Wind turbine blade overturning vehicle

A technology for wind turbine blades and turning vehicles, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of inability to adjust the clamping position, complex device structure, and high cost of use, and can shorten the production cycle and conform to the shape. Good, improve the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

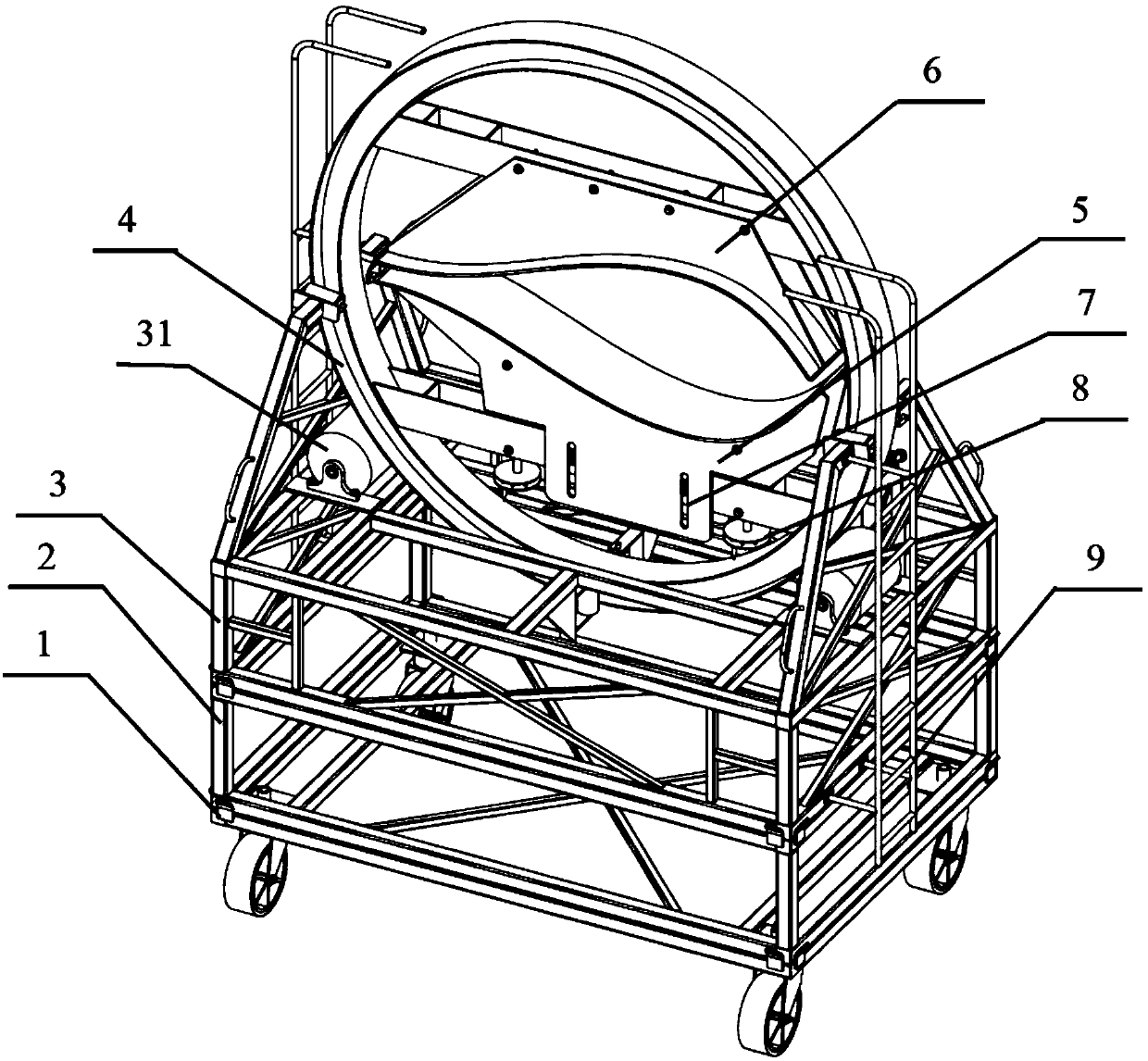

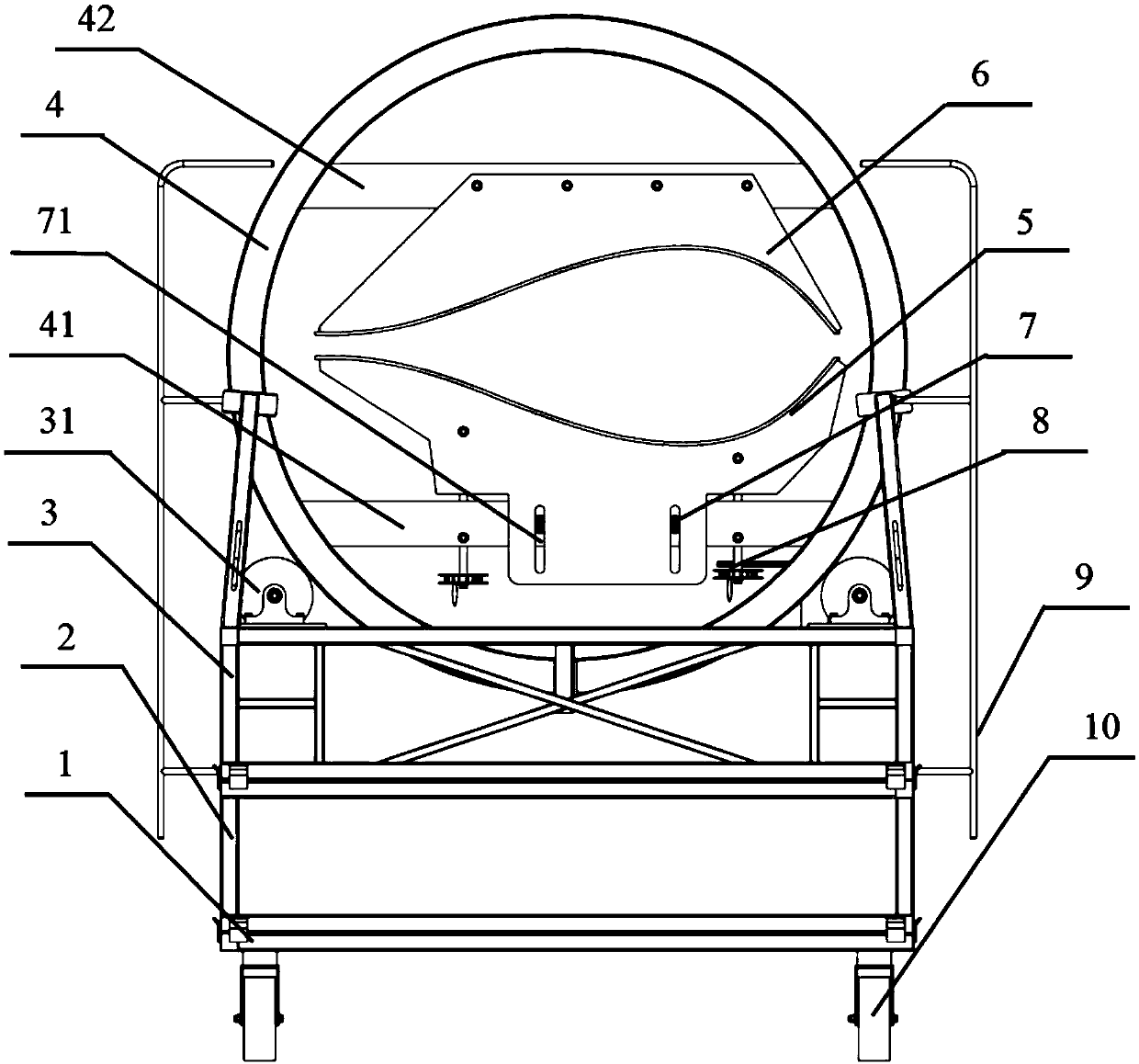

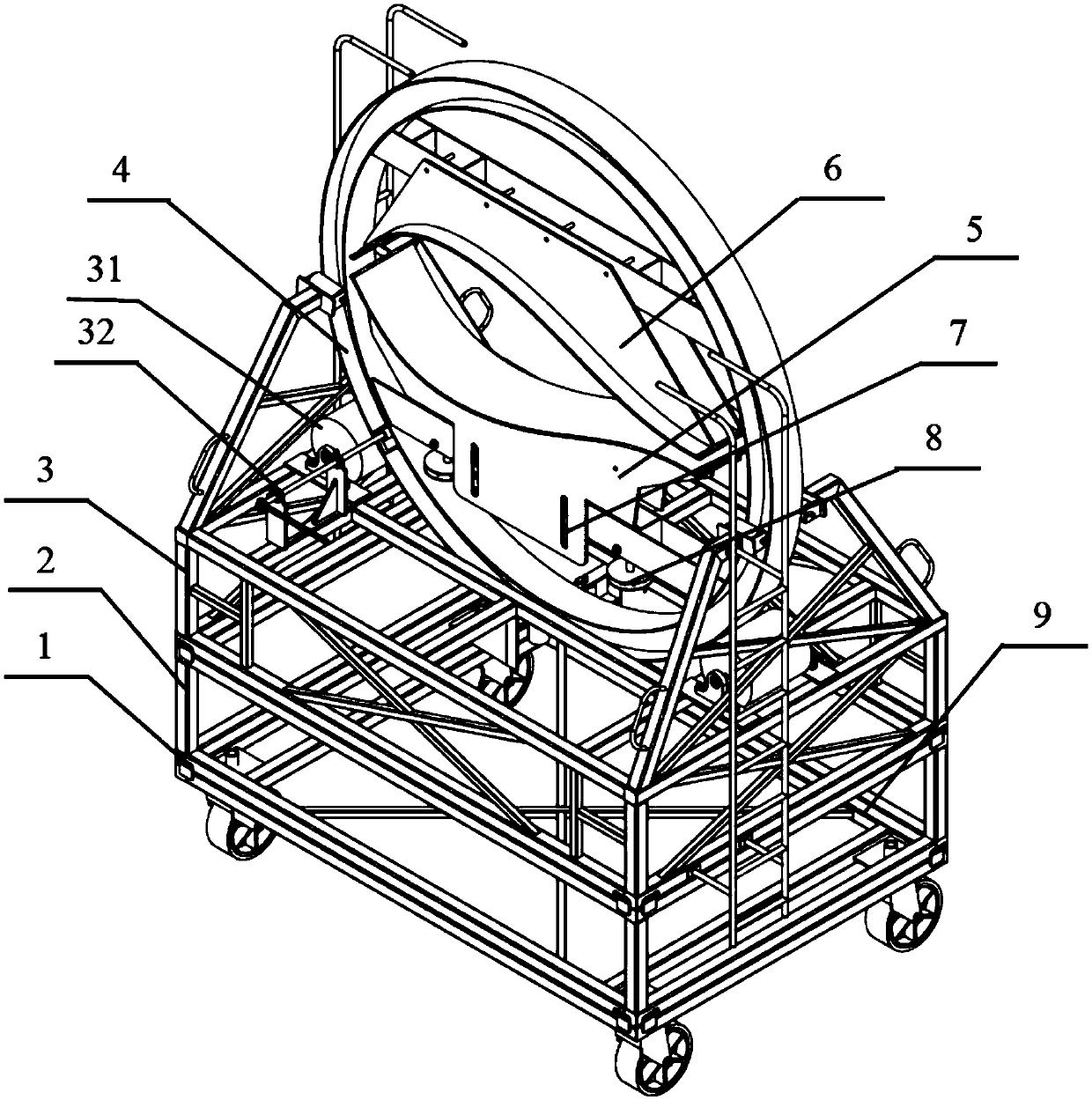

[0028] like Figure 1-6 As shown, the present invention includes a vehicle frame and an overturning device installed on the vehicle frame. The overturning device includes a rolling ring 4, a first clamp 5 and a second clamp 6 mounted on the rolling ring 4 and facing oppositely, the first clamp 5 and the second clamp 6 form the clamping area of the wind power blade, the first clamp 5 is connected with the rolling ring 4 through two position adjustment mechanisms 8, and a position adjustment guide is provided between the two position adjustment mechanisms 8 Agency 7;

[0029] The position adjustment guide mechanism 7 includes a guide groove 71 arranged on the first clamp 5 and an adjustment bearing 72 installed in the guide groove, the direction of the guide groove 71 is consistent with the adjustment direction of the position adjustment mechanism 8, and the adjustment bearing 72 The outer diameter of the adjustment bearing 72 is consistent with the width of the guide groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com