Patents

Literature

64results about How to "No positional deviation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

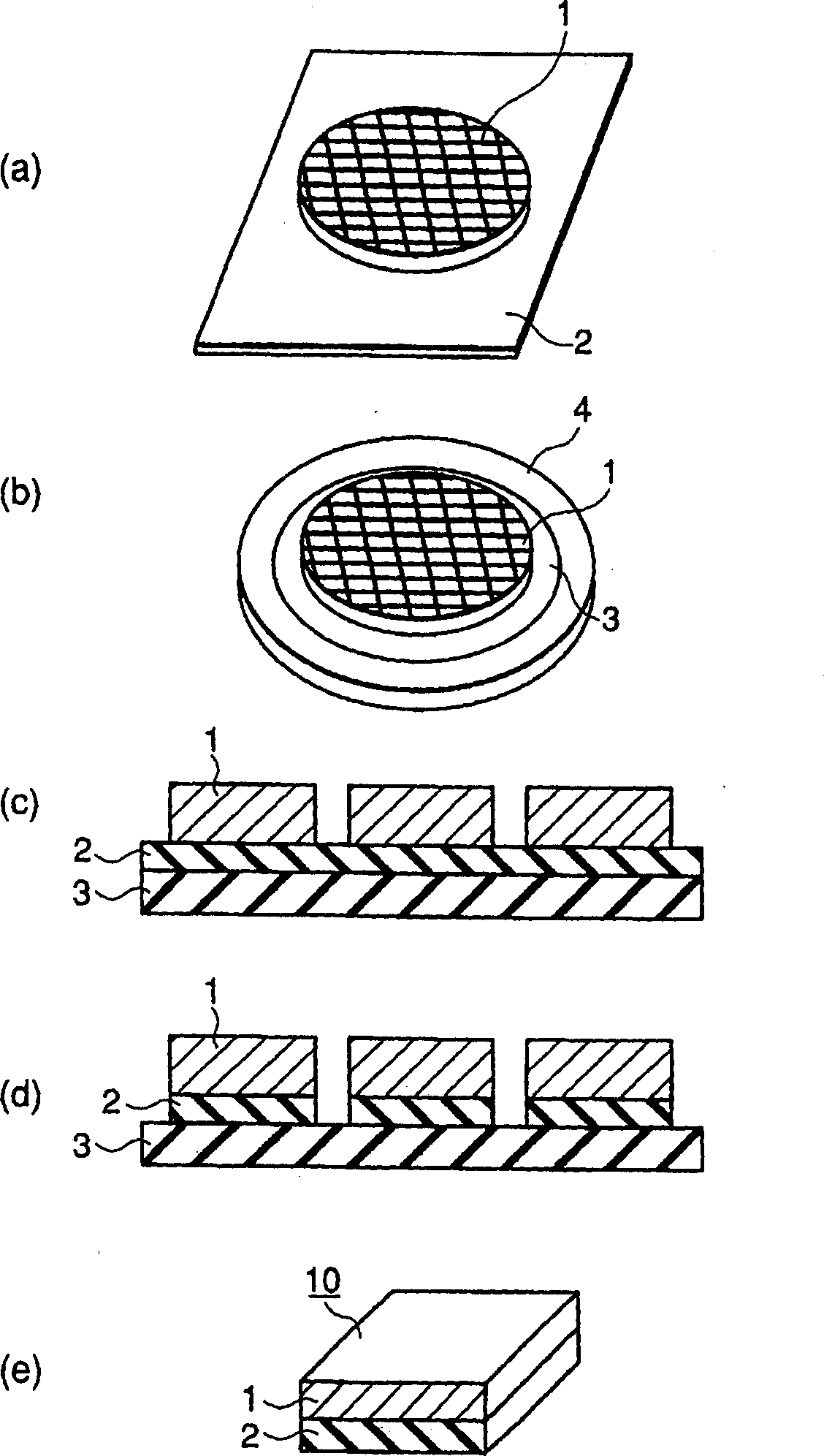

Manufacturing method of semiconductor device

InactiveCN1348208ACurb complicationNo positional deviationSolid-state devicesSemiconductor/solid-state device manufacturingWaferingDicing tape

A semiconductor wafer on which elements have been formed is diced and a rear surface of the semiconductor wafer is ground by a dicing before grinding method to form discrete semiconductor chips. The discrete semiconductor chips are adhered to an adhesive film and then the surface of the adhesive film is removably affixed to a dicing tape. After this, any excess portions of the adhesive film disposed between the respective semiconductor chips are removed.

Owner:KK TOSHIBA

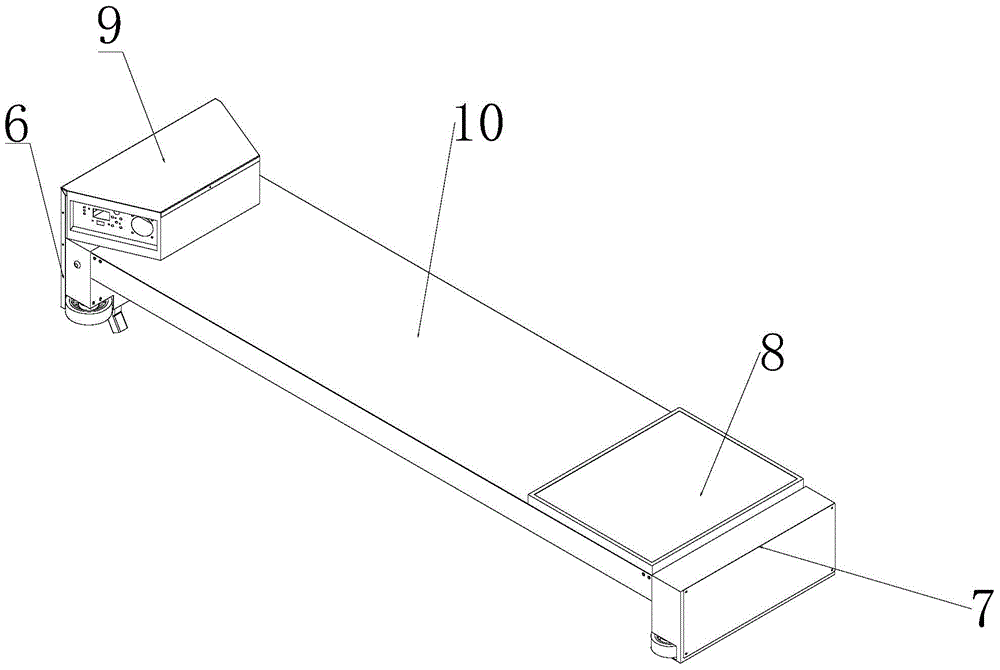

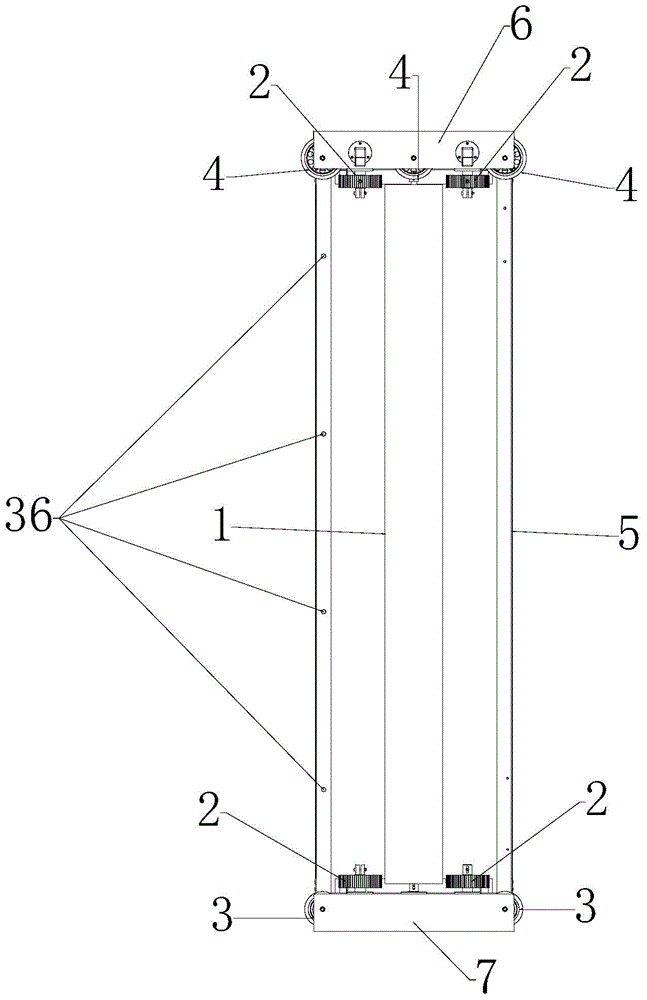

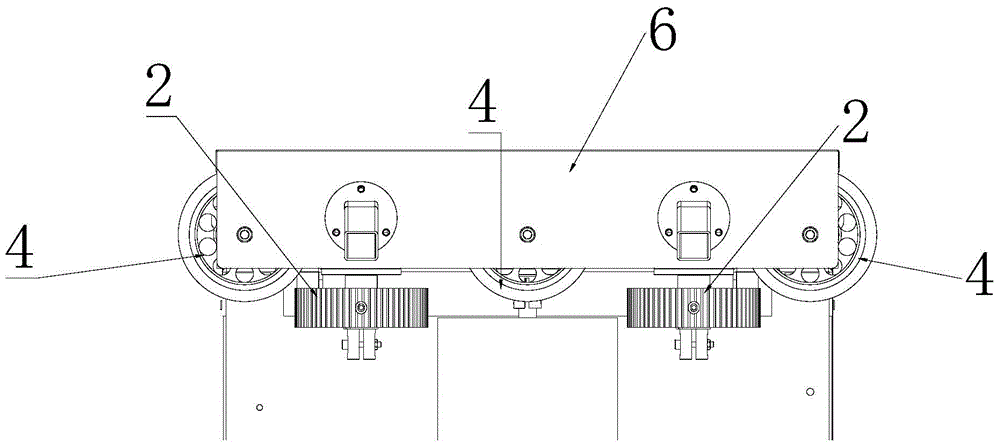

Detection system and detection method for detecting faults of photovoltaic module

InactiveCN104980107AImprove power generation efficiencyExtended service lifePhotovoltaic monitoringPhotovoltaic energy generationElectricityCommunication unit

The invention discloses a detection system and a detection method for detecting the faults of a photovoltaic module. The system is arranged on an automatic cleaning device of the photovoltaic module. The automatic cleaning device is used for cleaning a to-be-cleaned photovoltaic panel while moving along the photovoltaic panel. The detection system comprises a first temperature detection unit, an intelligent control unit and a wireless communication unit. The first temperature detection unit is used for detecting the temperature of the photovoltaic panel during the cleaning process of the photovoltaic panel by the automatic cleaning device. The intelligent control unit is connected with the first temperature detection unit and is used for receiving and processing the detected temperature of the first temperature detection unit. The wireless communication unit is connected with the intelligent control unit and is used for sending the processed temperature of the intelligent control unit to a master control chamber. According to the invention, the photovoltaic panel is cleaned, while the temperature of the photovoltaic panel is detected at the same time. Meanwhile, the detected temperature is transmitted to the master control chamber. Therefore, once a photovoltaic panel generates electricity abnormally, the photovoltaic panel can be replaced just in time. As a result, the power generation efficiency of the photovoltaic module is greatly improved, and the service life of the photovoltaic module is greatly prolonged.

