A high-precision seamless dripping CNC glue filling device

A high-precision, glue-filling technology, used in packaging, bottle filling, liquid bottling, etc., can solve the problems of affecting glue filling accuracy, complex structure, low work efficiency, etc., to improve glue filling accuracy, optimize the selection of bottles, The effect of improving the efficiency of glue filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

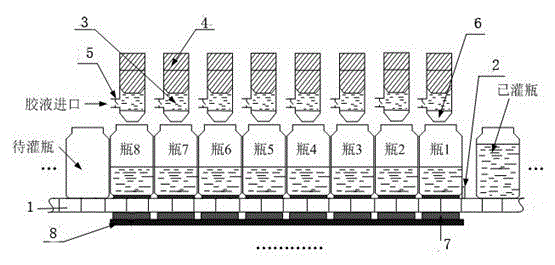

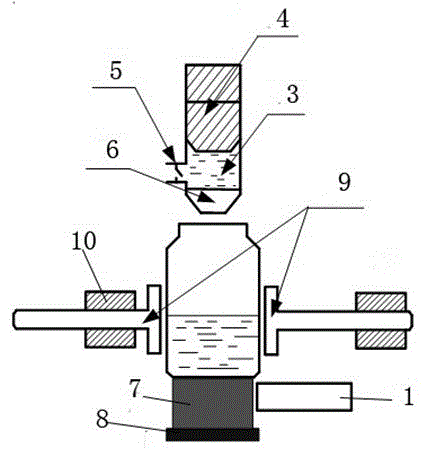

[0017] Such as figure 1 As shown, a high-precision dripping CNC glue filling device is composed of a conveyor belt 1, an isolation rotating plate 2, eight buffer chambers 3, and eight pistons 4 corresponding to the eight buffer chambers, installed in the eight buffer chambers 3- Eight one-way valves 5 on the side, flow regulating valves 6 installed at the bottom of the eight buffer chambers 3, eight load cells corresponding to the eight buffer chambers 7, load cell control boards 8, bottle filling control rods 9 And the fixed catheter 10 is formed.

[0018] The height of the buffer chamber 3 can be adjusted up and down according to the bottle filling height. The load cell 7 is fixed on the load cell control board 8, and the load cell 7 of the conveyor belt 1 is arranged adjacently.

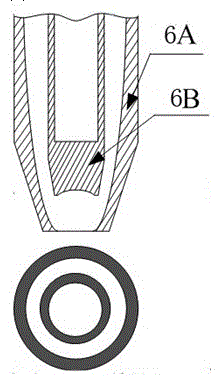

[0019] Such as image 3 As shown, the load cell control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com