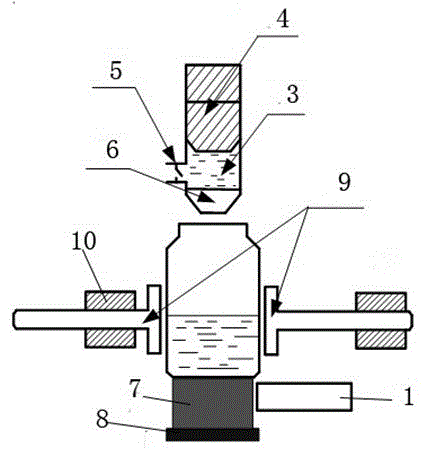

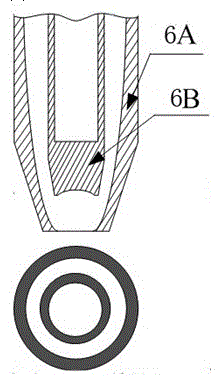

High-precision left-drop-free numerical control glue filling device

ActiveCN103569924APrecise control of glue filling accuracyEliminate the effects ofLiquid bottlingNumerical controlBottle

The invention discloses a high-precision left-drop-free numerical control glue filling device. The high-precision left-drop-free numerical control glue filling device consists of a conveying belt (1), an insulation rotary plate (2), buffer chambers (3), pistons (4), unidirectional valves (5), flow rate regulating valves (6), weighing sensors (7), weighing sensor control panels (8), filling bottle control rods (9) as well as fixing guide pipes (10); the unidirectional valves (5) are connected to inlets at one sides of the buffer chambers (3); the lower ends of the buffer chambers (3) are connected with the flow rate regulating valves (6); the upper parts of the buffer chambers (3) are provided with the pistons (4); the weighing sensors (7) are fixed on the weighing sensor control panels (8); the conveying belt (1) and the weighing sensors (7) are arranged in adjacency. The glue filling precision can be controlled accurately through controlling the weighing precision; the influence to the glue filling precision by air bubble generation randomness in filling glue is eliminated completely; the glue filling precision is improved effectively.

Owner:溧阳常大技术转移中心有限公司

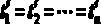

Rotary glue-pouring machine

InactiveCN105537061AReduce wasteLow costLiquid surface applicatorsCoatingsRotary stageElectric machinery

The invention discloses a rotary glue-pouring machine, which includes a glue barrel, a curing agent barrel, a control box, a rack, a workbench, a rotary device, a driving device and a mixing device. The glue barrel and the curing agent barrel are arranged above the control box, the top of the glue barrel is provided with a stirring motor, the glue barrel and the curing agent barrel are both connected to the mixing device, the rotary device consists of a rotary table, a rotary suspension arm and a pneumatic slide arm, the workbench is mounted on the rack, the pneumatic slide arm is L-shaped, one end of the rotary suspension arm is connected to the driving device through the rotary table, the other end of the rotary suspension arm is connected to one end of the pneumatic slide arm, and the other end of the pneumatic slide arm is connected to the mixing device through a fixed plate. The rotary glue-pouring machine provided by the invention feeds materials to a mixing pipe according to a set ratio of the glue barrel and the curing agent barrel, the materials are compounded on site for immediate use, the materials are mixed evenly, the dosage is accurate, and the waste of raw materials is reduced. By means of combination with the rotary device and the driving device, the rotary glue-pouring machine realizes automatic glue pouring, improves the work efficiency, and reduces the cost.

