A battery module glue filling tank device

A battery module and glue filling technology, which is applied to primary batteries, primary battery manufacturing equipment, battery assembly machines, etc., can solve the problems of small battery cell assembly gap, low glue filling efficiency, poor contact, etc., and achieve low investment cost , High glue filling efficiency, good conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

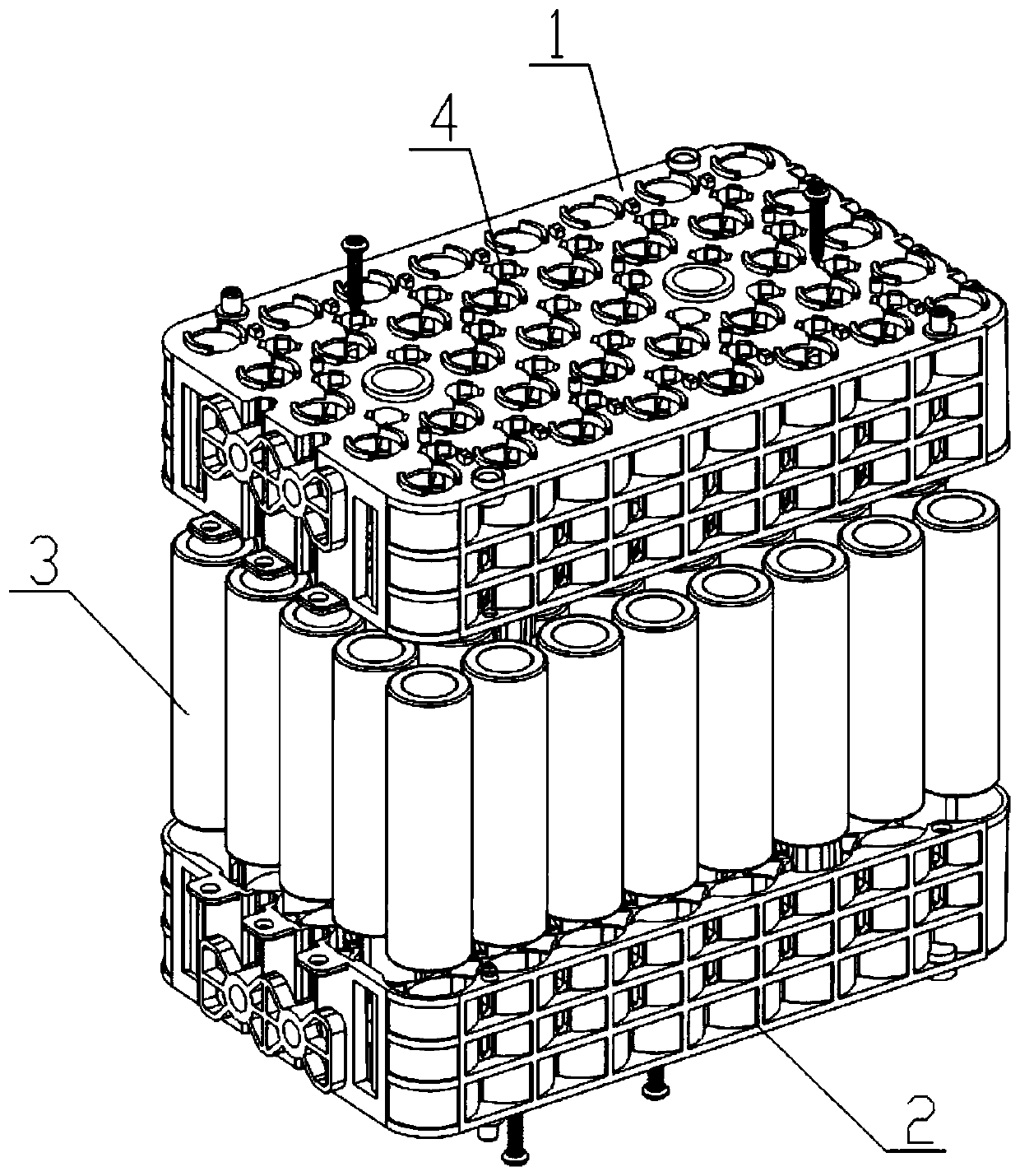

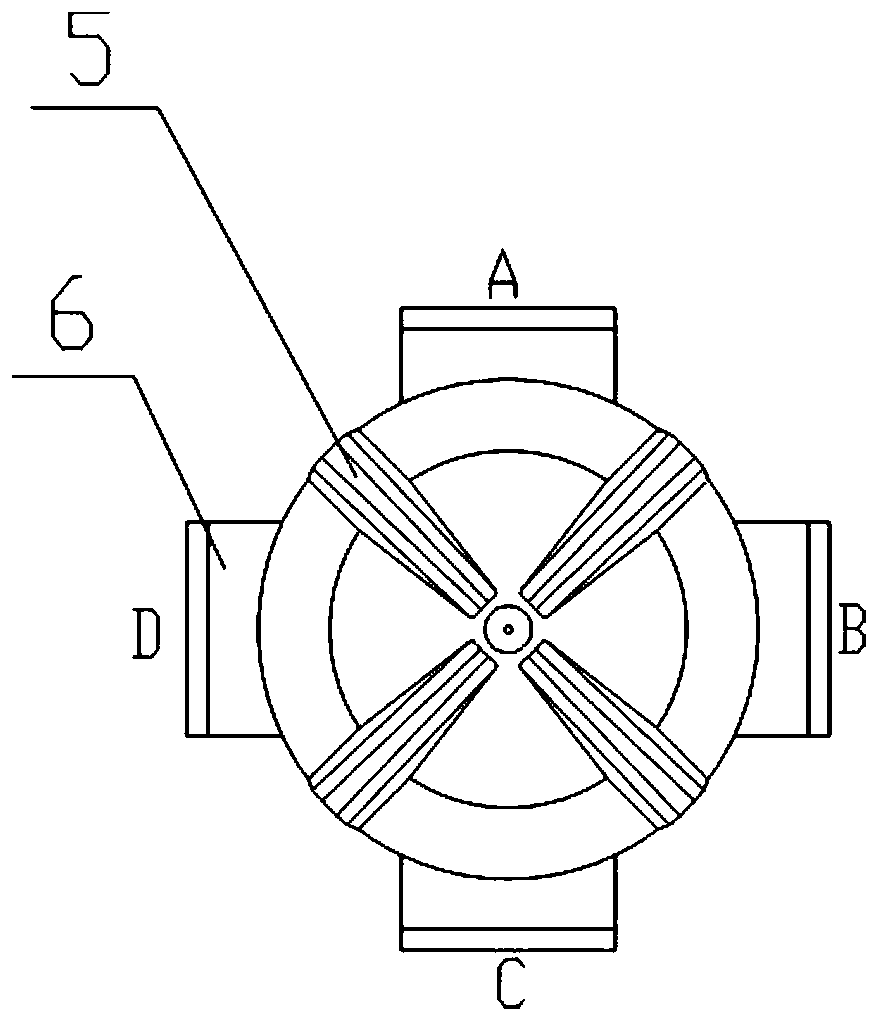

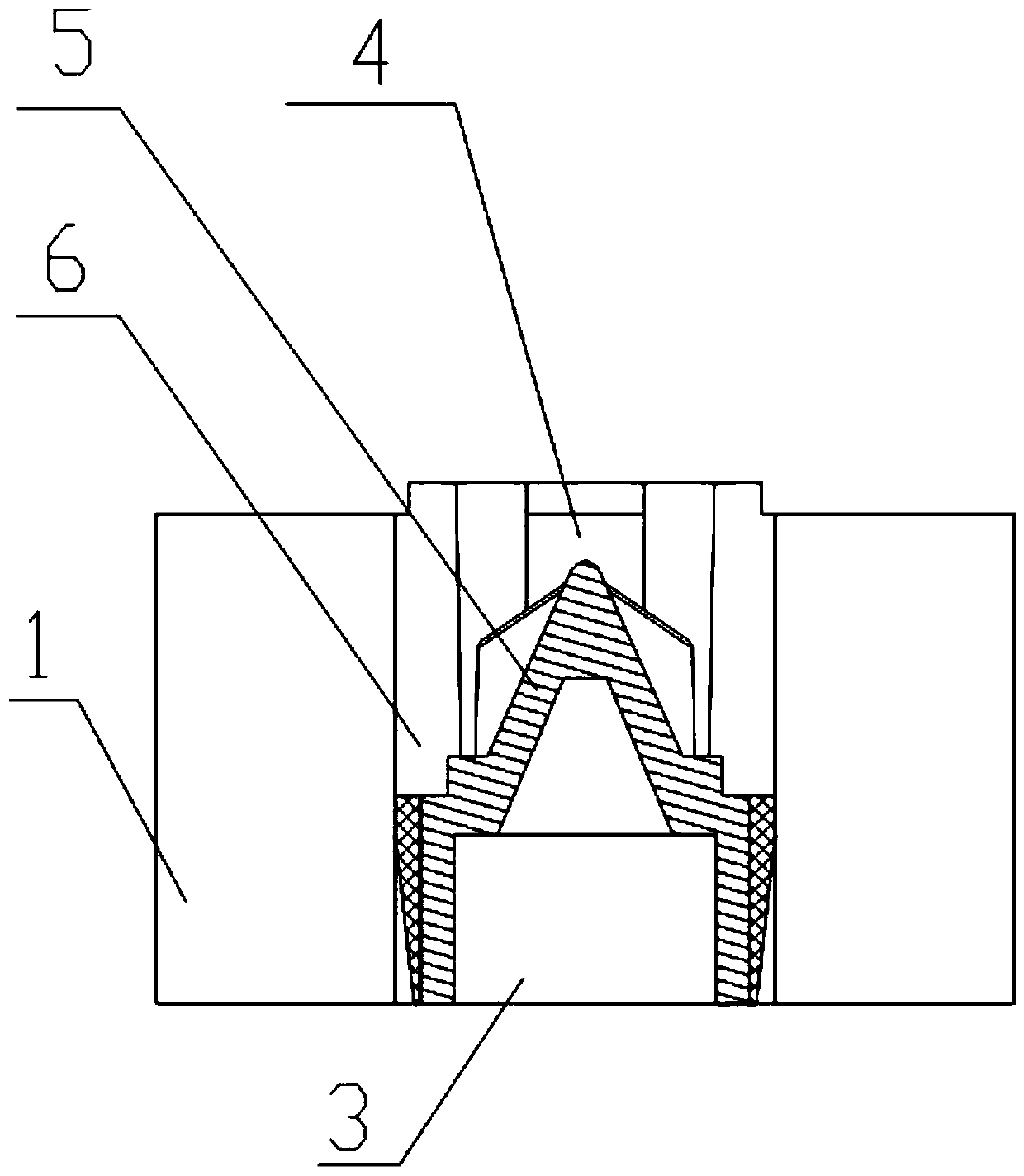

[0026] like figure 1 figure 2 image 3 The battery module glue filling tank device shown includes an upper bracket 1 and a lower bracket 2. The battery cell 3 of the battery module is installed in the middle of the two brackets. The upper bracket 1 and the lower bracket 2 are provided with glue filling The hole 4 and the glue filling hole 4 are cylindrical counterbore structures; the middle of the glue filling hole 4 is provided with a cross-shaped baffle 5, which divides the glue filling hole 4 into several glue filling areas, and there are guides connected to the glue filling areas. The glue groove 6 and the glue guide groove 6 have a rectangular cross section extending into the inside of the two brackets and communicate with the installation cavity of the battery cell 3; a clamping area is formed between the bottoms of each of the glue guide grooves 6, and the clamping area Clamp the outer edge of the battery cell 3, and chamfer the bottom of the glue guide groove 6 to f...

Embodiment 2

[0029] like Figure 4 In the battery module glue filling groove device shown, there are three glue guide grooves, and the order of glue filling is clockwise.

Embodiment 3

[0031] like Figure 5 In the battery module glue filling tank device shown, there are four glue guide grooves, there is no baffle to separate the glue filling area, and the order of glue filling is clockwise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com