A kind of aircraft skin glue pouring rotating equipment

A technology for aircraft skinning and glue filling, which is applied in the aviation field and can solve problems such as labor waste, scratches on the skin surface, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

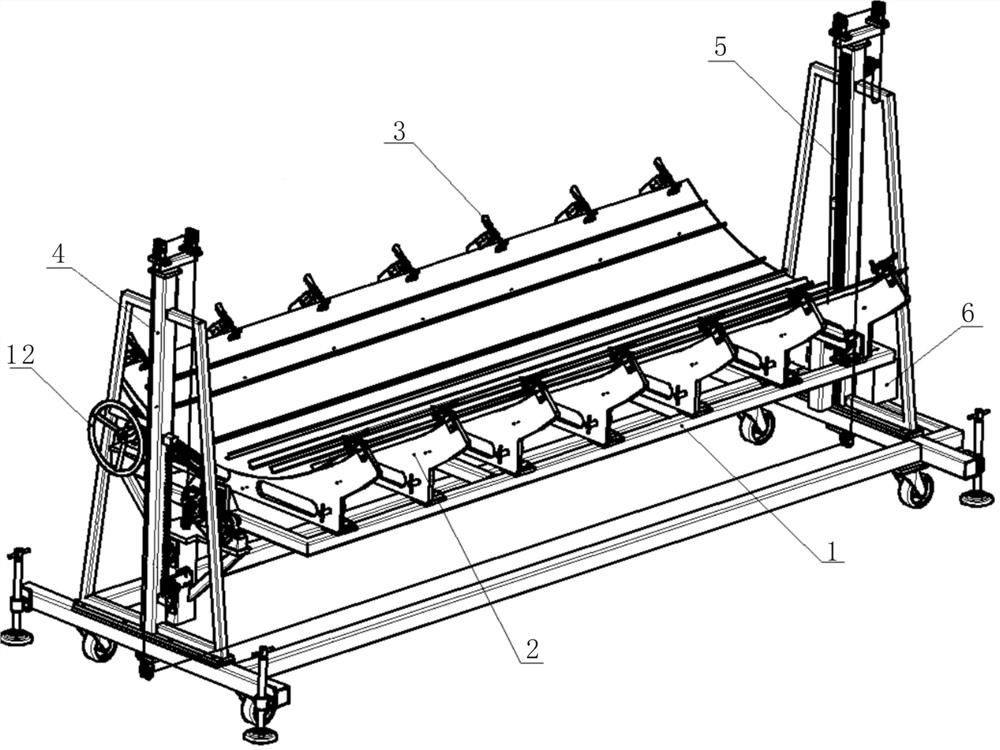

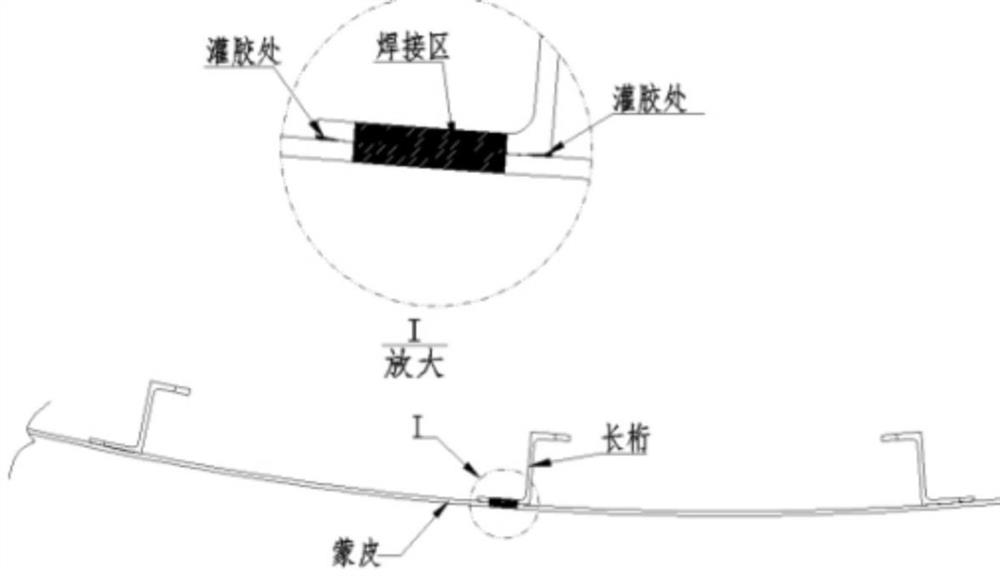

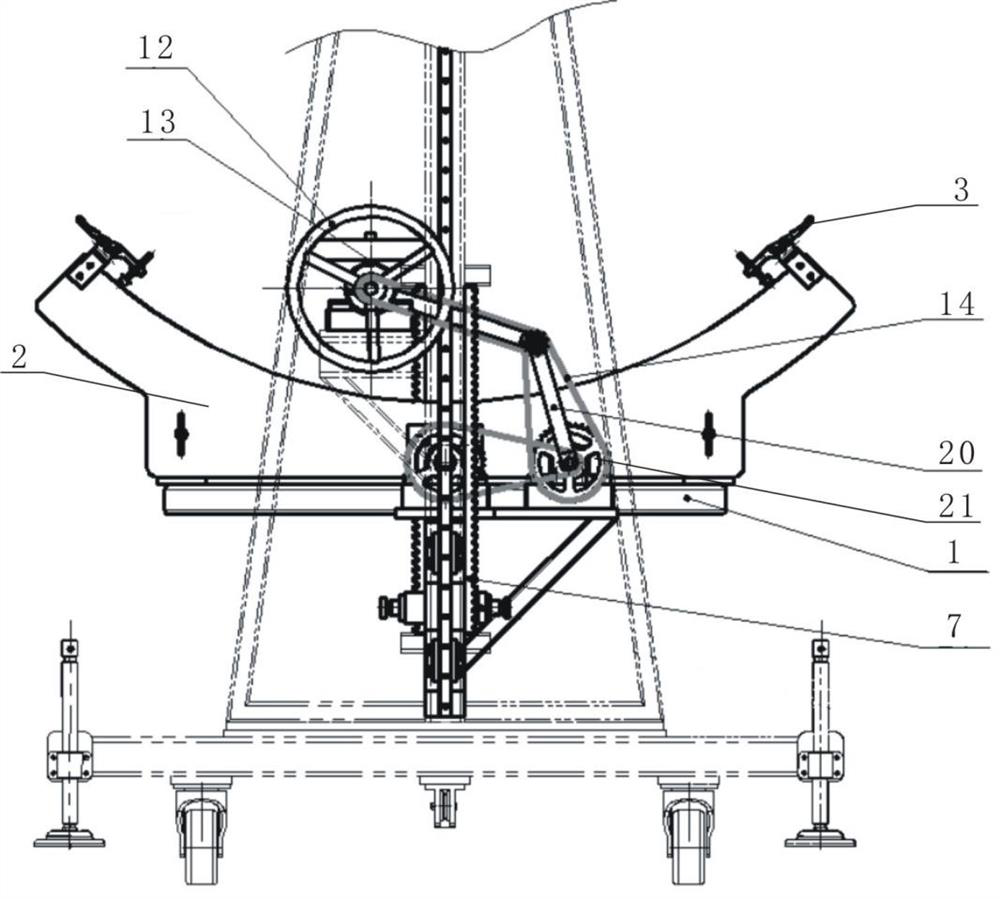

[0030] Such as figure 1 , 3 Shown: the present invention provides a kind of aircraft skin gluing rotary equipment, the equipment includes a mounting table 1, a skin fixing frame 2 and a rotating lifting mechanism. The bottom of the mounting table 1 is provided with a rotating shaft, the skin fixing frame 2 is fixedly installed on the mounting table 1 , and the rotating lifting mechanism is installed at the end of the mounting table 1 and connected with the rotating shaft of the mounting table 1 .

[0031] Wherein said skin fixing frame 2 adopts more than two and is arc-shaped structure, is fixedly installed on the mounting table 1 by its arc-shaped top, and the arc-shaped opening faces upwards, and fast pressing clip 3 is installed at its top at two ends. The quantity of the skin fixing frame 2 is determined according to the actual length of the skin during actual operation like this, so that the skin fixing frame 2 can just support and fix the skin.

[0032] The rotating l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com