Owner:JIANGYIN LEXU PHOTOELECTRIC CO LTD

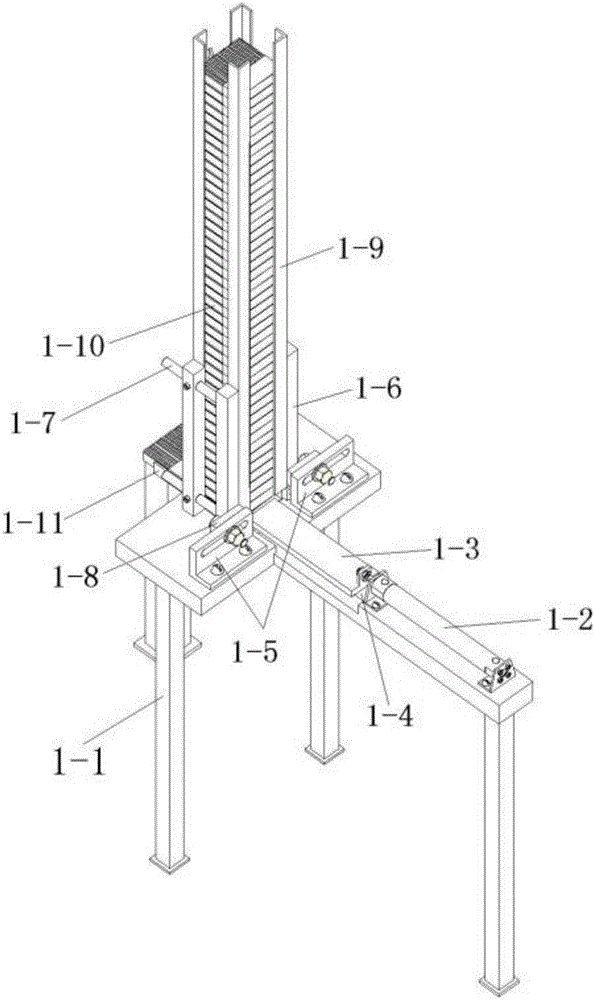

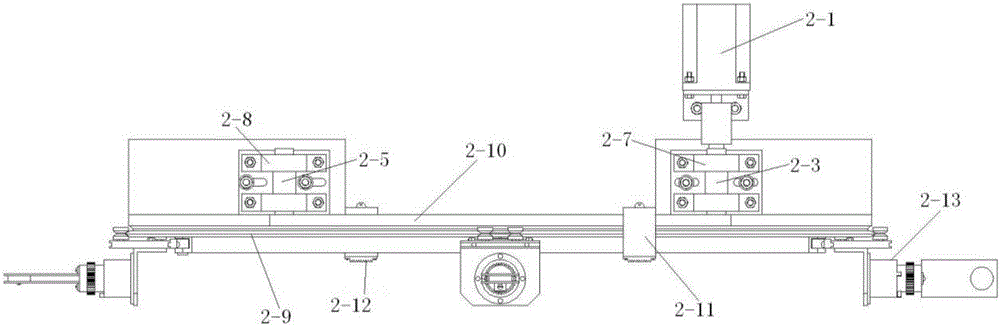

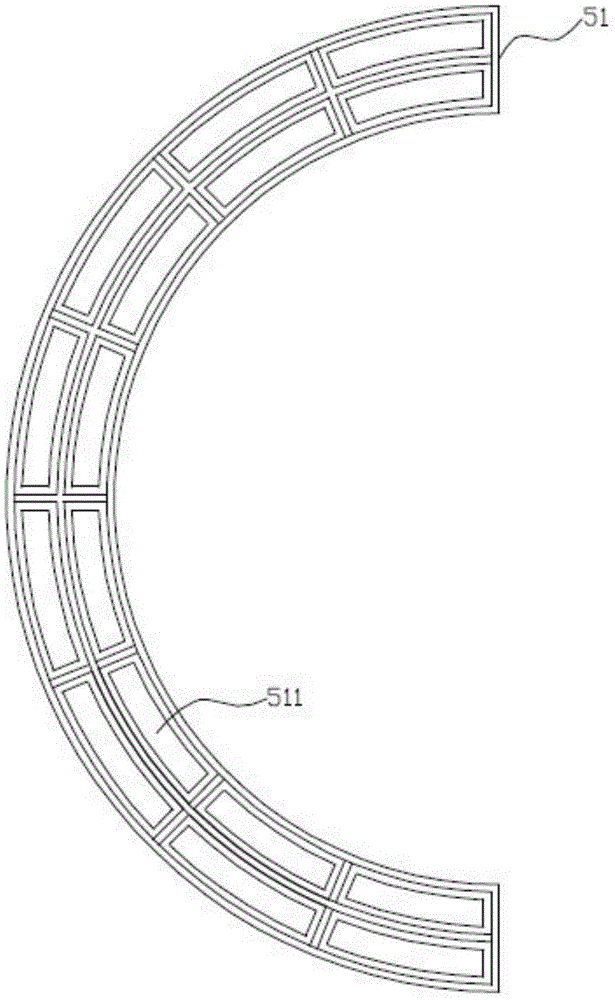

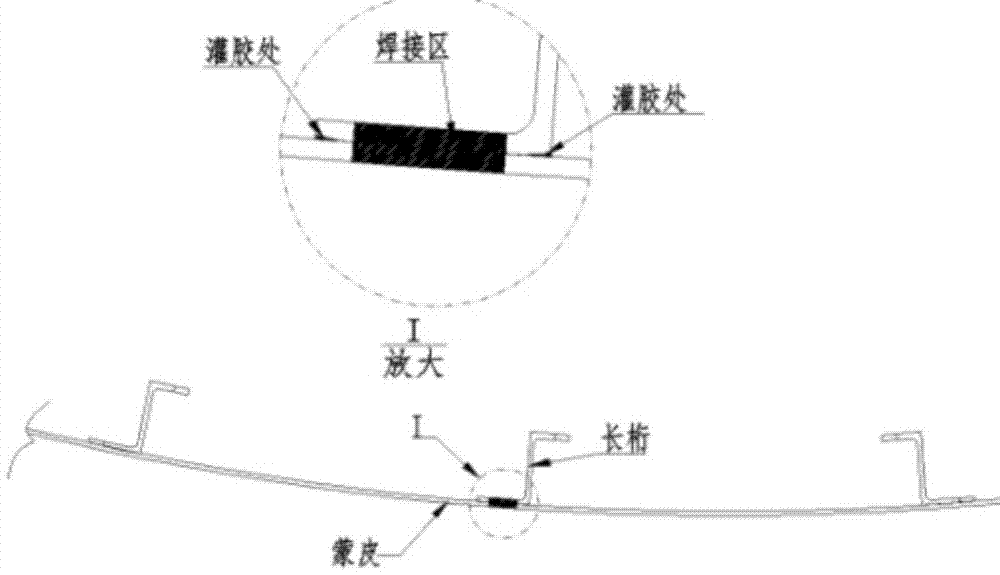

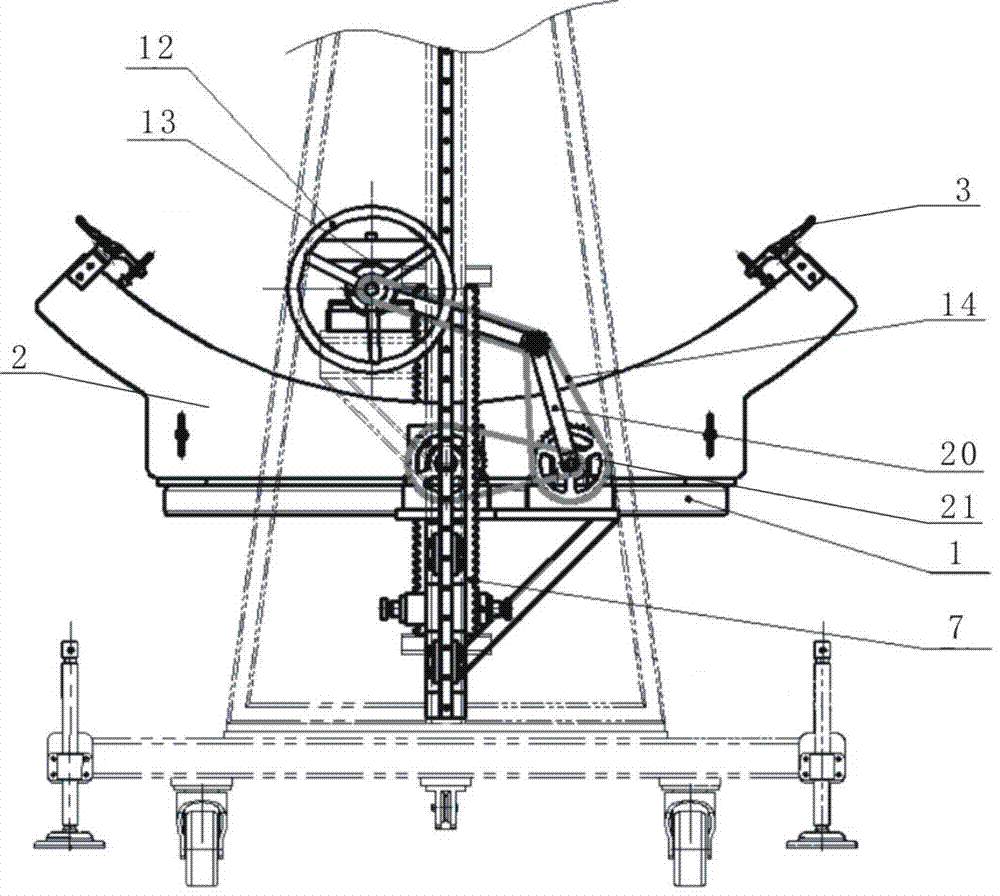

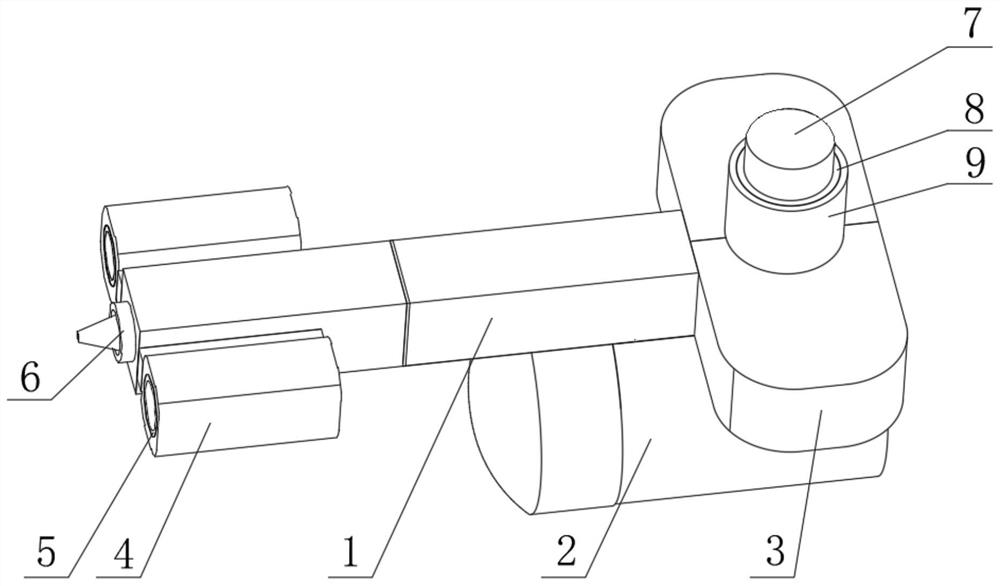

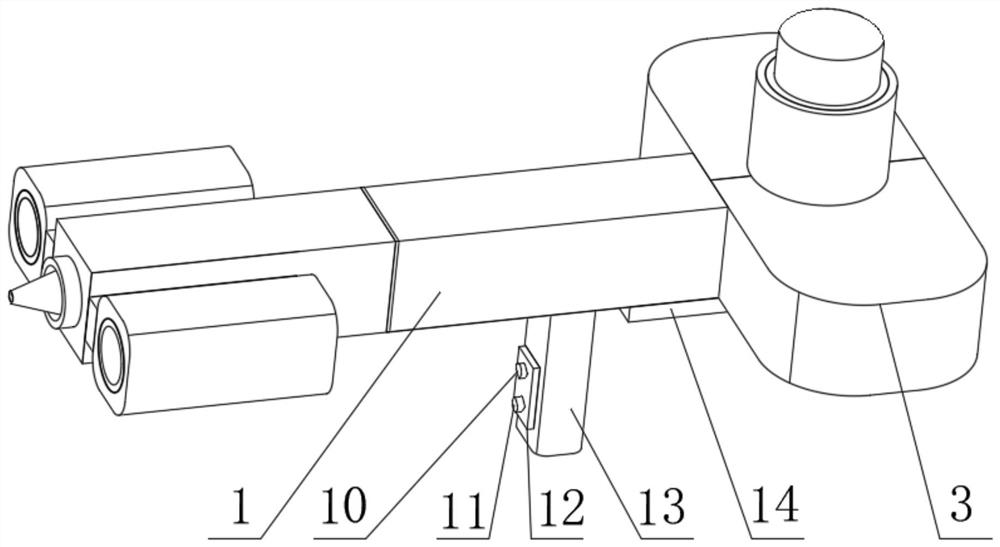

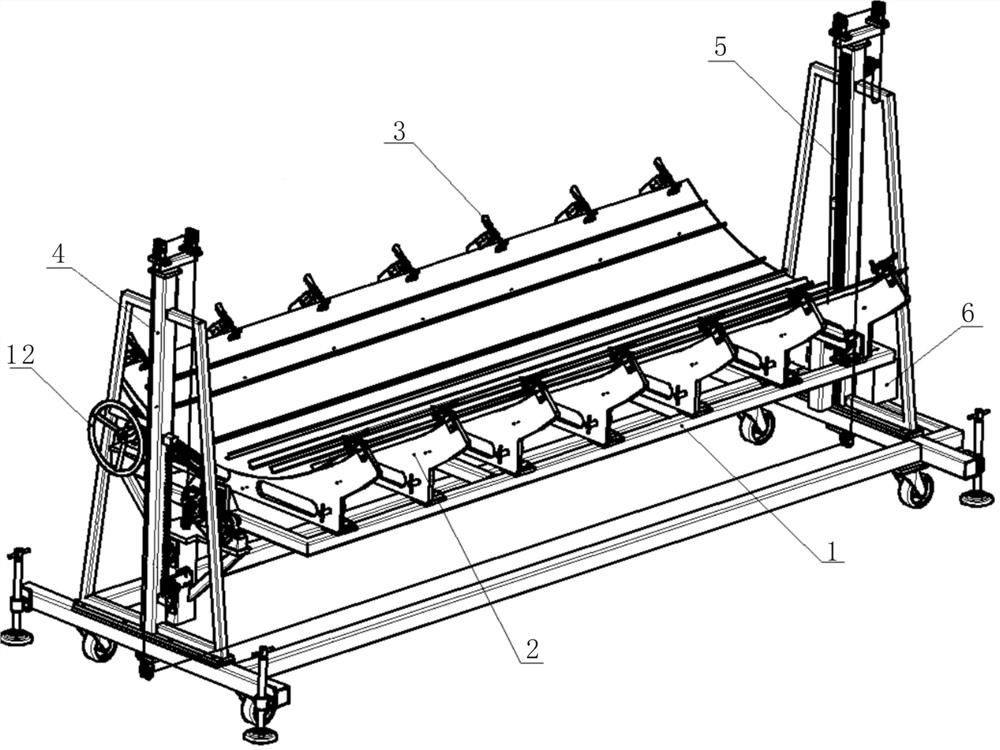

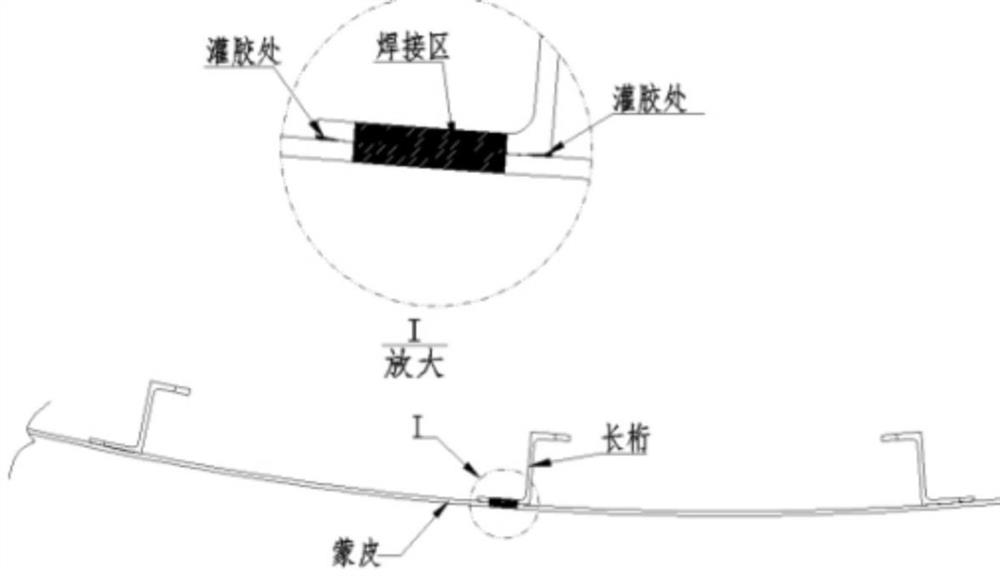

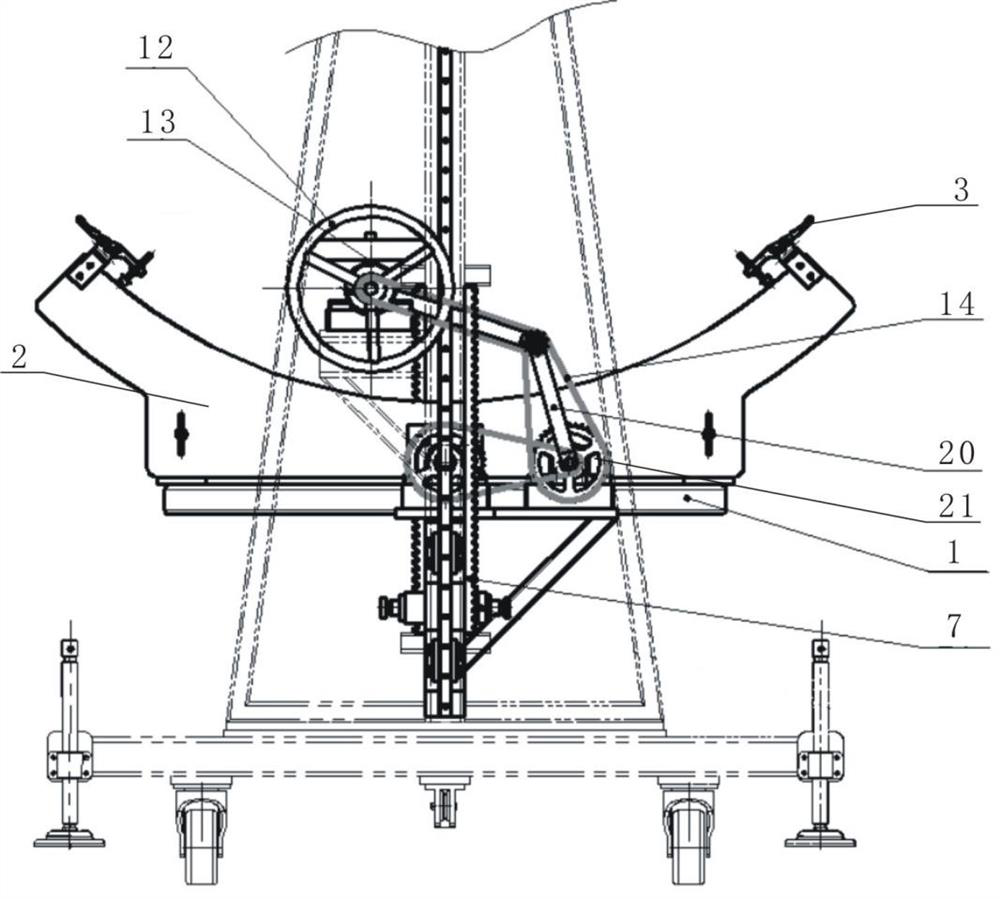

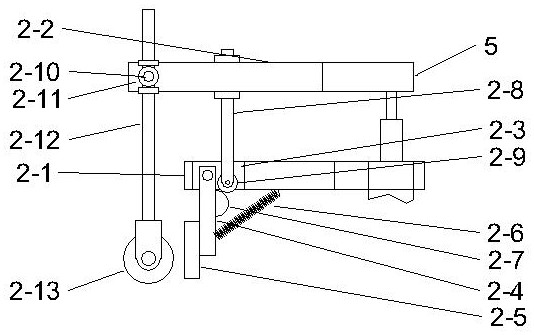

Glue filling and rotating device of aircraft skin

ActiveCN107983598AReduce labor intensityImprove glue filling efficiencyLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses a glue filling and rotating device of aircraft skin. The glue filling and rotating device comprises a mounting table, skin fixing racks and a rotating lifting mechanism, wherein a rotating shaft is arranged at the bottom of the mounting table; the skin fixing racks are fixedly mounted on the mounting table; the rotating lifting mechanism is mounted at the end of the mounting table and is connected with the rotating shaft of the mounting table; and quick press clamps are mounted on the skin fixing racks. The glue filling and rotating device has the advantages that structural design is reasonable, operation is easy and convenient, working efficiency is higher, product quality is better, and the like, and the device has relatively high practical value and popularization value.

Owner:CHENGDU HONGXIA TECH CO LTD

Three-axis linked glue pouring machine

InactiveCN105363630ARealization costReduce wasteLiquid surface applicatorsCoatingsEngineeringSupport plane

The invention discloses a three-axis linked glue pouring machine. The three-axis linked glue pouring machine comprises a cabinet, a workbench, an X-axis movement mechanism, a Y-axis movement mechanism, a Z-axis movement mechanism, a glue water barrel, a curing agent barrel, a control box and a mixing device, wherein the X-axis movement mechanism is installed on the cabinet; the workbench is slidably arranged on the X-axis movement mechanism; support frames are arranged at the two sides of the cabinet; the Y-axis movement mechanism is fixed on the support frames; the Z-axis movement mechanism is slidably arranged on the Y-axis movement mechanism; the mixing device is