Owner:KASHGAR SOL BRIGHT PHOTOVOLTAIC TECH CO LTD

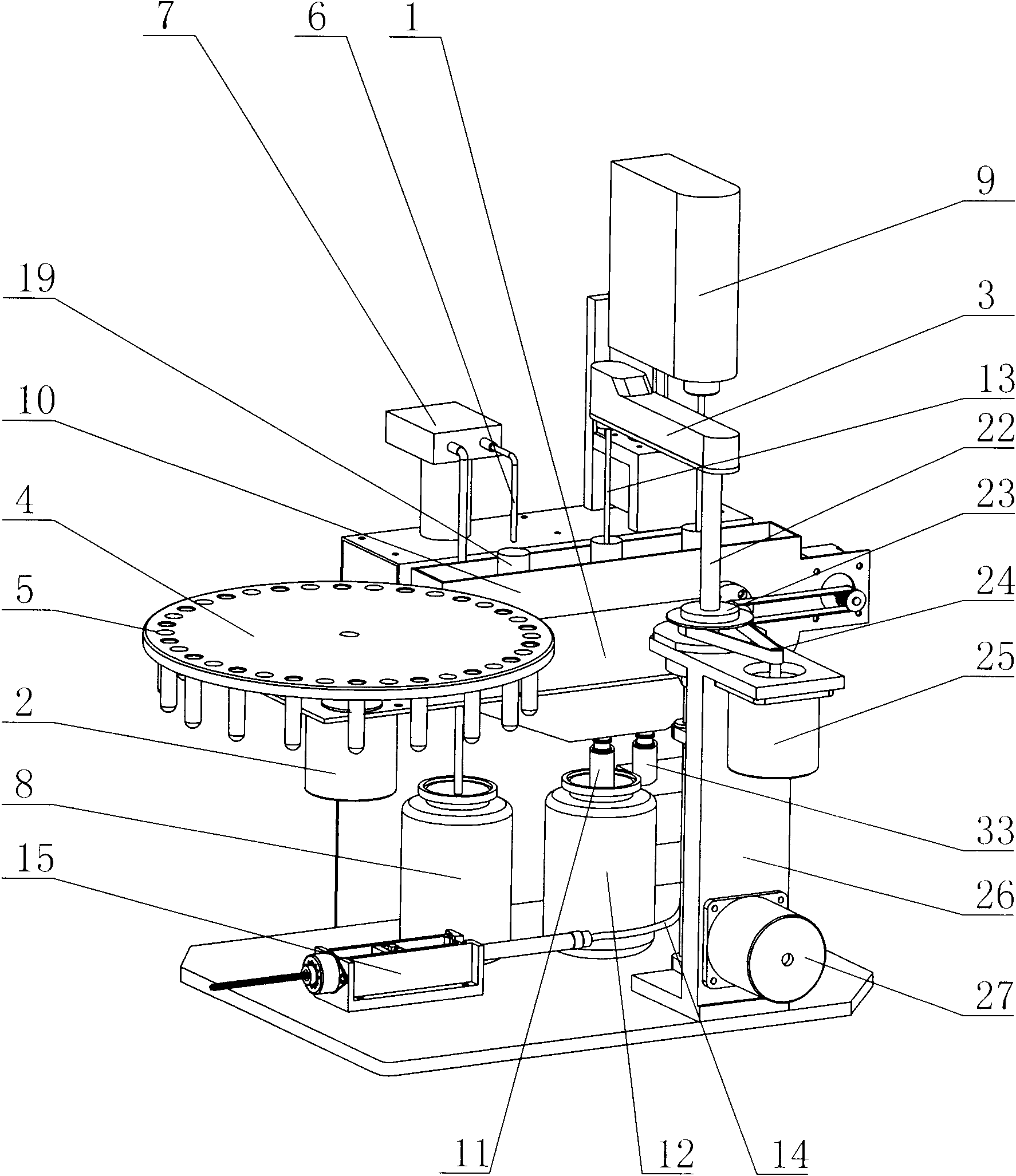

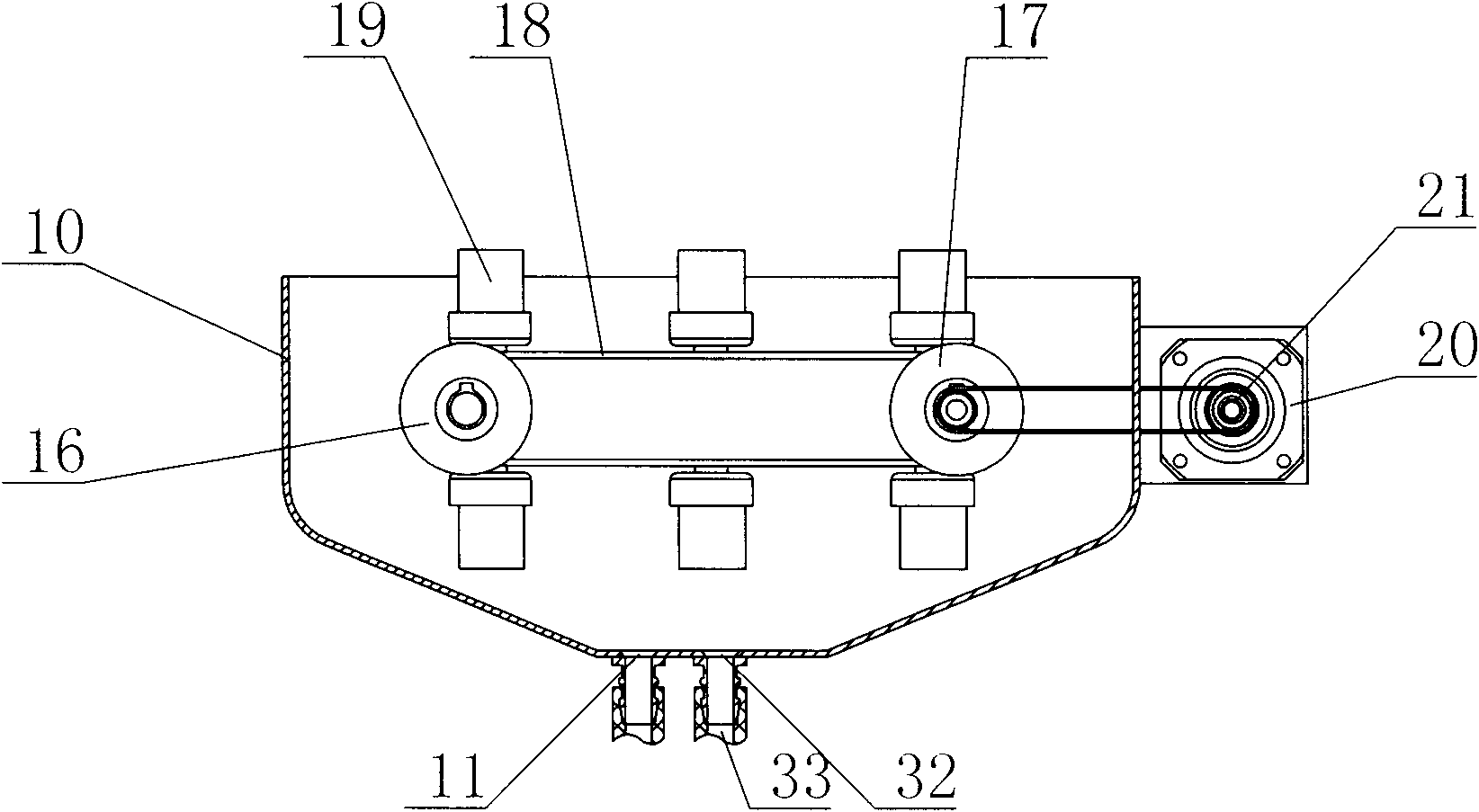

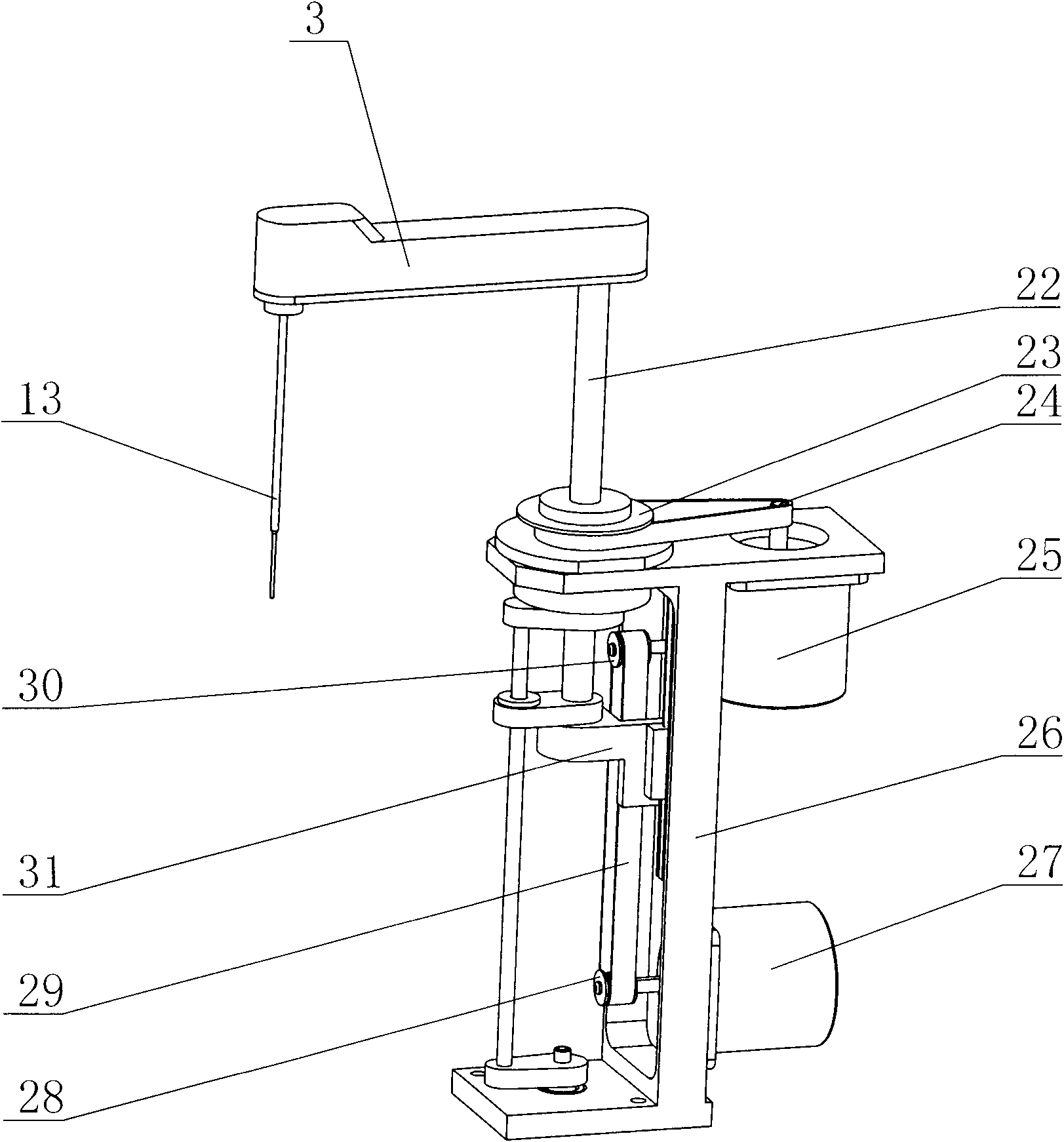

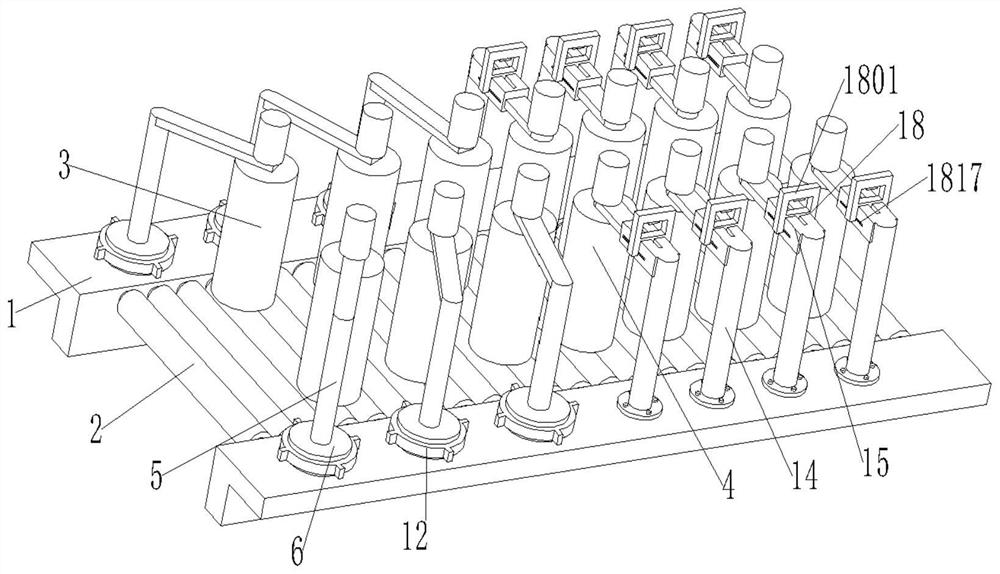

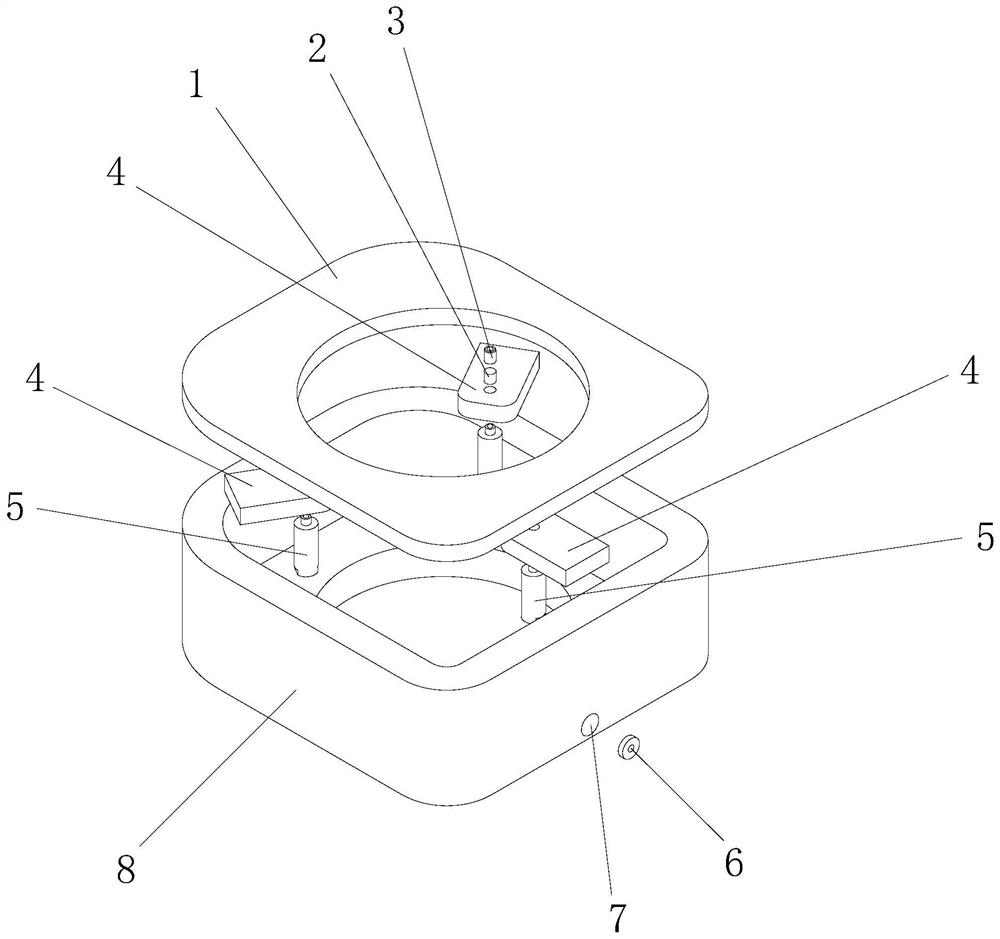

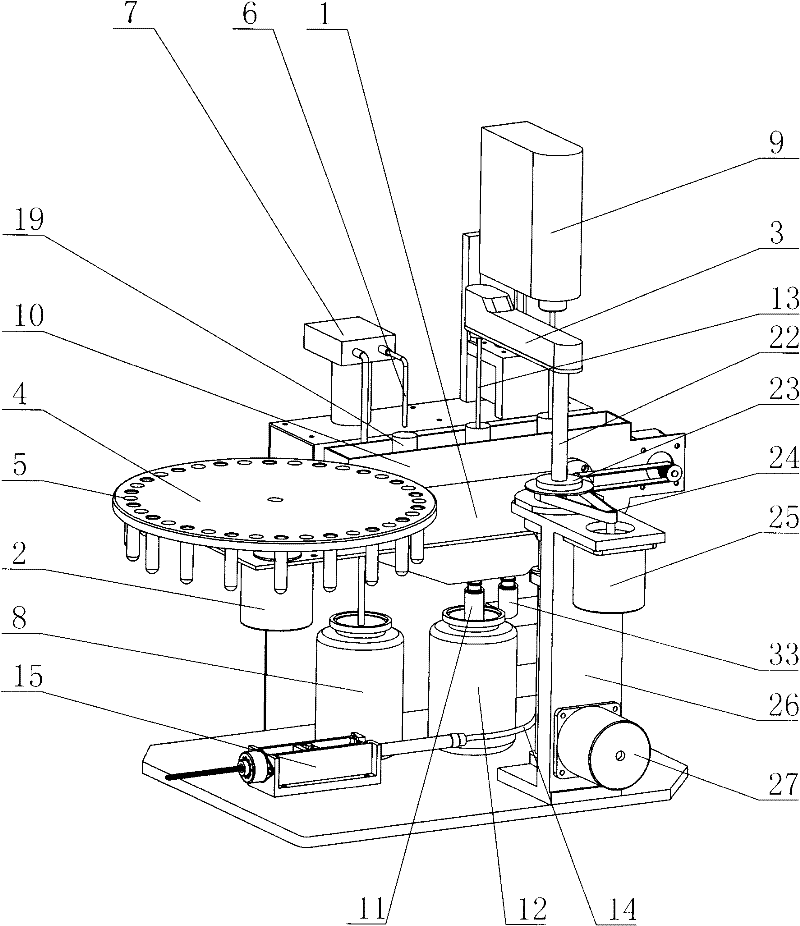

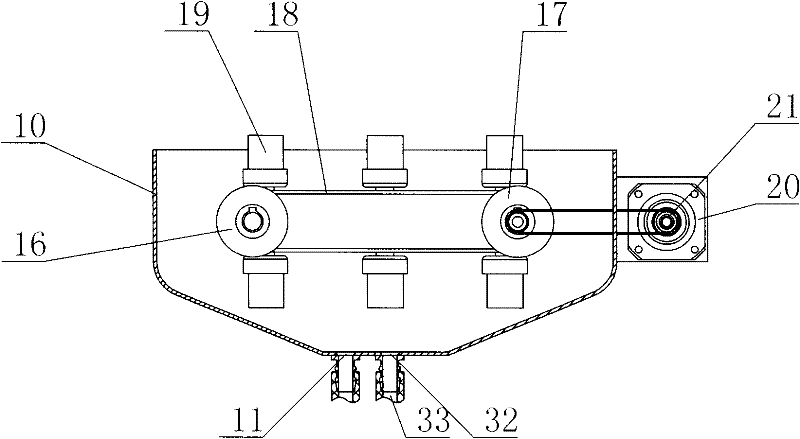

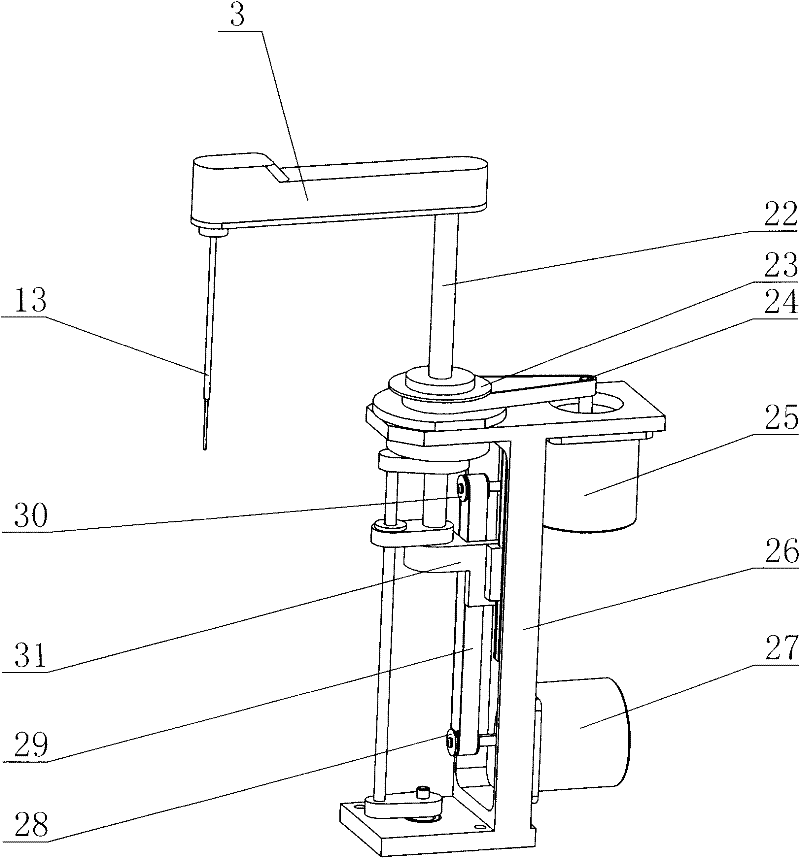

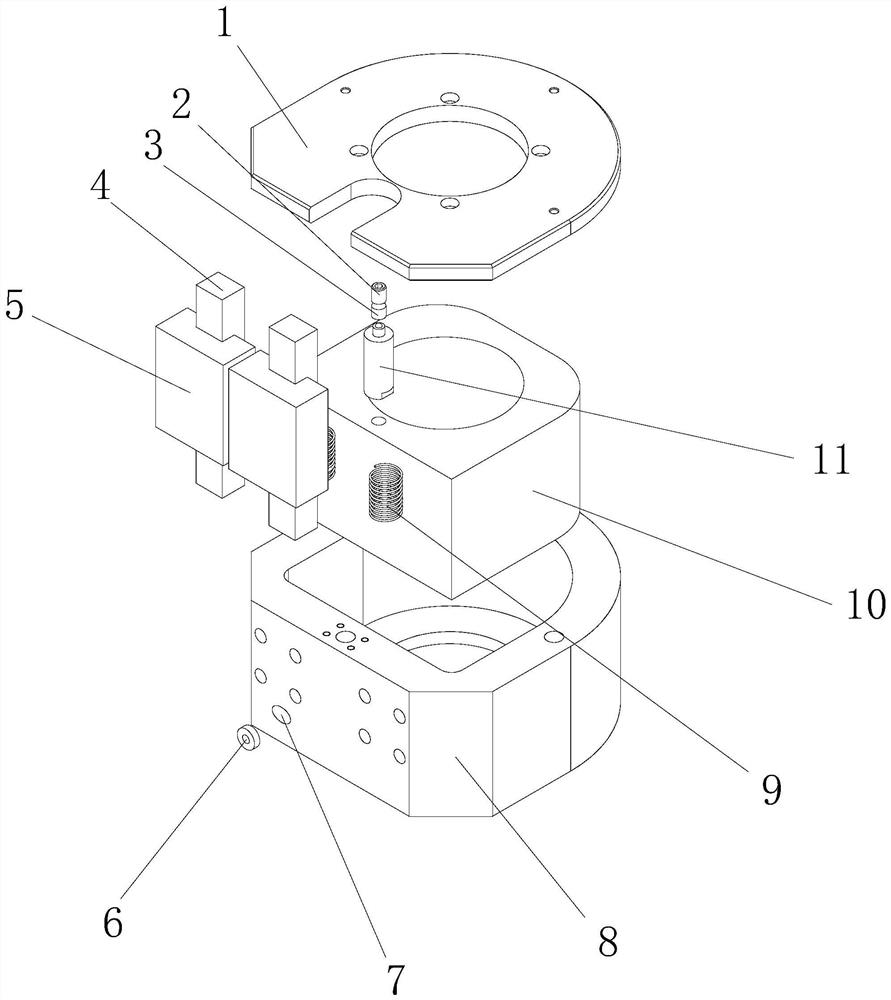

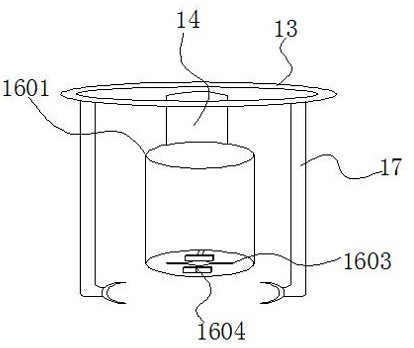

Automatic sampling mechanism of analytical instrument

InactiveCN101982779ANo positional deviationHigh running precisionMaterial analysisPipetteEngineering

The invention provides an automatic sampling mechanism of an analytical instrument, comprising a rack; the rack is provided with a first stepped motor, a pipette drive device and a liquid collecting box, wherein, the output shaft of the first stepped motor is provided with a rotary table; a plurality of test tube fixing holes are evenly arranged on the edge of the rotary table; the pipette drive device is provided with a pipette which is connected with a liquid sucking pump through a conduit; the liquid collecting box is provided with a detection cup transmission device which is provided with a plurality of detection cups; a reagent filling tube and a measuring electrode are arranged above the liquid collecting box; the reagent filling tube is connected with a reagent container through a liquid adding pump; and the bottom of the liquid collecting box is provided with a water outlet which is connected with a waste liquor collecting tank through a pipeline. The automatic sampling mechanism provided by the invention has the advantages of high operation precision, rapid sampling speed, simple structure and low cost.

Owner:济南齐力医疗器械有限公司

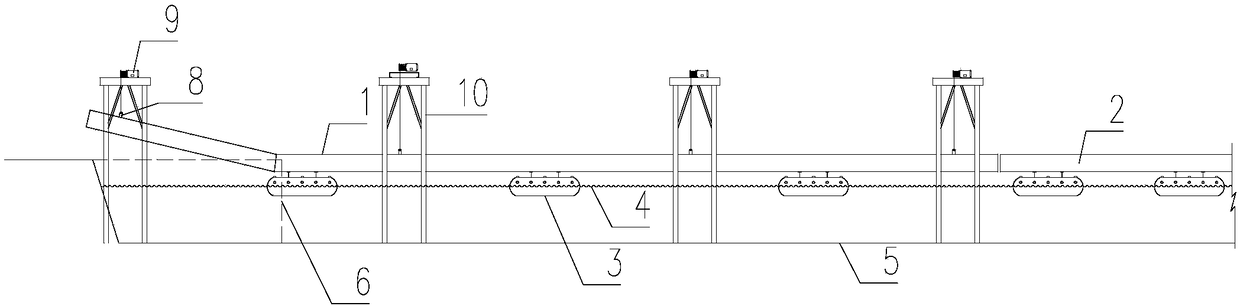

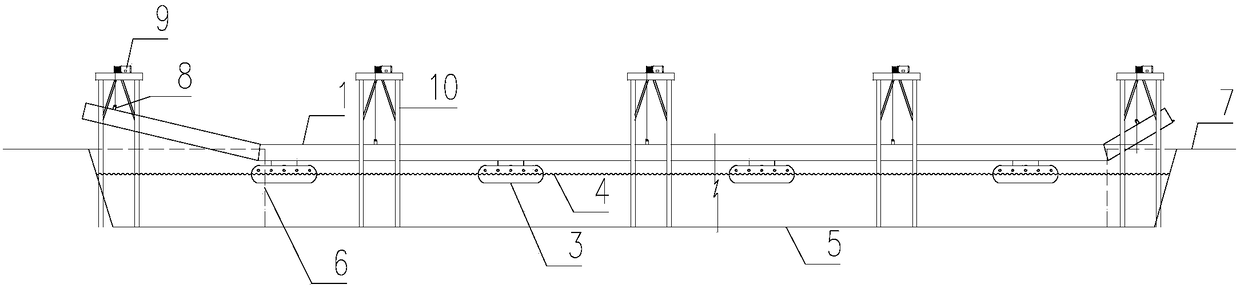

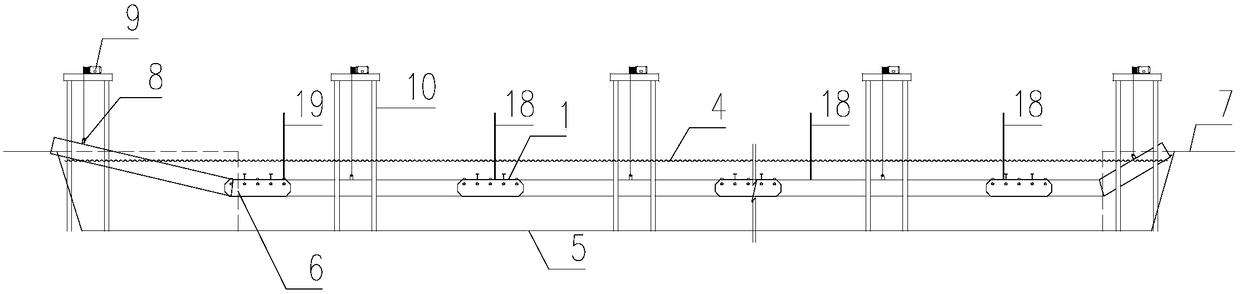

Buoyant box type water floating gantry crane pipeline sinking construction method

ActiveCN108571621ASimple construction principleLow costPipe laying and repairButt weldingWater channel

The invention discloses a buoyant box type water floating gantry crane pipeline sinking construction method. The method comprises steps as follows: step 1, long steel pipes are welded ashore and lifted onto a controllable buoyant box on the water surface; step 2, all small sections of steel pipes floated by the controllable buoyant box on the water surface are welded into a large section of steelpipe; step 3, a gantry crane lifts steel pipes with inclined pipe sections to be welded with the large section of steel pipe; step 4, a hydrostatic test of the steel pipes is conducted after the wholesection is mounted; step 5, the controllable buoyant box is reversely buckled on the steel pipes, and water is injected into two ends of the steel pipes to make the steel pipes to gradually sink; step 6, after the steel pipes sink, the controllable buoyant box is dismounted, the dismounted controllable buoyant box is inflated to automatically float on the water surface, and trenches are backfilled. Interface butt welding, water surface transportation, pipeline pressure test, sinking and other procedures of pipelines spanning long-distance water channels can be realized. The construction principle is simple and easy to implement, construction machinery such as a large crane is not required, the sinking positions are accurate, and the method is low in cost, safe and reliable.

Owner:CHINA FIRST METALLURGICAL GROUP

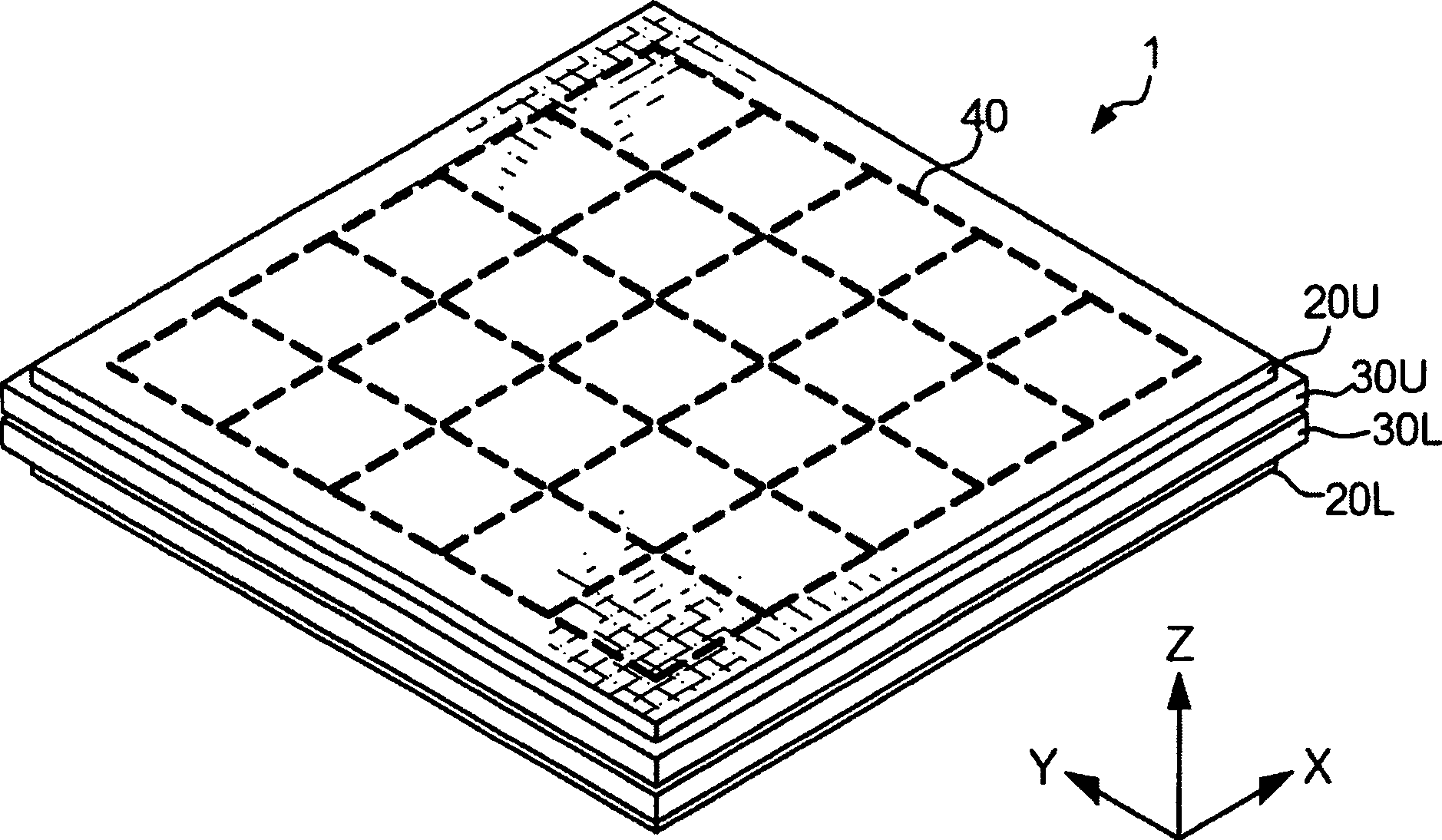

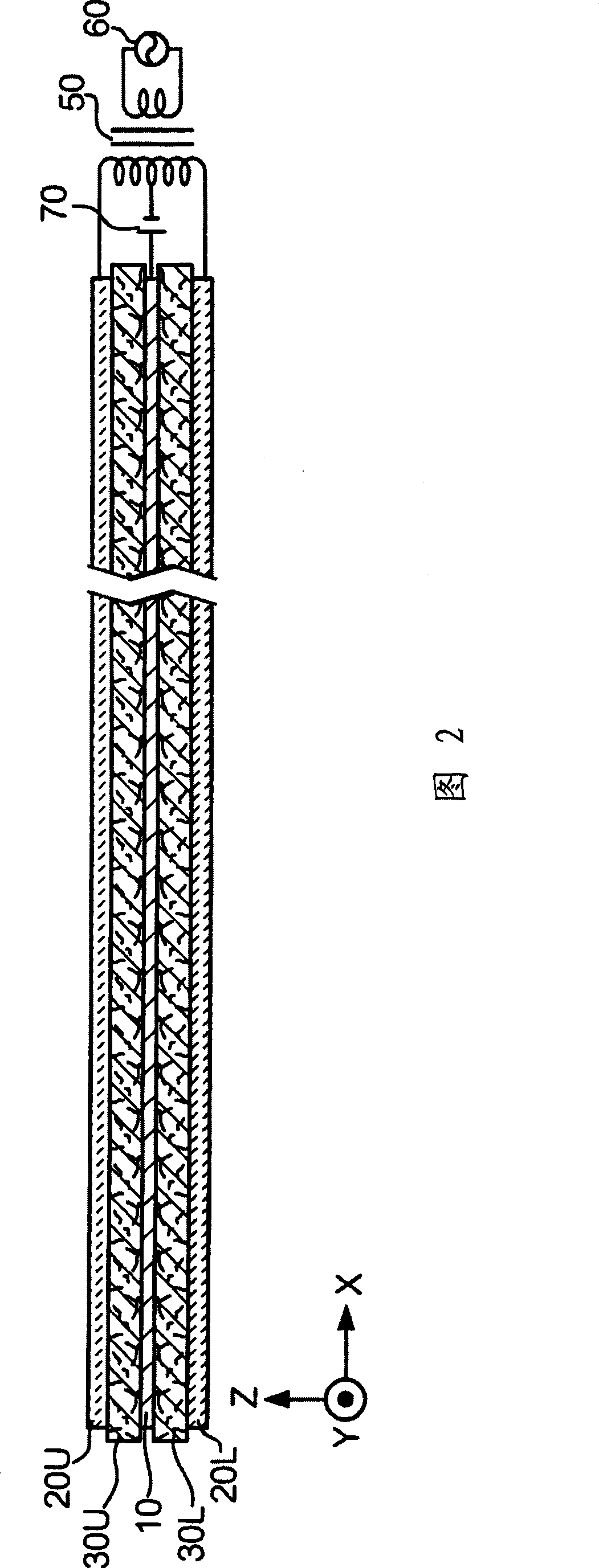

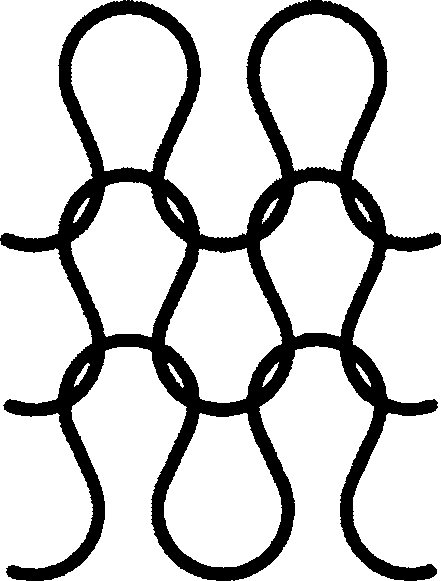

Electrostatic speaker

InactiveCN101400013ANo positional deviationElectrostatic transducer loudspeakersConductive polymerEngineering

An electrostatic speaker is constituted of a vibrator, conductive cloths, and elastic members, which are laminated together and woven together using strings. Since all the constituent elements are restrained in positioning by strings, the overall structure thereof is not substantially changed even when the electrostatic speaker is deformed in shape by bending or curving, wherein it is possible to secure the prescribed positional relationship between the constituent elements, which are not deviated in positioning. It is possible to introduce a sheet composed of a thermoplastic resin, which holds the vibrator and elastic members therein. The conductive cloths can be replaced with film electrodes, each of which is formed such that a conductive polymer layer is formed on a base film composed of a thermoplastic resin.

Owner:YAMAHA CORP

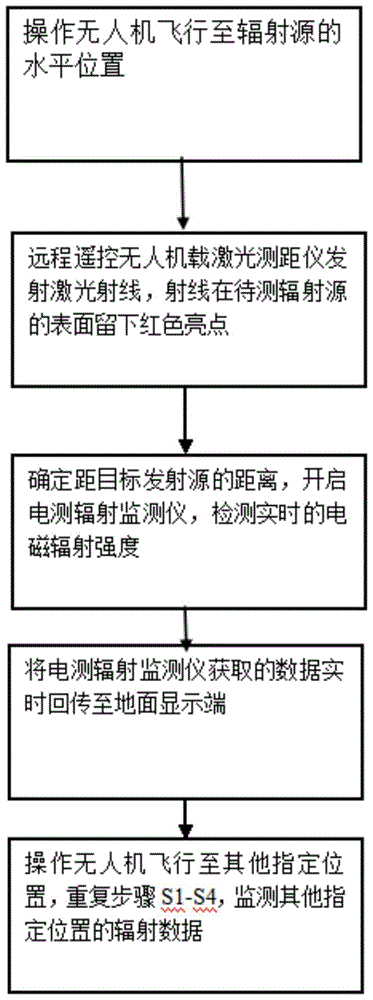

Detection method for electromagnetic radiation via unmanned aerial vehicle (UAV)

InactiveCN105676004AReduce human inputEnsure your own safetyElectromagentic field characteristicsRadiation monitoringLaser ranging

The invention provides a method for detecting electromagnetic radiation of an unmanned aerial vehicle, which includes the following steps: S1: operate the unmanned aerial vehicle to fly to the horizontal position of the radiation source; S2: remotely control the unmanned aerial vehicle-borne laser range finder to emit laser rays, the rays The terminal will show that a red bright spot is left on the surface of the radiation source to be measured; S3: after determining the distance from the target emission source by the laser range finder, turn on the electric radiation monitor to detect the real-time electromagnetic radiation intensity; S4: turn on the electric The data obtained by the radiation monitor is sent back to the ground display terminal in real time; S5: operate the UAV to fly to other designated positions, repeat steps S1-S4, and monitor the radiation data of other designated positions. The invention realizes the monitoring of electromagnetic radiation by no one, and the monitoring is convenient and the process is safe. The image is acquired by the camera, and the specified position required for measurement can be accurately reached without position deviation.

Owner:HEFEI INST FOR PUBLIC SAFETY RES TSINGHUA UNIV +1

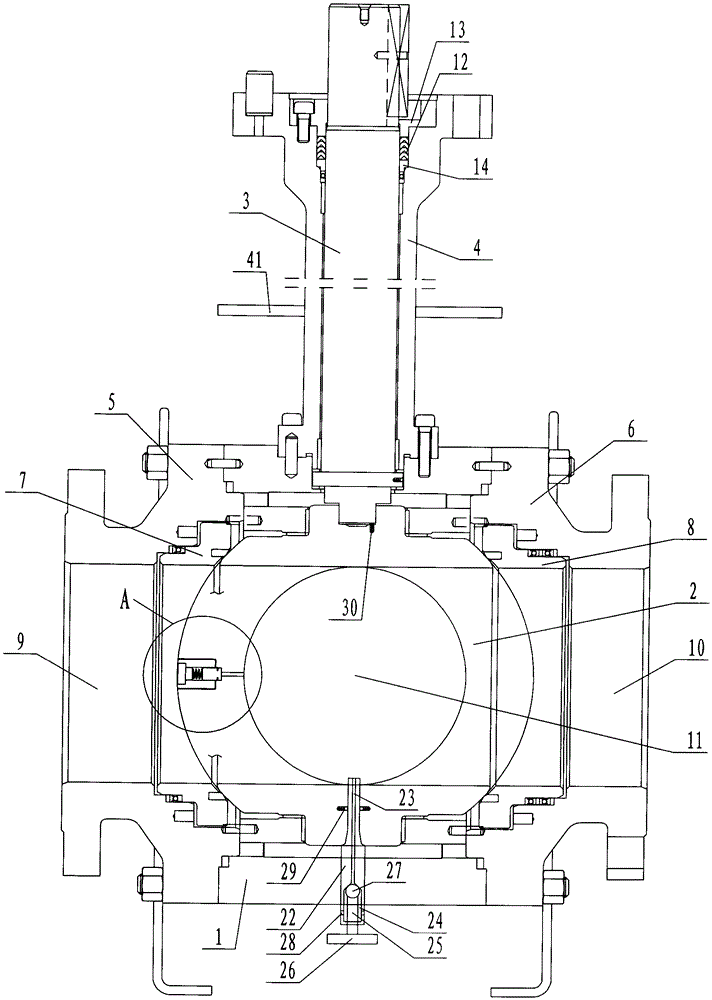

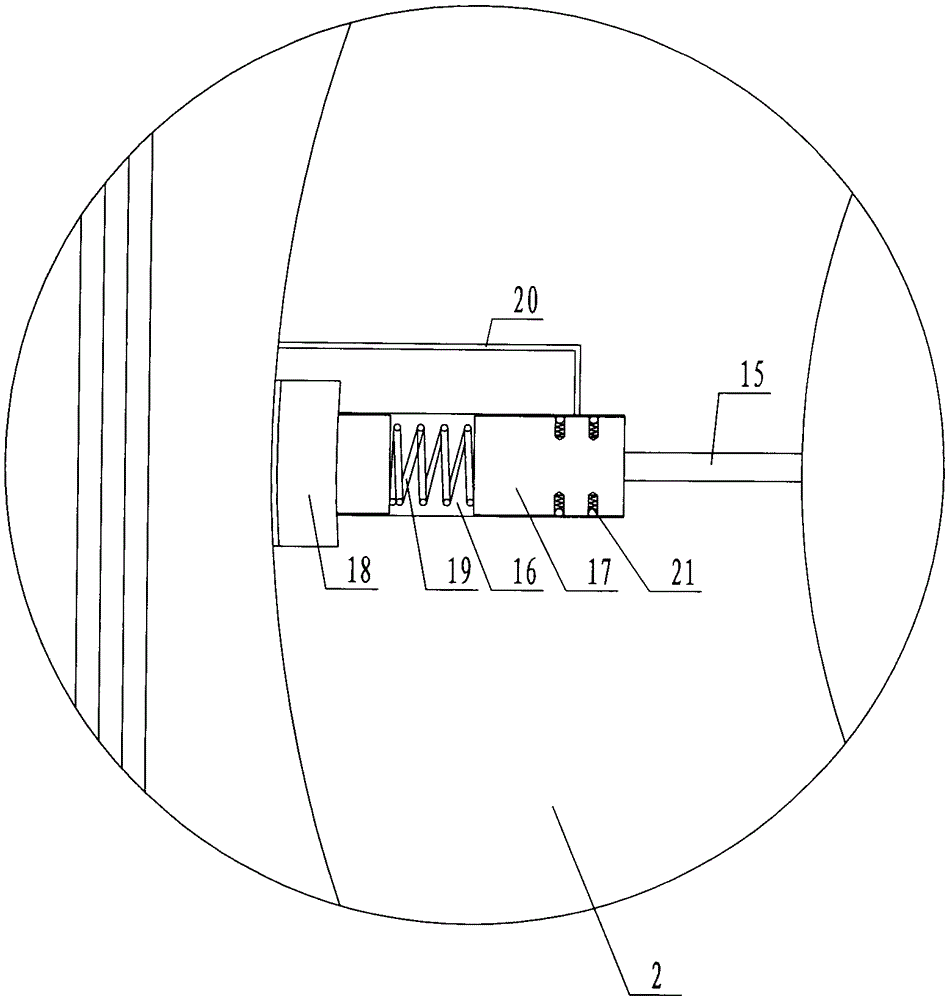

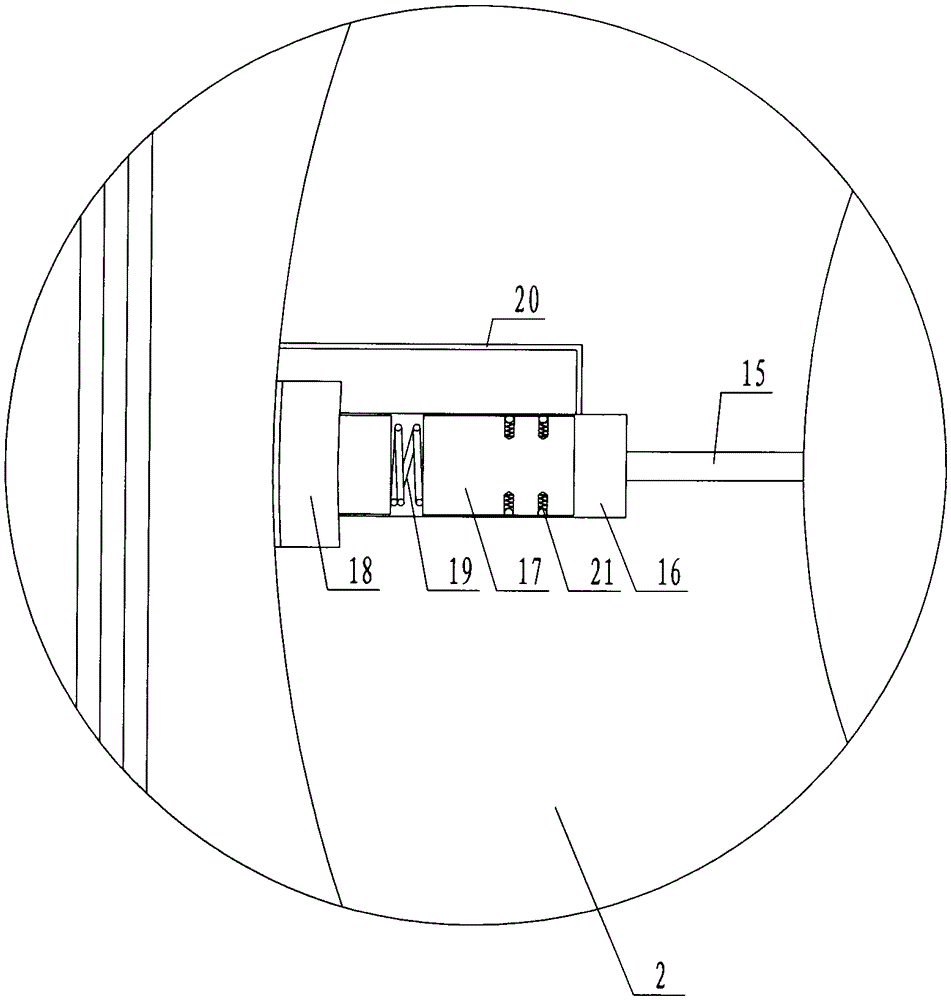

Ultra-low temperature ball valve

InactiveCN105422897APrevent leakageIncrease exhaust efficiency and safety performancePlug valvesValve housingsBall valveEngineering

