Bearing device for rolling stock axle

A technology for bearing devices and railway vehicles, applied in the direction of railway vehicles, shafts, bearings, bearings, etc., can solve problems such as difficult to suppress failures, lubricant deterioration, and increased quantity, and achieve easy maintenance and management, easy manufacturing and assembly, and reduced production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

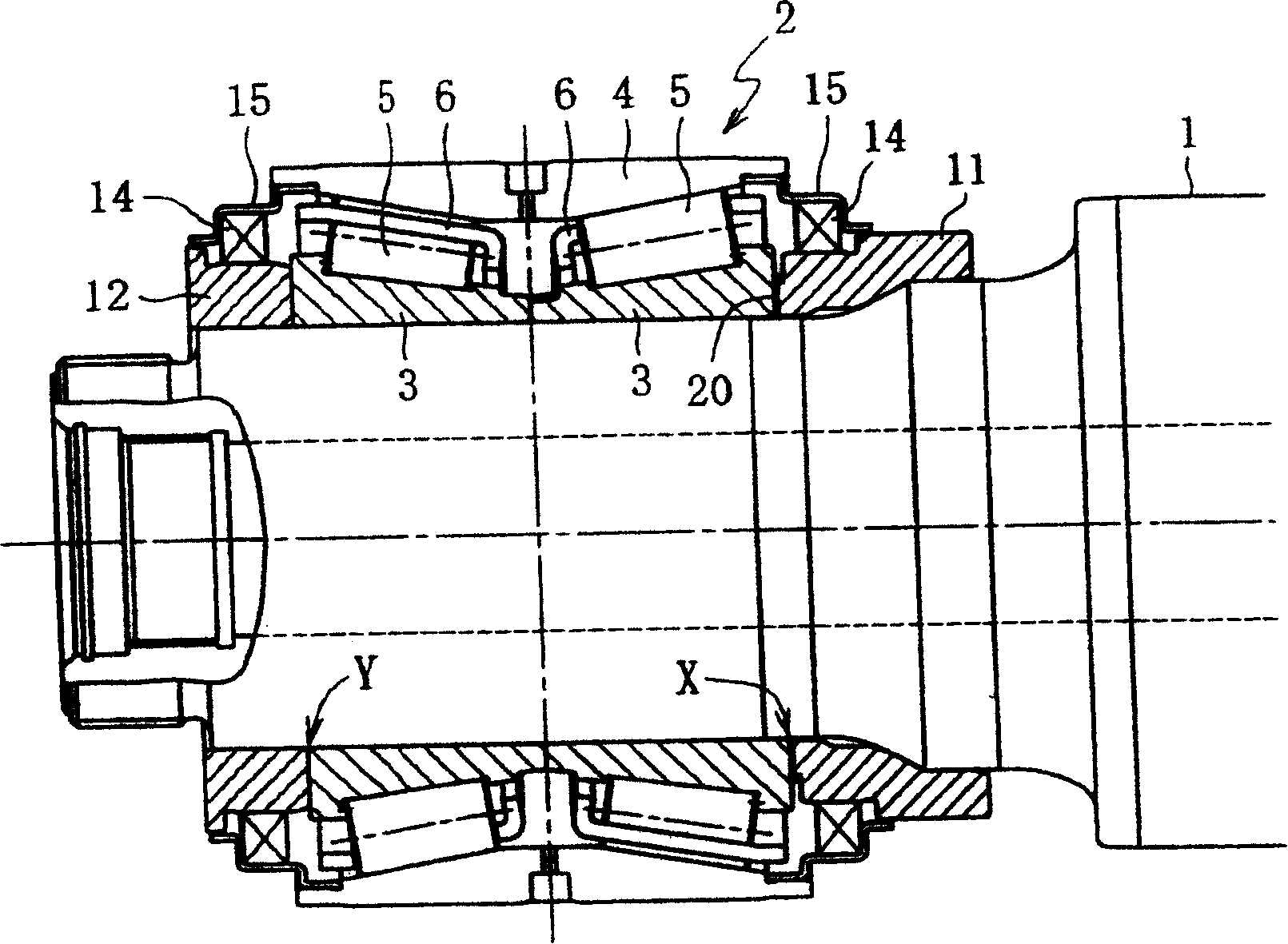

[0063] Below, refer to Figure 1A ~ Figure 3B To describe the first embodiment, refer to Figure 4A ~ Figure 6B The second embodiment will be described. In addition, the bearing devices for railway vehicles of these embodiments are related to Figure 7 And the bearing device that has been described is basically the same in structure, so it is substantially the same as the Figure 7 The same components or parts are attached with the same symbols and repeated explanations are omitted.