installed on the Z-axis movement mechanism; the glue water barrel and the curing agent barrel are arranged above the control box; and the glue water barrel and the curing agent barrel are both connected with the mixing device. The three-axis linked glue pouring machine disclosed by the invention is simple in structure, and scientific and reasonable; accurate location for a glue pouring position is realized by virtue of the X-axis movement mechanism, the Y-axis movement mechanism and the Z-axis movement mechanism, and materials are supplied to a mixing tube according to the proportions set by the glue water barrel and the curing agent barrel, and prepared while being used, so that material waste is reduced, automatic glue pouring is realized, the glue pouring efficiency is increased, and the labour cost is reduced.

Owner:JIANGYIN LEXU PHOTOELECTRIC CO LTD

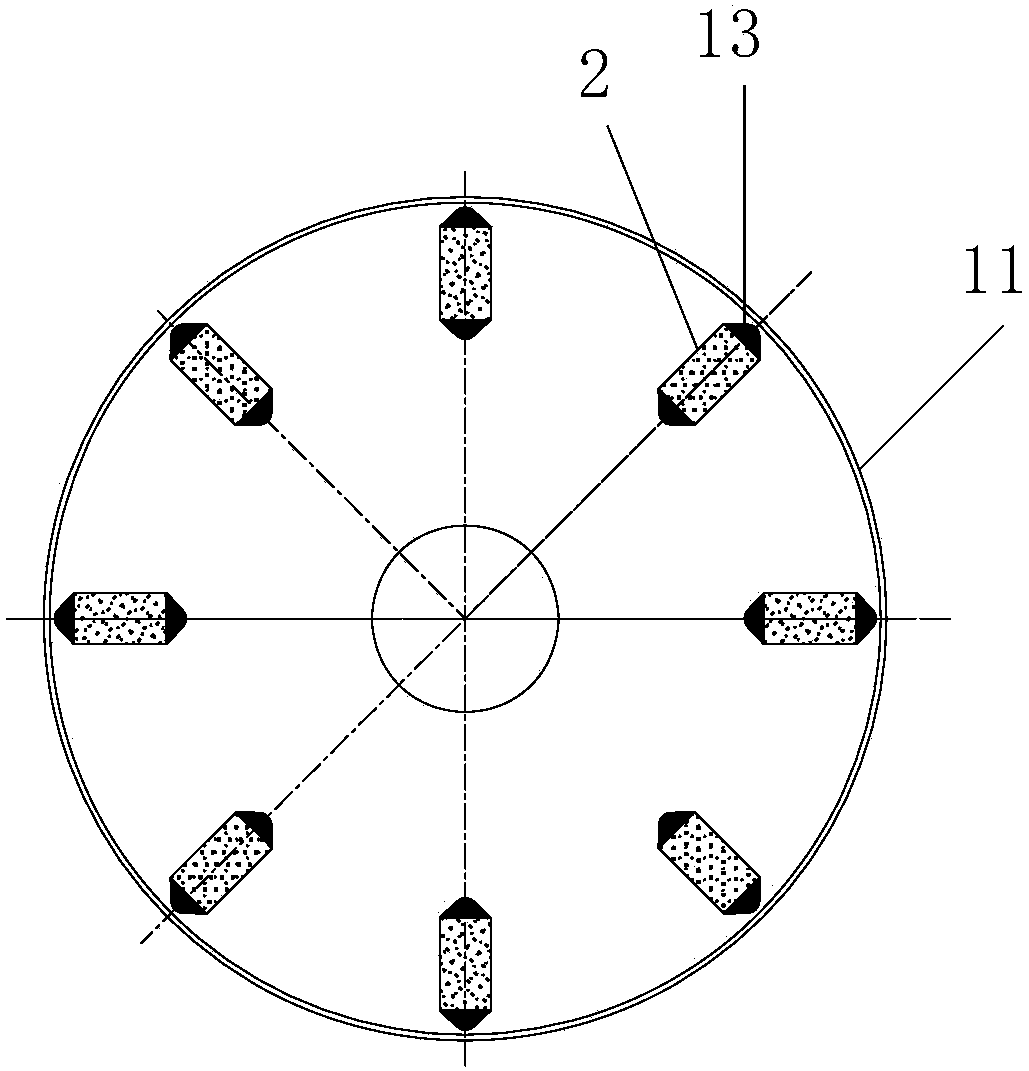

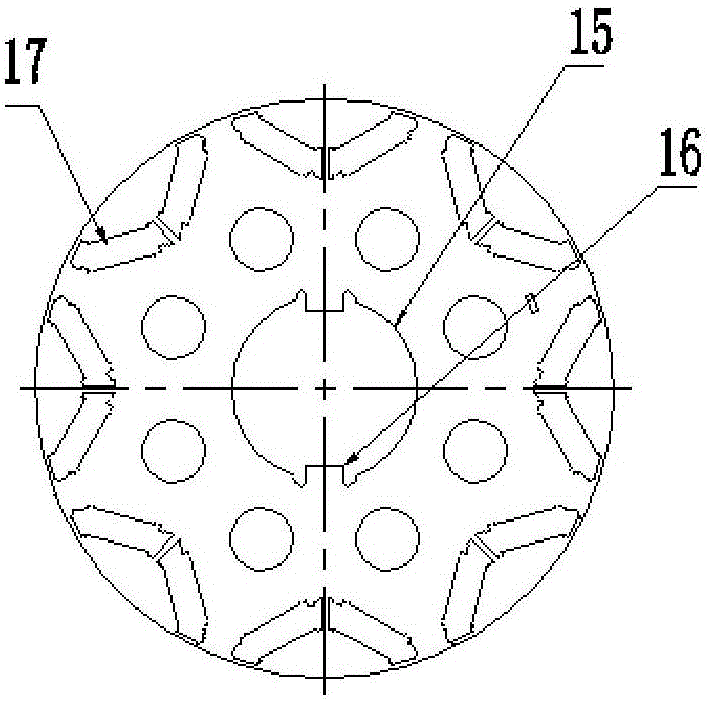

Rotor of drive motor of new energy automobile

PendingCN106655571AReduce unbalanceAchieve direct fixationMagnetic circuit rotating partsSupports/enclosures/casingsNew energyDrive motor

The invention discloses a rotor of a drive motor of a new energy automobile. The rotor is provided with a rotor iron core, wherein the rotor iron core is provided with a permanent magnet groove extending from the upper end face of the lower end face of the iron core and, the middle part of the rotor iron core is provided with an axial iron core inner round hole and the inner wall of the inner round hole of the rotor iron core is provided with a boss; a rotor shaft fitting with the inner round hole of the rotor iron core and provided with an axial open groove fitting with the boss; an upper end board whose lower end face fits the upper end face of the iron core and is provided with a first guide groove communicating with a permanent magnet groove and also provided with an air inlet and air outlet both communicating with the first guide groove; a lower end board whose upper end face fits the lower end face of the iron core and provided with a second guide groove communicating with the permanent magnet groove. Therefore, rotor structural weight and rotation inertia are reduced; the manufacture cost is reduced; and the integral performance of the drive motor is improved.