The invention discloses an ultra-low temperature ball valve long in service life. The ultra-low temperature ball valve comprises a valve body, a ball arranged in the valve body, a valve rod connected with the upper end of the ball, a long-neck cover, an inlet end valve cover, an outlet end valve cover, an inlet end valve base ring and an outlet end valve base ring. The long-neck cover is arranged on the outer side of the part, at the upper end of the valve body, of the valve rod. The inlet end valve cover and the outlet end valve cover are arranged on the two sides of the valve body. The inlet end valve base ring is arranged between the inlet end valve cover and the ball. The outlet end valve base ring is arranged between the outlet end valve cover and the ball. An inlet channel is arranged in the inlet end valve cover and the inlet end valve base ring. An outlet channel is arranged in the outlet end valve cover and the outlet end valve base ring. A middle cavity channel communicated with the inlet channel and the outlet channel is arranged in the ball. Sealing padding is arranged between the upper end of the long-neck cover and the valve rod. A gland matched with the sealing padding is arranged between the part, at the upper end of the sealing padding, of the long-neck cover and the valve rod.

Owner:DAFENG OKAY FLUID MACHINERY

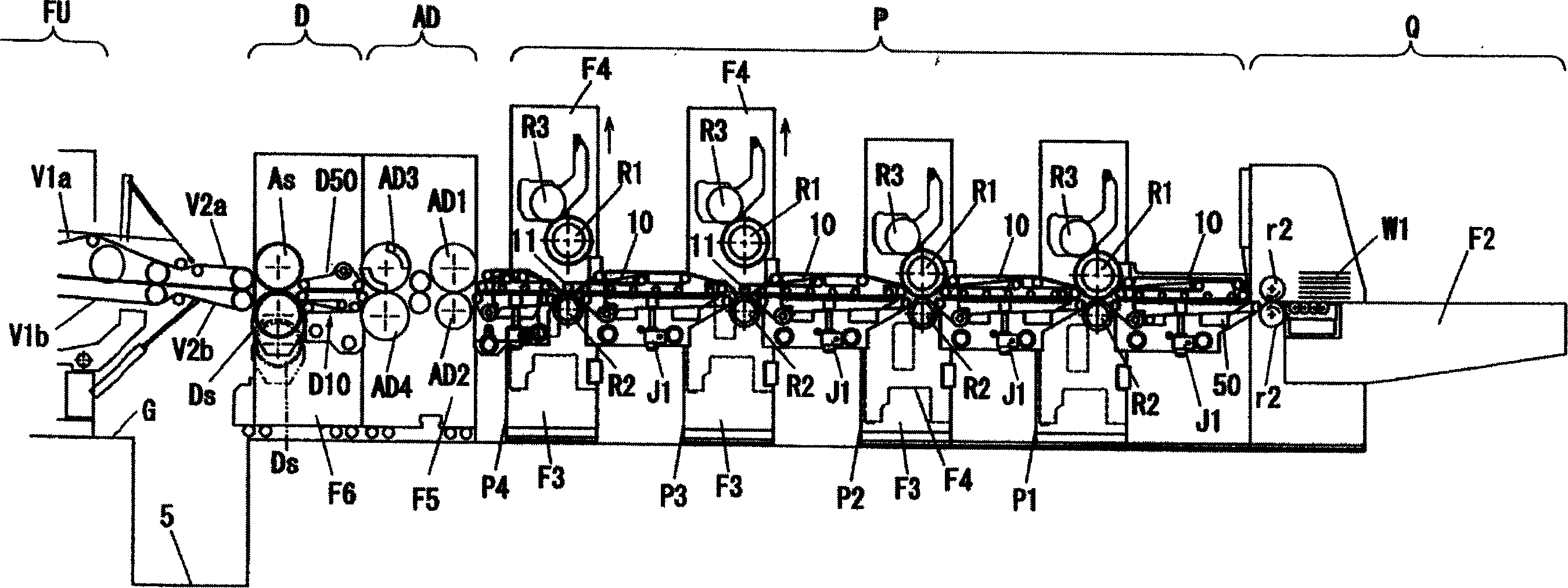

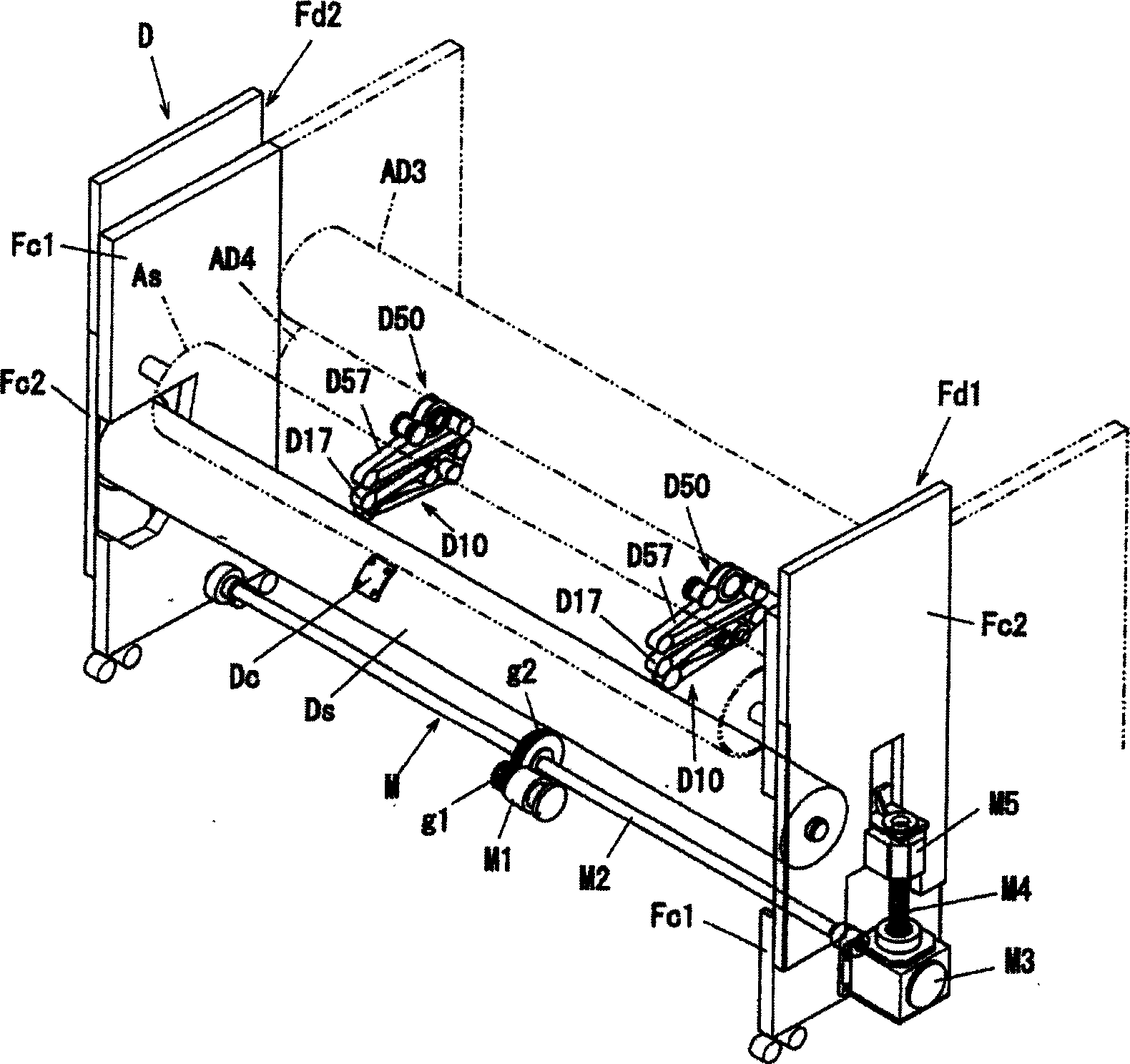

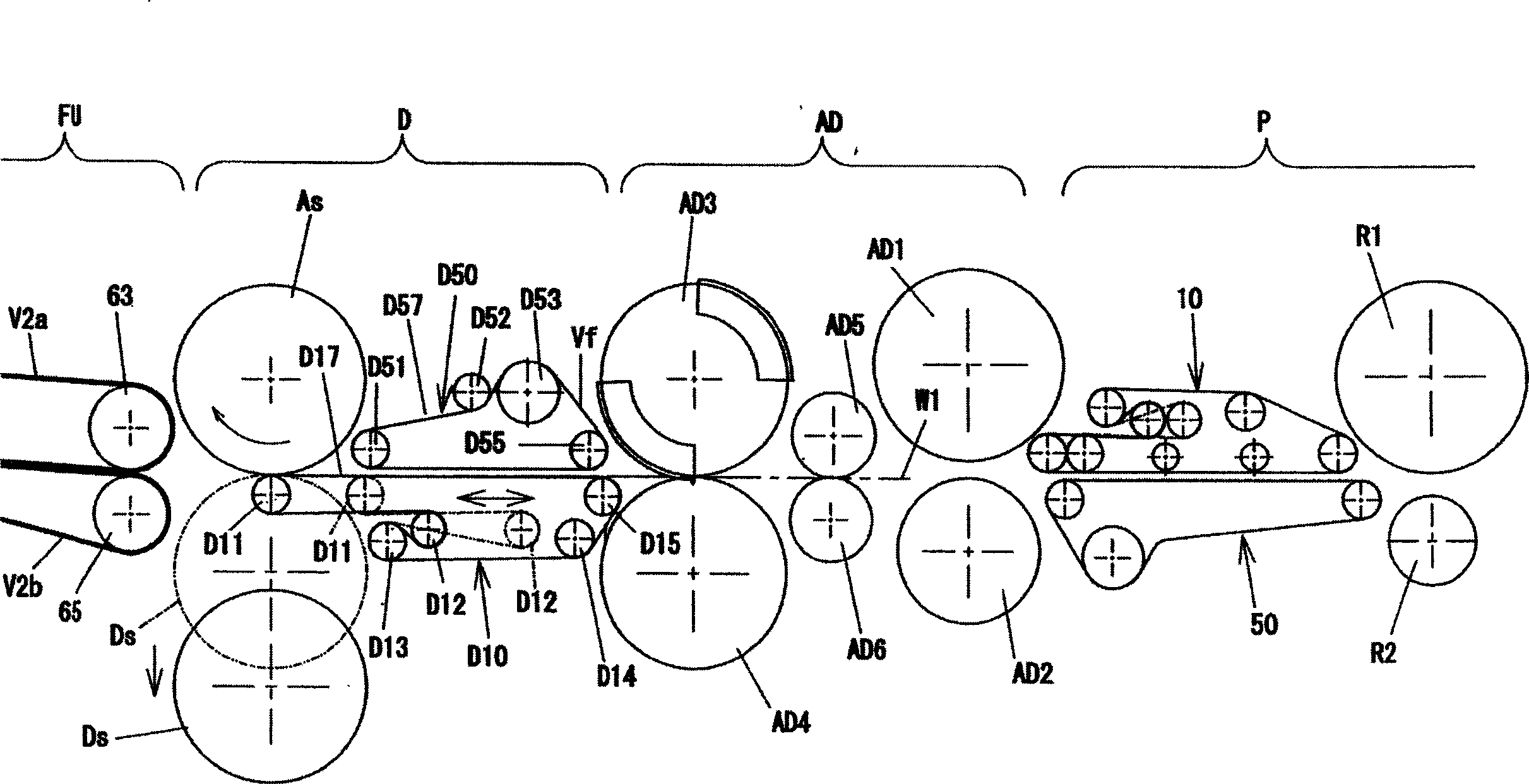

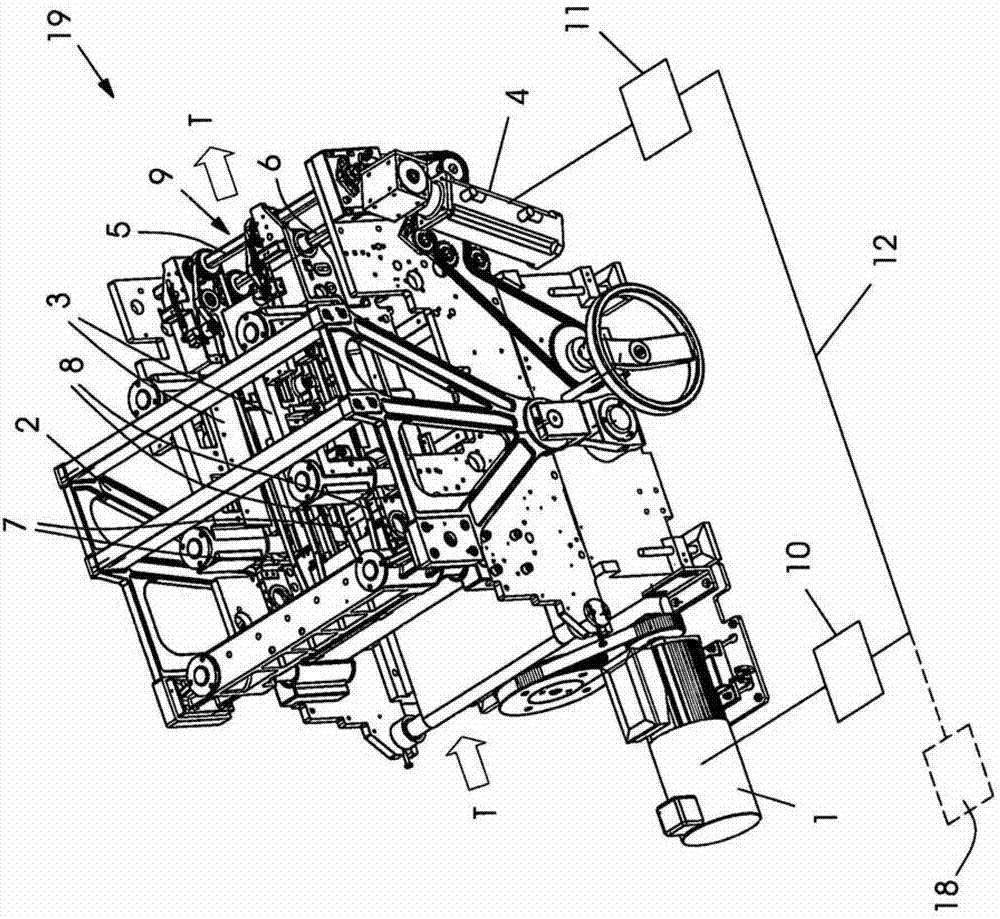

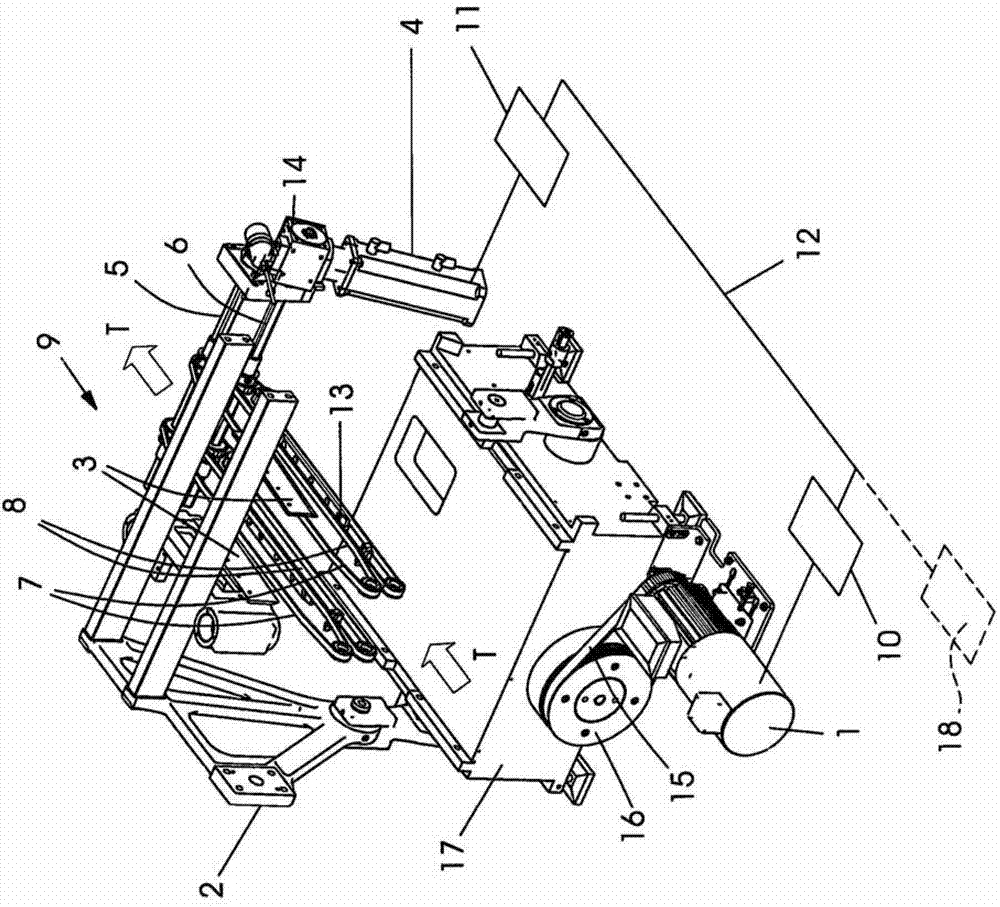

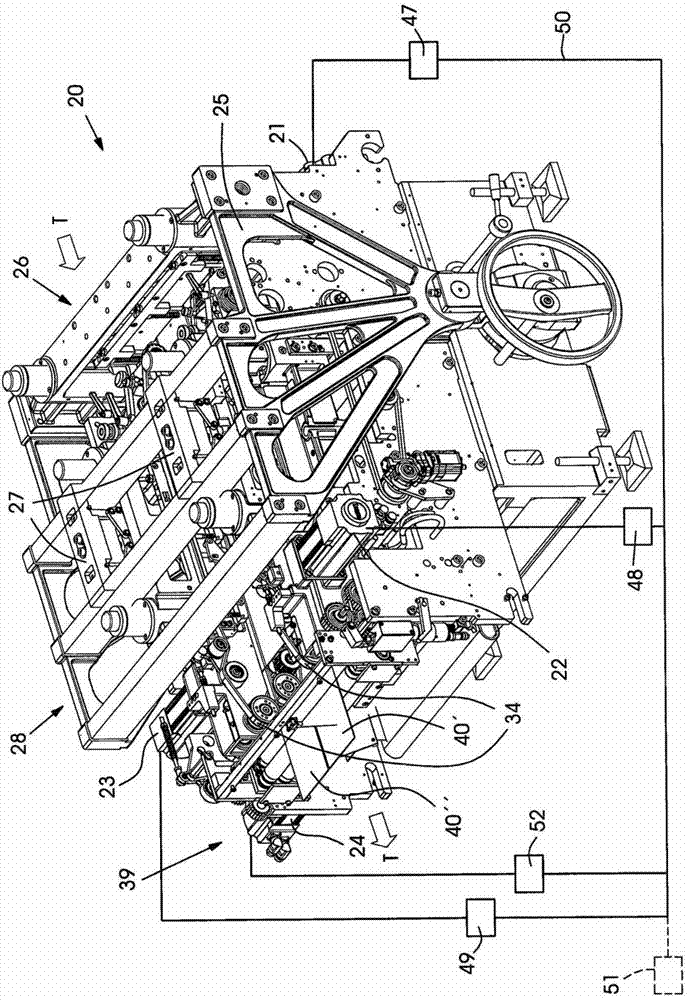

Punching cutting assembly and folding assembly for single workpiece

To achieve the facilitation of the replacement of a die in a die cutter unit constituting a box making machine and the stable feed of a sheetlike work at the time of replacement of the die and to prevent the transfer of cut refuse produced in the die cutter unit to a folding unit. The front end of the feeder belt of a feeder conveyor unit D10 placed in front of a die cylinder Ds is formed into a movable structure and the front end of the feeder belt is allowed to approach an anvil cylinder As in place of the die cylinder Ds retracted in the direction separated from the anvil cylinder As at the time of replacement of a cutting die. The sheetlike work W1 is forcibly fed by the anvil cylinder As and a feeder belt, and the folding belts V2a and V2b of the folding unit FU placed behind the die cutter unit D are made susceptible to on-off operation centering around a pulley on the downstream side to be retracted from the die cylinder Ds at the time of replacement of the cutting die. (C)2005,JPO&NCIPI.

