Method and apparatus for bonding workpieces

A workpiece and process technology, applied in the field of workpiece lamination devices, can solve problems such as workpiece position deviation, decline in yield, workpiece positioning, etc., and achieve the effect of achieving yield, curing shrinkage reduction, and positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] Next, various embodiments of the present invention will be described with reference to the drawings.

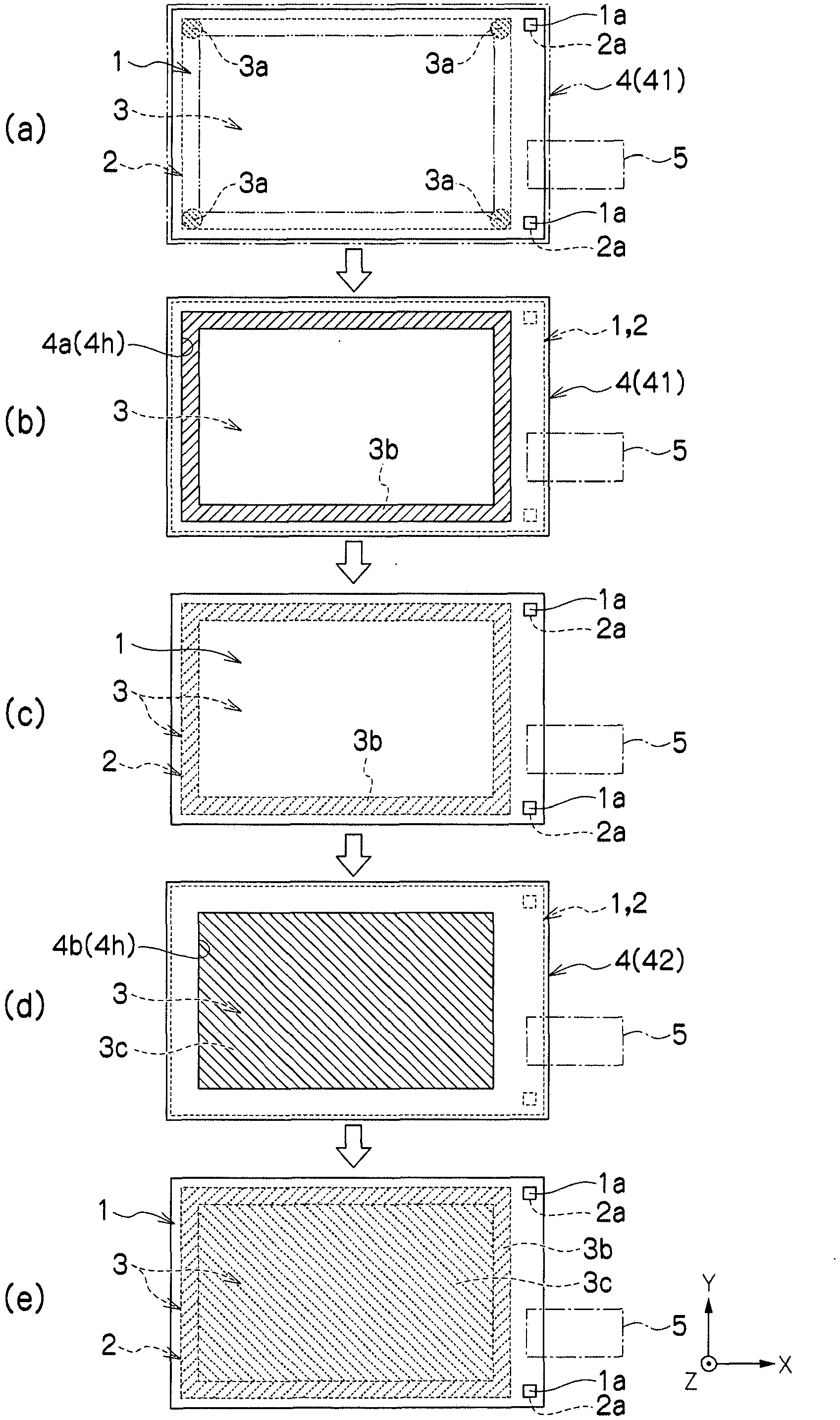

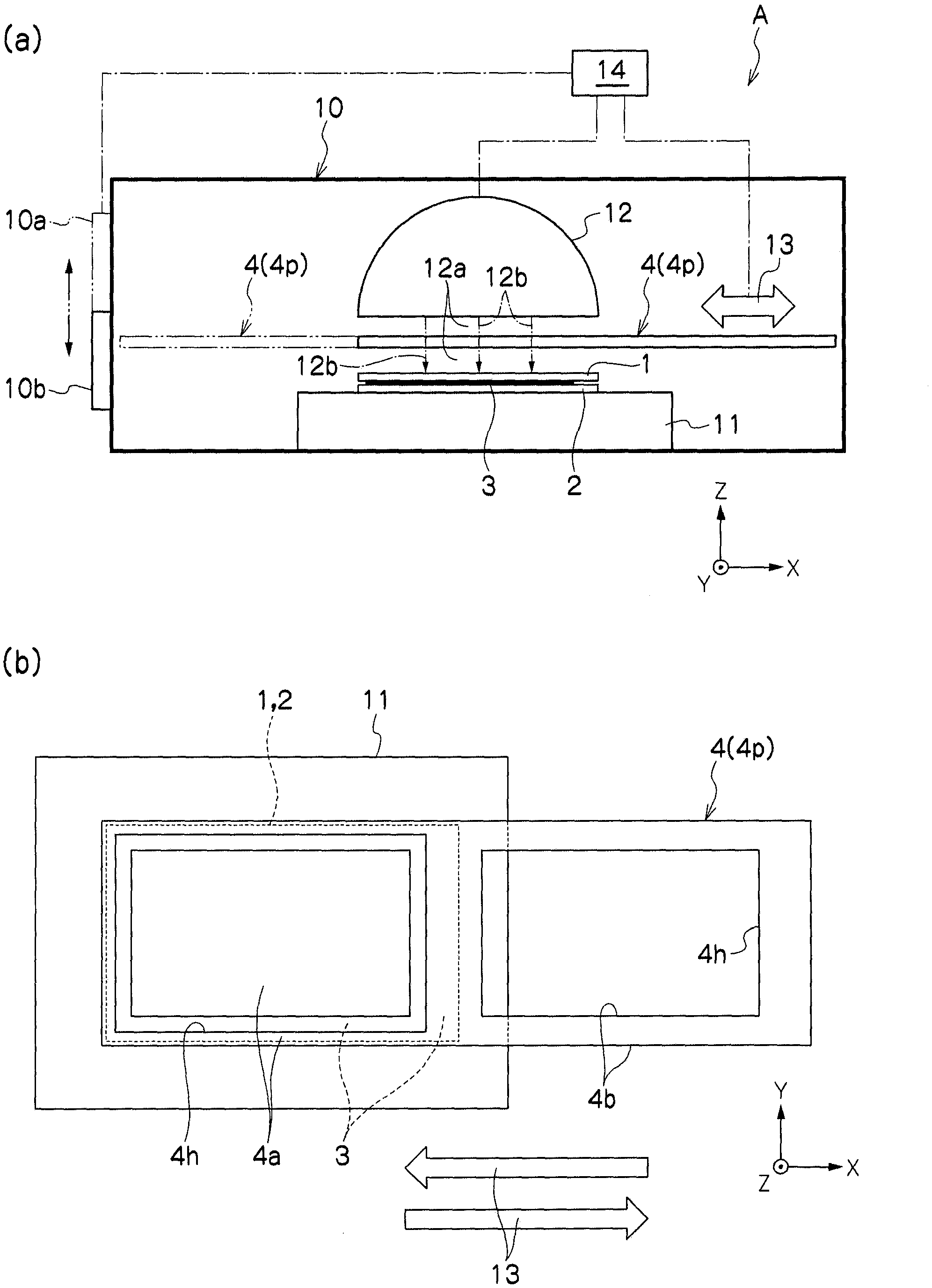

[0093] like figure 1 As shown in (a) to (e), in the workpiece bonding method according to Example 1 of the present invention, the adhesive 3 is sandwiched between the workpieces 1 and 2 in a rectangular shape smaller than the outer shapes of the workpieces 1 and 2 . As a plurality of light-shielding masks 4 with different light-transmitting shapes, in the first step in the main curing process, a first light-shielding mask 41 having a first light-shielding pattern 4a with a frame-shaped light-transmitting hole 4h opened is used. In the next second time, use the second light-shielding mask 42 having the second light-shielding pattern 4b opened with the rectangular light-transmitting hole 4h to divide the divided regions 3b and 3c of the adhesive 3 into two times, sequentially and respectively. Perform partial formal curing.

[0094] That is, with respect to the frame-s...