Owner:芜湖杰诺瑞汽车电器系统有限公司

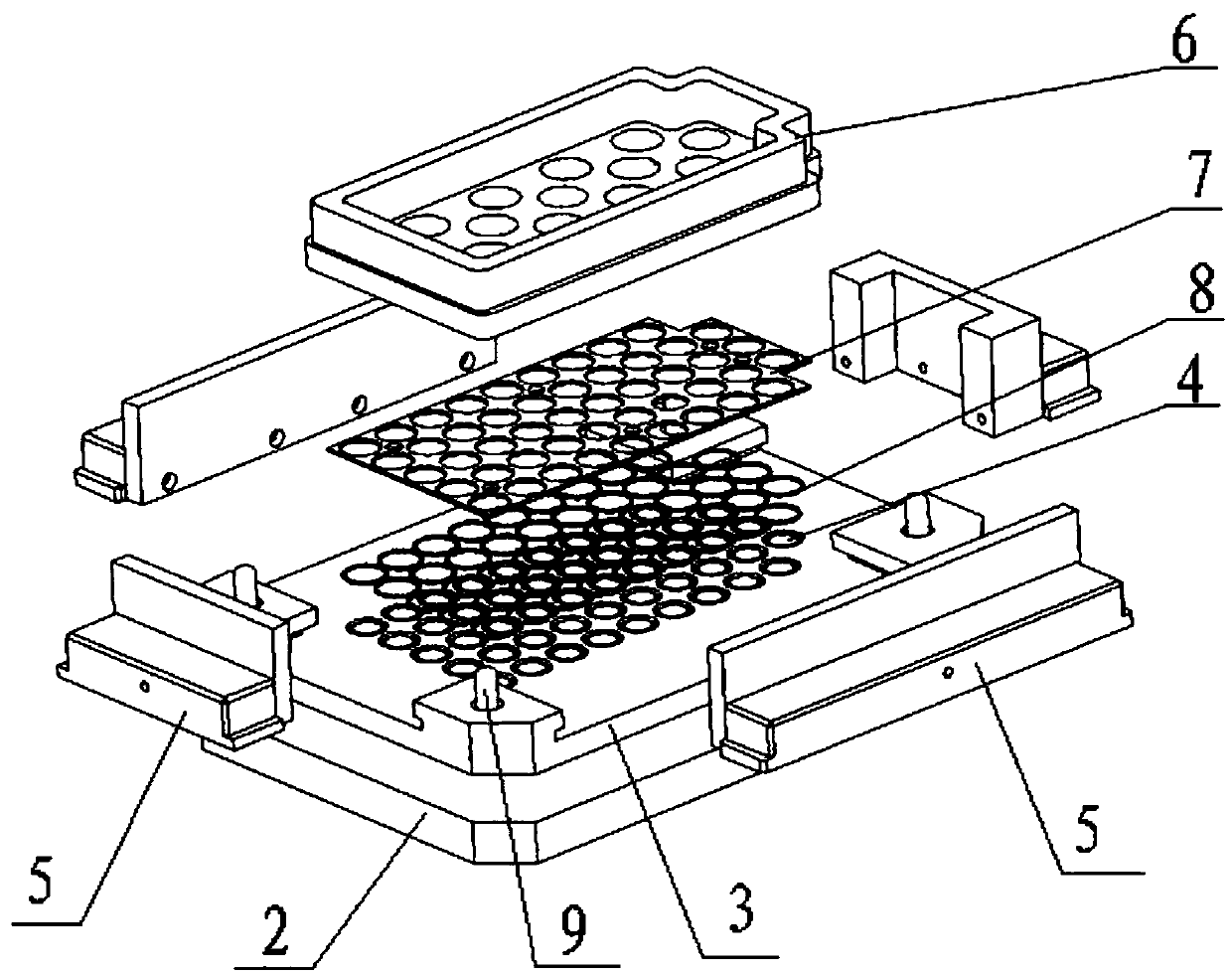

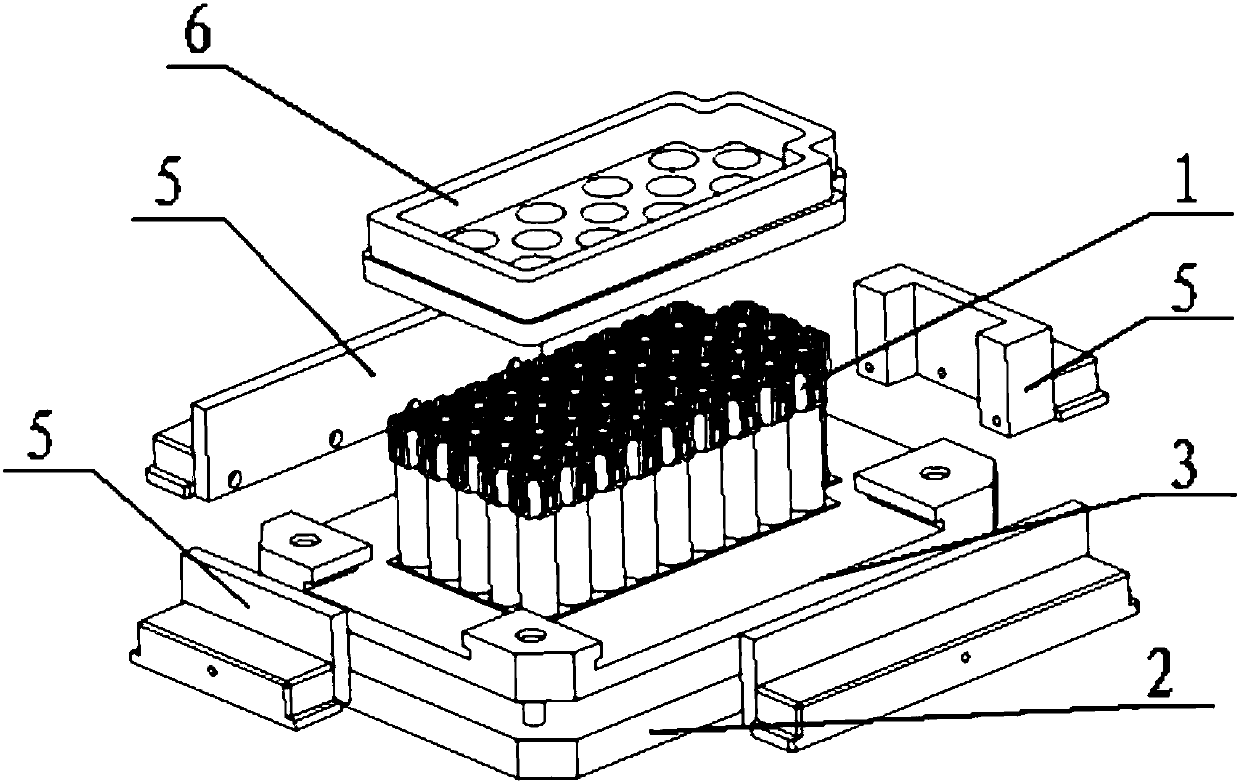

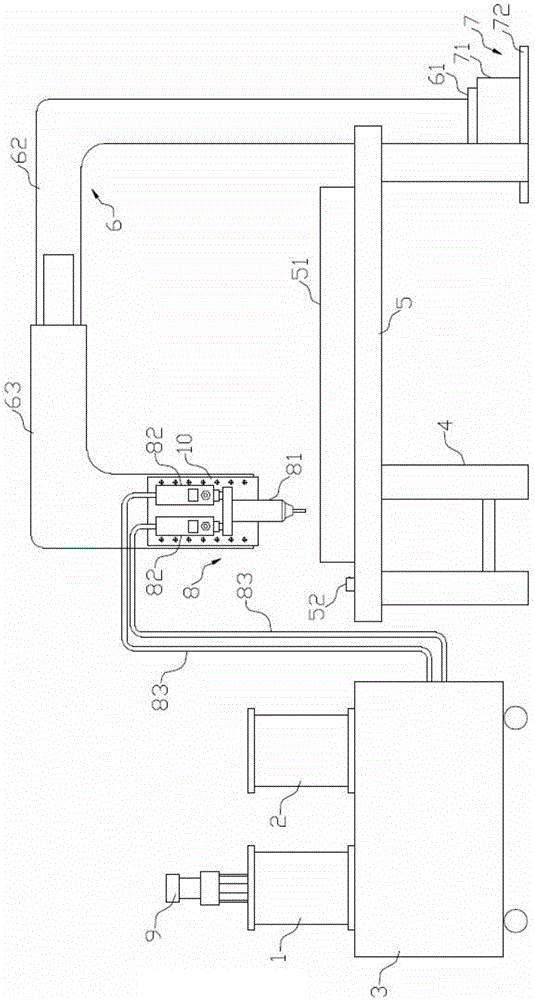

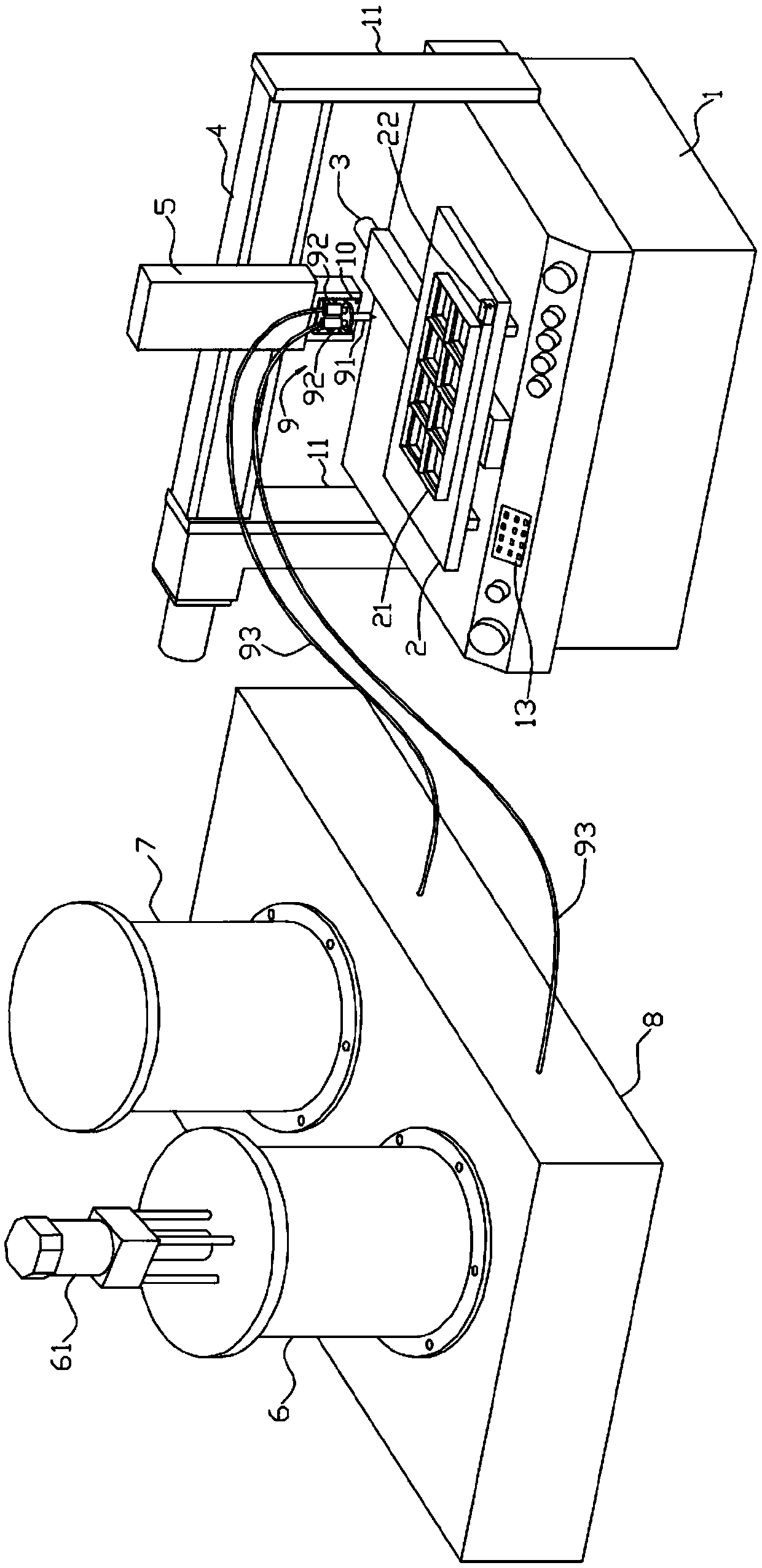

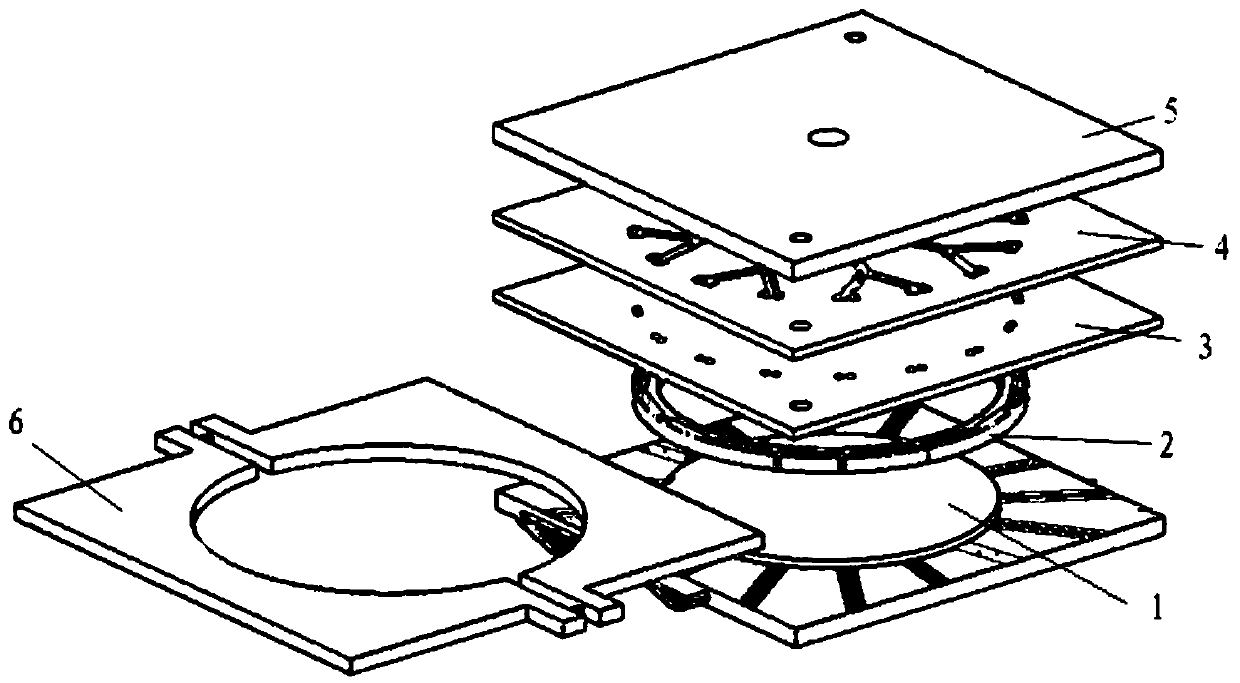

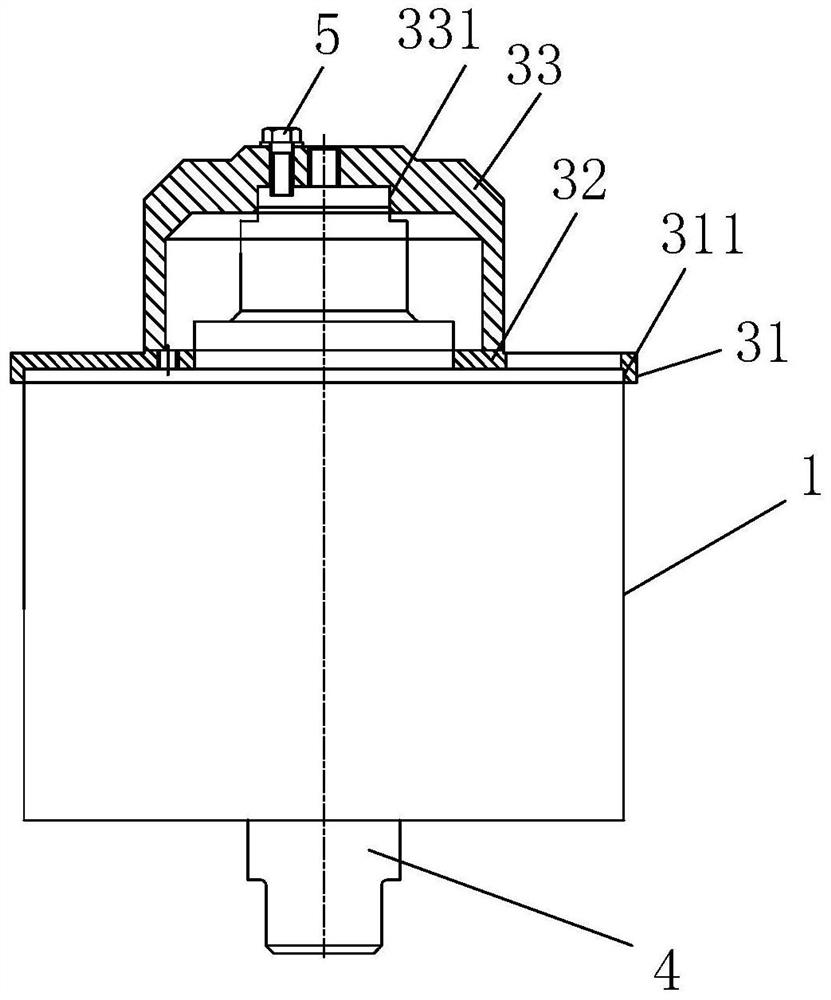

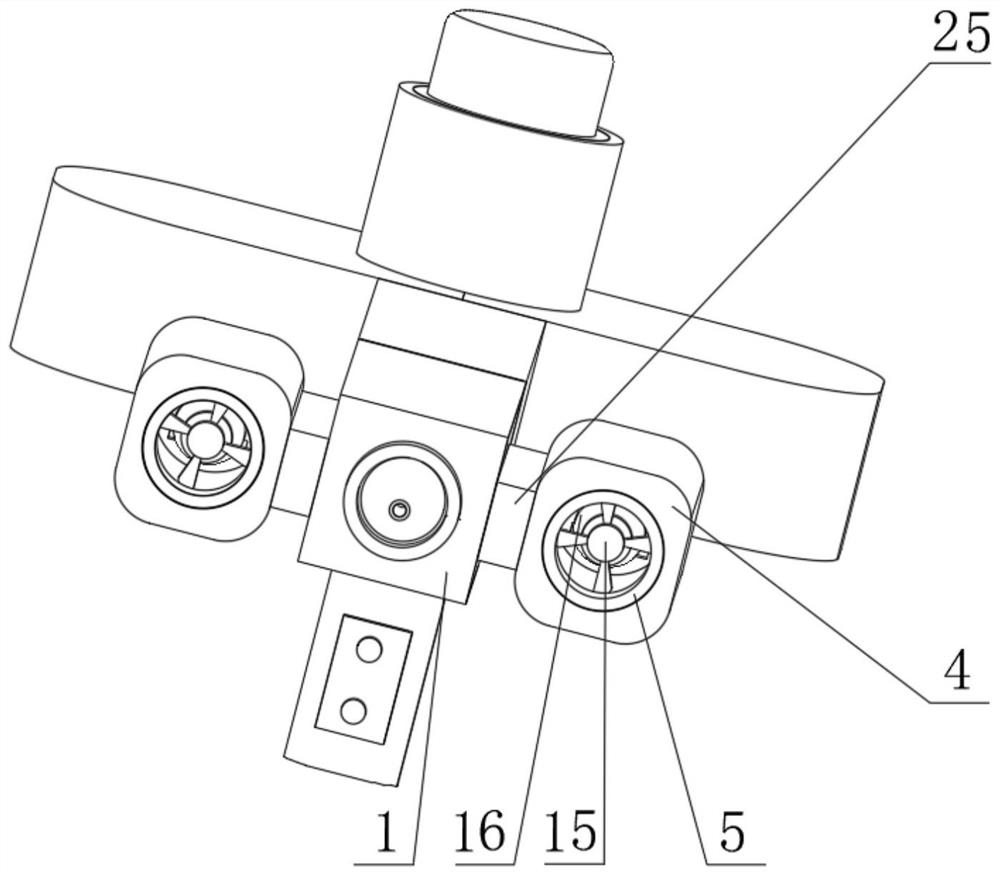

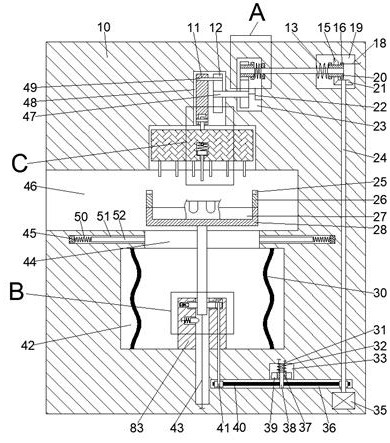

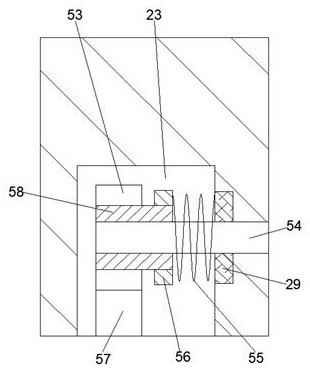

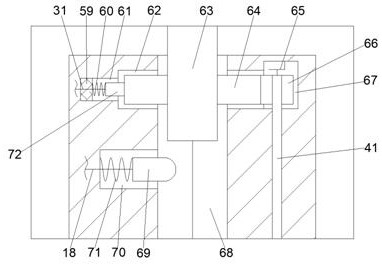

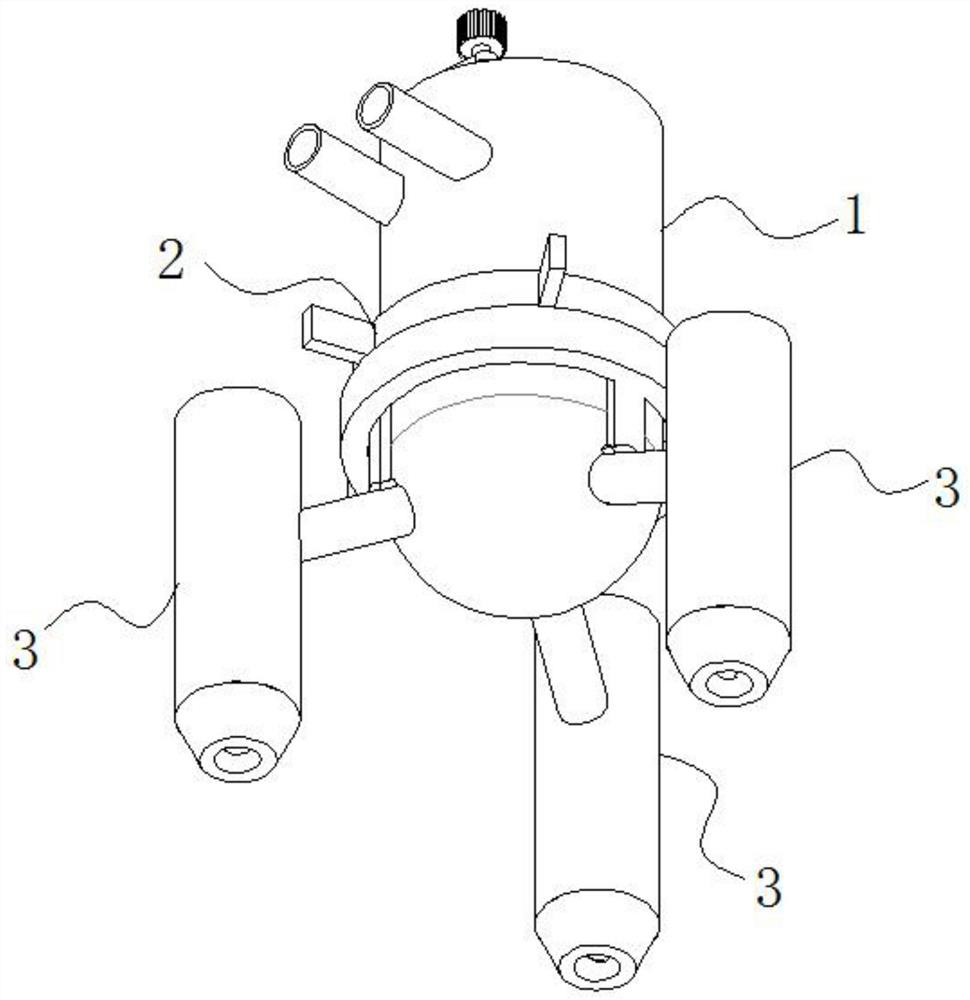

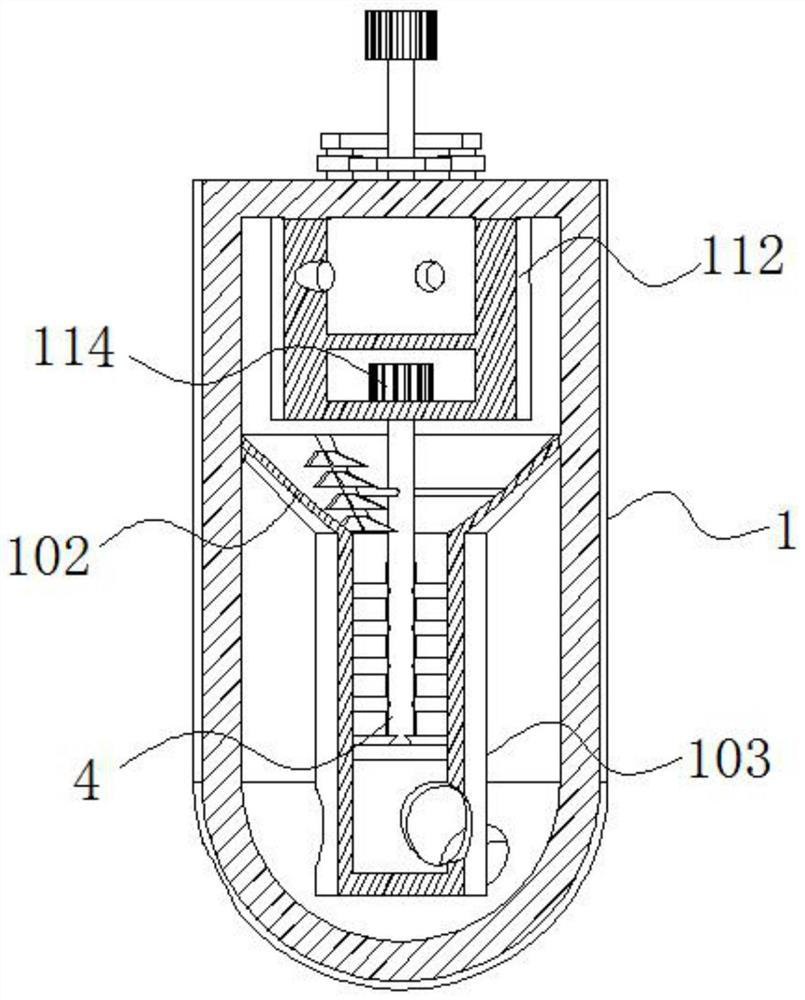

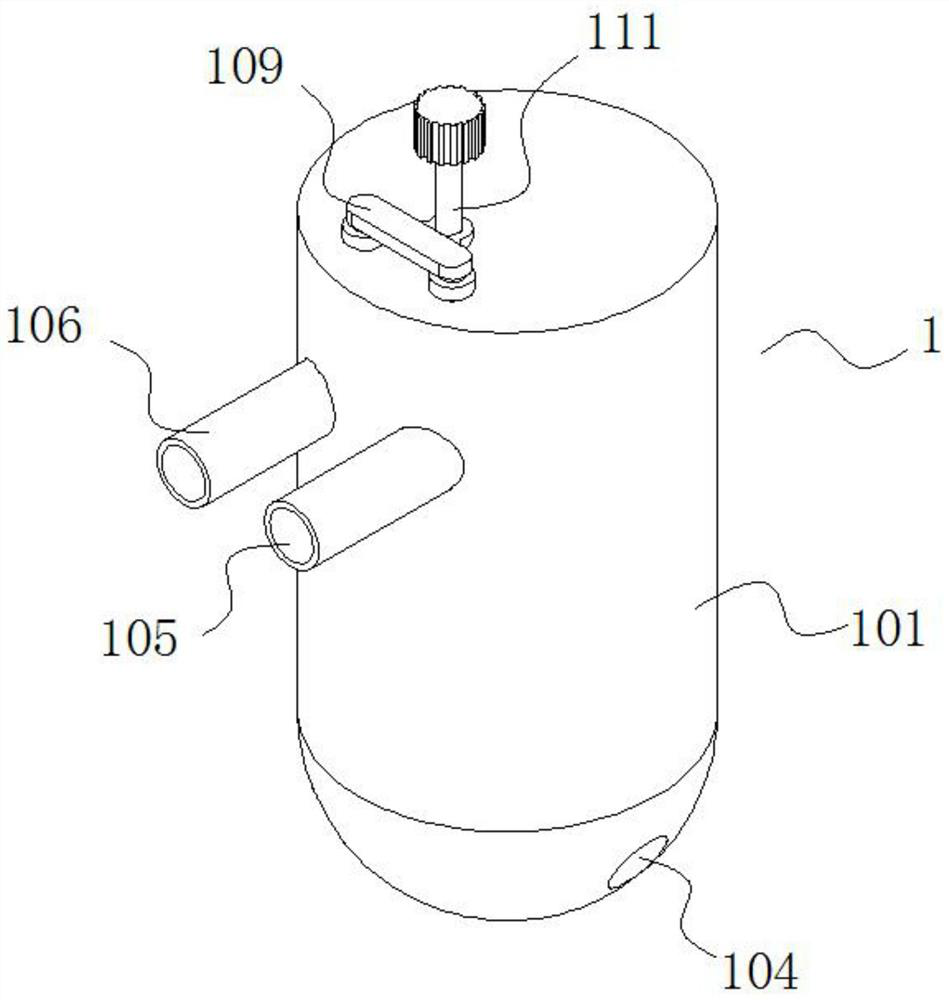

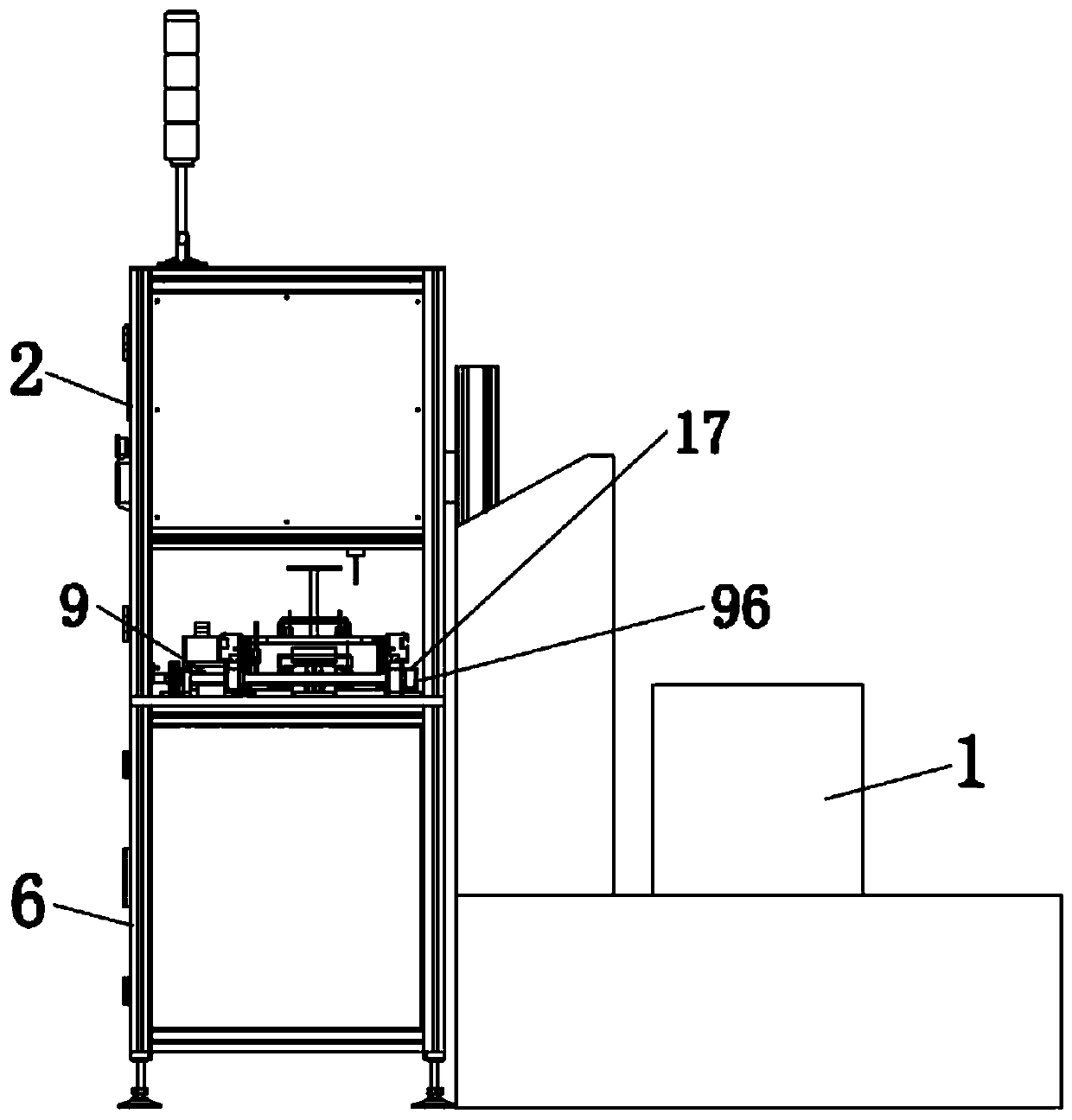

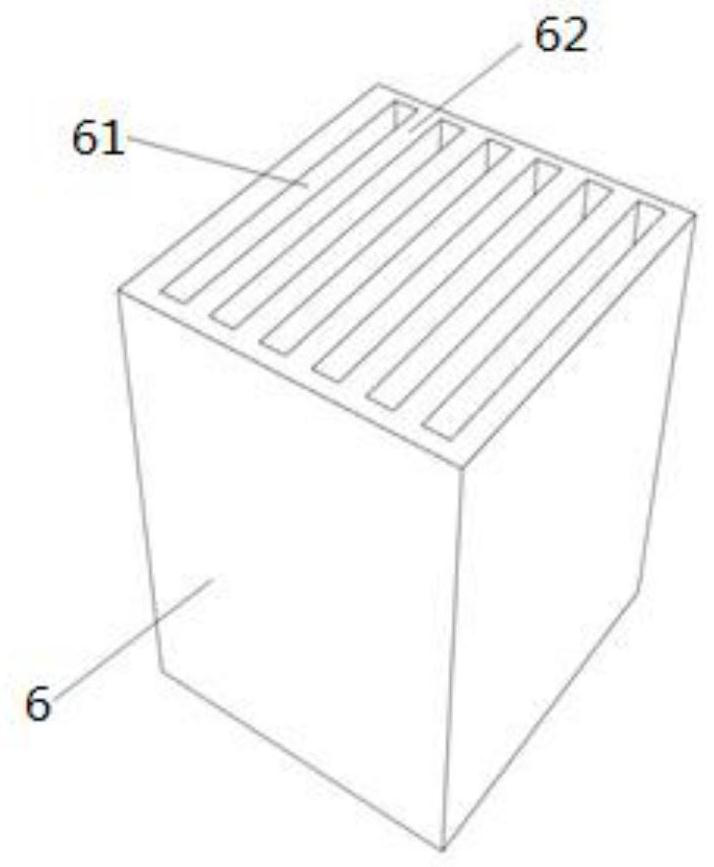

Glue filling equipment for rotor magnetic steel

ActiveCN109624199AReduce use costEasy to operateElectric machinesManufacturing stator/rotor bodiesElectrical and Electronics engineeringEngineering

The invention discloses glue filling equipment for rotor magnetic steel. The glue filling equipment comprises a base, a fixing ring, a glue port plate, a flow channel plate and a covering plate; the fixing ring is used for fixing magnetic steel and placed on the base together with the magnetic steel; the fixing ring is covered with the glue port plate, and a plurality of penetrating first throughholes are formed in the glue port plate; the glue port plate is covered with the flow channel plate, a plurality of flow channels are formed on the flow channel plate, second through holes are formedin the tail ends of the flow channels, and the positions of the second through holes correspond to the positions of the first through holes; the glue port plate is covered with the covering plate, anda glue injection hole which communicates with the flow channels is formed in the covering plate. According to the glue filling equipment for the rotor magnetic steel, the glue port plate is matched with the flow channel plate, the periphery of the magnetic steel is subjected to glue filling in a targeted mode, glue flows to an appointed position of the glue port plate on the periphery of the magnetic steel along the flow channel plate, the operation is easy and convenient, additional treatment is not needed, the glue filing efficiency is improved, and the using cost of the glue is reduced.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