Owner:ISHIKAWA SEISAKUSHO

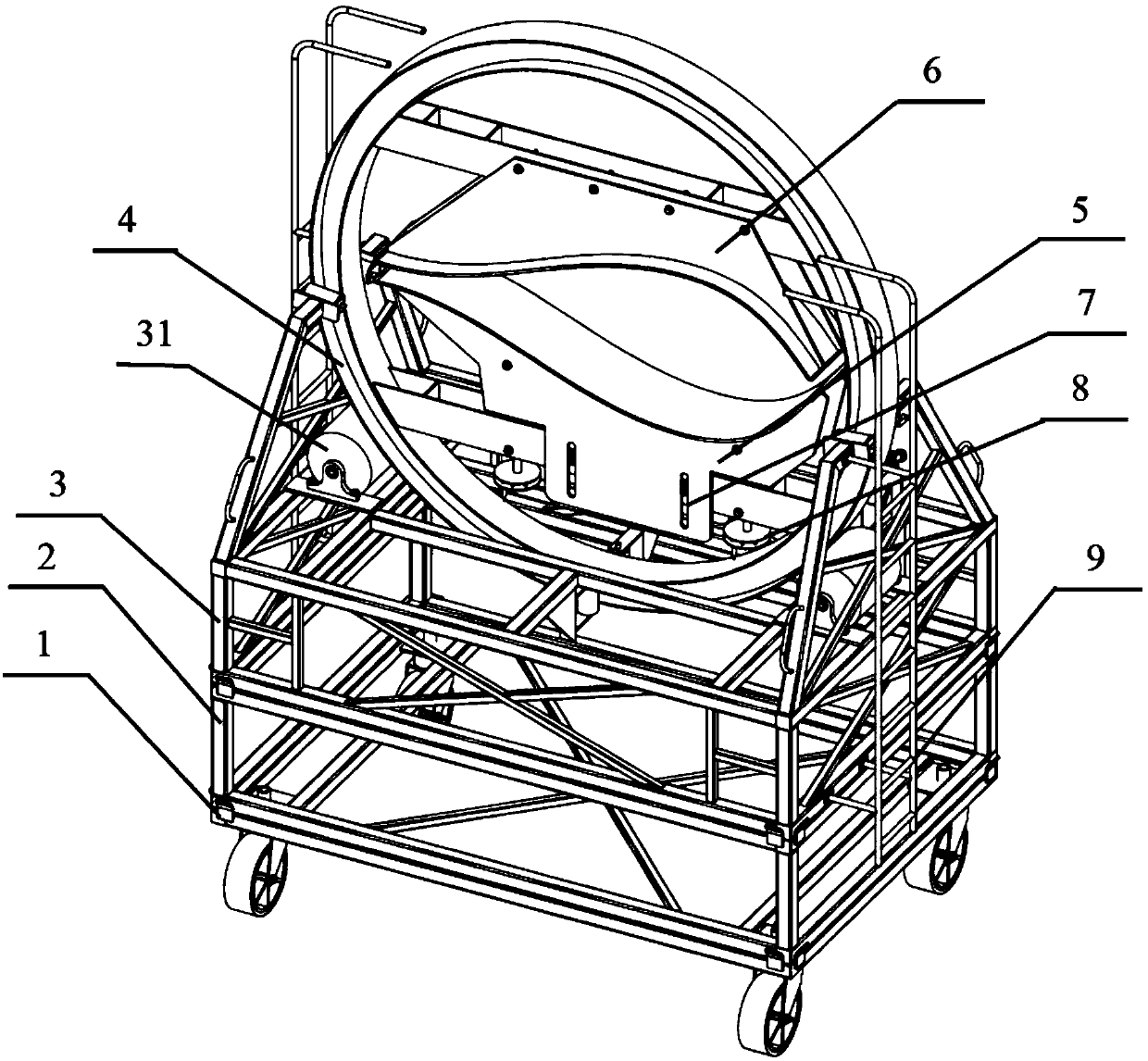

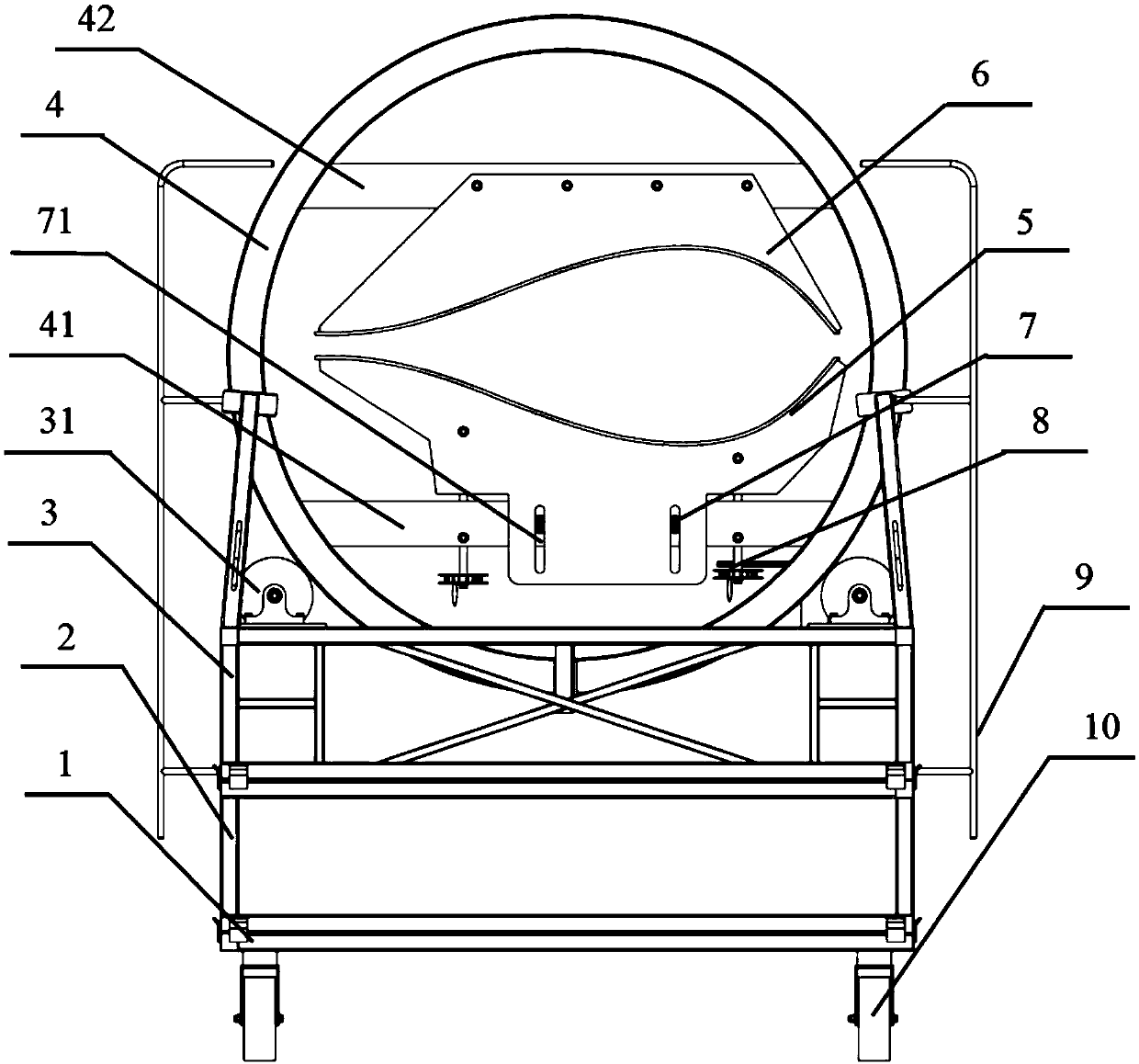

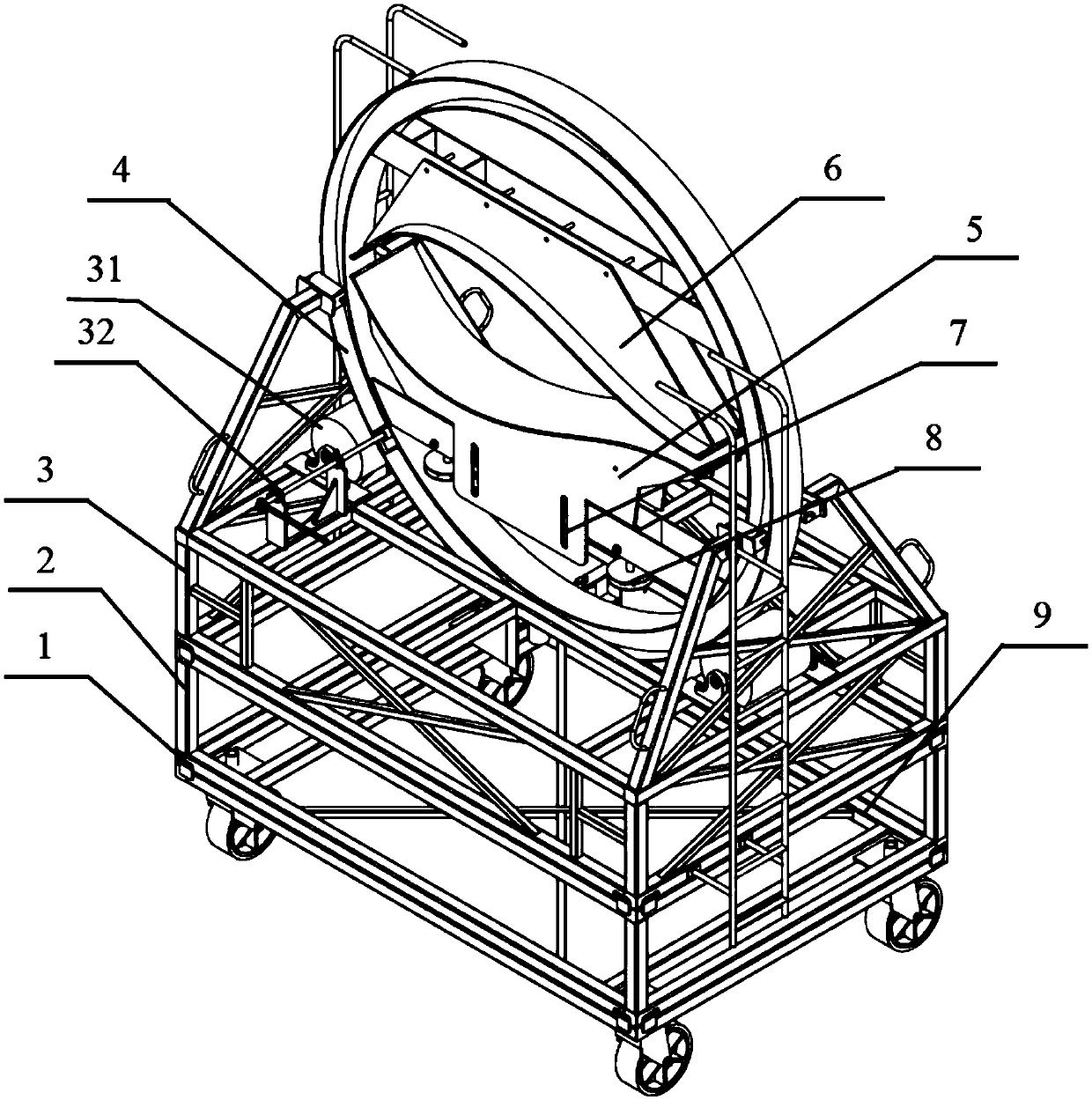

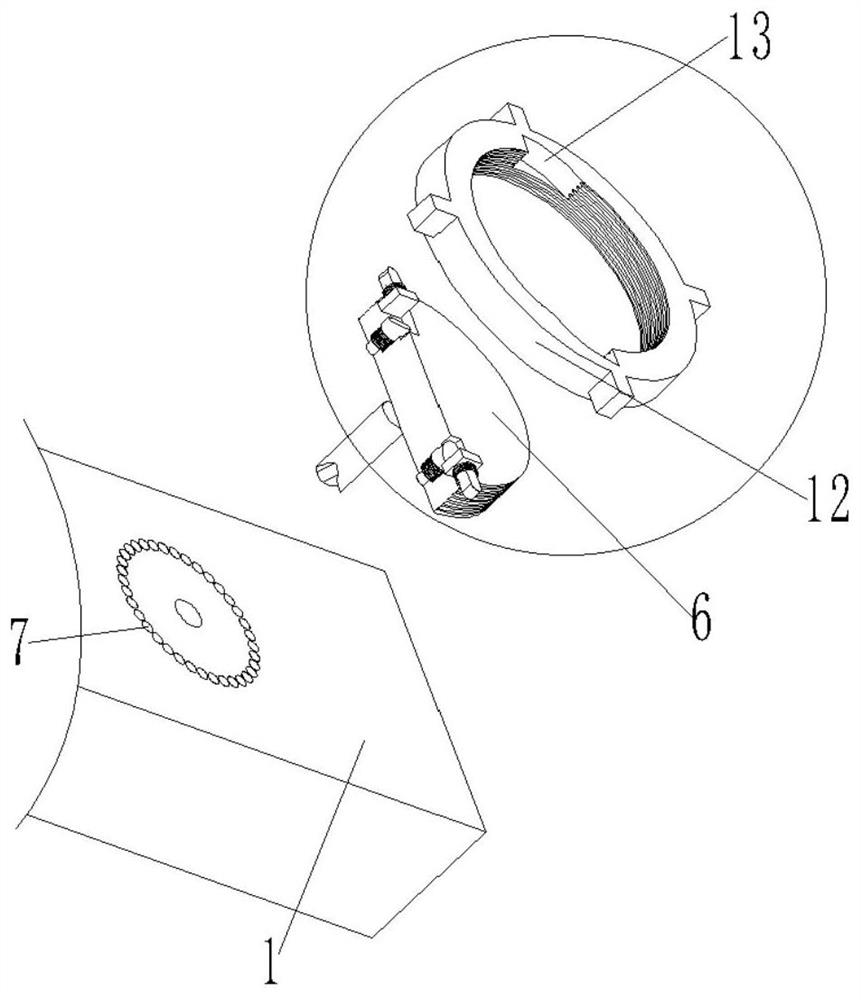

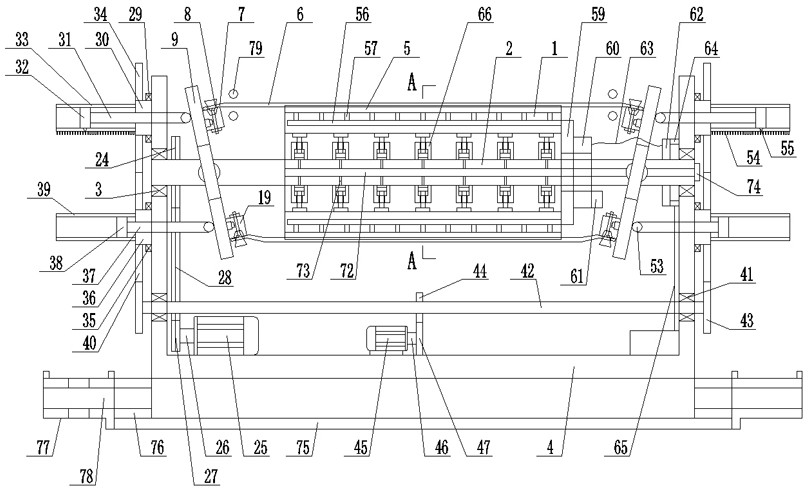

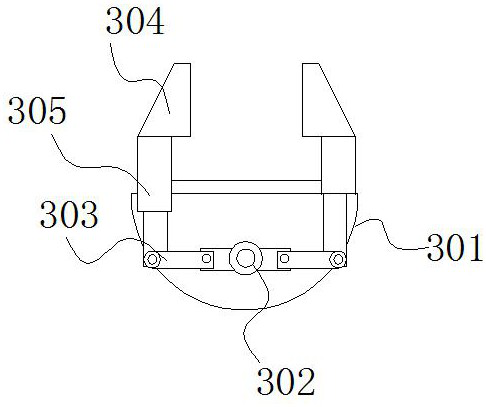

Wind turbine blade overturning vehicle

The invention discloses a wind turbine blade overturning vehicle. The wind turbine blade overturning vehicle comprises a vehicle frame and an overturning device mounted on the vehicle frame; the overturning device comprises a rolling ring, and further comprises a first clamp and a second clamp which are mounted on the rolling ring and face oppositely; a clamping area for wind turbine blades is formed between the first clamp and the second clamp; the first clamp is connected with the rolling ring through two position adjusting mechanisms, and a position adjusting guiding mechanism is arranged between the two position adjusting mechanisms; the position adjusting guiding mechanism comprises a guiding groove formed in the first clamp and an adjusting bearing mounted in the guiding groove; andthe guiding groove and the position adjusting mechanisms are consistent in direction, the outer diameter of the adjusting bearing is consistent with the width of the guiding groove, and the adjustingbearing is fixedly mounted on the rolling ring through bolts. The wind turbine blade overturning vehicle is simple in structure, safe and reliable, it can be ensured that the molded surfaces of the blades are better attached to the clamps and the shape following property is good, and scraping damage of the clamps to the blades in the machining process is reduced.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

