Automatic sampling mechanism of analytical instrument

An automatic sampling and analysis instrument technology, applied in the direction of instruments, analysis materials, etc., can solve the problems of high price and maintenance cost, low operation accuracy, slow sampling speed, etc., achieve simple structure, high operation accuracy, and increase sampling speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

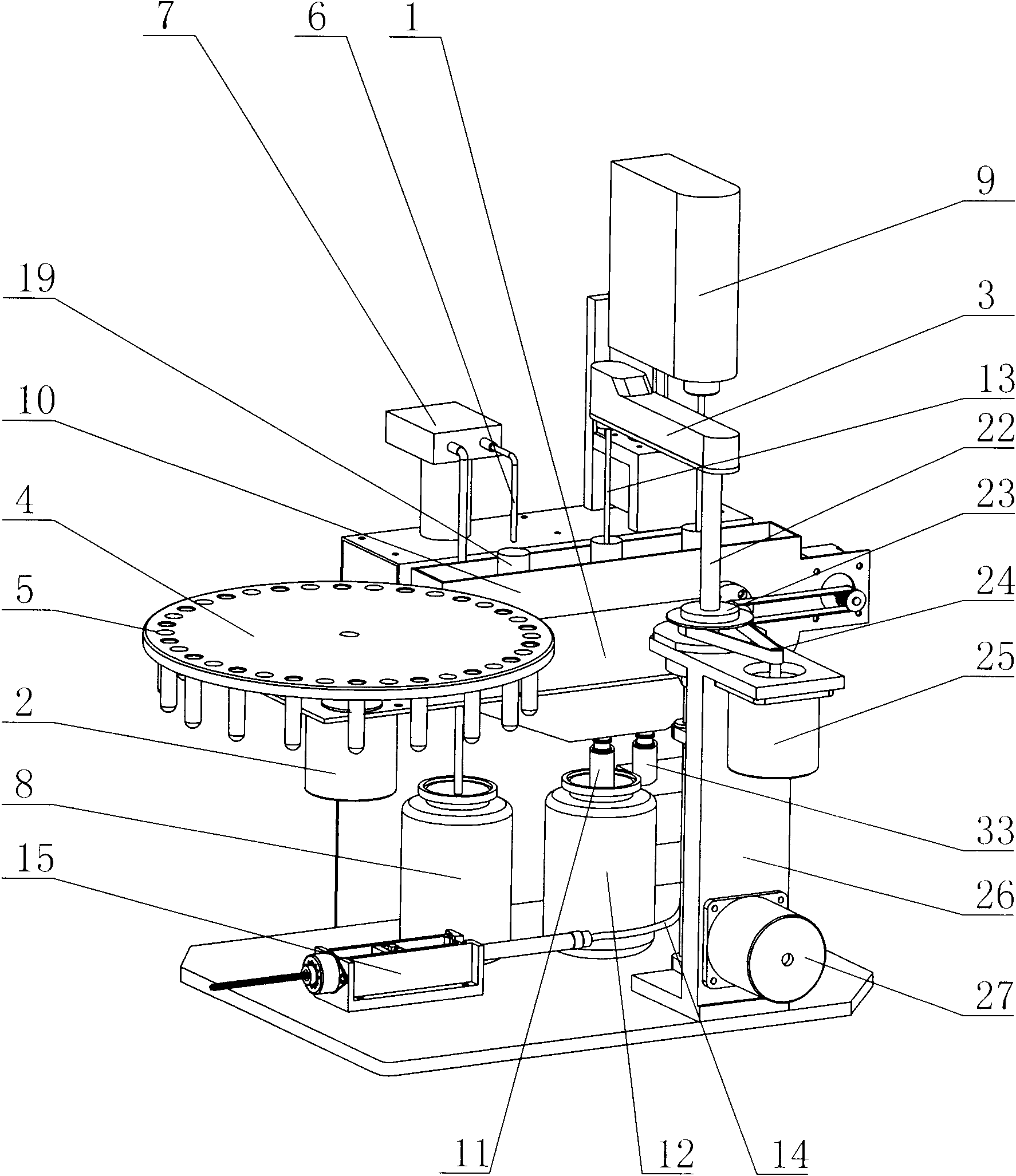

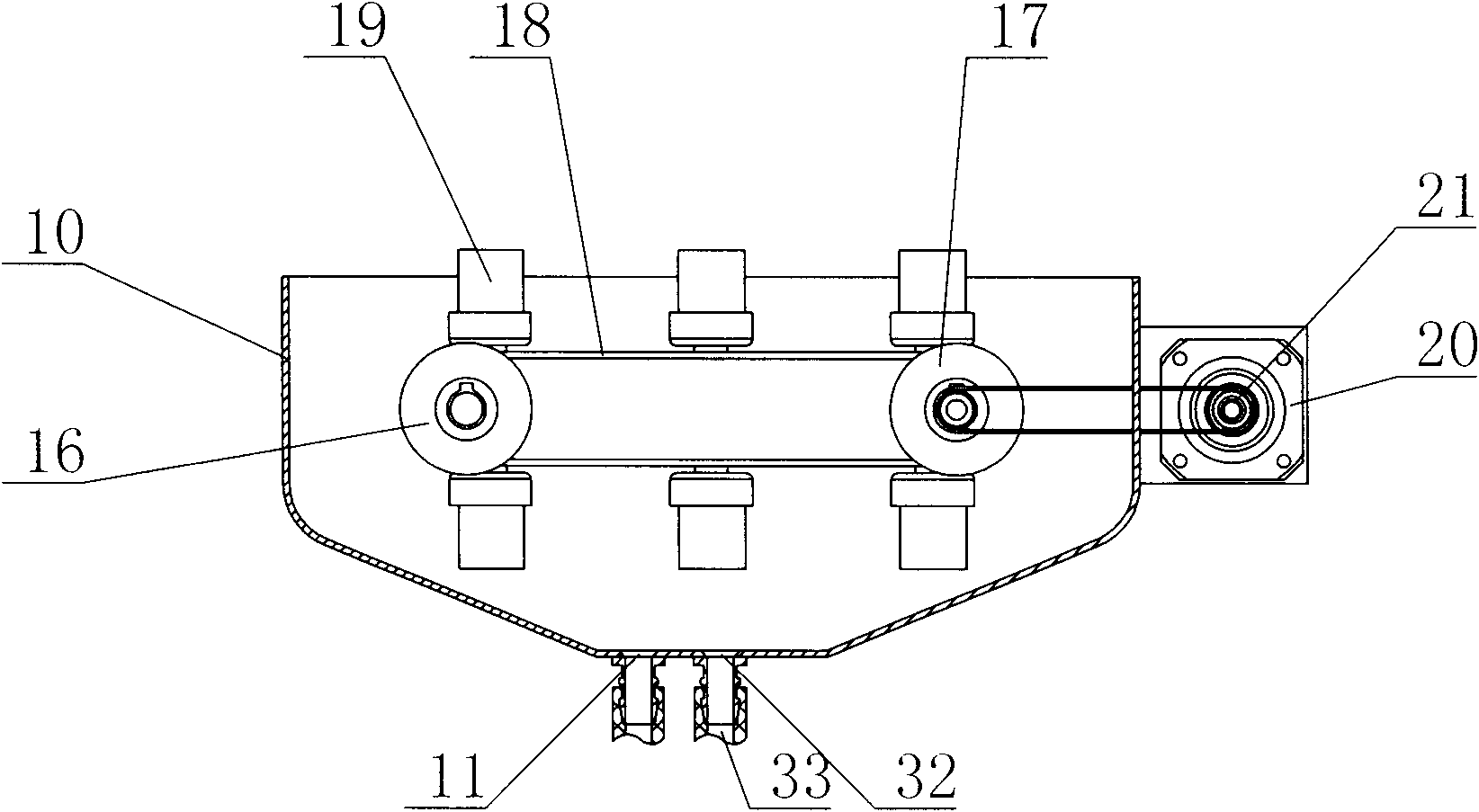

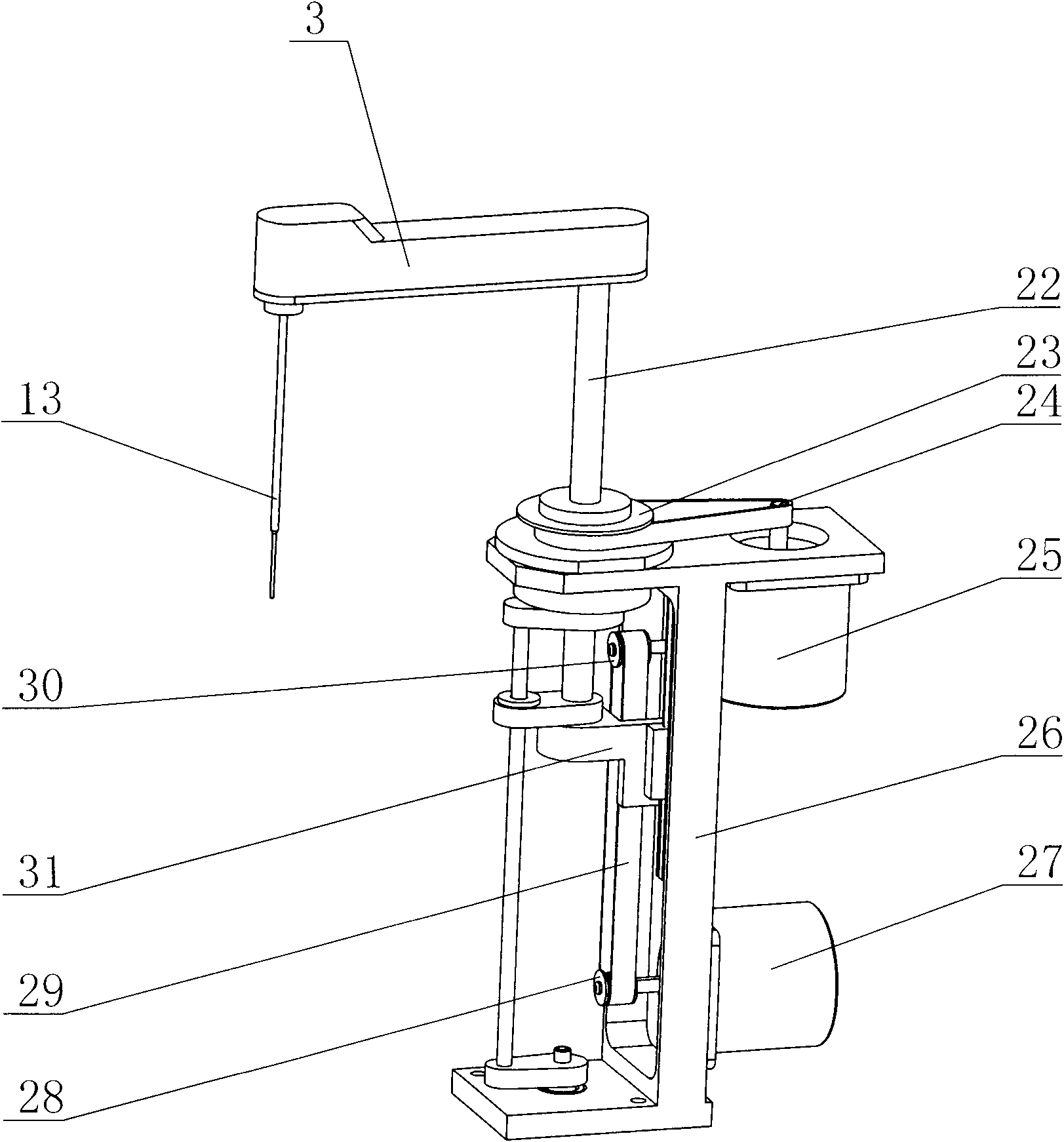

[0007] The automatic sampling mechanism of an analytical instrument of the present invention includes a frame 1, on which a first stepping motor 2, a pipette driving device, and a liquid collection box 10 are installed, and the output shaft of the first stepping motor 2 The turntable 4 is installed on the upper side, a number of test tube fixing holes 5 are evenly arranged on the edge of the turntable 4, the suction pipe 13 is arranged on the pipette driving device, and the suction pipe 13 is connected to the suction pump 15 through the pipe 14, and the liquid collection box 10 is installed and tested Cup transmission device. Several detection cups 19 are installed on the detection cup transmission device. A reagent filling pipe 6 and a measuring electrode 9 are arranged above the liquid collection box 10. The reagent filling pipe 6 is connected to the reagent container 8 through the filling pump 7 for liquid collection A water outlet 11 is provided at the bottom of the box 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com