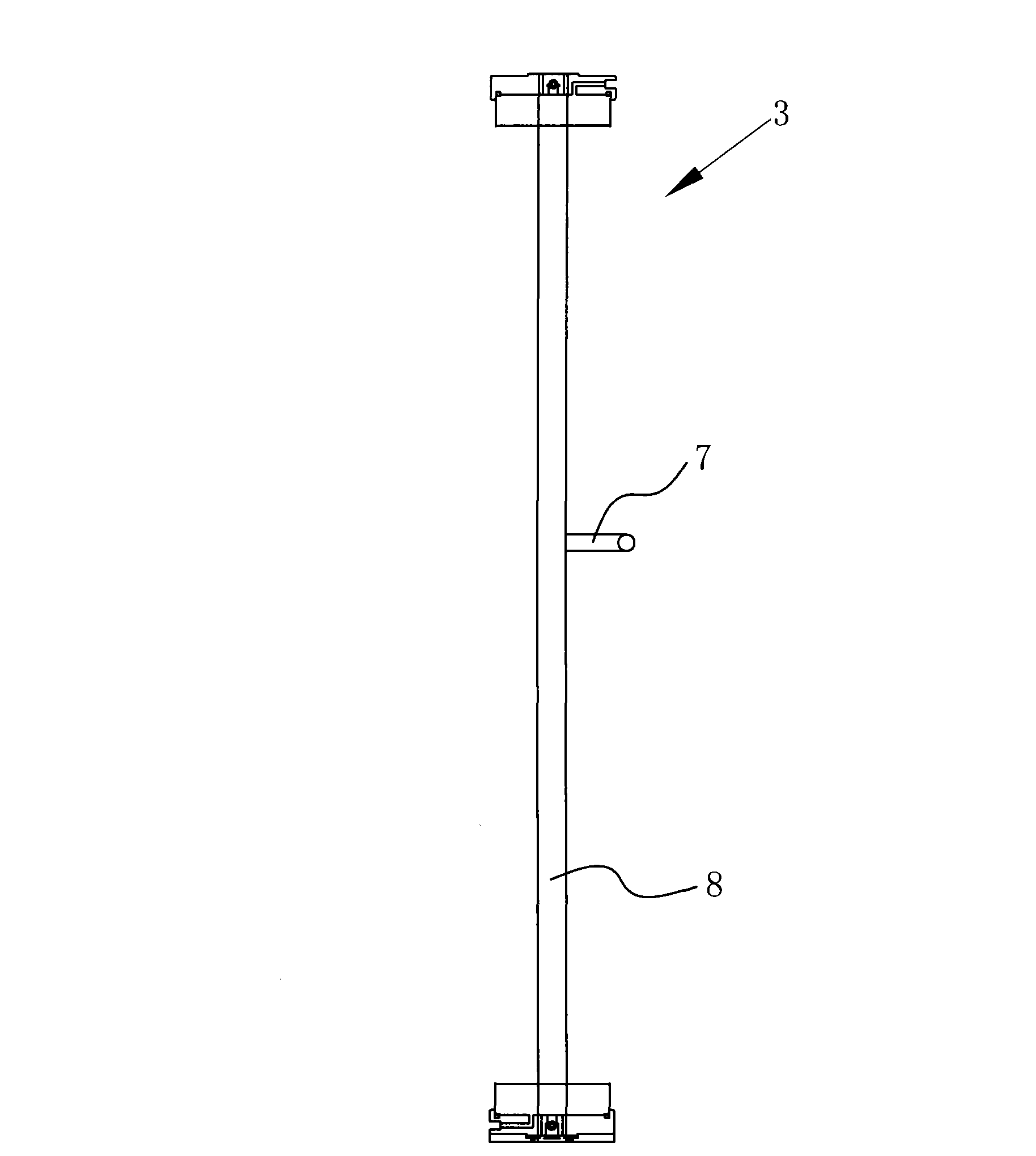

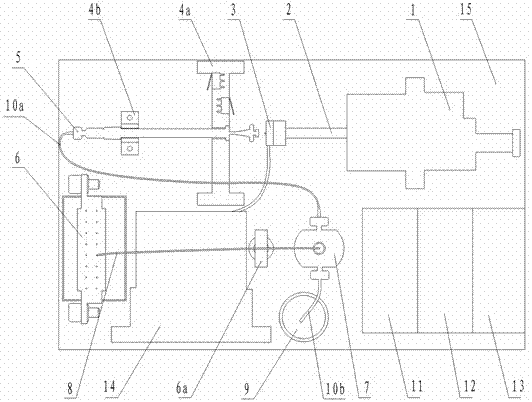

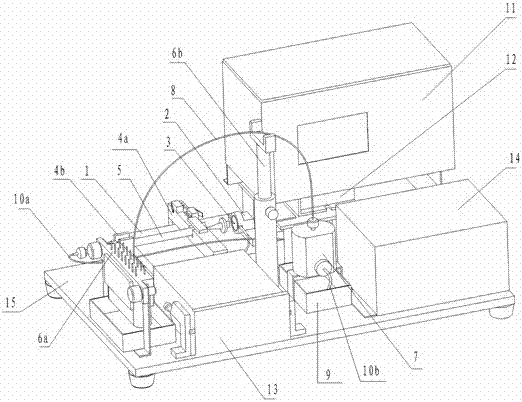

Automatic cleaning and glue pouring platform for capillary array

InactiveCN102253104AHigh degree of automationImprove cleaning efficiencyMaterial analysis by electric/magnetic meansEngineeringDirect current

The invention discloses an automatic cleaning and glue pouring platform for a capillary array. A push rod is arranged on an electric translation stage; a pressure sensor is arranged on an end surface of the push rod; a microscale sample injector support and a microscale sample injector are arranged on a direction on which the push rod travels; a tail end of the microscale sample injector is clinging to the pressure sensor, and a head of the microscale sample injector is connected with a conduit. A capillary support comprises a capillary head pedestal and a capillary central support, which areseparated, wherein a height of the central support can be adjusted manually. A first path of a transparent tee joint is connected with the head of the microscale sample injector through a conduit; a second path is connected with a head of a capillary; and the third path is connected with a liquid bath liquid bath through a conduit. A pressure sensor display meter is disposed on a platform. The translation stage is equipped with a meter controller with a faceplate, a stepping motor and a direct-current power supply thereon. The platform of the invention can carry out repetitive automatic cleaning and glue pouring on the capillary array, and has advantages of high degree of automation, high cleaning and glue pouring efficiency, compact structure, simple operation and reliable performance, etc.