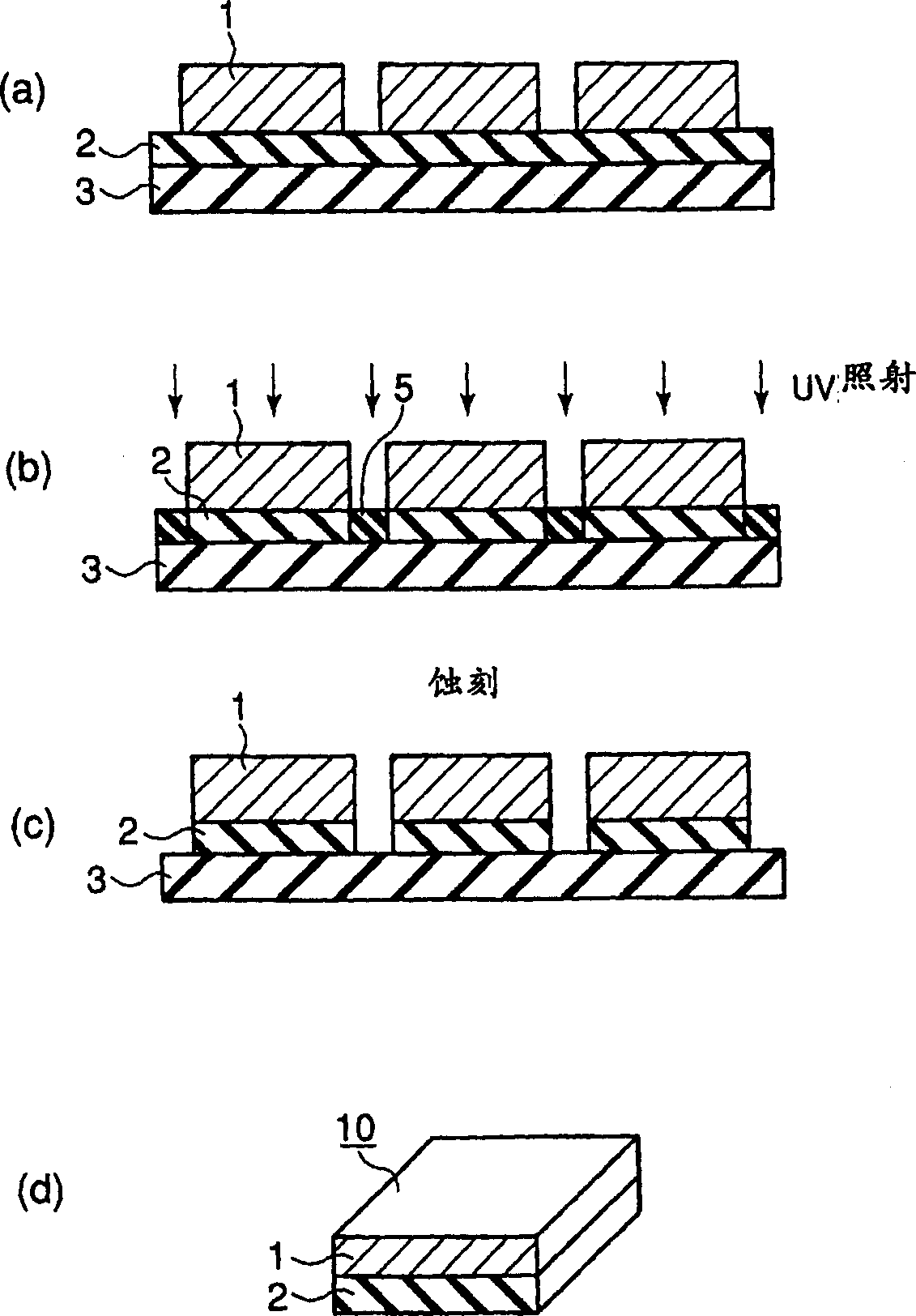

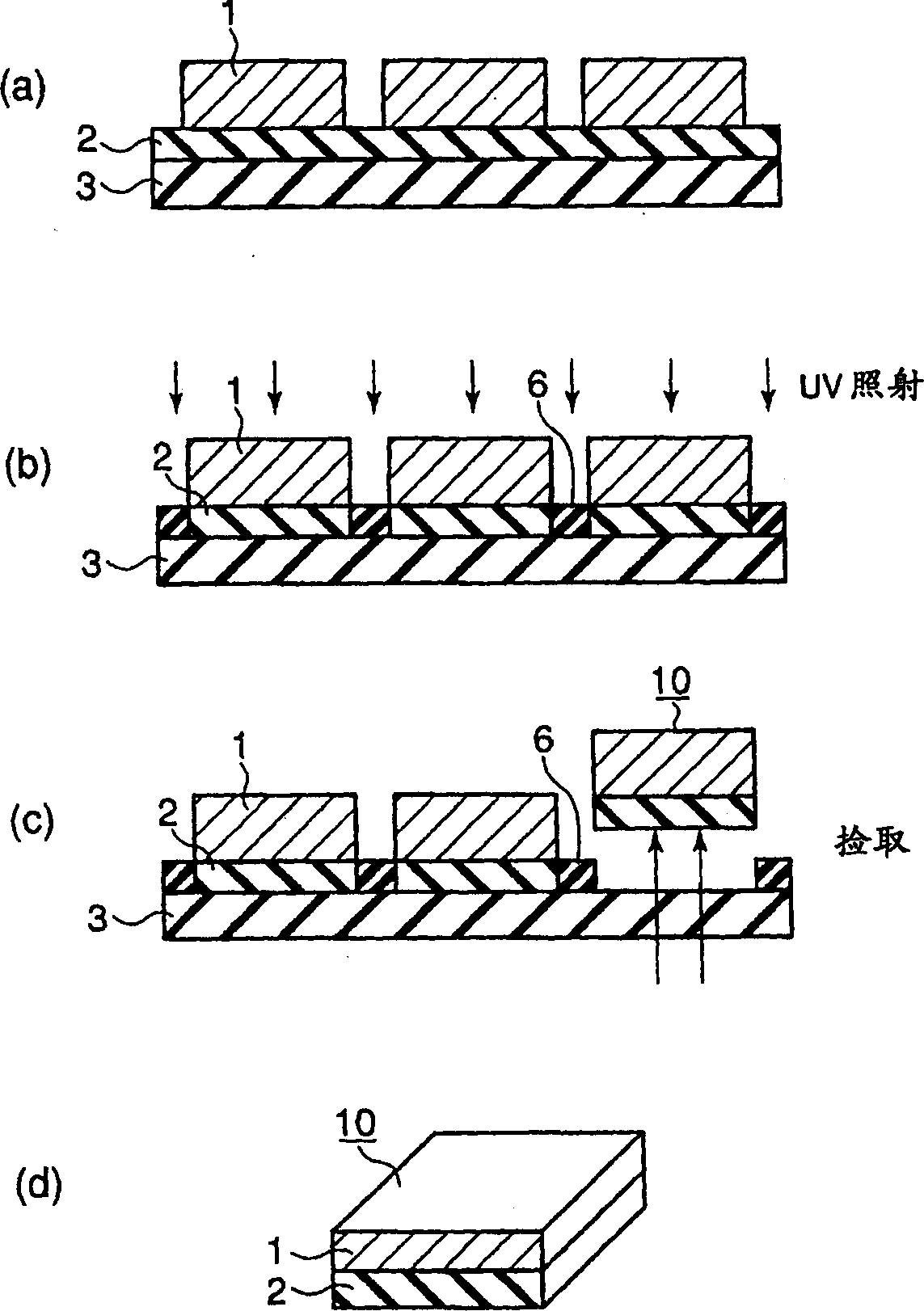

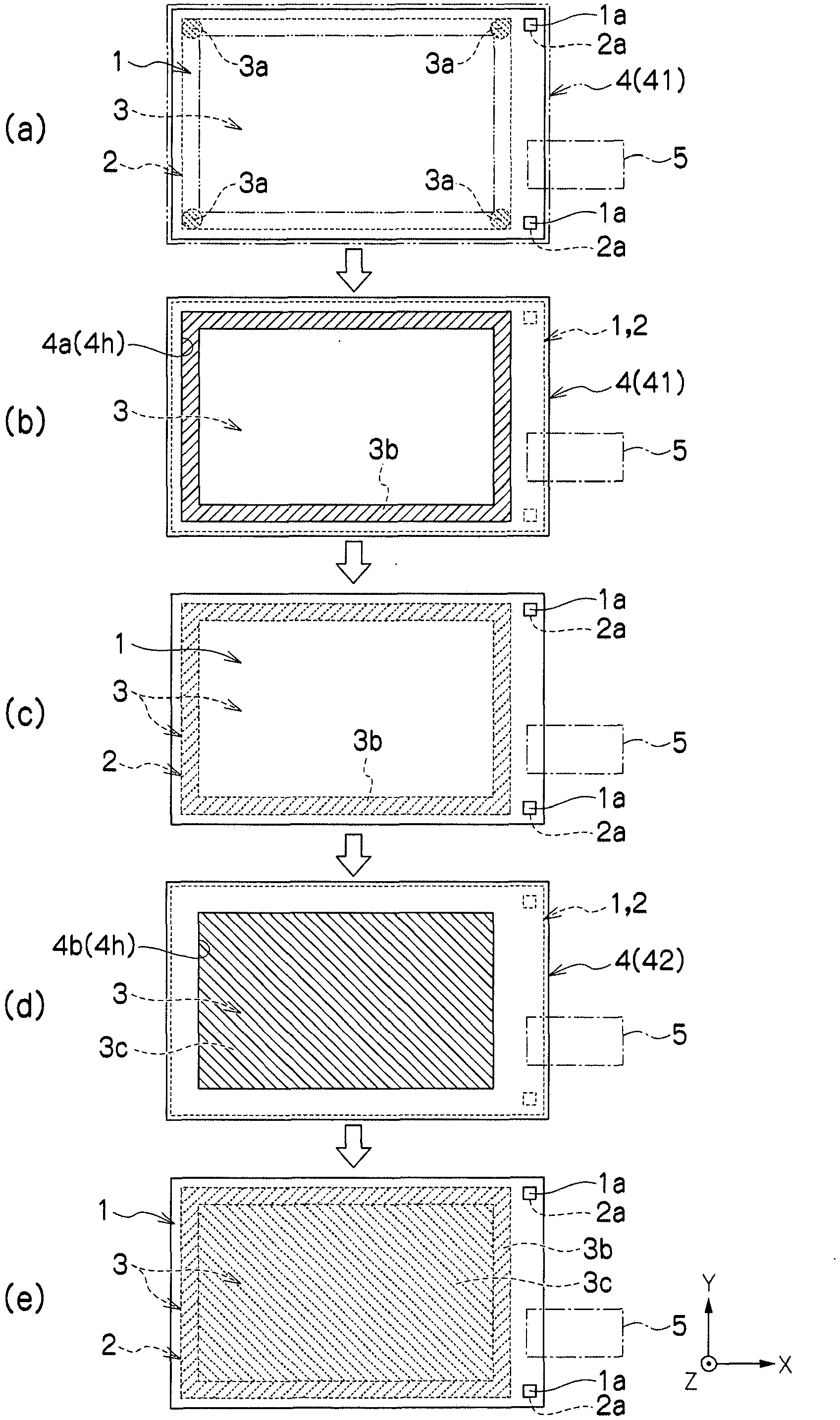

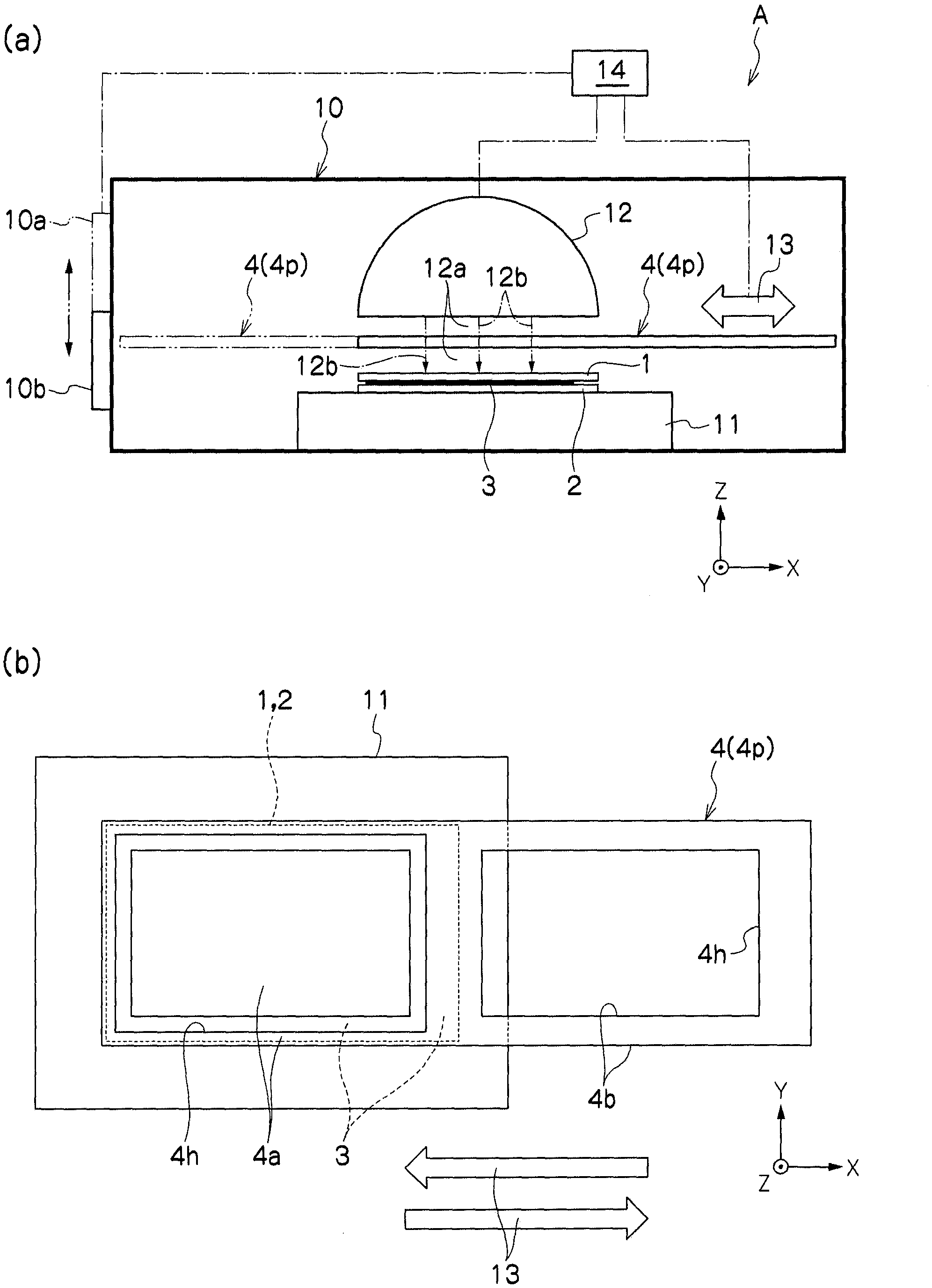

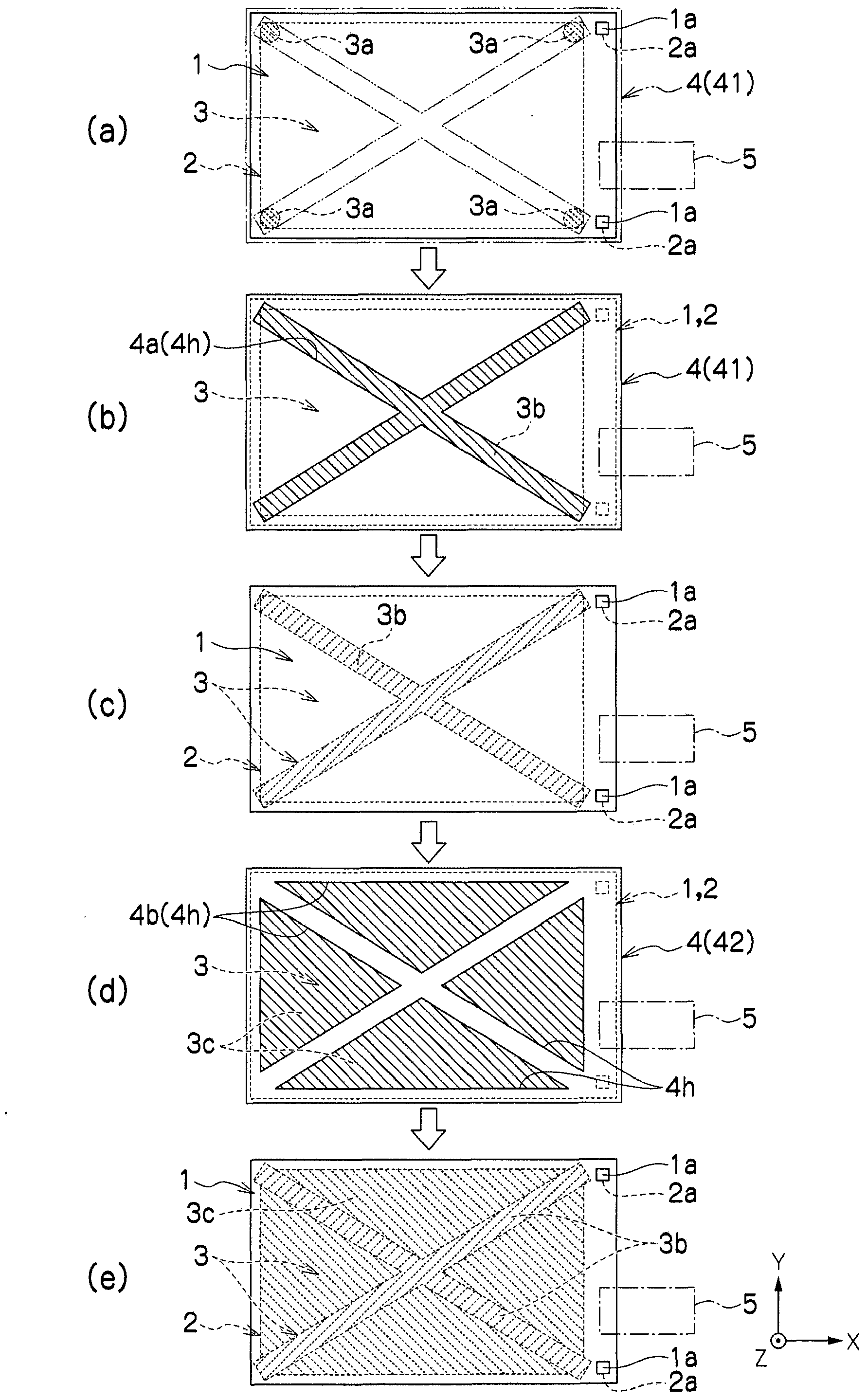

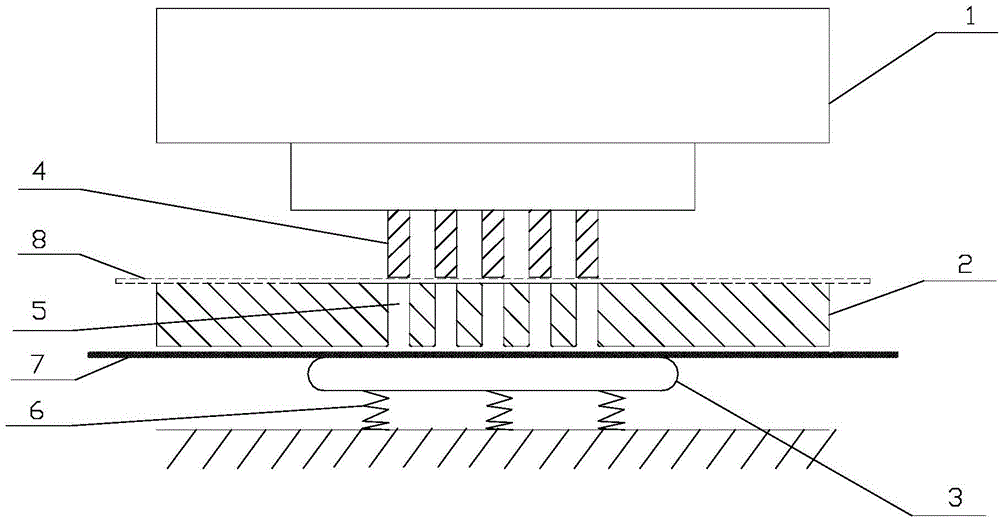

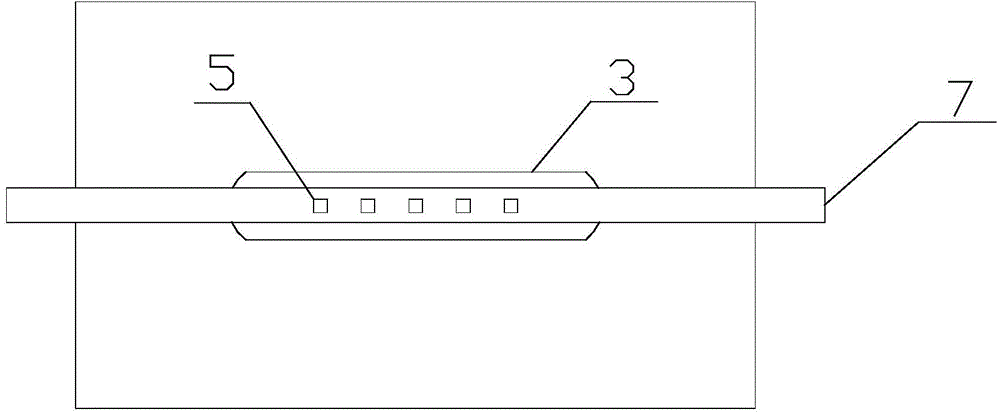

Method and apparatus for bonding workpieces

ActiveCN103881594AReduced curing shrinkageNo positional deviationAdhesive processesLaminationAdhesiveEngineering

The invention provides a method and an apparatus for bonding workpieces, which suppresses workpiece deformation and adhesive solidification contraction and simultaneously causes the adhesive to solidify integrally and formally. The apparatus for bonding the workpiece according to the invention causes one part of the adhesive (3) clamped between the overlapped workpiece (1,2) to partially and temporarily solidify and the workpieces (1,2). Afterwards, the adhesive (3) is integrally divided into a plurality of areas and partial formal solidification occur on divided areas (3b,3c,3d) in multiple times successively. Therefore, even total area of integer of the adhesive (3) is large, the parts which are divided into a plurality of narrow areas are respectively and successively solidified. Therefore, compared with a method of formally solidifying integer of large-area adhesive in one time, the method provided by the invention is advantageous in that temperature increase amount of the workpieces (1,2) in each time of formal solidification and solidification contraction amount of the divided areas (3b,3c,3d) in the adhesive (3) are greatly reduced.

Owner:SHIN ETSU ENG

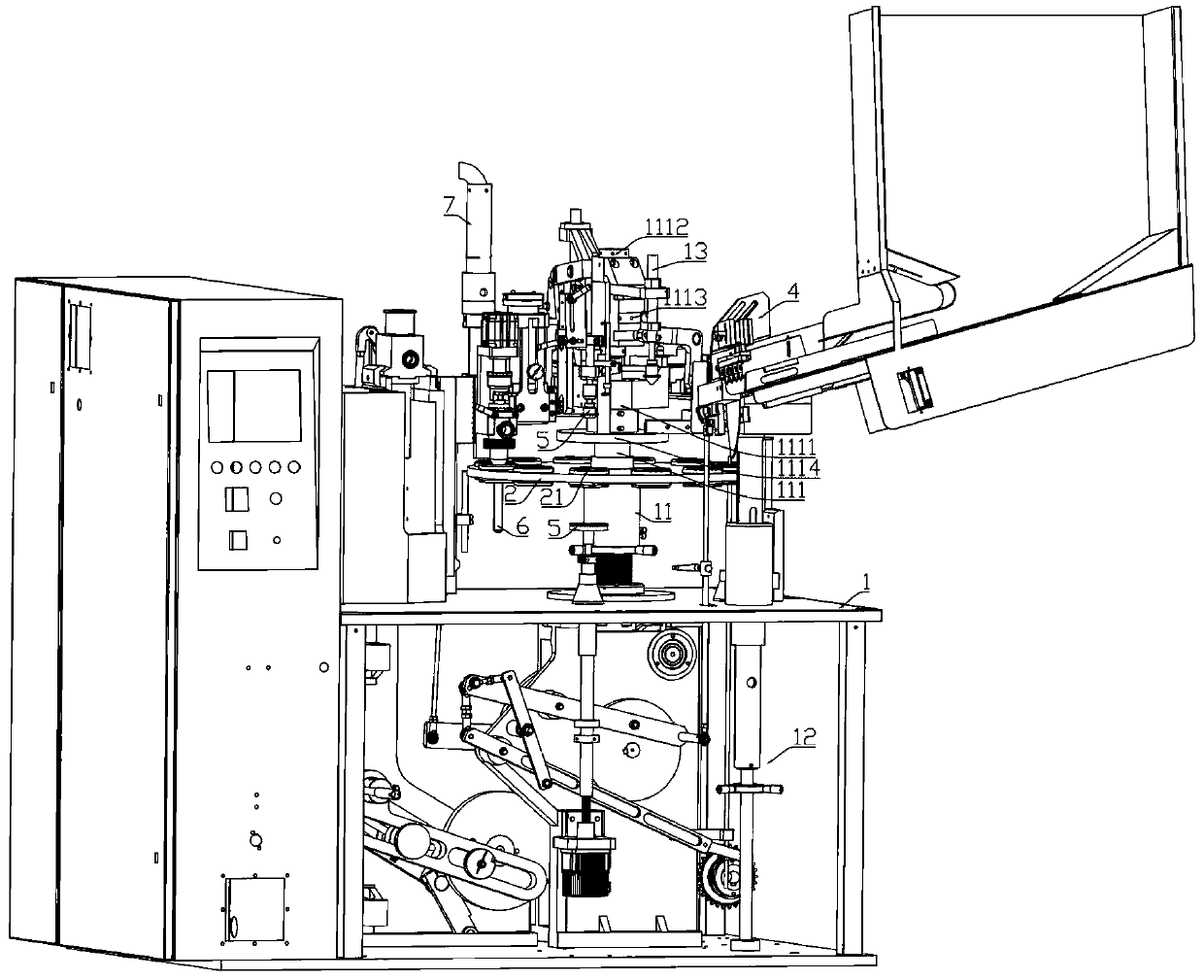

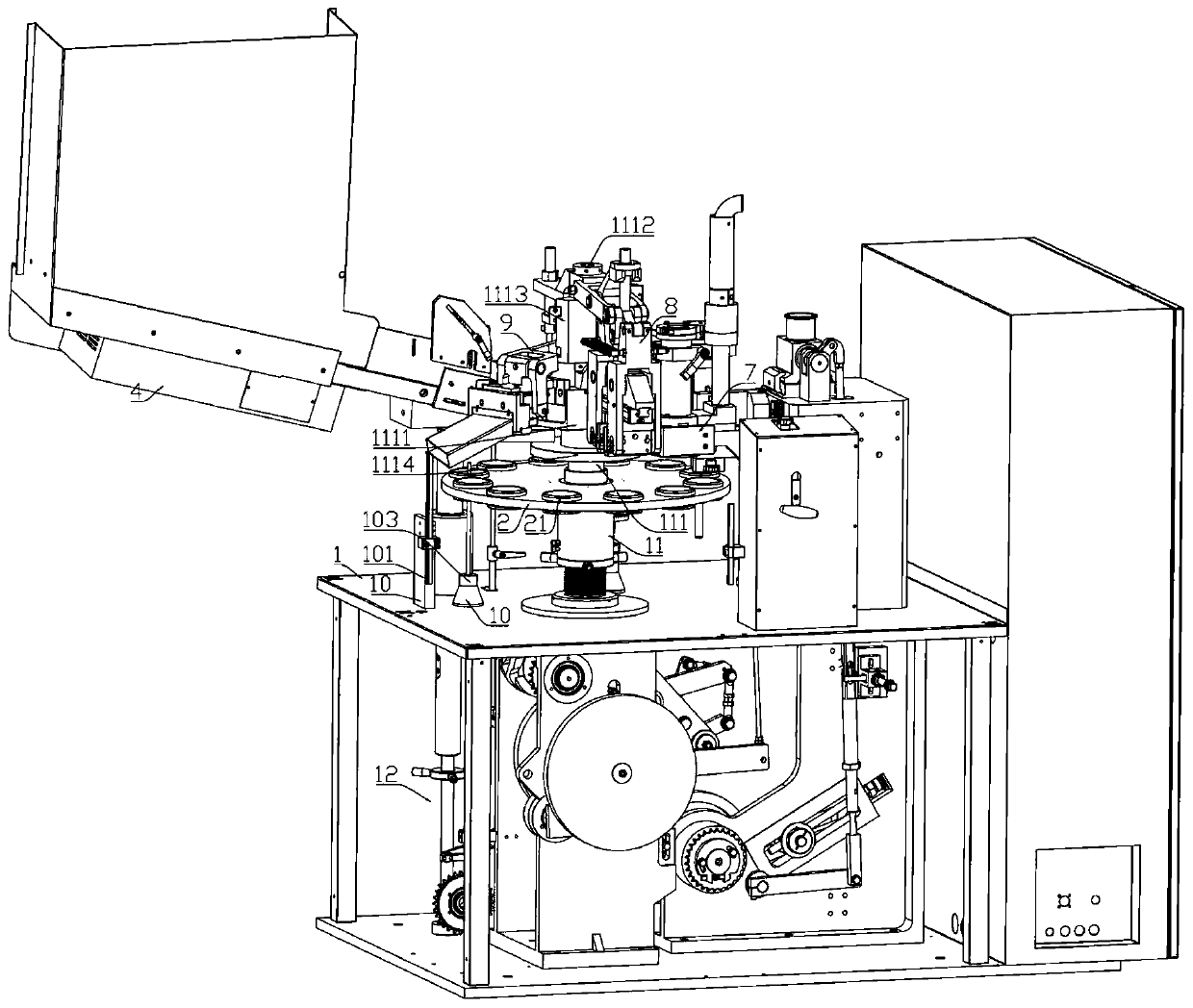

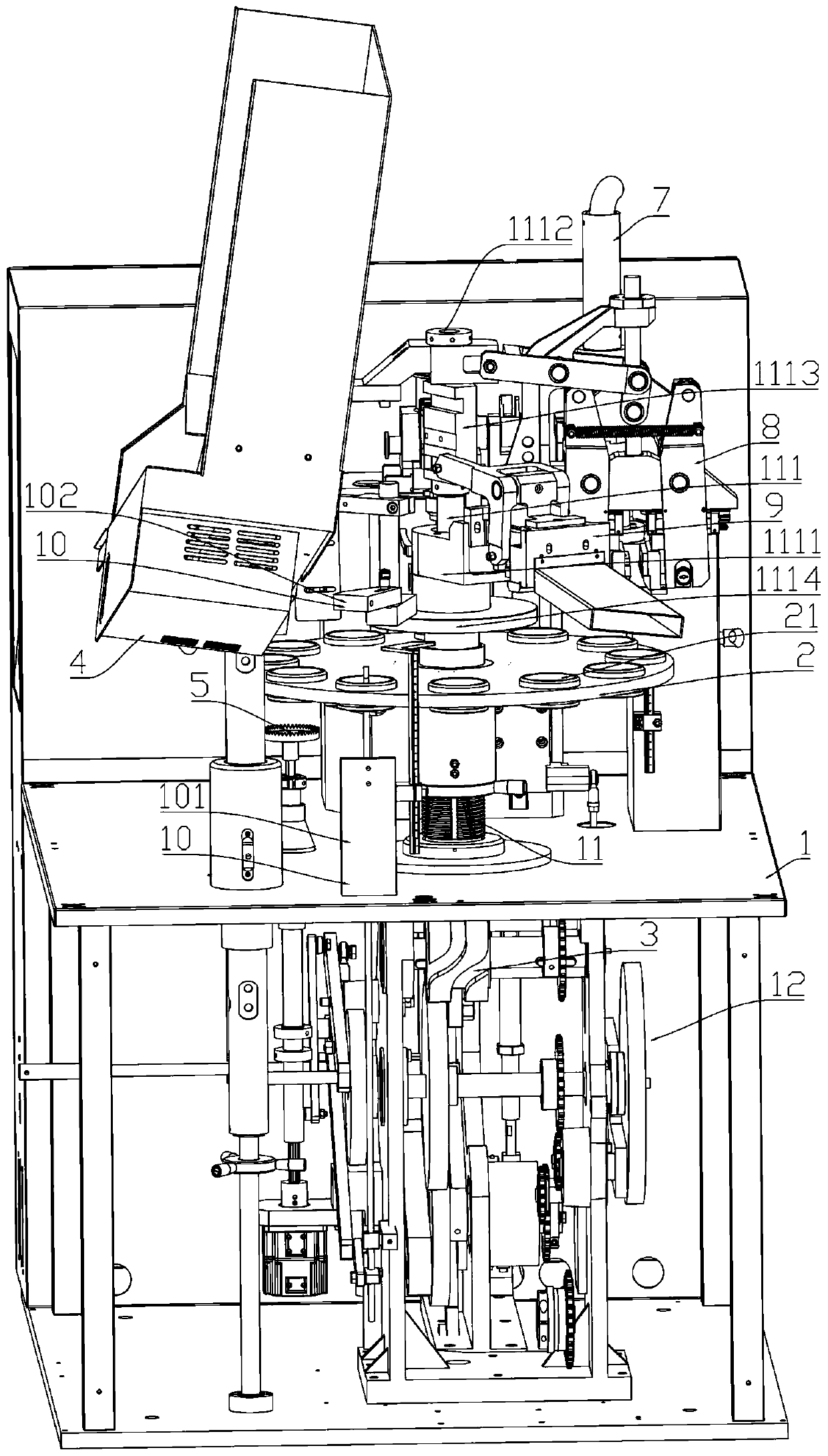

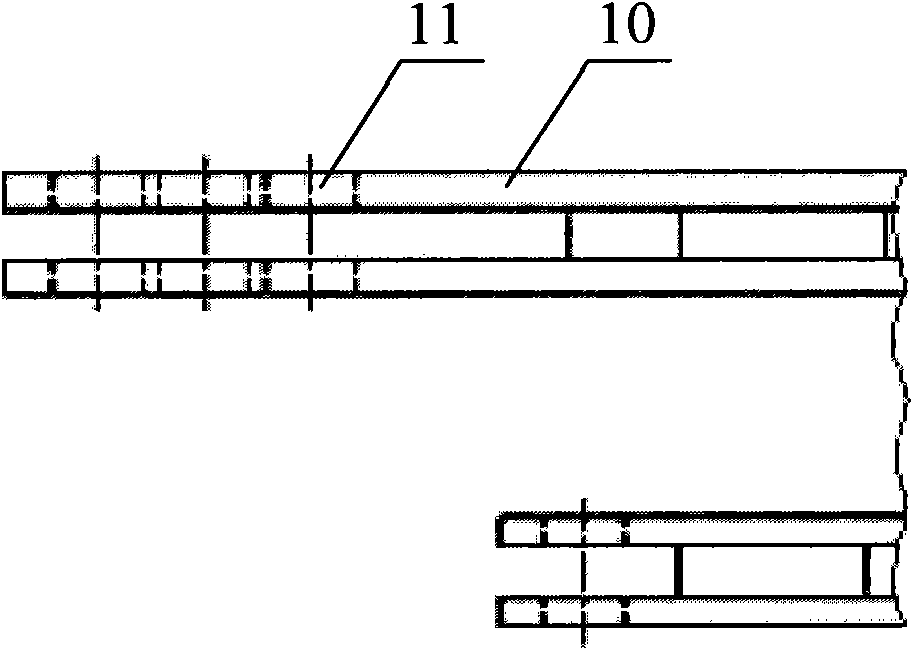

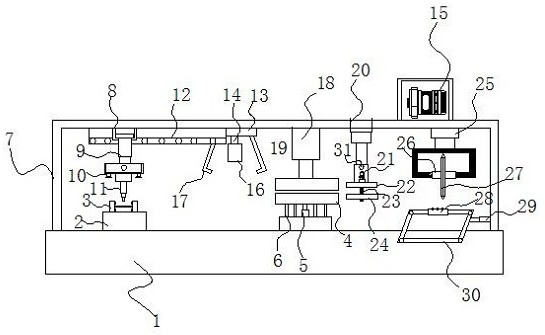

Hose filling and tail sealing machine

PendingCN111099079AOutstanding and Beneficial Technical EffectsImprove work efficiencyWrapper twisting/gatheringEngineeringMechanical engineering

The invention belongs to the technical field of filling machines, and particularly relates to a hose filling and tail sealing machine. The hose filling and tail sealing machine comprises a supportingplate and a station turntable installed above the supporting plate, wherein a supporting column used for connecting the station turntable is installed on the supporting plate and capable of rotating relative to the supporting plate; a linkage rod penetrating through the supporting plate and the station turntable and capable of lifting is installed in the supporting column; at least six hose cup bases are formed on the station turntable; a transmission device for controlling the rotation of the supporting column and a driving device for providing power for all devices are connected to the lowerend of the supporting plate; a feeding device, an injecting device and a heating device which correspond to the hose cup bases are sequentially installed at the upper end of the supporting plate; a marking device, a tail sealing device and a tail cutting device which correspond to the hose cup bases are sequentially installed on the linkage rod; and the marking device is positioned between the feeding device and the injecting device. The hose filling and tail sealing machine has the advantages that the precision and the working efficiency are high, and the manufacturing cost can be saved.

Owner:WENZHOU ZHONGHUAN MACHINERY EQUIP

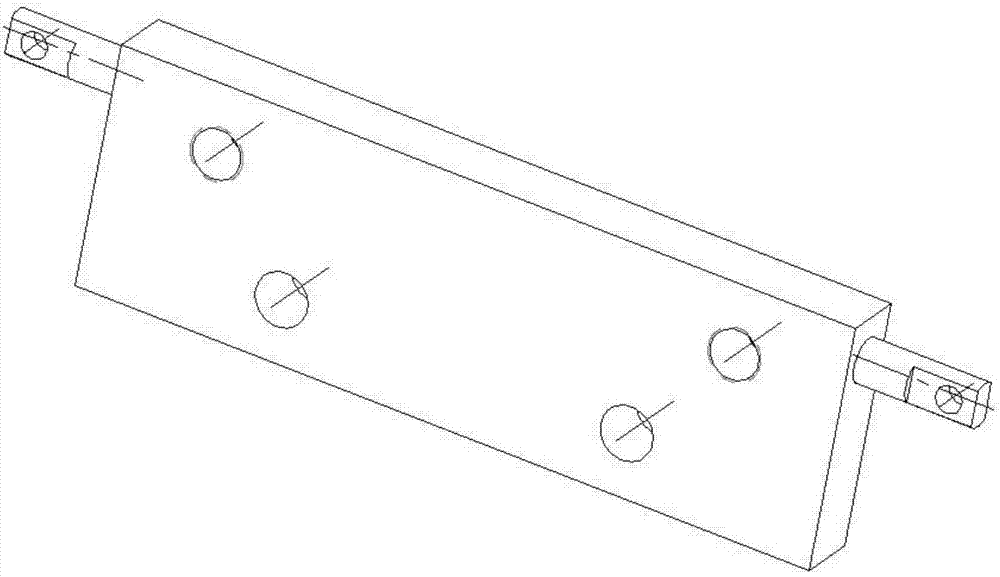

Method for mounting bushing

InactiveCN102371477ANo positional deviationSimple and fast operationMetal working apparatusEngineeringChange positions

The invention provides a method for mounting a bushing. The method comprises the following steps of: aligning the guiding end of the bushing with a mounting hole passing through a mounting plate; inserting a mounting shaft into the bushing and the mounting hole; and screwing a nut in the mounting shaft, so that the bushing is extruded into the mounting hole in the screwing process. By the method, the bushing can be mounted under the adverse conditions of narrow space, incapability of changing positions at random and the like, so the method is easy and convenient to operate and high in practicality; and the positional deviation of the mounted bushing in the mounting hole can be avoided, and a mounting effect is good.

Owner:CRRC BEIJING ERQI LOCOMOTIVE CO LTD

Combined type wooden door

InactiveCN107587815AEasy to assemble and disassembleEasy to disassembleWindow/door framesWood layered productsSolid woodEngineering

The invention discloses a combined type wooden door. The combined type wooden door comprises a door frame part which is hinged to a door leaf part through a hinge; the door frame part comprises a pairof first connection parts arranged in an up-down symmetry manner; the first connection parts are each connected with a second connection part in a joggled joint manner; a tenon is arranged on each first connection part; and a groove matched with the corresponding tenon is formed in each second connection part. The door leaf part comprises a three-layer solid wood structure, wherein thin wood board layers are on the two sides, and a spliced layer is sandwiched and arranged between the thin wood board layers; the spliced layer comprises a pair of symmetrically arranged first C-shaped wood boards; a bottom cross beam is connected between the first C-shaped wood boards in a joggled joint manner; second C-shaped wood boards are connected to the upper portions of the first C-shaped wood boardsthrough double-end bolts and nuts; a middle cross beam is connected between the second C-shaped wood boards in a joggled joint manner; third C-shaped wood boards are connected to the upper portions ofthe second C-shaped wood boards through double-end bolts and nuts; and a top cross beam is connected between the third C-shaped wood boards in a joggled joint manner. The combined type wooden door has the beneficial effects that a door frame is easy to disassemble and assemble, convenient to transport and high in inner structural strength.

Owner:湖州欧贝得门业有限公司

Flexible hinge phase shifter

PendingCN111854611AReduce lossesImprove work efficiencyUsing optical meansShielding blockStructural engineering

The invention discloses a flexible hinge phase shifter, which comprises a base and a main body, wherein an actuator assembly is fixed on the base; the actuator assembly is electrically connected witha wire harness, the wire harness is jointly connected with a wire harness connector, the wire harness connector is sleeved with a wire buckle, and the wire buckle is fixed to the base; the main body comprises a front main body and a rear main body; an elastic reset structure is installed between the opposite side surfaces of the front body and the rear body; the end part of the actuator assembly is fixedly connected to the rear main body; and a plurality of shielding blocks are arranged on the side surface of the front main body and are fixedly connected between the base and the front main body so as to achieve the fixed connection of the front main body and the base. According to the invention, stable and precise displacement is obtained in a multi-point supporting and synchronous phase shifting mode, rigid connection between the main body and the base is achieved through the structure of the flexible hinge, position deviation is avoided, the service life is greatly prolonged, enterprises are indirectly helped to reduce losses, and the working efficiency of an interferometer is improved.

Owner:SHANGHAI STEM YAO OPTICAL TECH CO LTD

Hole aligning punching machine for pipe

InactiveCN104550427AHigh precisionReduce labor intensityMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention discloses a hole aligning punching machine for a pipe. The machine comprises a rack, a die seat which is fixedly arranged at the front end of the rack, a transverse feeding channel and a first vertical punch guide hole, wherein the transverse feeding channel and the first vertical punch guide hole are formed in the die seat; a punching cylinder is arranged on the rack at the upper end of the die seat; a piston rod of the punching cylinder is connected with the punch; the punch is matched with the first vertical punch guide hole; a slide rail is arranged on the rack at the rear end of the die seat; a sliding table is glidingly arranged on the slide rail through a sliding block; a servo driving motor which is electrically connected with the sliding block is arranged on the sliding table; a pipe pushing block is connected to one side of the sliding table; a pipe end positioning hole is formed in one side of the pipe pushing block; a compressing cylinder is arranged at the upper end of the pipe pushing block.

