Electrospinning direct-writing closed-loop control method

A closed-loop control and electrospinning direct writing technology, which is applied in textiles and papermaking, fiber processing, filament/thread forming, etc., to achieve the effects of ensuring uniformity, simplifying the amount of control, and improving controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with embodiment the present invention is described in further detail.

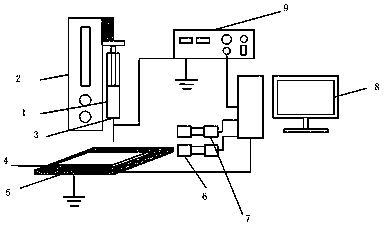

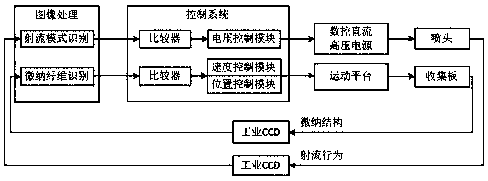

[0035] see figure 1, the embodiment of the present invention is provided with syringe reservoir 1, precision syringe pump 2, shower head 3, collecting plate 4, motion platform 5, charge-coupled device image sensor (CCD) 6, charge-coupled device image sensor (CCD) 7, numerical control High voltage direct current power supply 9 and control computer 8. The syringe reservoir 1 supplies the polymer solution to the nozzle 3 at a stable liquid supply speed through the precision syringe pump 2; the collection plate 4 is grounded and placed on the motion platform 5 for collecting micro-nano structures; CCD6 and CCD7 are connected to the control On the computer 8, it is respectively used to monitor the jet movement behavior and the micro-nano structure morphology, convert the analog signal into a digital signal and transmit it to the control computer 8, so that the control computer 8 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com