Silica gel strip scutching roller capable of automatically adjusting breadth

An automatic adjustment, silicone strip technology, applied in the direction of winding strips, fabric elongation, textiles and papermaking, etc., can solve the problems of different lengths of rubber strips, high work intensity, inconvenient disassembly and assembly, etc., to ensure the opening The effect of reducing the length of the width, reducing the working intensity, and ensuring the effect of the opening width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

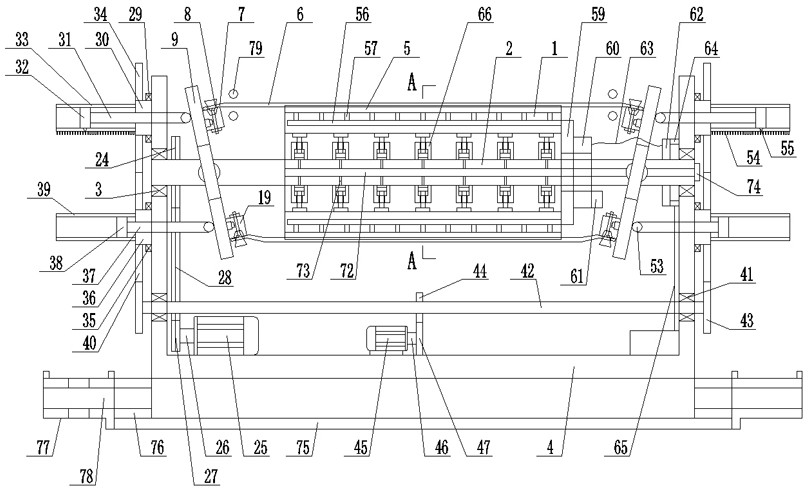

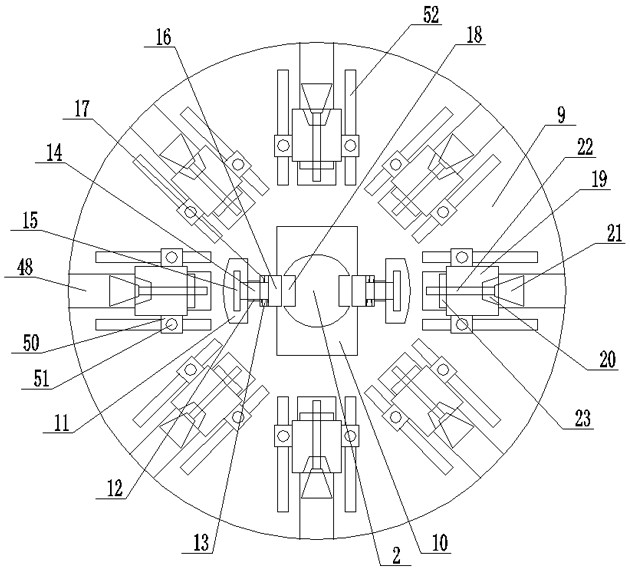

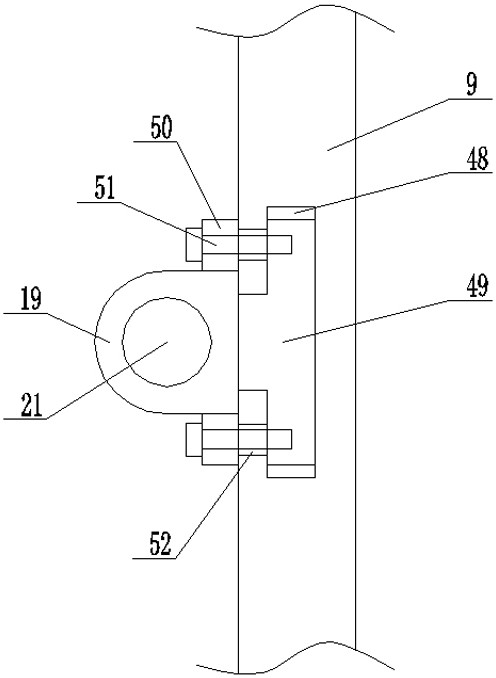

[0018] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a silicone strip open-width roll that can automatically adjust the width includes: a roll body 1 and a mandrel 2 arranged in the roll body 1, and the two ends of the mandrel 1 protruding from the roll body 1 respectively pass through the first A bearing seat 3 is rotatably arranged on the frame 4, and a plurality of rubber strip slots 5 are uniformly arranged on the outer side of the roller body 1, and I-shaped rubber strips 6 are respectively slidingly arranged in the rubber strip slots 5, Fixing parts 7 are respectively arranged at both ends of the I-shaped rubber strip 6, fixing holes 8 are arranged on the fixing parts 7, and a swash plate 9 is respectively symmetrically sleeved at both ends of the mandrel 2, The central part of the swash plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com