Owner:JIANGSU YAFENG TECH GRP CO LTD

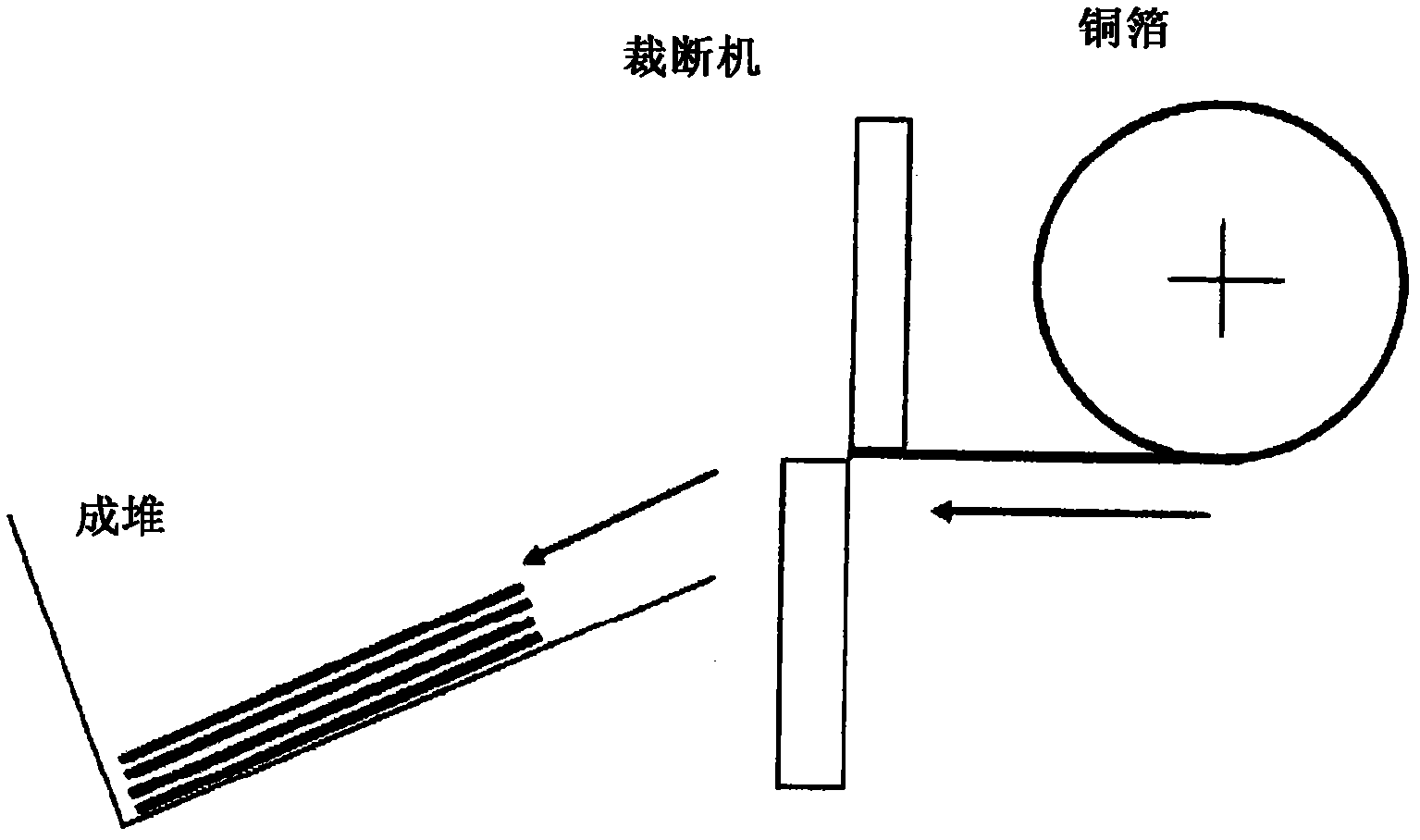

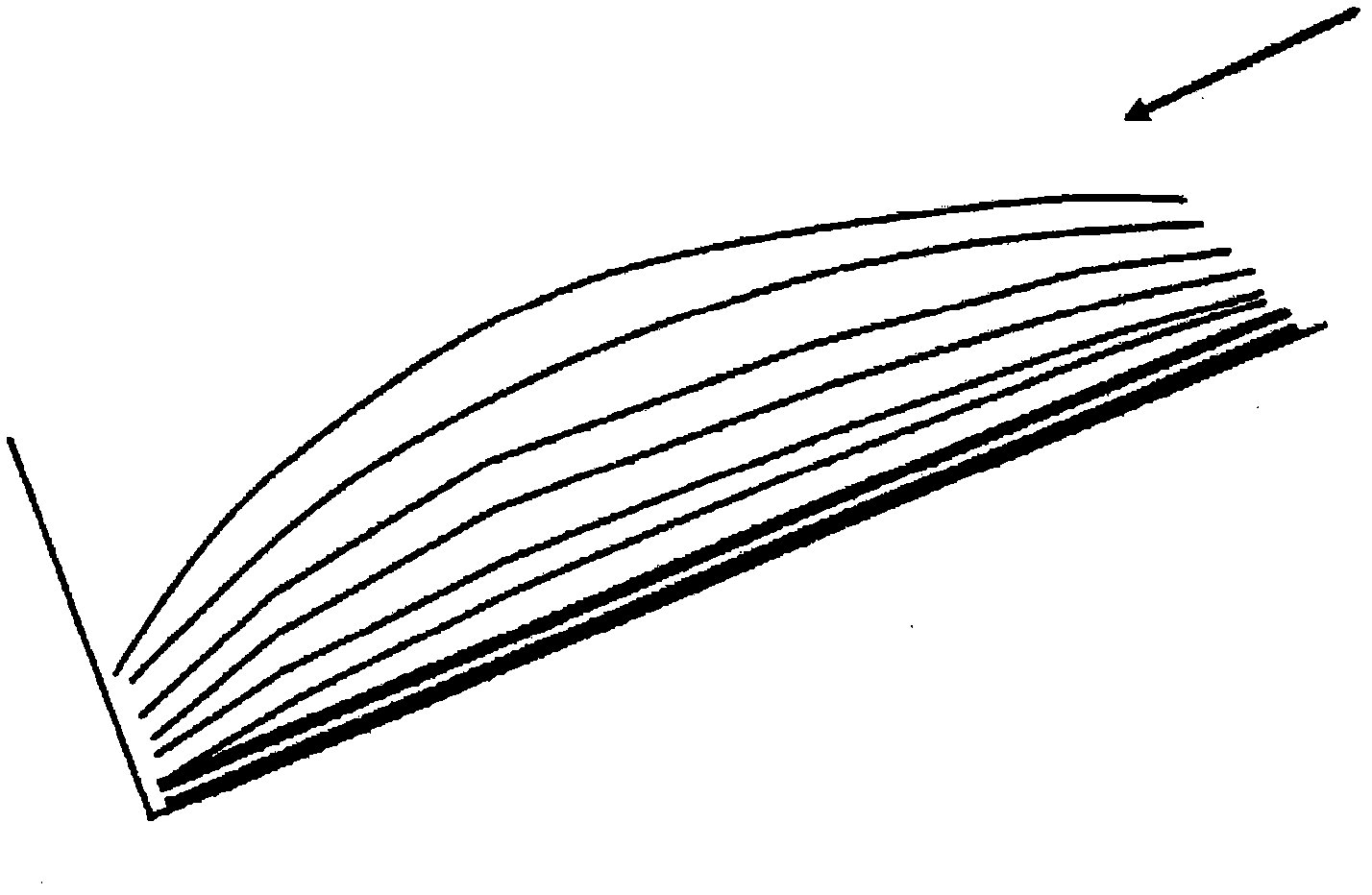

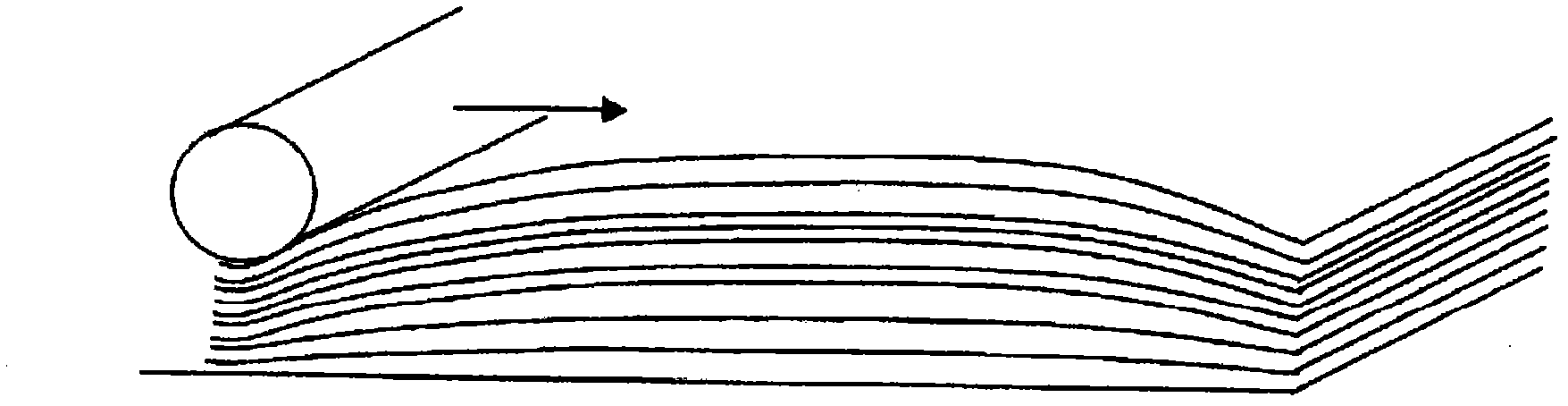

Method for producing laminate, and laminate

ActiveCN102216078AEasy to handleEasy to peelLamination ancillary operationsLayered product treatmentProduction rateBobbin

The disclosed method comprises applying an adhesive onto both of the opposing edge portions of a carrier (A) being fed by winding-off from a bobbin, adhering a metal foil (B) continuously wound off from a second bobbin to the adhesive-applied side of the face of the carrier in lamination, cutting this laminate into sheets, and stacking orderly the cut laminate sheets; and when the cut and stacked laminate sheets constituted of the orderly stacked laminates comes to rise remarkably at the middle portion thereof, the stack of laminates is roll-pressed on the upper face of the cut and stacked laminate sheets to remove the air from the spaces between the cut laminate sheets and inside of the laminates, and then, curing the adhesive to allow the laminated sheets to adhere together. In particular, the disclosed method is characterized by the carrier-supported copper foil employed in the production of laminate plates, and intends cost reduction in a print substrate production process by improvement of handling property and the production yield.

Owner:JX NIPPON MINING & METALS CORP

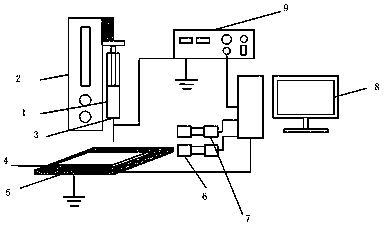

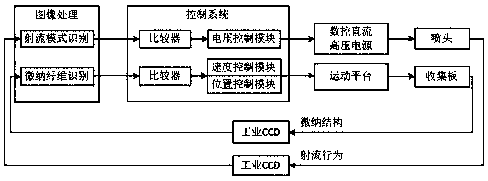

Electrospinning direct-writing closed-loop control method

InactiveCN109306527AGuaranteed uniformityEjaculation behavior is stableFilament/thread formingMicro nanoJet flow

The invention provides an electrospinning direct-writing closed-loop control method. By means of the control method, the direct-writing jet-flow stability, the micro-nano structure uniformity and thedeposition precision can be improved. A visual detection technology is adopted for making real-time judgments according to the jet flow behaviors and the morphology position of a micro-nano structureand conducting control separately, the jet flow behaviors and the morphology position of the micro-nano structure are adjusted and controlled by means of applying voltage adjustment and motion platform speed and position adjustment respectively, mutual interference is avoided, stable jet for a long time can be maintained, and patterned deposition is achieved.

Owner:肖佳楠

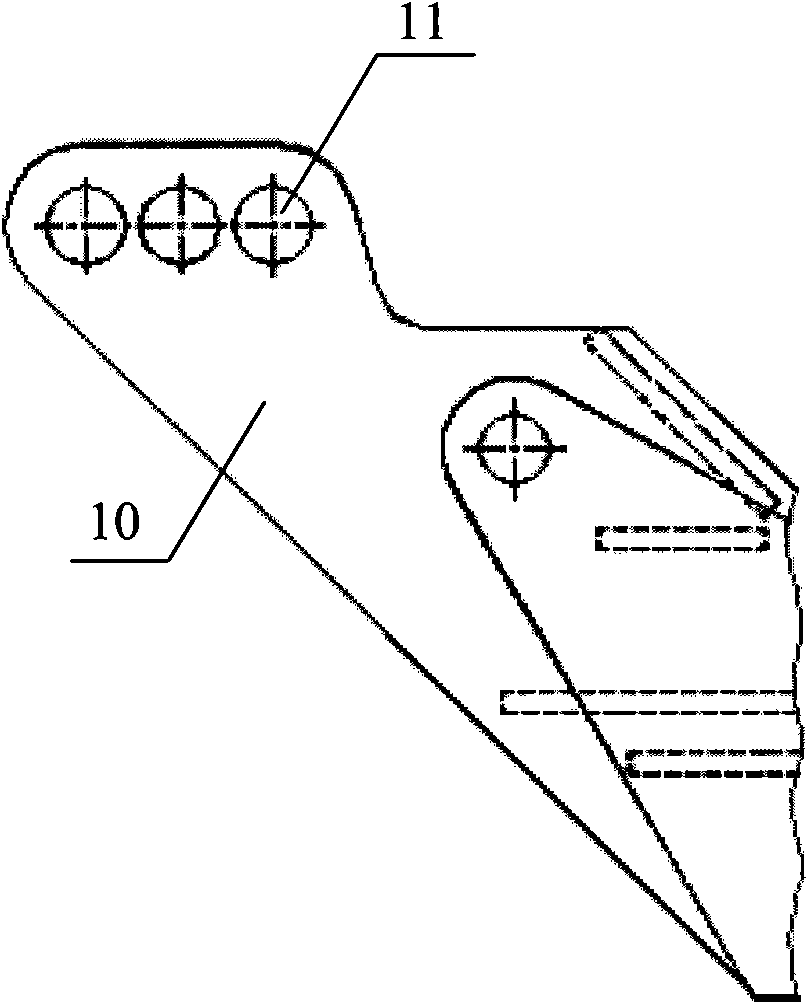

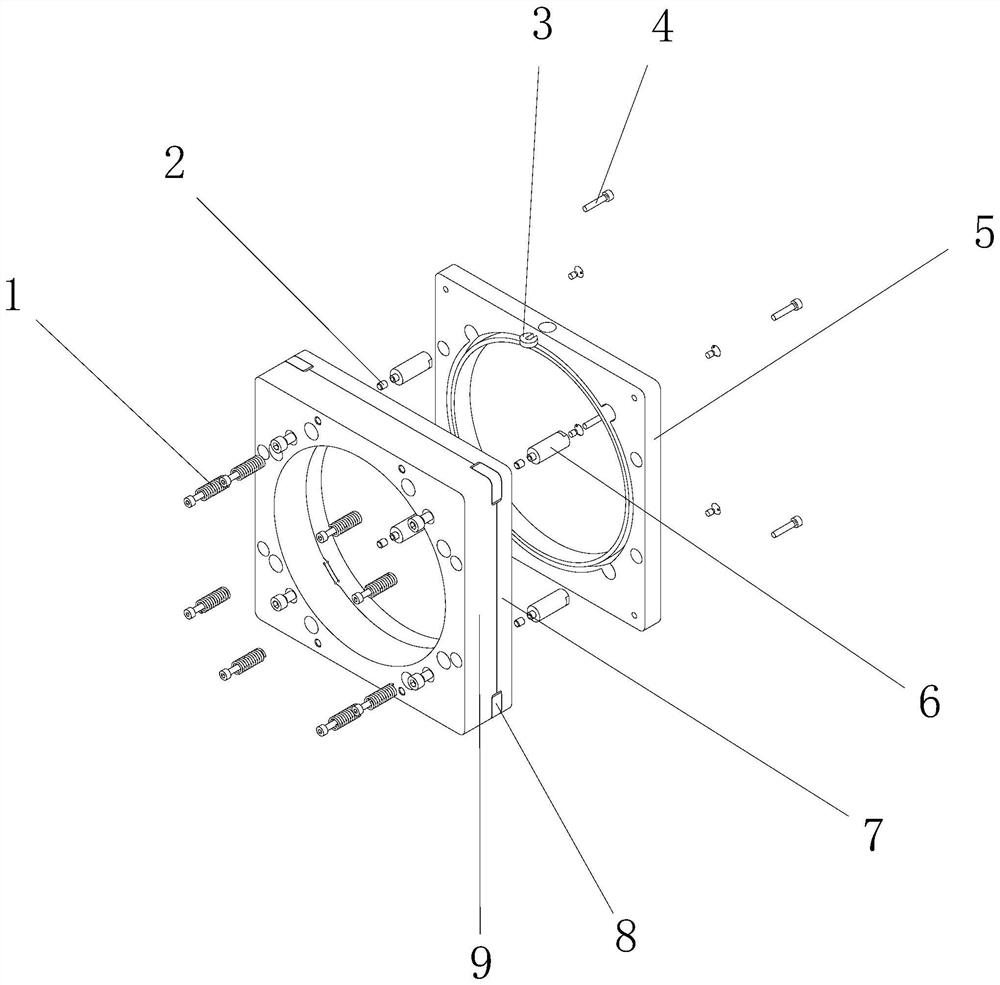

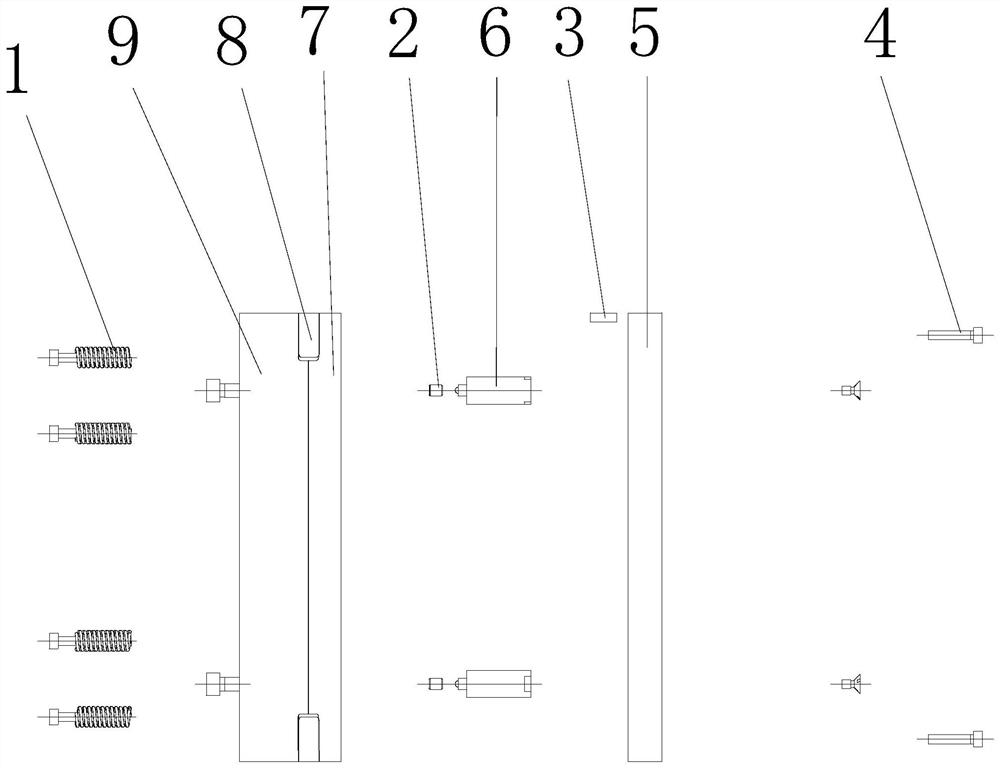

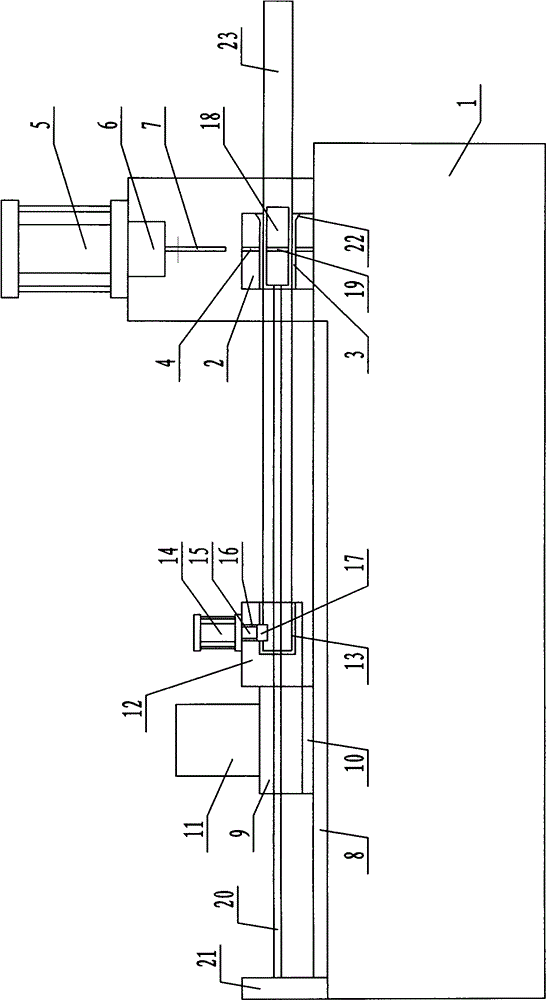

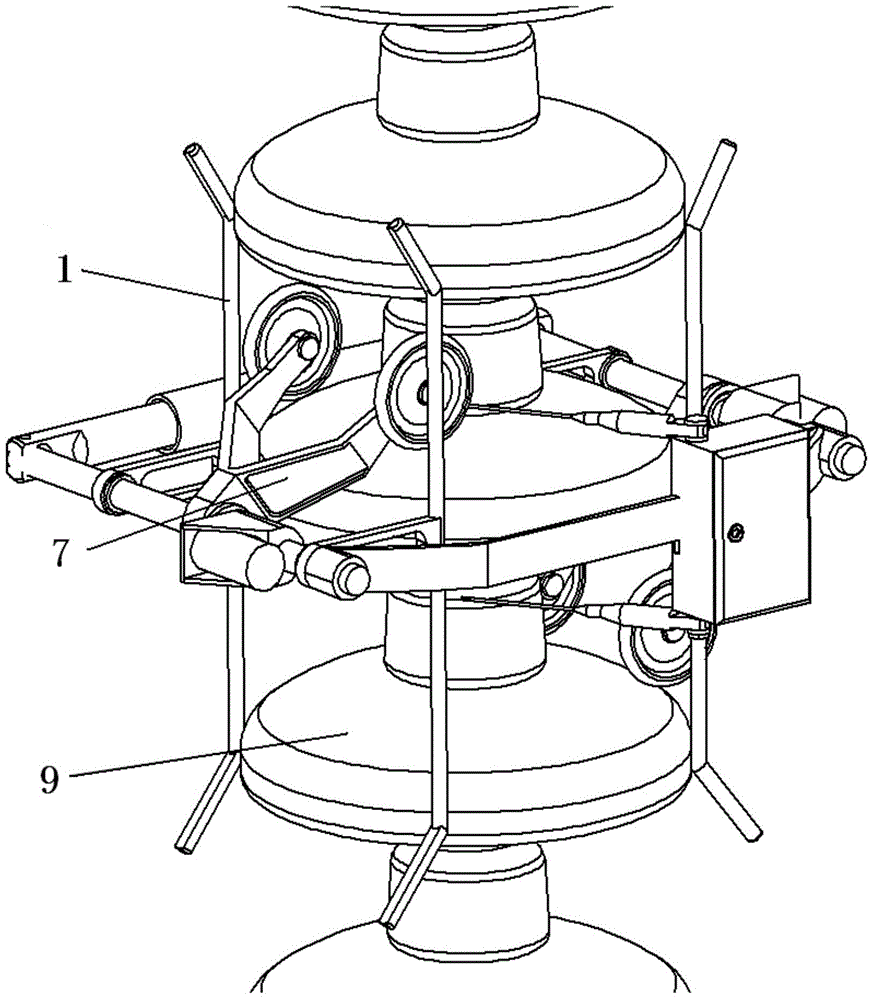

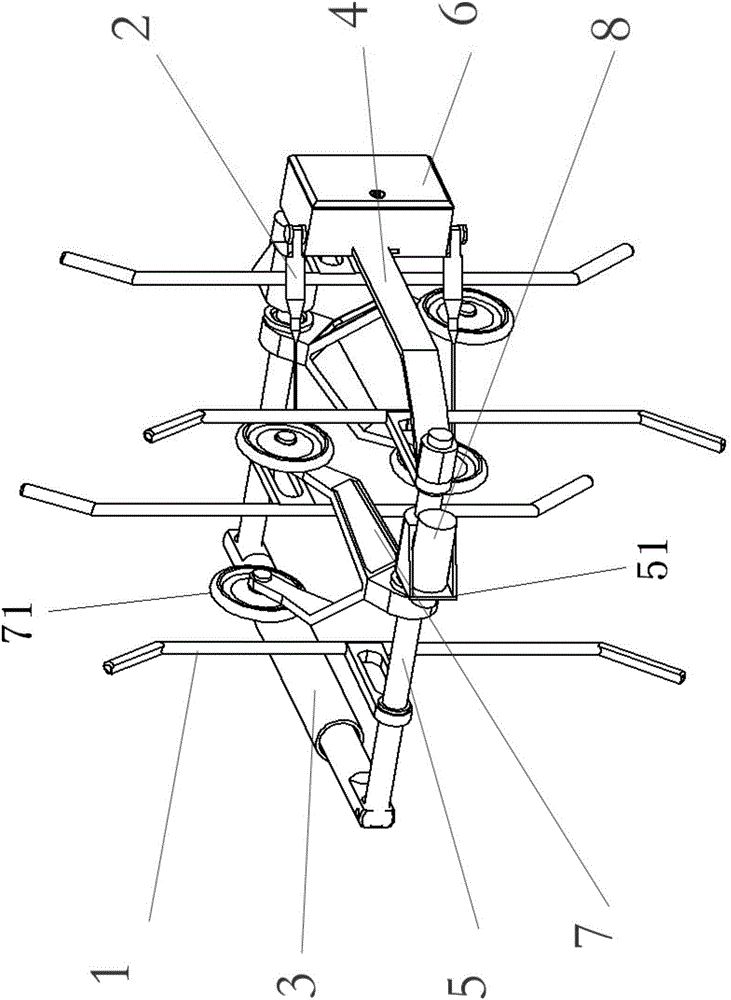

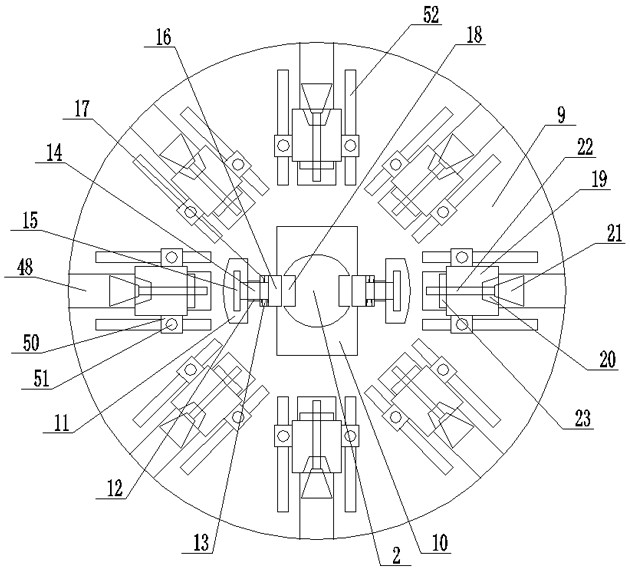

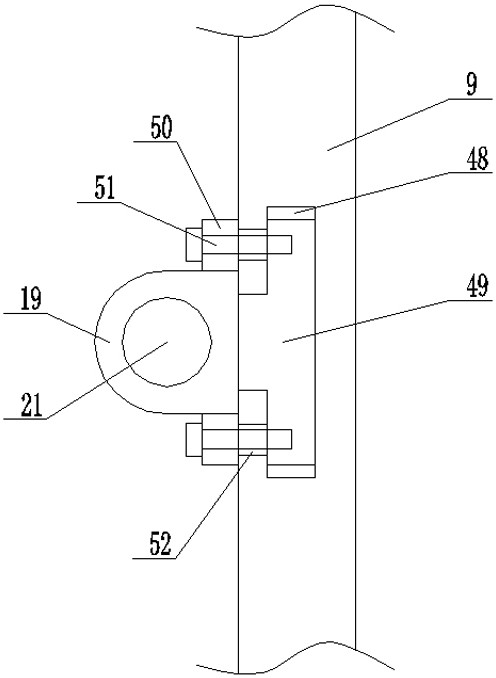

Intelligent insulator detection robot

The invention provides an intelligent insulator detection robot, and the robot comprises an annular rack and a plurality of guide racks (1) disposed in the peripheral direction of the rack. The rack is also symmetrically provided with walking arms (7) which are used for enabling the detector to walk along an insulator string. One end of each arm (7) is rotatingly connected with the rack in the length direction of the arm (7). The rack is also provided with a driving part (8) which is used for driving the walking arm (7) to rotate. The robot employs a structure of a double-arm alternate rotating climbing type, and the two arms (7) can be put in a gap between two adjacent insulator discs more accurately and simply through cooperation. The robot can be suitable for the detection of more types of insulator strings. Meanwhile, the robot is small in size, and is light in weight. Compared with a conventional insulator detector robot, the robot can be very portable for a worker, and brings convenience for the conveying, installation and disassembly.

Owner:STATE GRID CORP OF CHINA +2

Full-automatic feeding device of industrial aluminum profile machining assembly line

ActiveCN112124841AGuarantee the quality of production and processingEnsure delivery stabilityConveyor partsRoller-waysMachine partsEconomic benefits

The invention discloses a full-automatic feeding device of an industrial aluminum profile machining assembly line. The full-automatic feeding device carries out conveying work through conveying rollers in the aluminum profile machining and production feeding process and limits the positions of aluminum profile machining raw materials through guide rollers and limiting rollers, and therefore it isensured that aluminum profiles do not deviate when being conveyed and can be conveyed to accurate positions in a next machining site without deviating, the conveying stability of aluminum profile machined parts is guaranteed, the production and machining quality of the aluminum profiles can be guaranteed, and machining and production economic benefits are guaranteed; and the positions of the guiderollers and the limiting rollers can be adjusted, adjustment can be made according to the actual sizes of the aluminum profiles, and therefore it can be better guaranteed that position guiding and limiting work can be better conducted on the aluminum profile machined parts.