Owner:ZHEJIANG UNIV

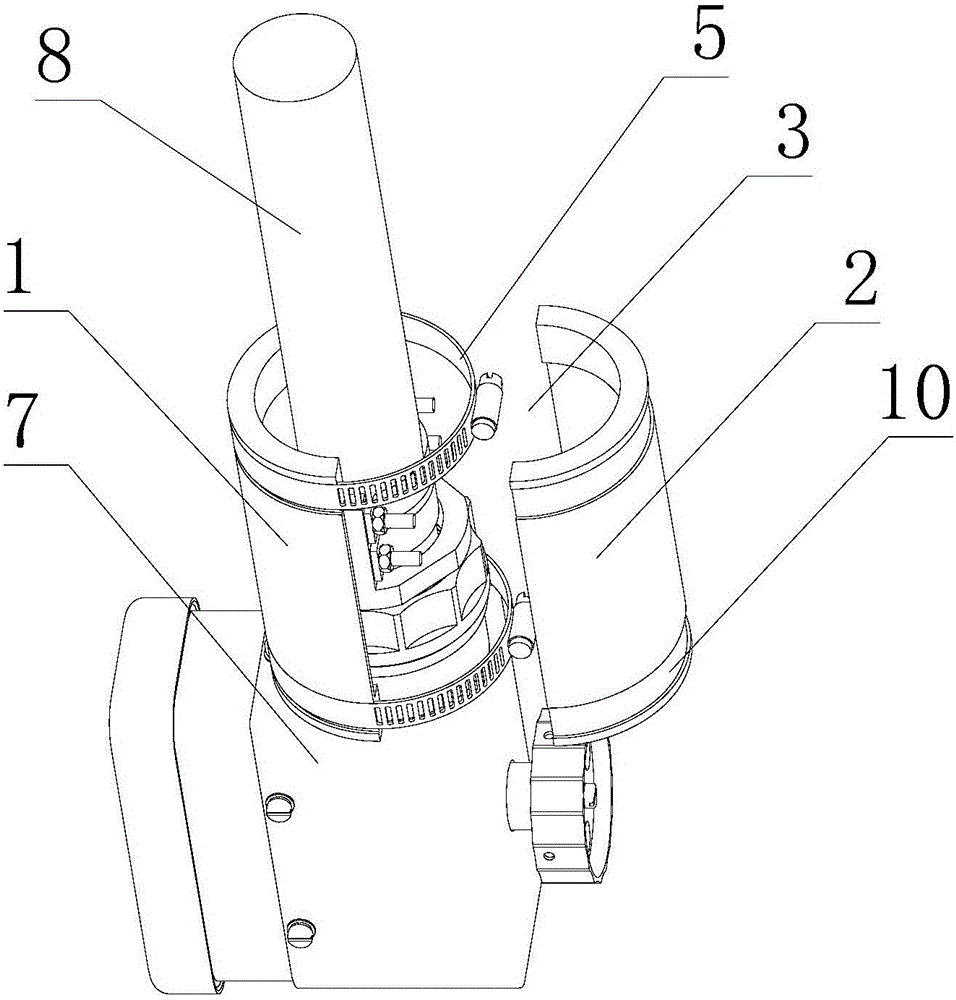

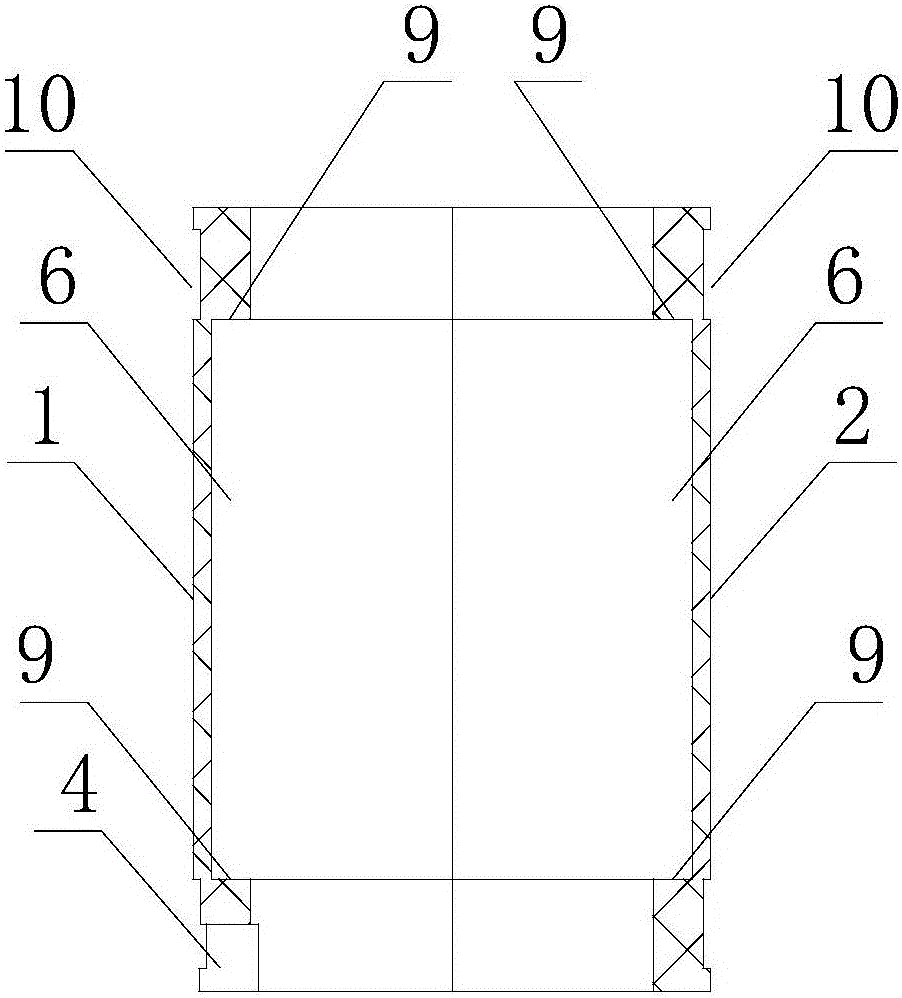

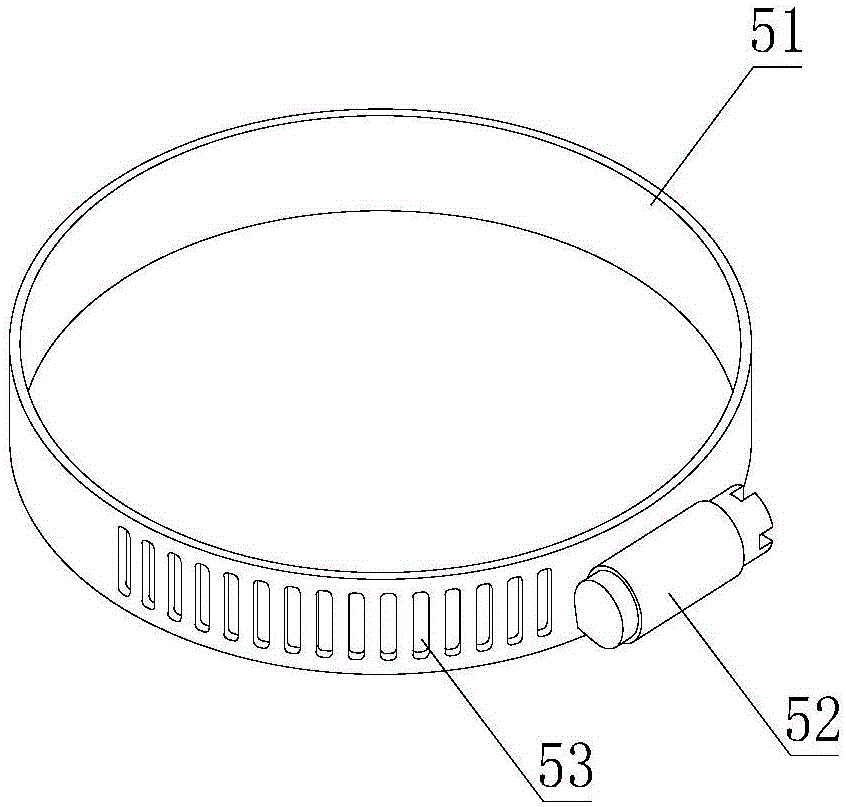

Glue filling tool

ActiveCN111589642AIncrease distribution speedImprove glue filling efficiencyLiquid surface applicatorsSecondary cellsElectrical batteryEngineering

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

A method of vacuum filling glue for permanent magnet motor rotor

ActiveCN109698590BReduce gapAvoid churnPretreated surfacesManufacturing stator/rotor bodiesEpoxyVacuum pumping

The invention discloses a vacuum glue pouring method for permanent magnetism motor rotors. The method includes the following steps: S1, a step of iron core profiling processing, namely the step of applying pressure to compress iron core punching sheets in an axial direction of a permanent magnetism motor; S2, a step of glue solution configuration, namely the step of uniformly mixing an A componentand B component of a two-component epoxy resin adhesive; S3, a step of vacuum glue pouring, namely the step of placing a rotor into a vacuum cavity to perform vacuum pumping, and then performing gluepouring; and S4, a step of heating and curing, namely the step of placing the rotor after glue pouring into a tunnel type baking channel to perform segment drying. The method has high glue pouring efficiency, tooth tension and glue loss phenomenon is not easy to occur, and the quality of products can meet the filling technical requirements of the permanent magnetism motor rotor.

Owner:湖南中车商用车动力科技有限公司

Self-cleaning glue-pouring machine

The invention discloses a self-cleaning glue-pouring machine. The self-cleaning glue-pouring machine comprises a machine cabinet, a workbench, an X-axis movement mechanism, a Y-axis movement mechanism, a Z-axis movement mechanism, a glue barrel, a curing agent barrel, a cleaning fluid barrel, a mixing device and a control cabinet, wherein the X-axis movement mechanism is mounted on the machine cabinet; the workbench is arranged on the X-axis movement mechanism in a sliding mode; supporting frames are arranged on the two sides of the machine cabinet; the Y-axis movement mechanism is fixed to the supporting frames; the Z-axis movement mechanism is arranged on the Y-axis movement mechanism in a sliding mode; the mixing device is mounted on the Z-axis movement mechanism; the glue barrel, the curing agent barrel and the cleaning fluid barrel are arranged above the control cabinet; the cleaning fluid barrel is provided with a pressure pump, a first fluid outlet and a second fluid outlet; the curing agent barrel is provided with a third fluid outlet; the glue barrel is provided with a fourth fluid outlet; the fourth fluid outlet and the second fluid outlet are communicated with the mixing device through a first switchover valve, and the third fluid outlet and the first fluid outlet are communicated with the mixing device through a second switchover valve. The self-cleaning glue-pouring machine has the self-cleaning and automatic-glue-pouring functions and can be used once being assembled.

Owner:JIANGYIN LEXU PHOTOELECTRIC CO LTD

Glue extrusion glue supplementing device for electronic equipment production

InactiveCN112547449AGood glueImprove convenienceLiquid surface applicatorsCoatingsAdhesive glueProcess engineering

The invention discloses a glue extrusion glue supplementing device for electronic equipment production, and relates to the technical field of electronic equipment production. The glue extrusion glue supplementing device comprises a shell, wherein a nozzle is arranged on one side of the shell, a positioning plate is fixedly connected to the other side of the shell, a heat conduction ring is fixedlyconnected to the inner side of a positioning sleeve, and a glue storage device is arranged in the heat conduction ring; and extrusion plates are arranged on the two sides of the bottom end of the glue storage device. According to the glue extrusion glue supplementing device for electronic equipment production, through cooperative arrangement of a hydraulic pump, a first heating device, an electric power supply device, fans and a motor, the nozzle of the device is moved into a gap needing glue supplementing, the electric power supply device is started, a hydraulic pump switch is pressed down,and the hydraulic pump is started; and glue with good fluidity in a conveying pipeline is conveyed into the nozzle, air is sprayed to the gap after being heated, glue supplementing is better conductedon electronic equipment, the glue supplementing efficiency of the device is improved, and it is guaranteed that the glue is rapidly dried.

Owner:HANGZHOU KUANFU TECH

A kind of aircraft skin glue pouring rotating equipment

ActiveCN107983598BReduce labor intensityImprove glue filling efficiencyLiquid surface applicatorsCoatingsStructural engineeringMechanical engineering

The invention discloses a glue filling and rotating device of aircraft skin. The glue filling and rotating device comprises a mounting table, skin fixing racks and a rotating lifting mechanism, wherein a rotating shaft is arranged at the bottom of the mounting table; the skin fixing racks are fixedly mounted on the mounting table; the rotating lifting mechanism is mounted at the end of the mounting table and is connected with the rotating shaft of the mounting table; and quick press clamps are mounted on the skin fixing racks. The glue filling and rotating device has the advantages that structural design is reasonable, operation is easy and convenient, working efficiency is higher, product quality is better, and the like, and the device has relatively high practical value and popularization value.

Owner:CHENGDU HONGXIA TECH CO LTD

Modified epoxy acrylic resin and preparation method thereof

The invention relates to modified epoxy acrylic resin and a preparation method thereof. The modified epoxy acrylic resin is mainly prepared from modified cycloaliphatic epoxy resin, acrylic monomers,a catalyst and a polymerization inhibitor, wherein the modified cycloaliphatic epoxy resin is prepared from raw materials in percentage by weight as follows: 65%-85% of polyfunctional cycloaliphatic epoxy resin, 14%-34% of methyl nadic anhydride and 0.1%-3% of a promoter, wherein the mole ratio of epoxy groups to acrylic monomers in the modified cycloaliphatic epoxy resin is 1:(0.7-1.5). The modified epoxy acrylic resin has good heat resistance, can reduce curing shrinkage and has lower viscosity. With addition of the modified epoxy acrylic resin, the Tg value of a UV curing product can be greatly increased, and the modified epoxy acrylic resin has better market prospects.