Embodiment 2

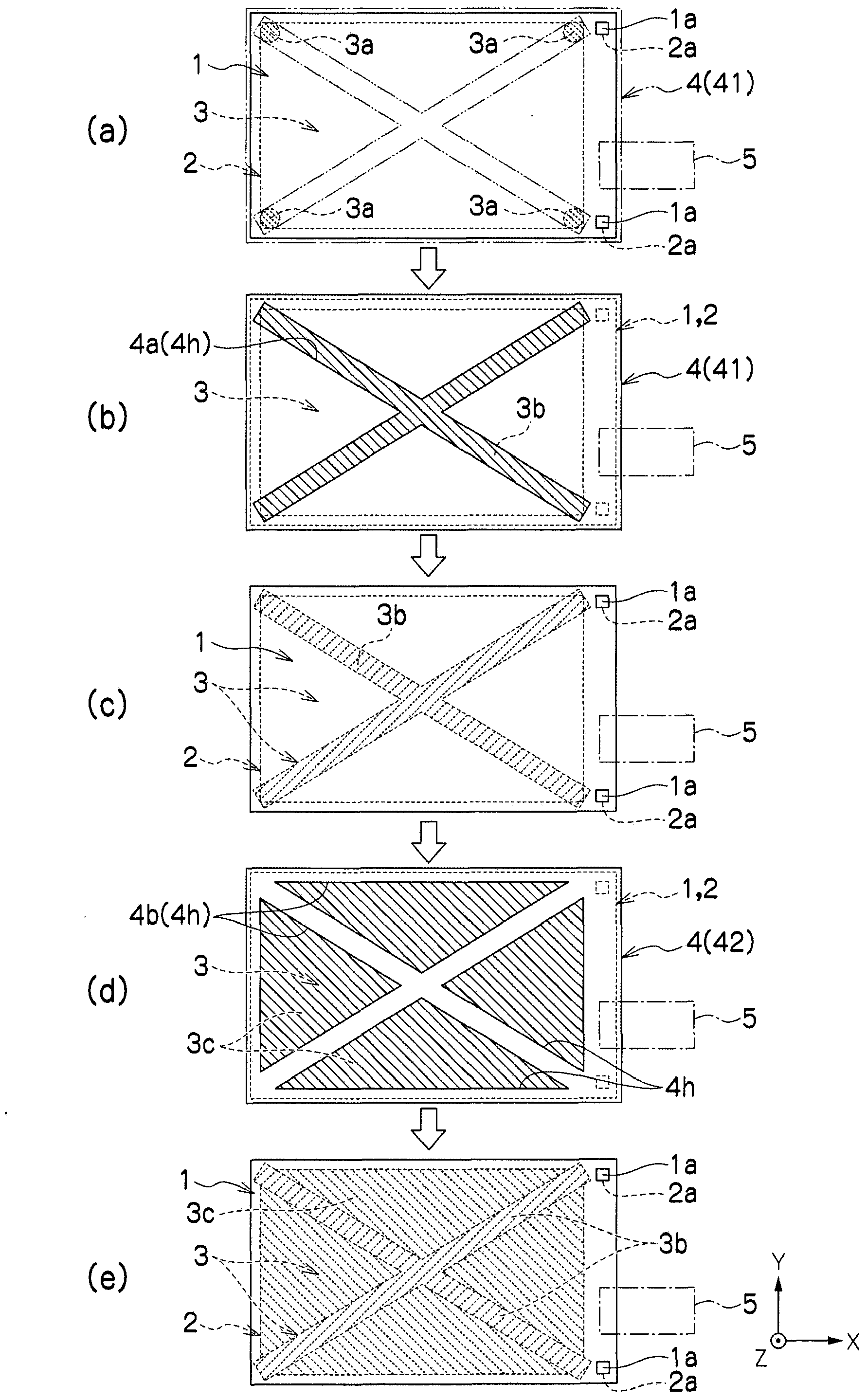

[0104] like image 3 (a)~(e) and Figure 4 As shown in (a) and (b), in the workpiece bonding method according to Example 2 of the present invention, as various kinds of light-shielding masks 4 with different light-transmitting shapes, in the first time of the main curing process, use Have the first light-shielding mask 41 of the first light-shielding pattern 4a that is opened with the X-shaped light-transmitting hole 4h along the diagonal line of the rectangular adhesive 3, in the next second time, use the first light-shielding mask 41 that has the X-shaped light-transmitting hole 4h that is opened with The second light-shielding mask 42 of the second light-shielding pattern 4b of the (4) triangular light-transmitting holes 4h sandwiched by the diagonals of the rectangular adhesive 3 divides the divided regions 3b and 3c of the adhesive 3 twice , sequentially, respectively, for partial formal solidification, this structure is the same as figure 1 and figure 2 The example 1...

Embodiment 3

[0110] like Figure 5 As shown in (a) to (e), in the workpiece bonding method according to Example 3 of the present invention, as a plurality of types of light-shielding masks 4 with different light-transmitting shapes, in the first step of the main curing process, a Have the first light-shielding mask 41 of the first light-shielding pattern 4a that is opened with the frame-shaped light-transmitting hole 4h, in the next second time, use the first light-shielding mask 41 that has the light-shielding pattern 4h that is opened with the square black-and-white checkered shape. The second light-shielding mask 42 of the second light-shielding pattern 4b, in the next third time, use the third light-shielding mask 43 of the third light-shielding pattern 4c having the light-transmitting holes 4h of the square black and white checkered pattern, The divided regions 3b, 3c, and 3d of the adhesive 3 are divided into 3 times, sequentially, and partially formally cured respectively. This stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com