Owner:JIANGXI TIAN YI ALUMINUM

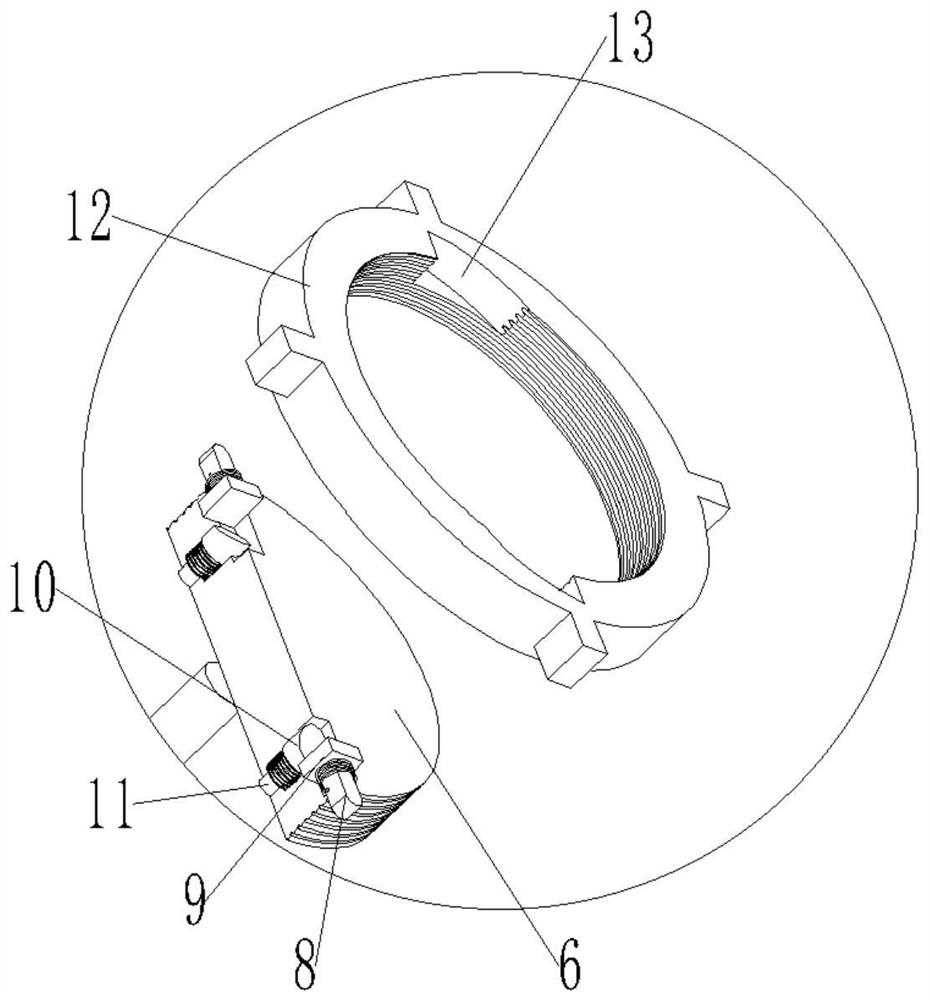

Motor air gap eccentric detection device

InactiveCN107356187ANo positional deviationEasy to install and adjustMechanical measuring arrangementsAir gap eccentricityFixed frame

A motor air gap eccentricity measurement device, including eccentricity measurement components and air gap measurement components; The air gap measurement components are respectively installed on the shaft; the fixed frame has adjusting threaded holes, and the adjusting bolts are installed in the holes, and the adjusting bolts are against the outer surface of the motor; the two ends of the fixed frame are respectively installed with support rods, and the ends of the support rods clamp the eccentricity detection device. The sub-meter, the eccentricity detection dial indicator is placed horizontally, and the measuring head of the eccentricity detection dial indicator is against the side of the motor machine foot; the air gap measurement assembly includes a magnetic table base, a universal adjustment rod and an air gap detection dial indicator; The meter base is adsorbed on the base plate, and the universal adjustment rod is installed on the magnetic meter base; the upper end of the universal adjustment rod holds the air gap detection dial indicator, and the measuring head of the air gap detection dial indicator is against the surface of the motor shaft. The invention can realize accurate measurement of the air gap eccentricity of the motor and is convenient for installation.

Owner:HARBIN ENG UNIV

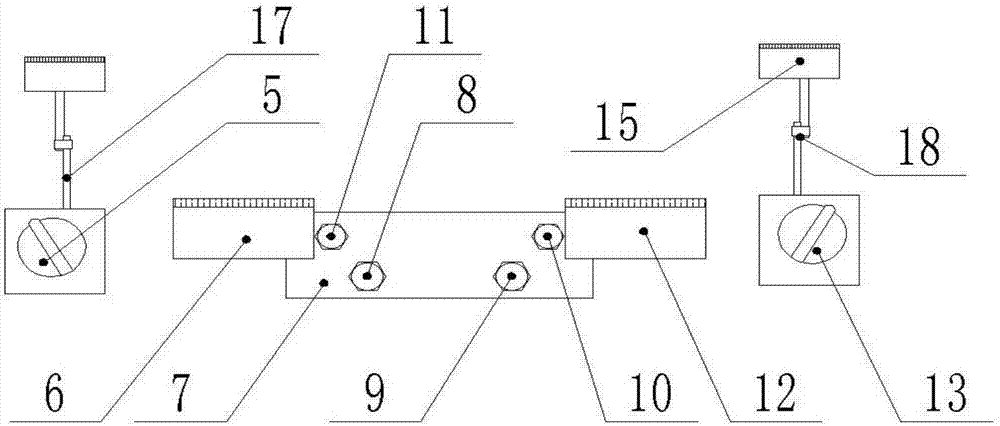

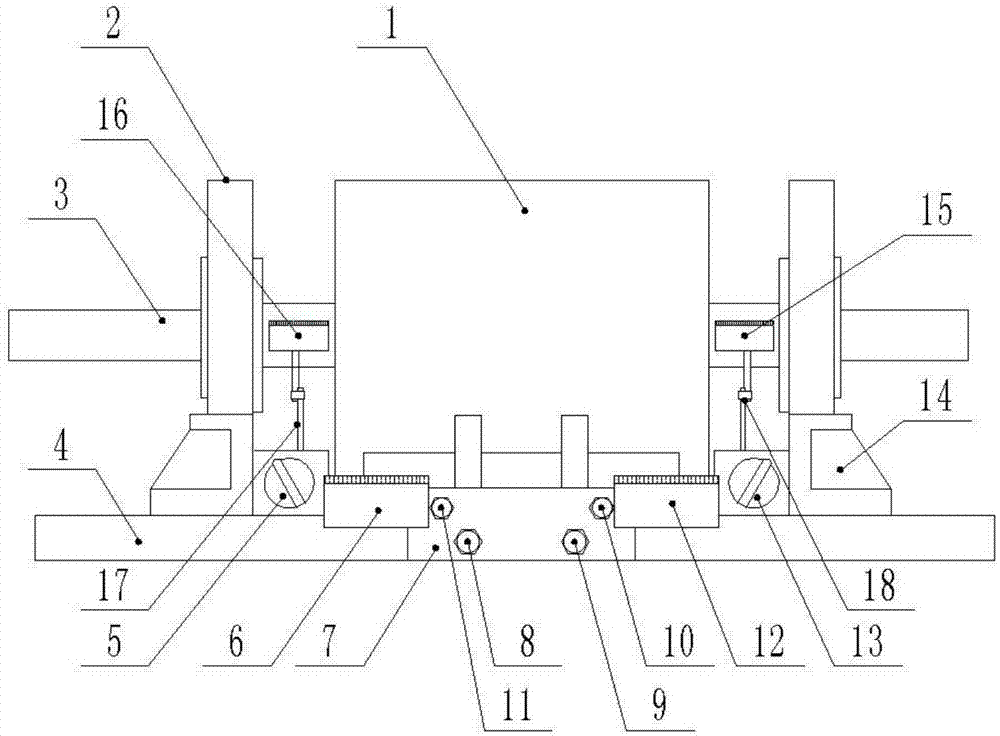

Stamping equipment of regularly arranged reinforcers

ActiveCN104438549AImprove typesetting accuracyNo positional deviationMetal-working feeding devicesPositioning devicesMechanical engineeringViscosity

The invention discloses stamping equipment of regularly arranged reinforcers and relates to the technical field of processing of flexible printed circuit boards. The stamping equipment comprises an upper die, a lower die and a lower die base; the upper die is provided with forming tools; the lower die is provided with tool holes matching with the forming tools; the forming tools can be inserted into the tool holes; the lower die base is disposed at the bottom of the lower die; elastic elements are disposed below the lower die base; a low-viscosity film for supporting the lower die base to move passes beneath the bottoms of the tool holes.

Owner:南通钢安机械制造有限公司

Phase shifter with flexible plate structure

PendingCN111879729AExtended service lifeReduce lossesOptical measurementsPhase-affecting property measurementsStructural engineeringCable harness

The invention discloses a phase shifter with a flexible plate structure. The phase shifter comprises a base and a main body, a working cavity is formed in the base; wherein the main body is arranged above the base; a vertical actuator assembly is mounted in the base; the actuator assembly is electrically connected with the wire harness assembly, the wire harness assembly is connected with the wireharness connector, and the wire harness connector is sleeved with the wire buckle. A through hole is formed in the side face of the base, and the wire buckle is installed in the through hole. The topof the actuator assembly is provided with a flexible plate assembly, and the main body is fixed on the flexible plate assembly. Position deviation cannot be generated, the service life is greatly prolonged, enterprises are indirectly helped to reduce losses, and the working efficiency of the horizontal interferometer is improved.

Owner:SHANGHAI STEM YAO OPTICAL TECH CO LTD

Automatic sampling mechanism of analytical instrument

InactiveCN101982779BNo positional deviationHigh running precisionMaterial analysisPipetteEngineering

Owner:济南齐力医疗器械有限公司

Phase shifter with guide rail structure

PendingCN111855616AReduce lossesImprove work efficiencyOptical measurementsPhase-affecting property measurementsElectrical connectionStructural engineering

The invention discloses a phase shifter with a guide rail structure. The phase shifter comprises a base, a main body and an adapter plate, wherein a working groove is formed in the base, and the mainbody is mounted in the working groove; an elastic reset structure is connected between the main body and the base; a round hole is formed in the lower end face of the main body, an actuator is installed in the working groove in the base, and the actuator is installed in the round hole; a guide rail mechanism is mounted on the inner wall of the working groove in the base, and is fixedly connected with the main body; a through hole is formed in the side surface of the base, the actuator is electrically connected with a wire harness, a wire buckle is arranged at the end part of the wire harness,and the wire buckle is fixed in the through hole; and the upper end of the main body is connected with an adapter plate. According to the invention, the constraint of main body movement is increased,position deviation is avoided, the service life is greatly prolonged, enterprises are indirectly helped to reduce loss, and the working efficiency of an interferometer is improved.