Owner:广州日高新材料科技有限公司

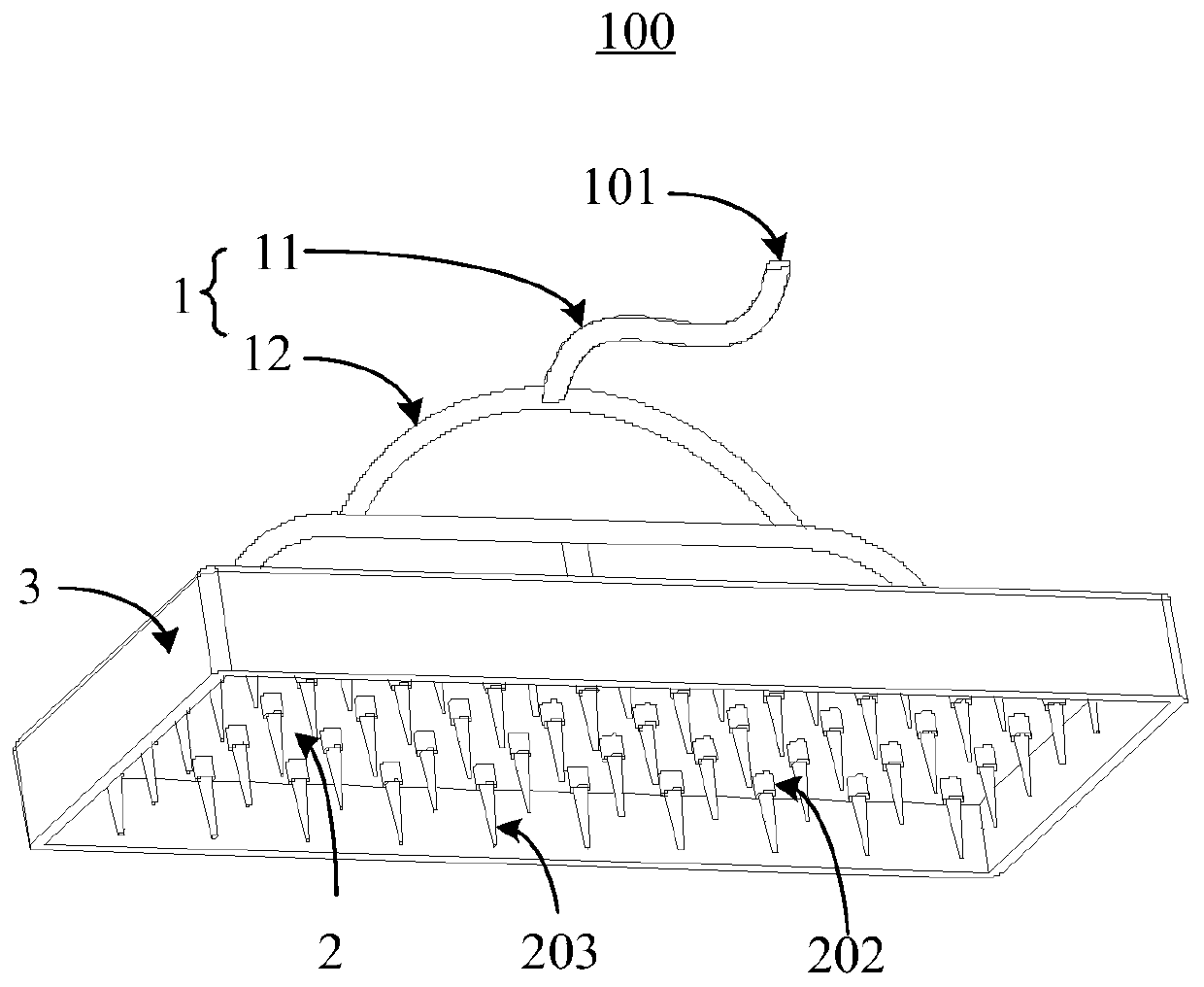

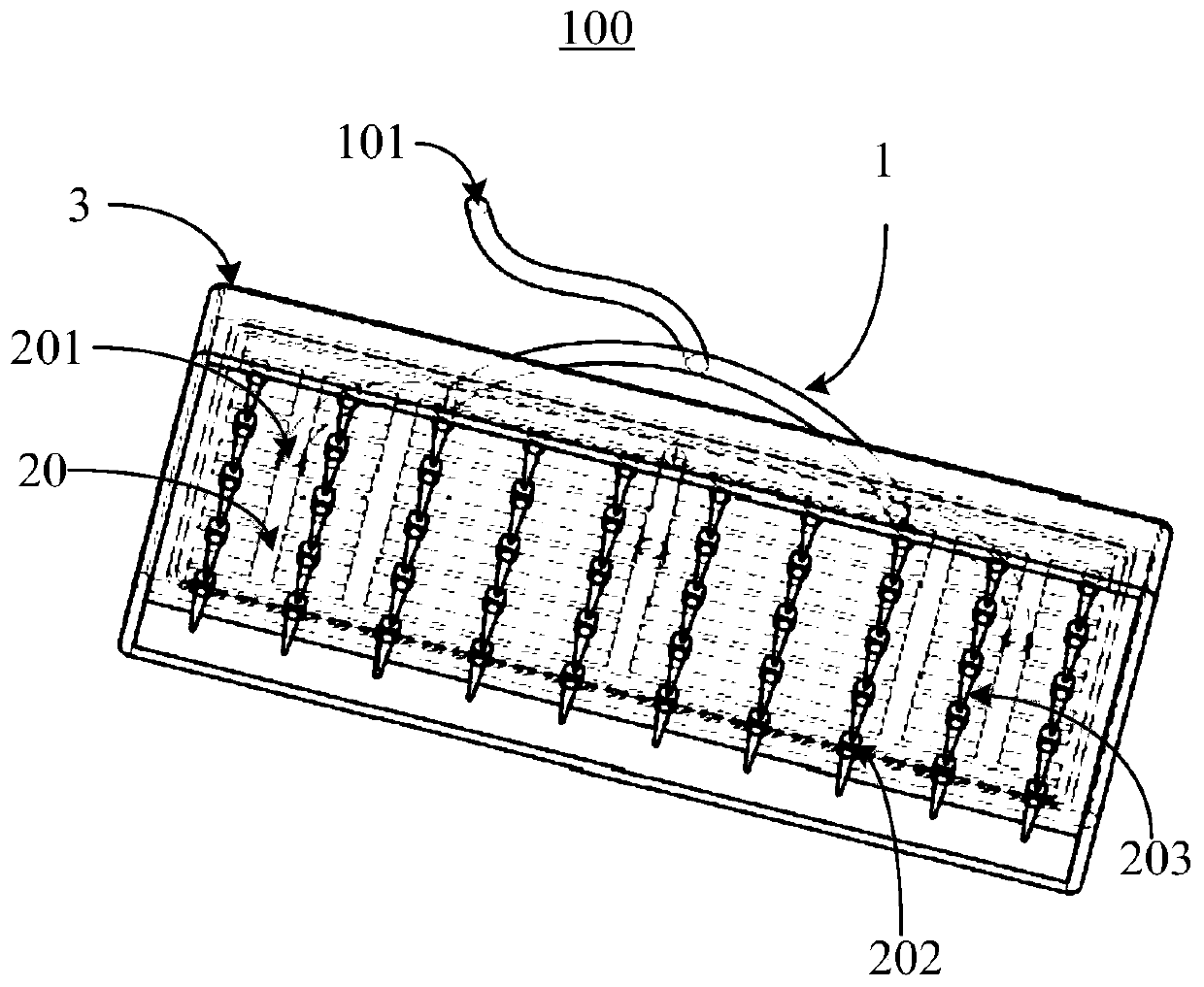

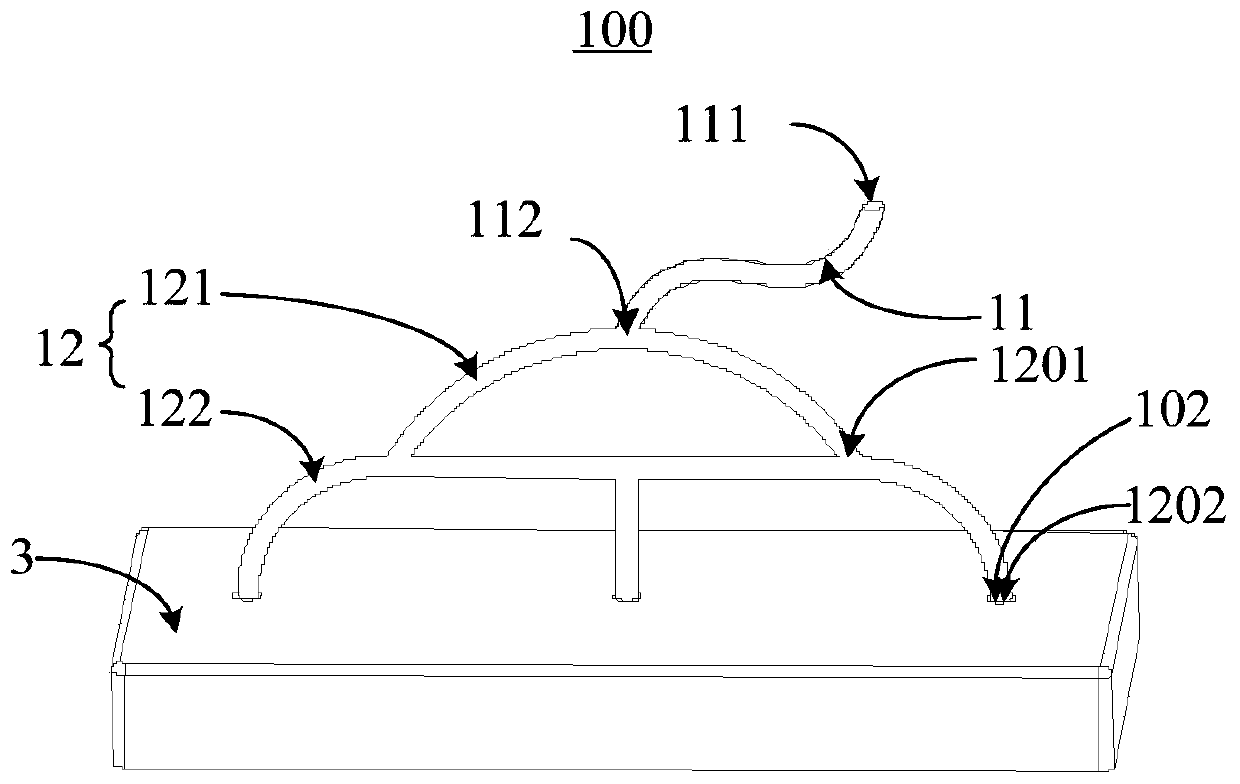

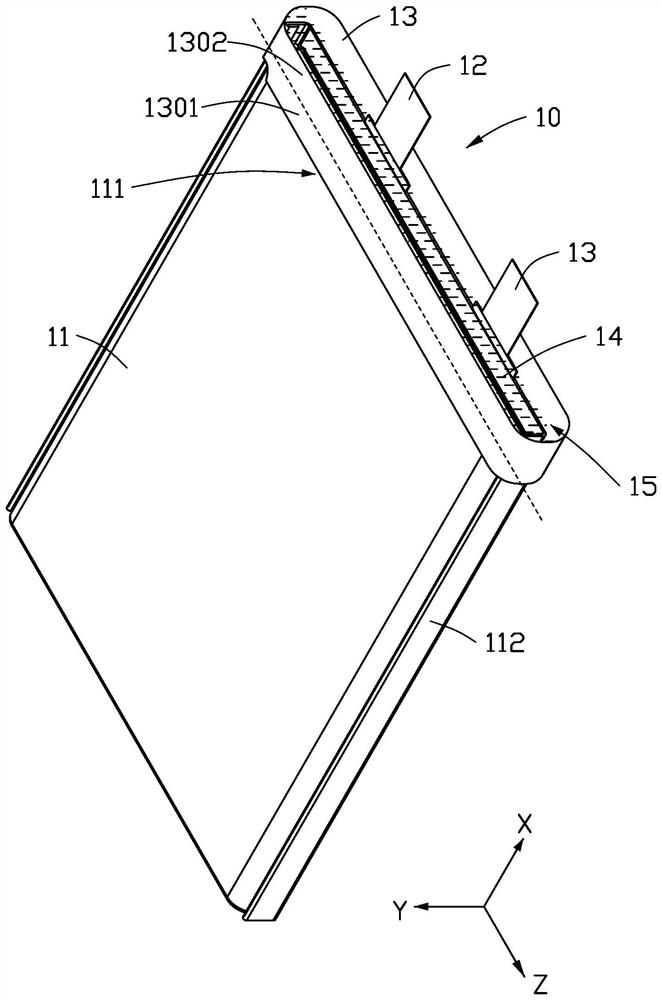

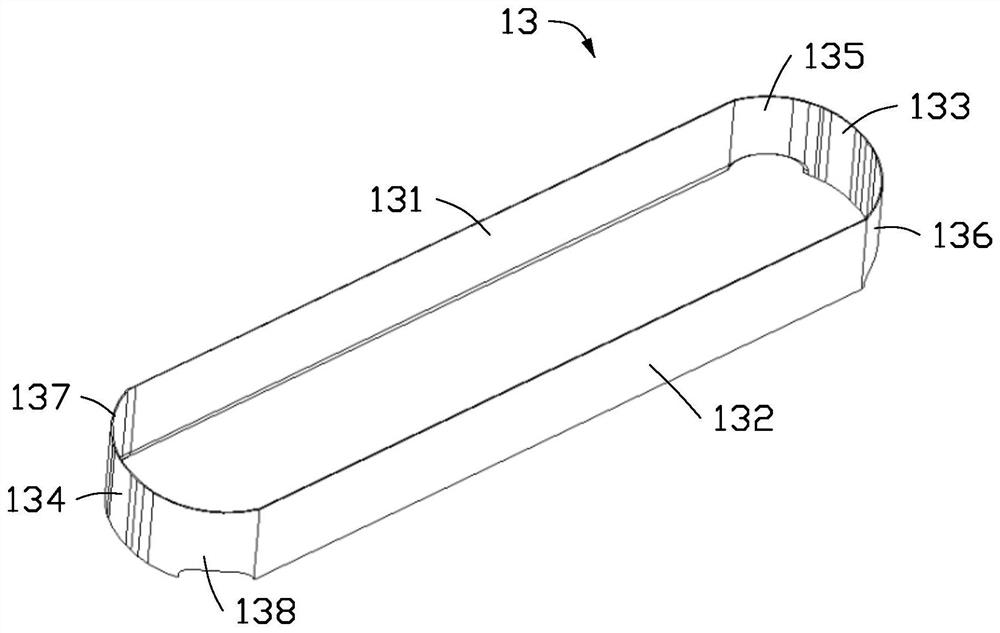

Battery cell and electrochemical device and power utilization device using same

PendingCN113113701AReduced risk of ruptureImprove glue filling efficiencyCell component detailsEngineeringMechanical engineering

The invention provides a battery cell. The battery cell comprises a body part, a tab and a protective sleeve, and the body part includes a first end part. And the tab extends out of the body part from the first end part. The protective sleeve comprises a first part and a second part, the first end part is sleeved with the first part in a surrounding manner, and the second part extends out of the body part and surrounds the tab. And a bonding piece is arranged between the second part and the first end part and between the second part and the tab. The head of the battery cell is sleeved with the protective sleeve, and the protective sleeve can reduce the risk that the battery cell is likely to be broken in the scenes of falling, vibration, impact, extrusion or expansion and the like and the risk that the battery cell is likely to be abraded, scraped and broken in the processes of manufacturing, assembling, transporting, storing and the like. And the protective sleeve can be matched with the battery cell and is used for accommodating a bonding piece during glue filling of the battery cell, so that the glue filling efficiency and the operation convenience of the battery cell are improved. The invention also provides an electrochemical device and an electric device using the battery cell.

Owner:DONGGUAN POWERAMP TECH LTD

An LED encapsulation glue filling device

ActiveCN112570213BGuarantee the quality of glue fillingPrevent deviationPretreated surfacesCoatingsEngineeringLED lamp

The invention relates to the related field of LED packaging, and discloses a glue filling device for LED packaging. The lower side of the through cavity of the mold seat is connected with a curing chamber, the upper side of the glue filling cavity is connected with a glue filling needle seat cavity, the upper side of the glue filling needle seat cavity is connected with a push block cavity, and the right side of the push block cavity is connected with a sliding straight hole. In the gear cavity, when the glue filling needle moves down to the upper side of the mold, the slider touches the glue filling sensor block, so that multiple glue filling needles can automatically fill the mold with glue, ensuring that multiple LED package glue can be completed at one time , instead of manually pouring glue one by one, greatly improving the efficiency of glue pouring, and at the same time, the mold base of the lamp cap drives the lamp frame to move vertically downward into the curing chamber, so that the LED lamp can be cured immediately after the glue is poured, avoiding the The light-emitting chip deviates from the center position due to shaking during the movement of the lamp holder, which ensures the quality of the LED lamp packaging glue filling.

Owner:台山鸿隆光电科技有限公司

Glue pouring machine for electronic components based on improvement of glue pouring quality

InactiveCN113245135AWell mixedImprove the mixing effectLiquid surface applicatorsCoatingsElectronic componentMaterials science

The invention discloses a glue pouring machine for electronic components based on improvement of glue pouring quality, and relates to the related technical field of electronic components. The glue pouring machine comprises a glue mixing valve, a positioning mechanism and a glue discharging mechanism. The positioning mechanism is in threaded fit with the glue mixing valve. The positioning mechanism is clamped with the glue discharging mechanism. A glue guide hopper is fixed on the inner wall of the valve body. A hollow mixing column is fixed at the bottom of the glue guide hopper. A glue mixing mechanism is arranged in the hollow mixing column. The outer wall of the hollow mixing column and the outer wall of the valve body are provided with co-location holes. The co-location holes are in clearance fit with the glue discharging mechanism. By arranging a first rotating shaft, a first scraping plate, a glue mixing strip, a second scraping plate, a third scraping plate and a glue guide plate, adhesion of mixed glue on the hollow mixing column and a sieve plate is effectively reduced through the first scraping plate and the second scraping plate, AB glue falling into the glue guide hopper is completely scraped into the hollow mixing column through the cooperation effect of the third scraping plate and the glue guide plate, and the mixing effect and the glue mixing efficiency of the glue mixing mechanism are greatly improved.

Owner:康生瑞

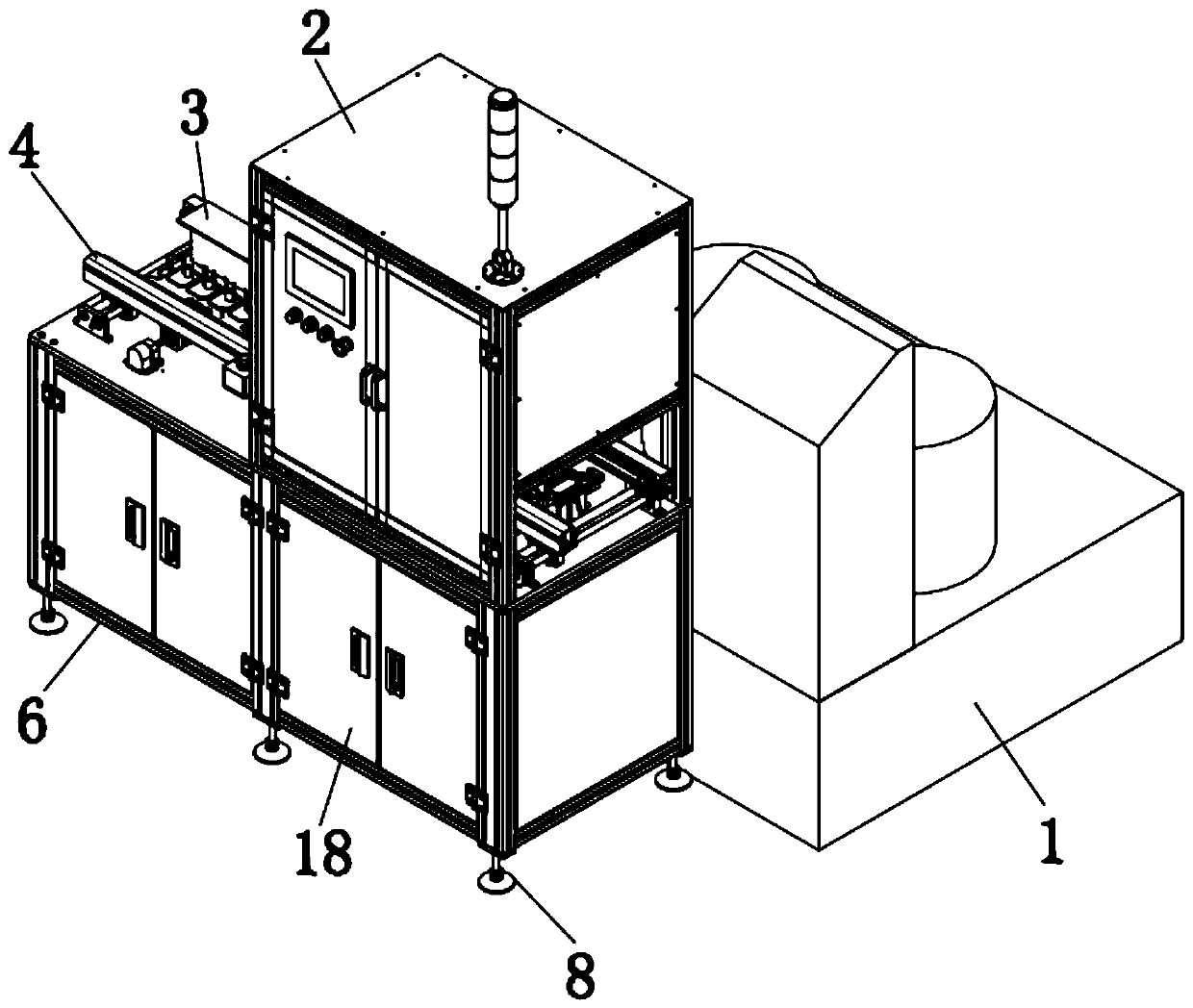

Automatic glue filling machine

PendingCN110711676AImprove glue filling efficiencyImprove efficiencyLiquid surface applicatorsCoatingsGear wheelElectric machinery

The invention discloses an automatic glue filling machine. The automatic glue filling machine comprises a glue dispensing machine, a lower supporting box and an upper supporting box; the glue dispensing machine is arranged on the side surface of the lower supporting box; a glue dispensing head of the glue dispensing machine is positioned at the top end of the lower supporting box; the glue dispensing machine belongs to the prior art; the upper supporting box is arranged on the right side of the lower supporting box; and the automatic glue filling machine also comprises a carrier mechanism, a movable rail, a gear, a lifting, transferring and rotating module, a moving mechanism, a fixed rail, a workbench, a first motor, a chain and a synchronous belt. A first motor drives the gear to rotate,the carrier mechanism is driven by the chain to move onto the lifting, transferring and rotating module, the carrier mechanism is driven by the lifting, transferring and rotating module to rotatablymove or ascend and descend to cooperate with the glue dispensing machine to fill products with glue, glue filling can be conducted without a manual assisting mode, butting with an automatic line bodycan be realized, and the glue filling efficiency is high.