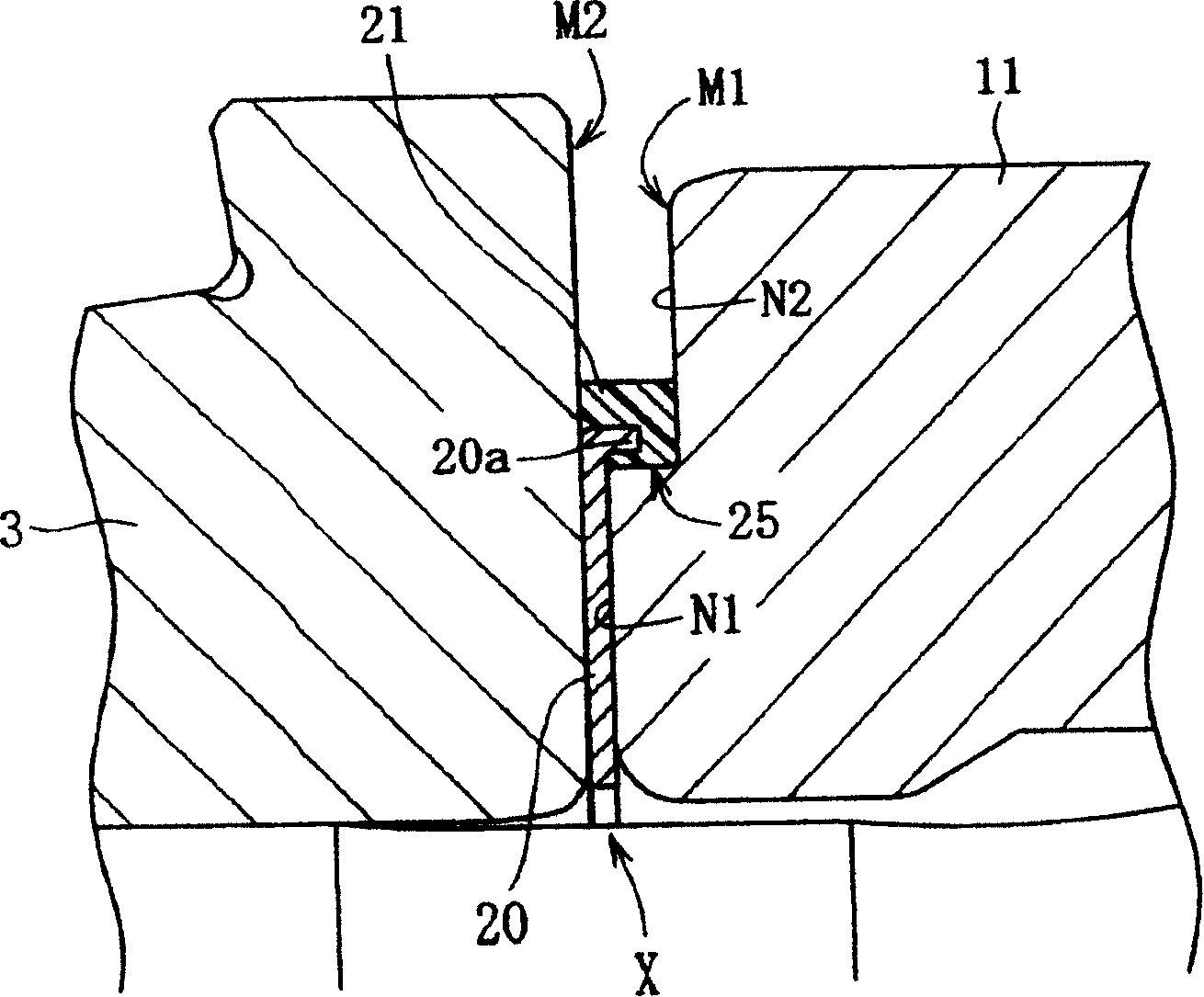

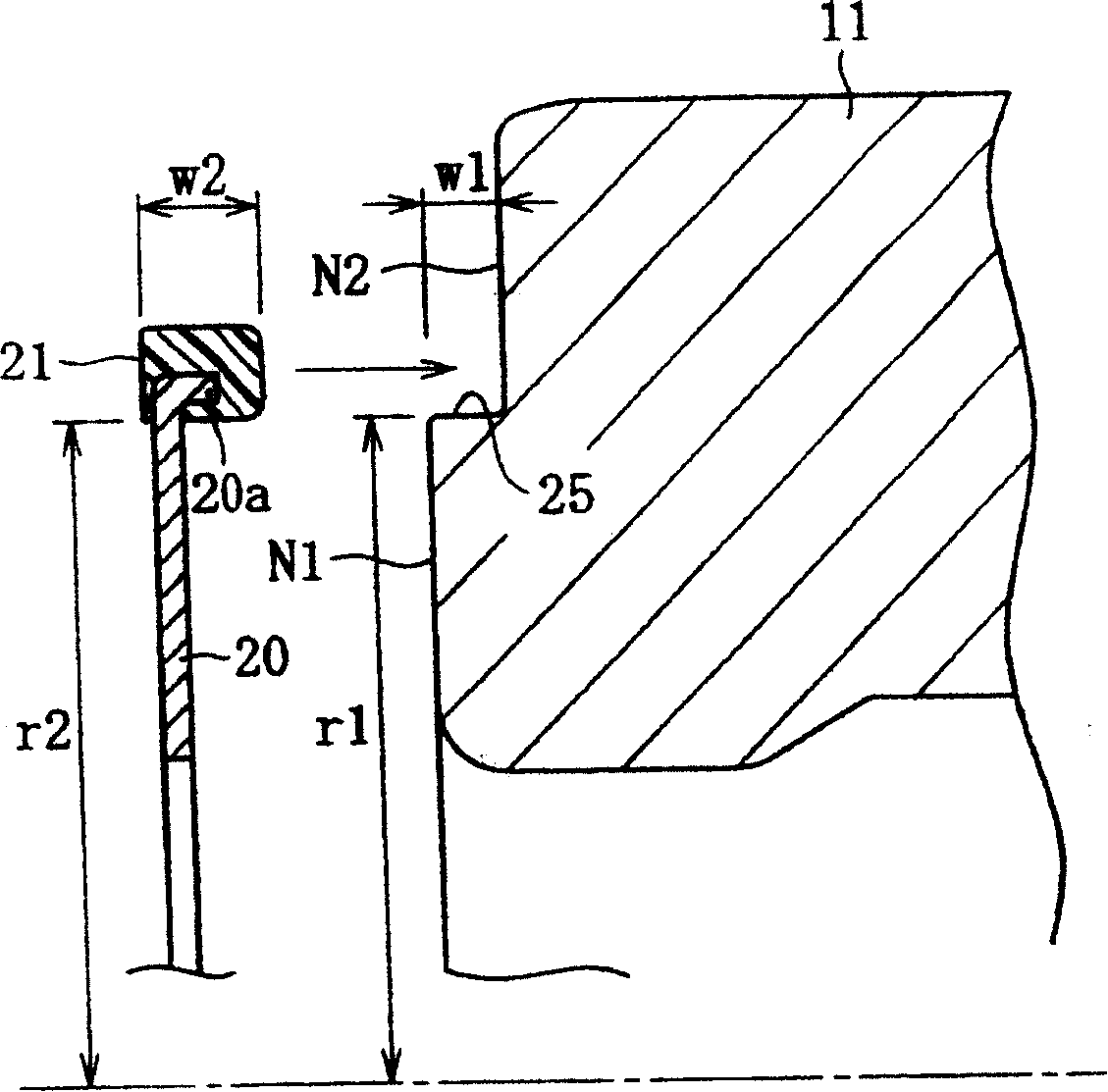

[0064] Figure 1A and 1B In the first embodiment shown, a piece of annular gasket 20 with elastic sealing material is interposed in the contact portion X between the inner wheel 3 and the rear cover 11 (annular member), and on both sides of the annular gasket 20, and The rear surface of the inner wheel 3 abuts against the front surface of the back cover 11 . The annular packing 20 with elastic sealing material is a member integrally fixed with an elastic sealing material 21 such as a ring-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com