Owner:SHANGHAI STEM YAO OPTICAL TECH CO LTD

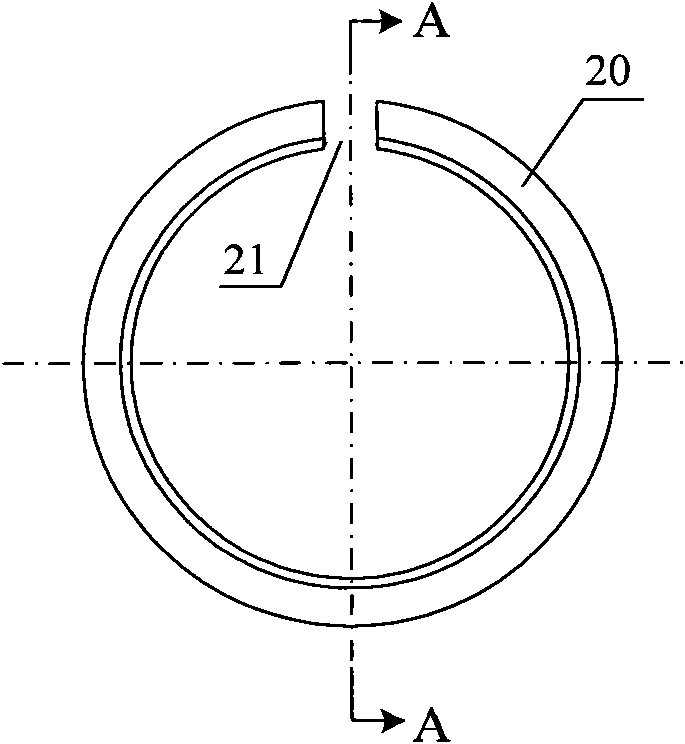

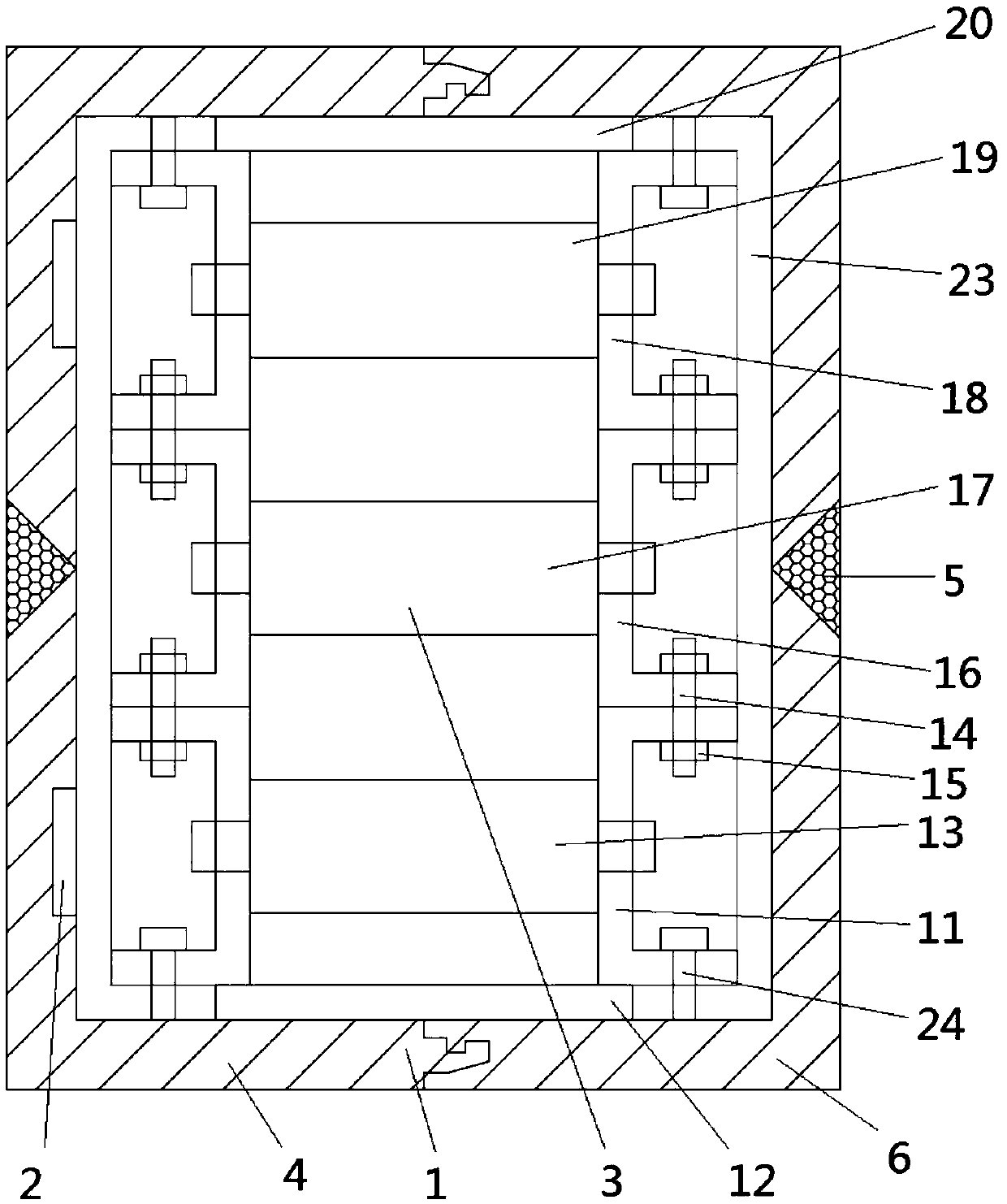

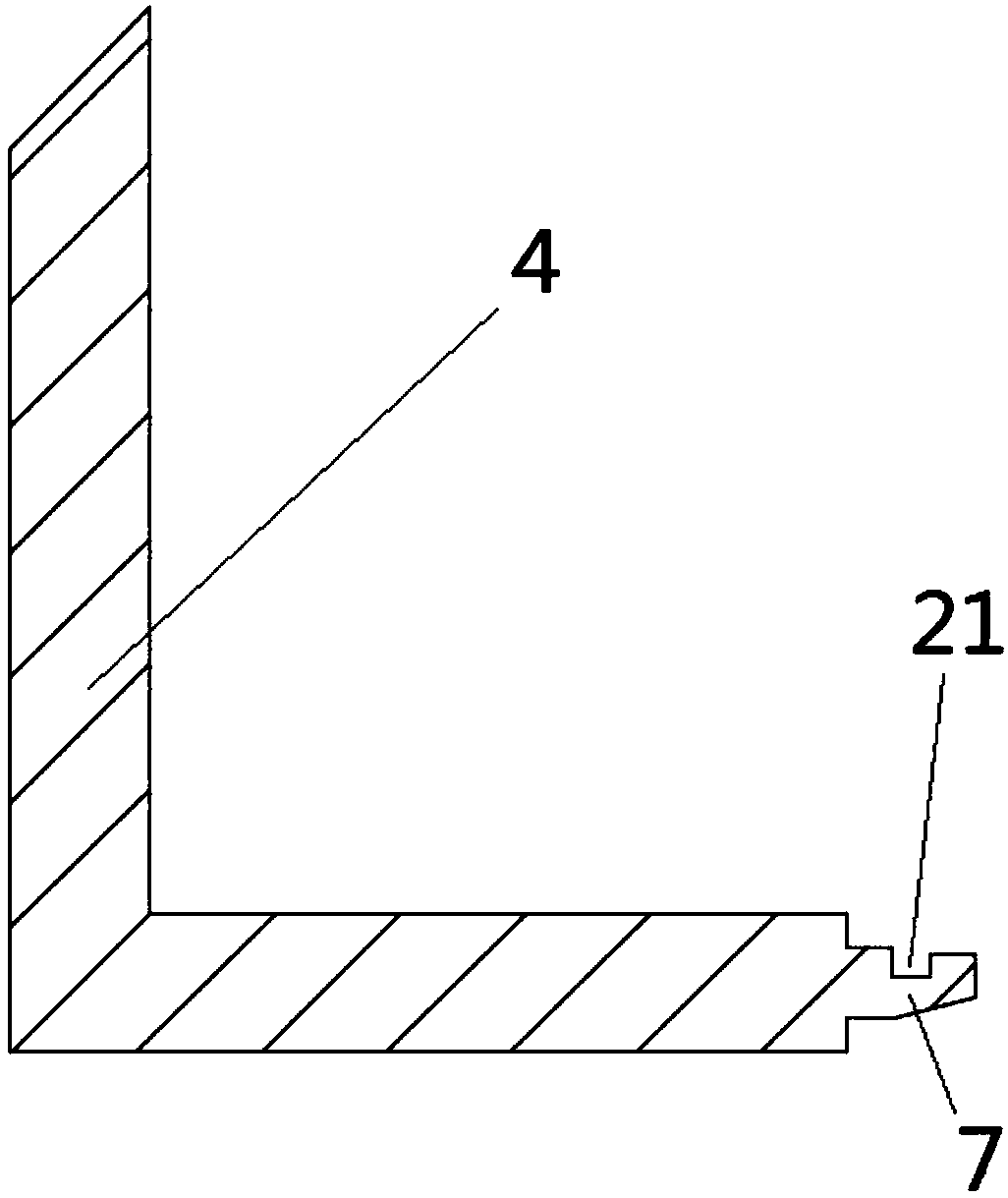

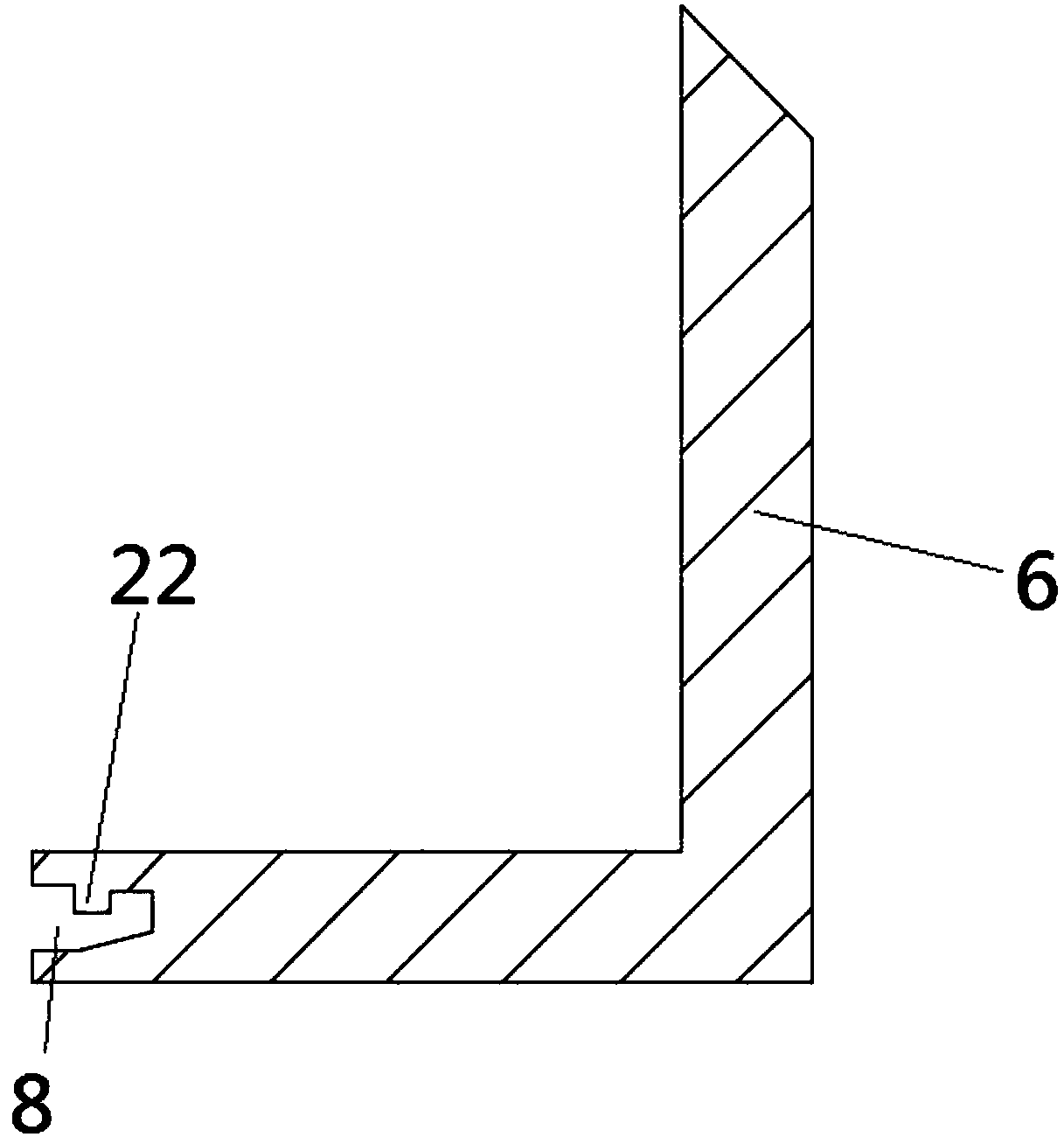

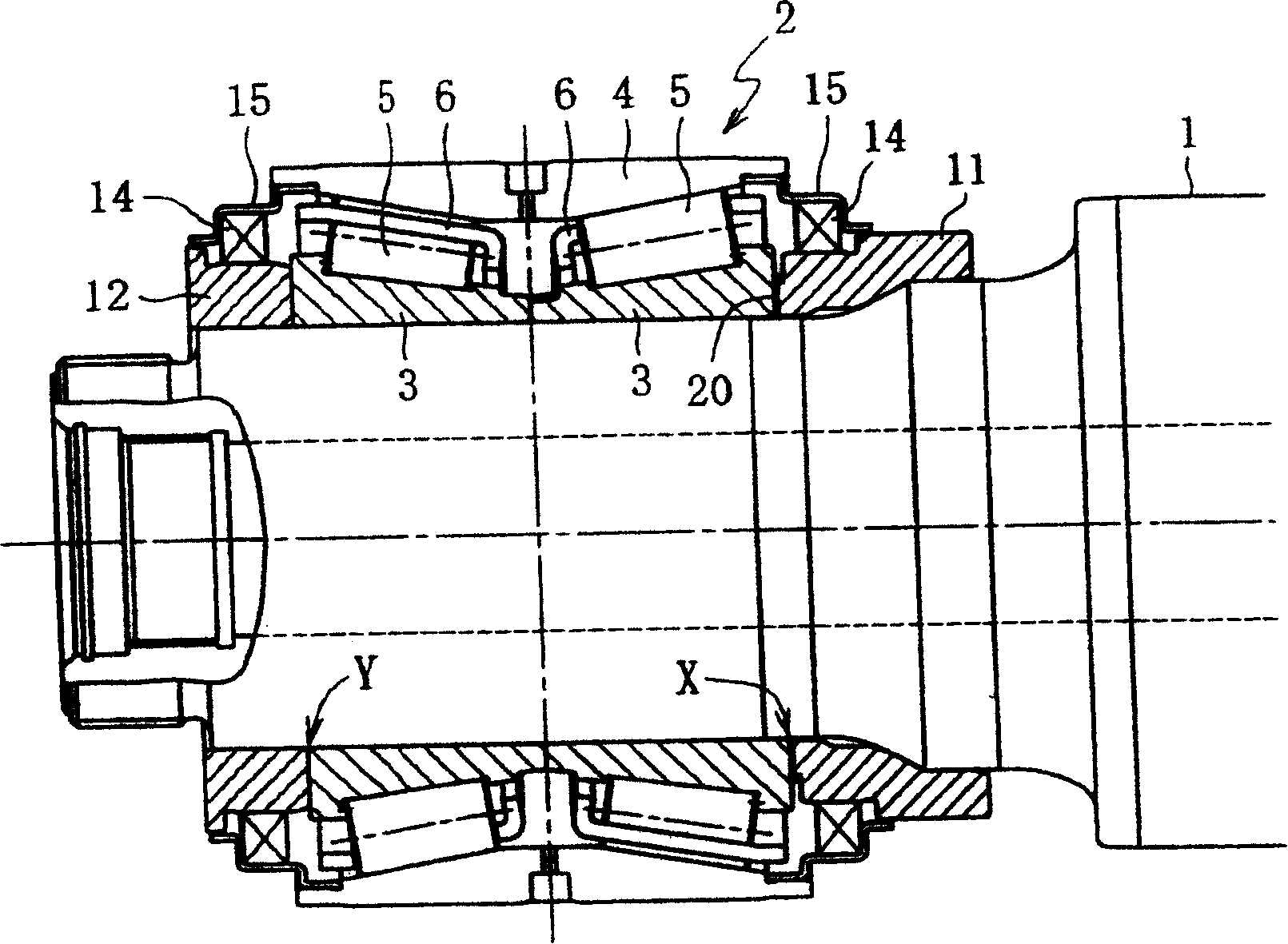

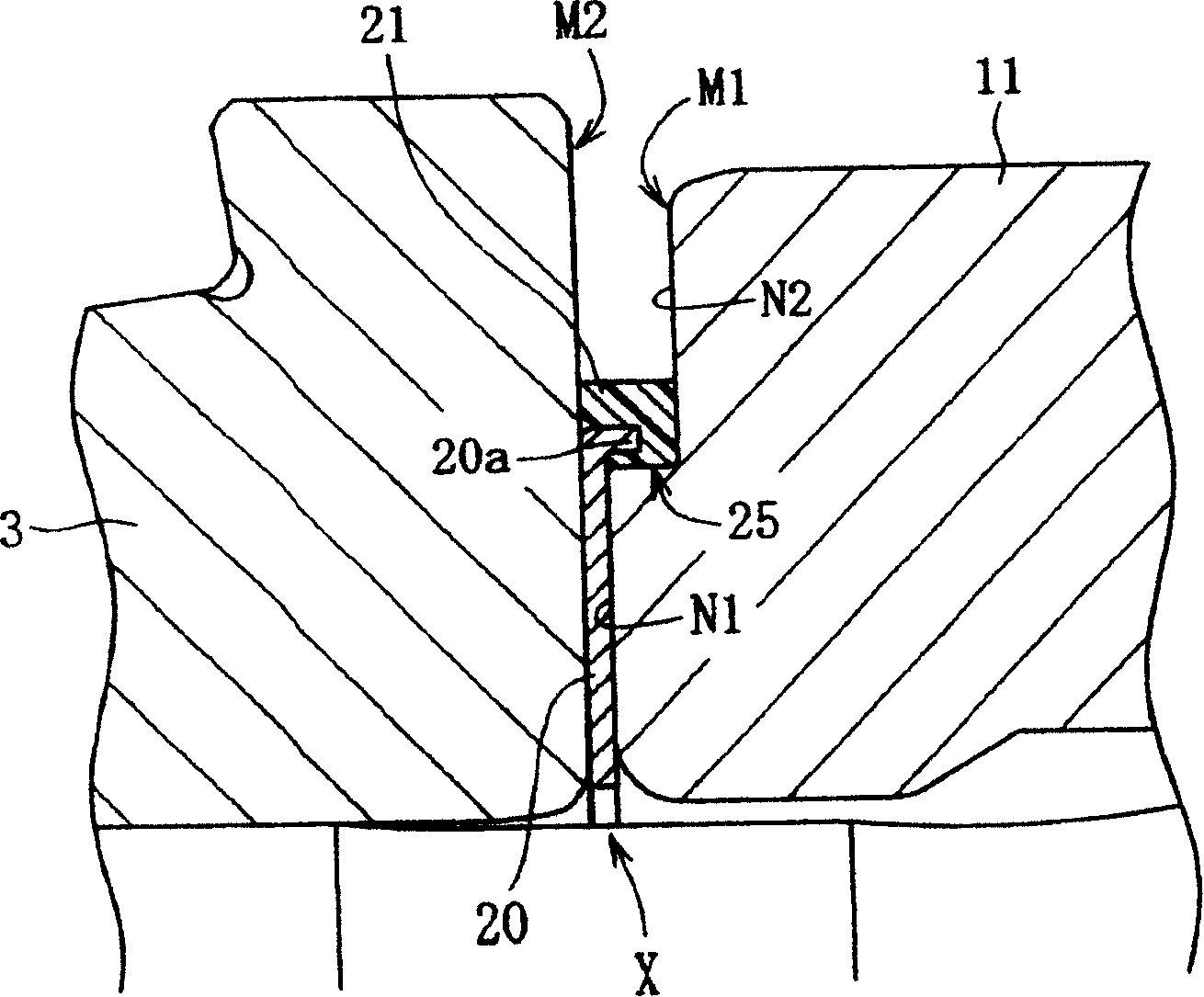

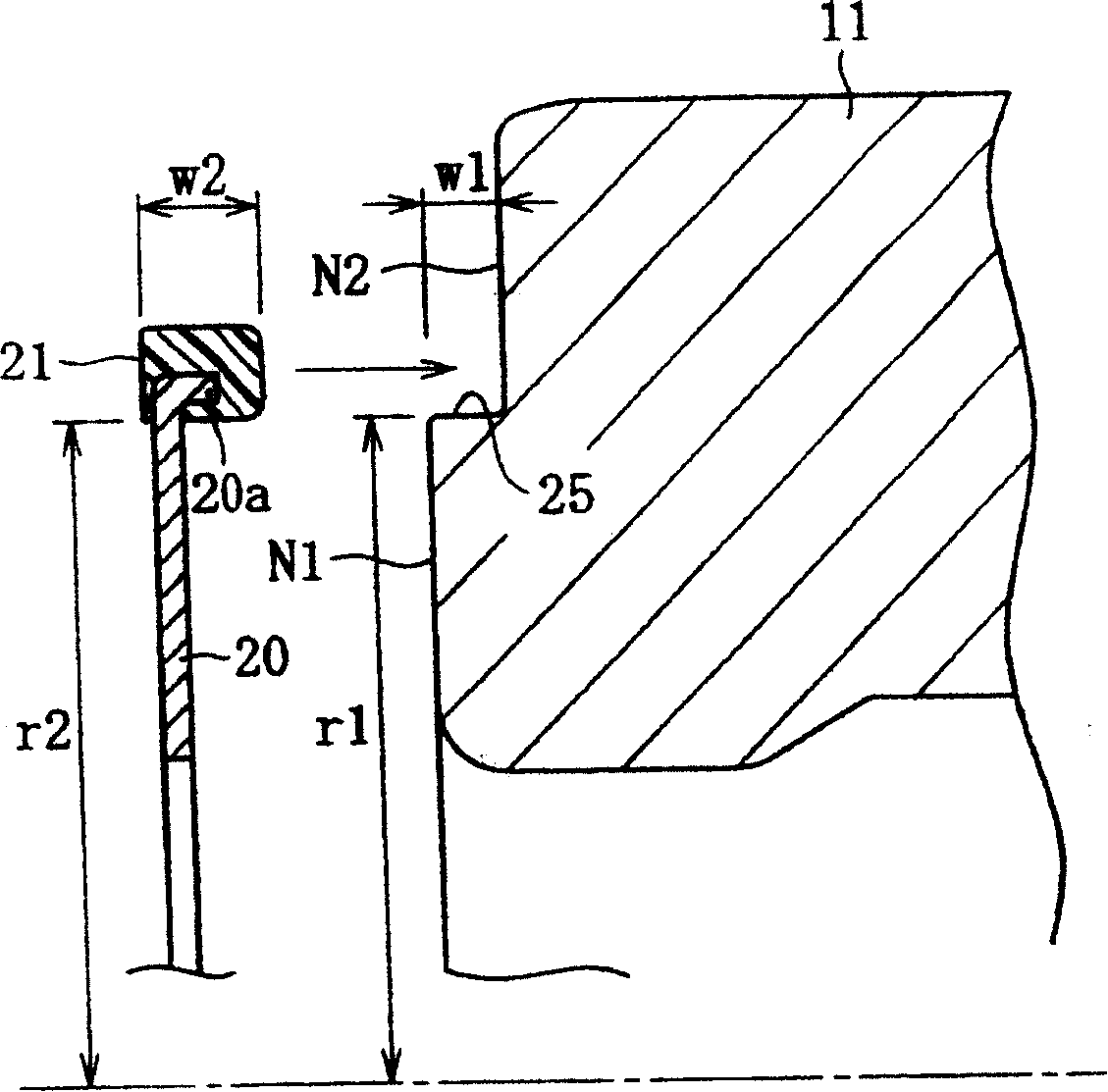

Bearing device for rolling stock axle

ActiveCN100386229CPrevent outflowEasy to assembleRoller bearingsRailway vehiclesRolling-element bearingEngineering

An annular spacer 20 formed by fixing an annular elastic seal material 21 to an outer diameter side peripheral edge part integrally with each other is installed between the width face of the inner ring 3 of a roller bearing 2 fitted to an axle 1 and the width face of a rear cover 11 (ring member) fitted to the axle 1 and restricting the axial position of the inner ring 3 relative to the axle 1 so as to be brought into a slidable contact with each other in the state of elastically and deformably fitting the elastic seal member 21 to the outer periphery of a projected step part 25 formed on the width face of the rear cover 11. The annular spacer 20 is sealed by the elastic seal material 21 in a contact part between the inner ring 3 and the rear cover 11 in the state of pressing the elastic seal member 21 by the width faces of the inner ring 3 and the rear cover 11 opposed to each other.

Owner:NTN CORP

Silica gel strip scutching roller capable of automatically adjusting breadth

ActiveCN113636395AGuaranteed opening lengthGuaranteed levelnessStretchingWebs handlingStructural engineeringSilica gel

The invention discloses a silica gel strip scutching roller capable of automatically adjusting breadth. The roller comprises a roller body and a mandrel arranged in the roller body, the two ends, extending out of the roller body, of the mandrel are rotationally arranged on a rack through first bearing seats correspondingly, and a plurality of silica gel strip clamping grooves are evenly formed in the outer side of the roller body. I-shaped silica gel strips are arranged in the silica gel strip clamping grooves in a sliding mode respectively, fixing parts are arranged at the two ends of each I-shaped silica gel strip respectively, fixing holes are formed in the fixing parts, the two ends of the mandrel are symmetrically sleeved with swash plates respectively, and mandrel avoiding through holes are formed in the middles of the swash plates. Handle avoiding through holes are symmetrically formed in the positions, on the two sides of the mandrel avoiding through holes, of the roller body, sliding holes and spring holes are symmetrically formed in the positions, between the handle avoiding through holes and the mandrel avoiding through holes, of the roller body, and sliding rods matched with the sliding holes are arranged in the sliding holes in a sliding mode.

Owner:JIANGSU KUNTAI MACHINERY

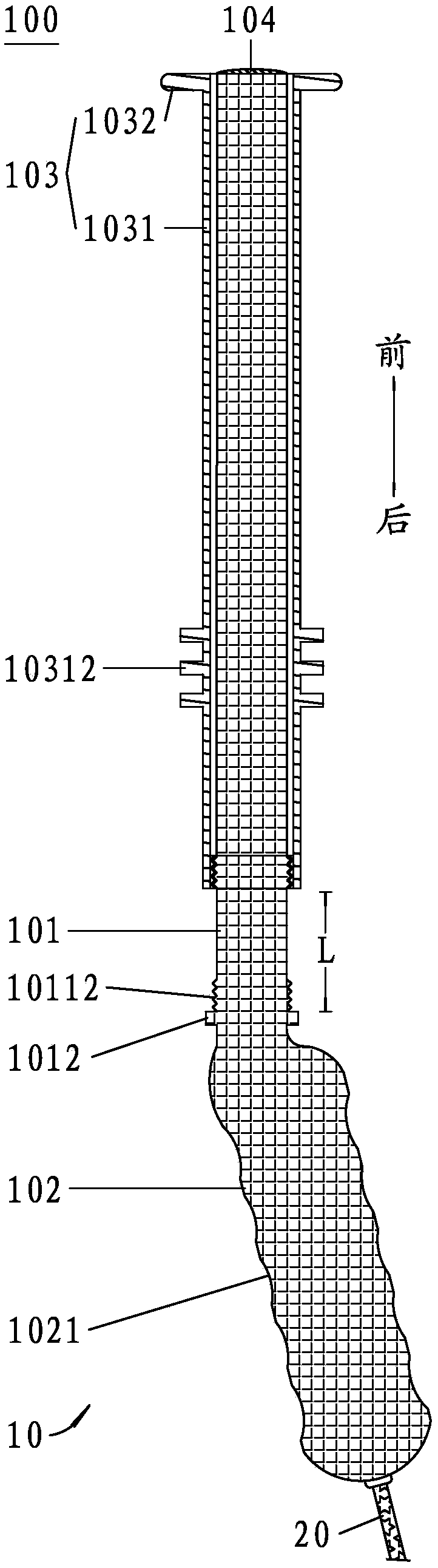

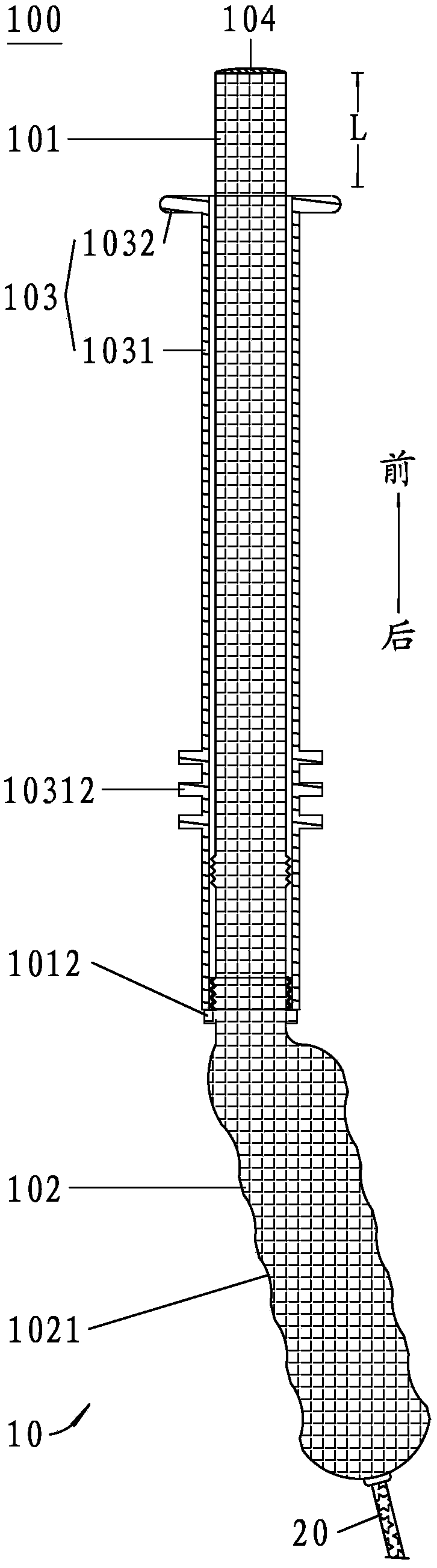

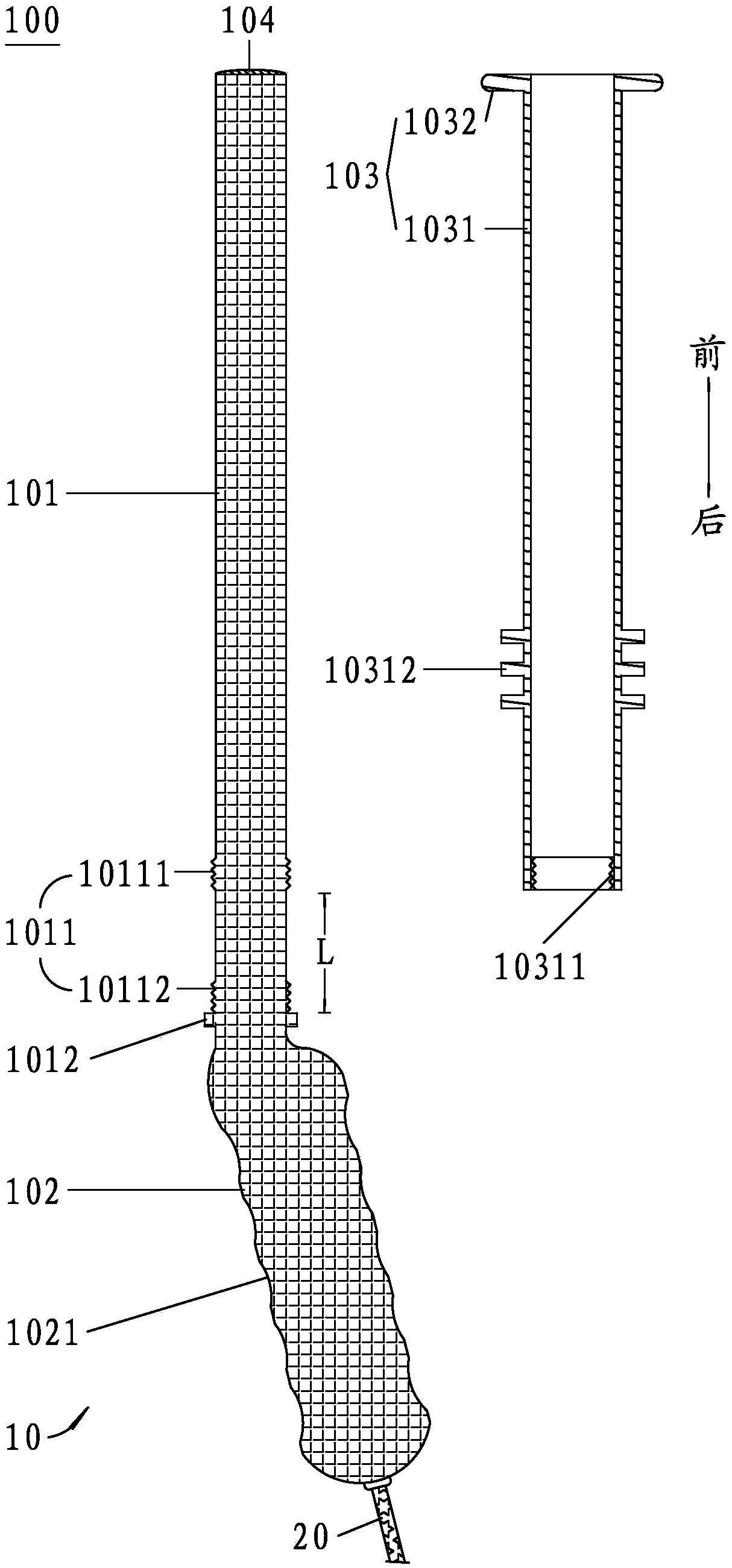

Special probe passing through inside of perineum pelvic floor ultrasonic cavity

PendingCN108742711AEasy to useEasy to operateUltrasonic/sonic/infrasonic diagnosticsSurgeryUltrasonic sensorPelvic diaphragm muscle

The invention discloses a special probe passing through the inside of a perineum pelvic floor ultrasonic cavity, which comprises a shell, an ultrasonic transducer arranged in the front end of the shell and a signal connection line which is connected with the ultrasonic transducer and lead from the tail end of the shell. The shell comprises a cylindrical extending-in part, a cylindrical hand-held part and a blocking part, wherein the cylindrical extending-in part is positioned at the front end and is suitable to insert into the vagina of a patient; the cylindrical hand-held part is positioned at the rear end and is suitable to hold with a hand; the blocking part can move front and back, is arranged outside the cylindrical extending-in part, is suitable to press against and adhere to the peripheral edge of the vaginal orifice of the patient and is used for defining the insertion depth of the end head of the cylindrical extending-in part in the vagina of the patient. The special probe passing through the inside of the perineum pelvic floor ultrasonic cavity has the beneficial effects that when the front-and-back position of the blocking part outside the cylindrical extending-in part is regulated, the insertion depth of the end head of the cylindrical extending-in part in the vagina of the patient is adjustable, and thus, the special probe can conveniently regulate the blocking part to a required position to define the insertion depth of the end head of the cylindrical extending-in part in the vagina of the patient, so that the special probe can conveniently carry out step-by-step checking on the patient in the perineum pelvic floor ultrasonic cavity, and is convenient and reliable to use, high in practicality and good in use effect.

Owner:PEKING UNIV SHENZHEN HOSPITAL

Cutting device

ActiveCN103317543AEasy transferSimple speedMetal working apparatusArticle deliveryEngineeringFront edge

The present invention relates to a device for simultaneous three-sided trimming of products in a plurality of cutting stations, comprising: a common upper knife carrier operable in a stroke motion, wherein at least blades for front edge trimming and for top and bottom trimming of the products are mounted on the upper knife carrier; a first drive for driving the upper knife carrier and a conveyor device, wherein the conveyor device has top-related and bottom-related pairs of conveyor belts for conveying the products through the cutting stations of the device; at least one second drive for driving the conveyor device, wherein the drives used for a stroke device and the conveyor device are each implemented as self-contained mutually independent drives, and connected to one another by control devices. The device has another collecting conveyor device downstream of the conveyor device for conveying the products through the cutting stations in a conveying direction of the products, wherein the collecting conveyor device has a self-contained and independent drive, the drive is connected with the other independent drives of the device through control devices.

Owner:MULLER MARTINI HLDG

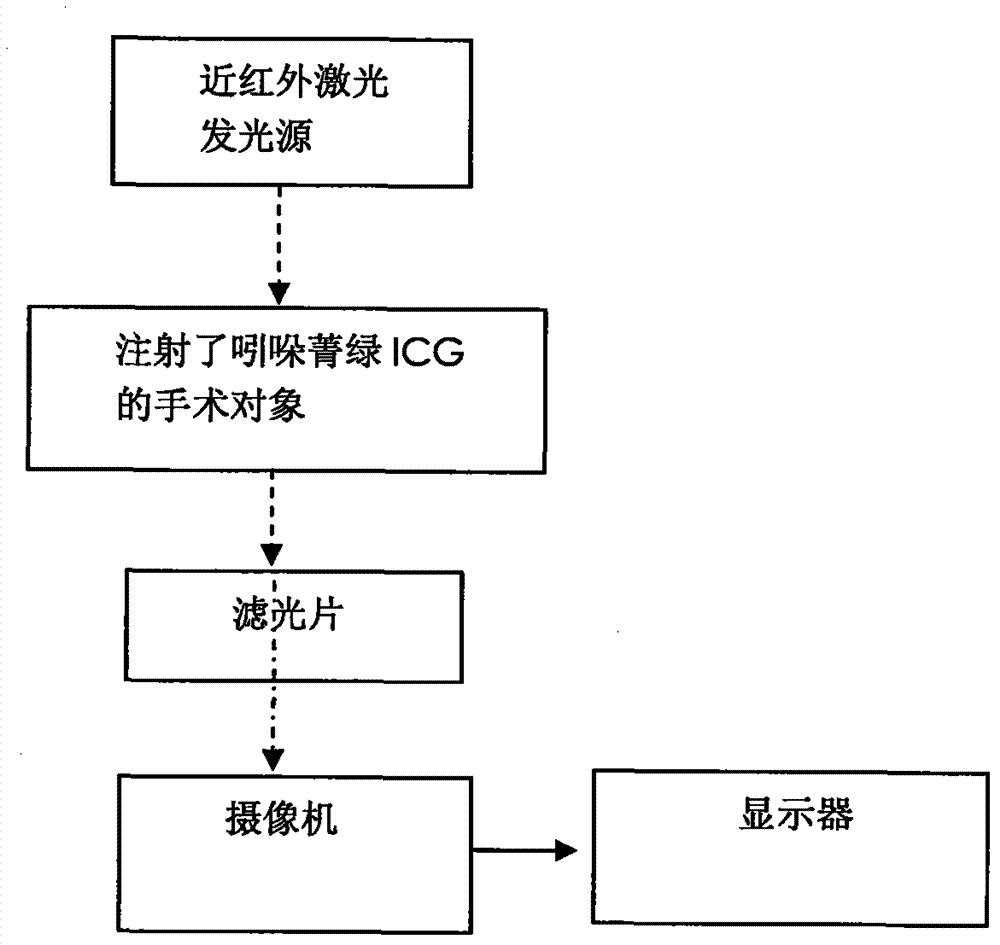

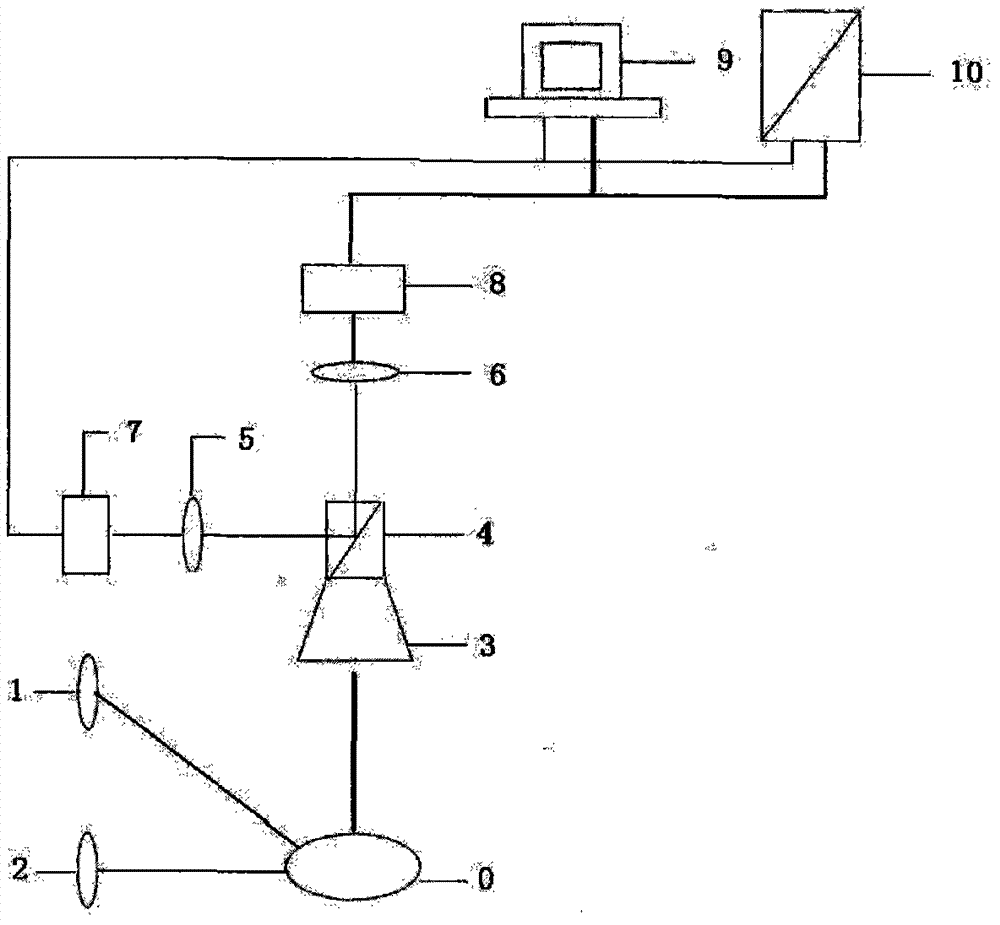

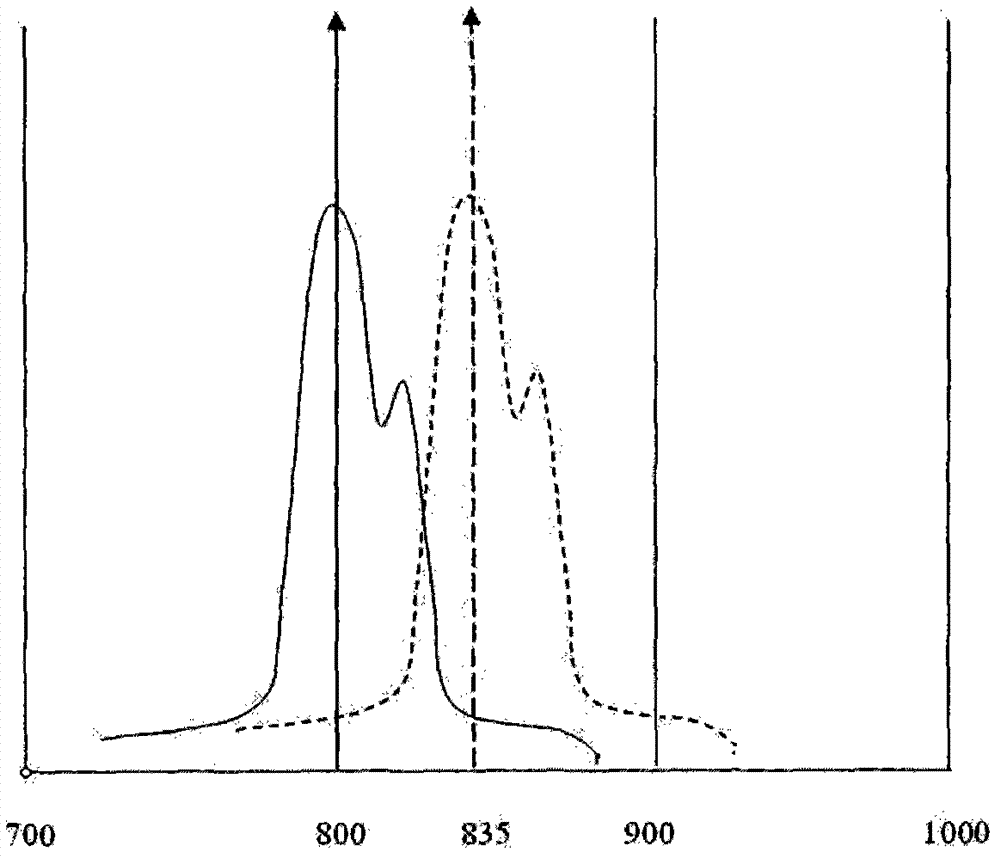

Near-infrared fluorescence imaging surgery guide device and application thereof

ActiveCN102319059BNo positional deviationImprove errorDiagnostic recording/measuringSensorsDisplay deviceTreatment experience

The invention relates to a near-infrared fluorescence imaging surgery guide device and an application thereof. The device comprises a near-infrared laser light source, a light collection optical system, a visual light filter, a near-infrared light filter, a color video camera, a near-infrared video camera and a terminal display. The device can conveniently perform position guide and morphic display functions in the process of a lymph excision or inactivation surgery, and meanwhile can be used for analyzing and evaluating the effect of the lymph excision or inactivation surgery. The device is favorable to improving surgery efficiency and accuracy and accumulating surgery treatment experience.

Owner:BEIJING TIANZHU JIYE TECH DEV

Scalpel production equipment with anti-skid structure and auxiliary blood adsorption function

InactiveCN111906547ANo positional deviationReduce the hassle of manual cleaningOther manufacturing equipments/toolsStructural engineeringGrinding wheel

The invention discloses scalpel production equipment with an anti-skid function and an auxiliary blood adsorption function. The equipment comprises a base, a limiting rod, a support, a conveying belt,a fifth hydraulic rod and a conductive sliding groove, a machining table is installed at the top of the base, the limiting rod is installed on the right side face of the machining table in a deviatedmode, and a lower grinding wheel is installed at the top of a first rotating shaft. The support is installed on the left side face of the machining table in a deviated mode, a first hydraulic rod isembedded in a sliding rail, a punching rotary head is installed on the side face of an adsorption opening in a deviated mode, a third hydraulic rod is installed on the side face of a second hydraulicrod in a deviated mode, a second rotating shaft is installed at the joint of a rotating motor and the third hydraulic rod, and an upper clamping plate is installed at the bottom of the rotating motor.Through the arrangement of the relation between the conveying belt and a limiting cylinder, when an anti-skid rod enters the limiting cylinder through the conveying belt, a push rod in the limiting cylinder can push the anti-skid rod to the position above a station hole, the anti-skid rod falls off from the station hole, and position deviation is avoided.

Owner:东莞市奇趣机器人科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com