Owner:苏州诺熠精密机械有限公司

A glue filling machine for the production of solid-state batteries

ActiveCN108155336BPrecise positioningNo positional deviationSecondary cellsCell component detailsConveyor beltProduction quality

The invention discloses a glue filling machine for the production of solid-state batteries, which comprises a frame, a workbench and a conveyor belt. The conveyor belt is installed on the frame, and a plurality of photoelectric reflection plates are uniformly arranged on the side of the conveyor belt. , the workbench is installed on the frame at the side of the conveyor belt, a photoelectric transmitter and receiver cooperating with the photoelectric reflector is installed on the workbench, a telescopic oil cylinder is fixedly installed on the workbench, and the telescopic oil cylinder The end of the telescopic rod is connected with a push plate that is slidably arranged on the workbench. The push plate is fixed with a plurality of glue injection nozzles through the bracket rod. Each glue injection nozzle is connected to the delivery main pipe through a rubber hose. Connected with the signal input end of the controller, the invention greatly improves the glue pouring efficiency, and the glue pouring process runs smoothly, the glue pouring error is small, and the production quality of the solid-state storage battery is guaranteed.

Owner:GUANGDE BAODA PRECISION CIRCUIT CO LTD

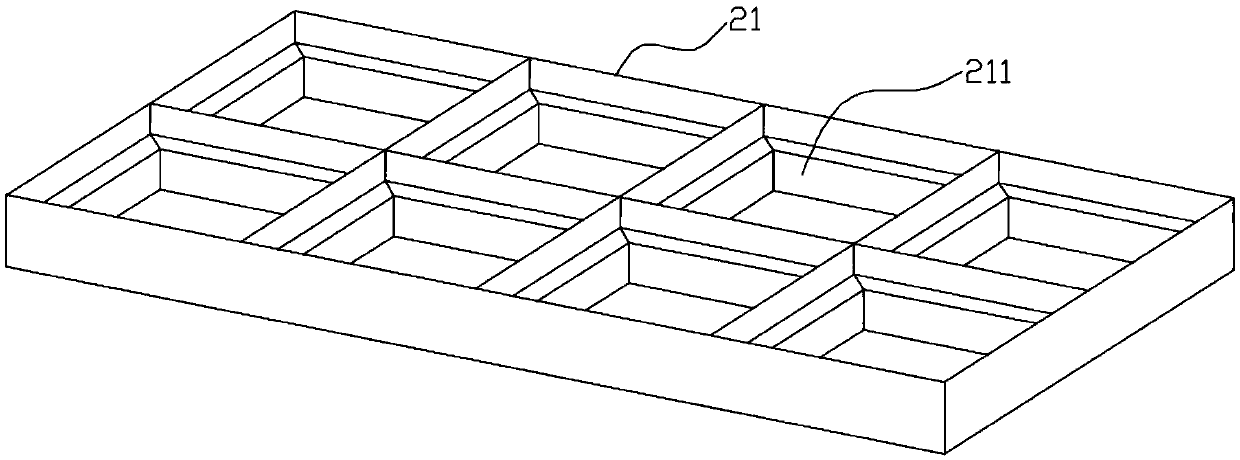

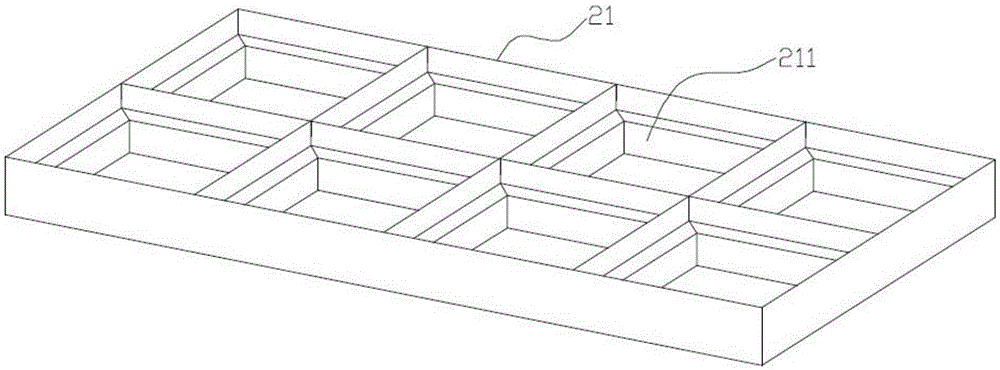

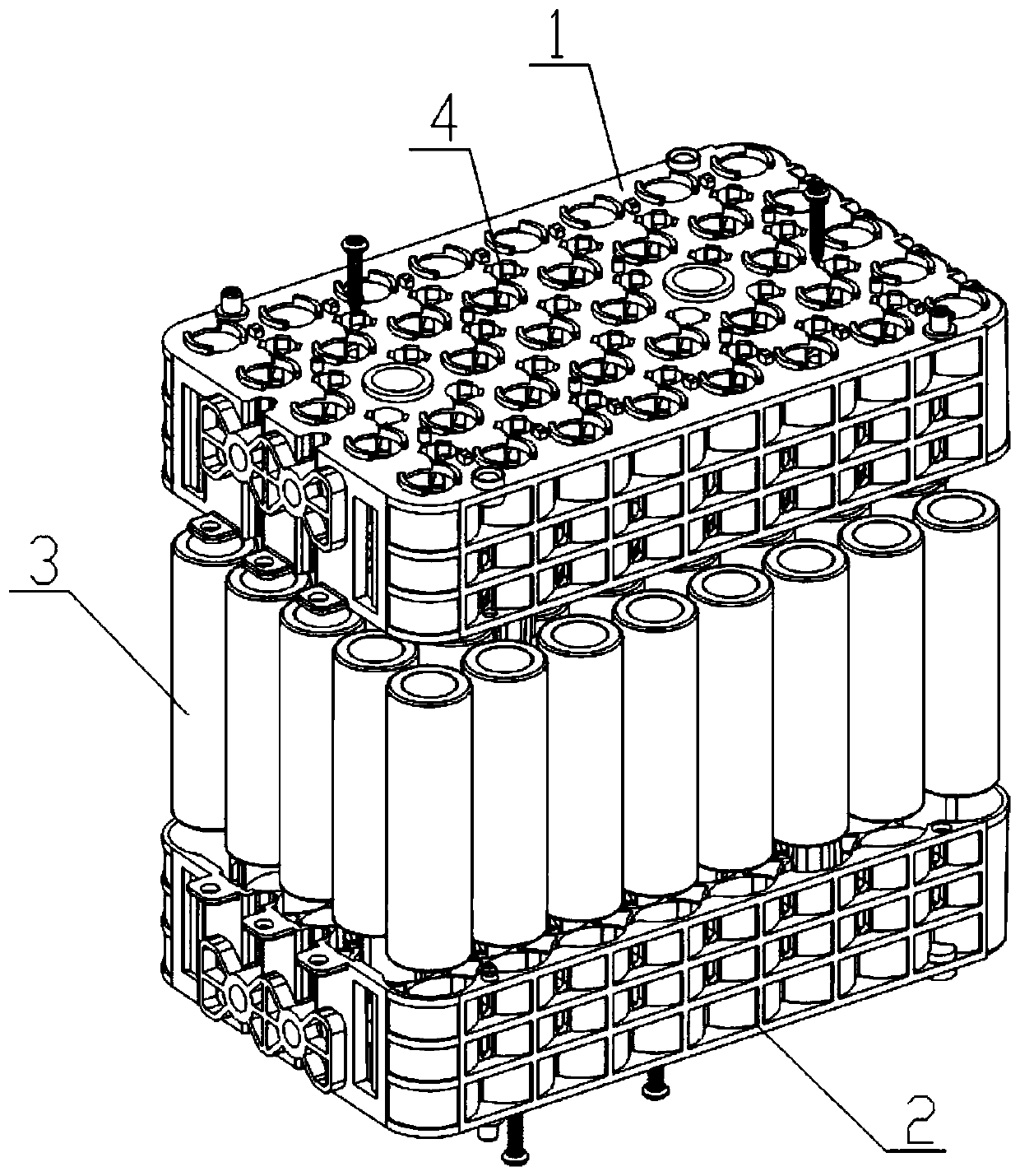

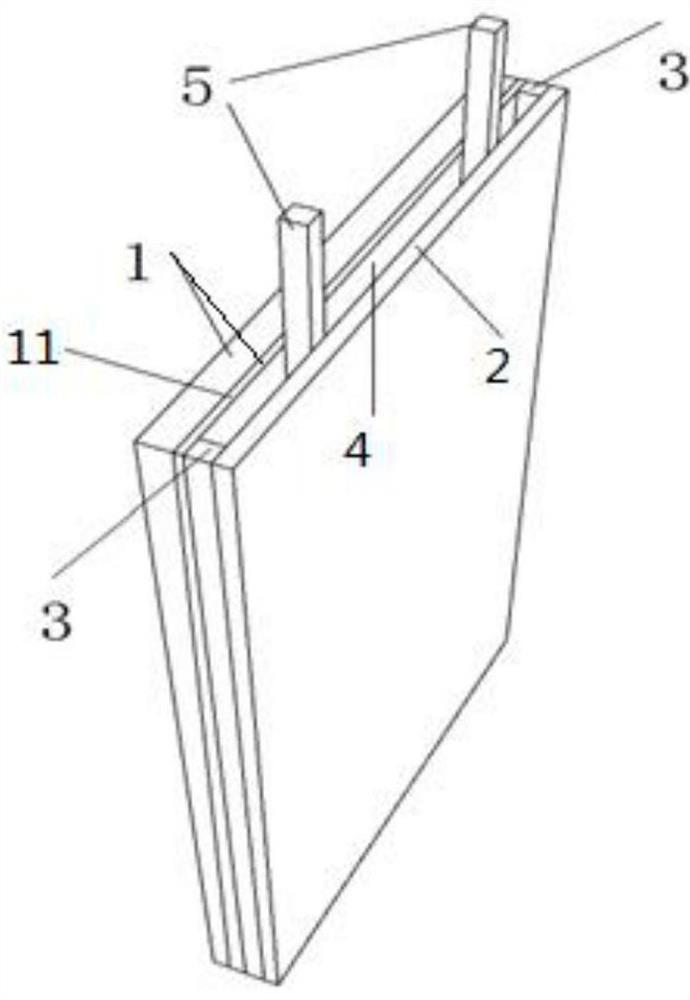

A battery module glue filling tank device

ActiveCN107863540BImprove conductivitySimple structurePrimary cell manufactureAssembling battery machinesElectrical batteryEngineering

The invention provides a battery module glue filling tank device. It includes an upper bracket and a lower bracket, and the battery cell of the battery module is installed between the two brackets. Both the upper bracket and the lower bracket are provided with glue filling holes, and the glue filling holes are cylindrical sink hole structures; There is a cross-shaped baffle in the middle of the glue hole, which divides the glue filling hole into several glue filling areas. Next to the glue filling area, there is a glue guide groove. The cross section of the glue guide groove is a rectangular groove extending into the two brackets. The installation cavities of the cores communicate with each other; a clamping area is formed between the bottoms of the respective glue guide grooves, and the clamping area clamps the outer edge of the battery core. The invention has simple structure and convenient operation, prevents glue overflowing during the glue pouring process, ensures good electrical conductivity of the battery module, and has low investment cost and high glue pouring efficiency.

Owner:烟台金潮宇科蓄电池有限公司

Potting device, LED display screen and packaging method of LED display screen

ActiveCN112259661ASimple structureSimple preparation processSolid-state devicesSemiconductor devicesLED displayEngineering

The invention is suitable for the technical field of photoelectricity, and provides a potting device, an LED display screen and a packaging method of the LED display screen. The potting device is simple in structure, simple in preparation process, low in production cost, suitable for batch production of potting products, and high in production efficiency; a dam colloid is applied between a first fitting layer and a second fitting layer, and the dam colloid is aligned and fitted to form a potting cavity with three closed sides and one opened side, so that the surface of the product is smooth, the overall thickness is consistent, the display effect is good, and the display distortion caused by non-uniform thickness of the potted product is avoided; besides, a height limiting strip with the height equal to the thickness of the potting cavity or the height of the dam colloid compressed after attachment is placed on the colloid applying surface of a certain attachment layer, the height uniformity of the potting cavity can be guaranteed, therefore it can be guaranteed that after encapsulation and potting, the surface of a product is smooth, the overall thickness is consistent, and the display effect is good.

Owner:新纶光电材料(深圳)有限公司

A paint brush automatic glue filling system and method

ActiveCN106423733BImprove glue filling efficiencyQuality improvementLiquid surface applicatorsCoatingsABSORPTION BASEControl system

Owner:XUZHOU NORMAL UNIVERSITY

A high-precision seamless dripping CNC glue filling device

ActiveCN103569924BPrecise control of glue filling accuracyEliminate the effects ofLiquid bottlingNumerical controlEngineering

The invention discloses a high-precision left-drop-free numerical control glue filling device. The high-precision left-drop-free numerical control glue filling device consists of a conveying belt (1), an insulation rotary plate (2), buffer chambers (3), pistons (4), unidirectional valves (5), flow rate regulating valves (6), weighing sensors (7), weighing sensor control panels (8), filling bottle control rods (9) as well as fixing guide pipes (10); the unidirectional valves (5) are connected to inlets at one sides of the buffer chambers (3); the lower ends of the buffer chambers (3) are connected with the flow rate regulating valves (6); the upper parts of the buffer chambers (3) are provided with the pistons (4); the weighing sensors (7) are fixed on the weighing sensor control panels (8); the conveying belt (1) and the weighing sensors (7) are arranged in adjacency. The glue filling precision can be controlled accurately through controlling the weighing precision; the influence to the glue filling precision by air bubble generation randomness in filling glue is eliminated completely; the glue filling precision is improved effectively.

Owner:溧阳常大技术转移中心有限公司

Glue filling and sealing system

PendingCN113247329AImprove glue filling efficiencyReasonable structureWrapper twisting/gatheringLiquid materialAdhesive glueEngineering

The invention provides a glue filling and sealing system. The glue filling and sealing system comprises a glue filling machine rotary table, wherein a plurality of glue filling stations are evenly distributed on the edge of the glue filling machine rotary table; a sleeve groove penetrating up and down is formed in the center of the glue filling machine rotary table; a fixed sleeve is installed on a rack below the glue filling machine rotary table; the top of the fixed sleeve upwards penetrates through the sleeve groove and then is connected to a fixing supporting plate; a power cylinder is fixed to the upper portion of an inner cavity of the fixed sleeve; a piston rod of the power cylinder stretches out of the fixed sleeve and is connected to an air cylinder supporting plate; a downward folding component is installed on the fixing supporting plate above the glue filling stations; and a flattening and bending component is installed on the fixing supporting plate in the input direction of the downward folding component. After the scheme is adopted, the structure is reasonable, and the using effect is good.

Owner:湖南浩森胶业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com