Glue filling and sealing system

A technology of sealing and glue, which is applied in the directions of packaging sealing/fastening, liquid materials, external support, etc., and can solve problems such as multiple processes and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

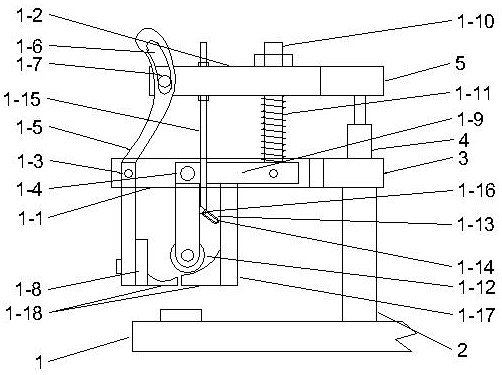

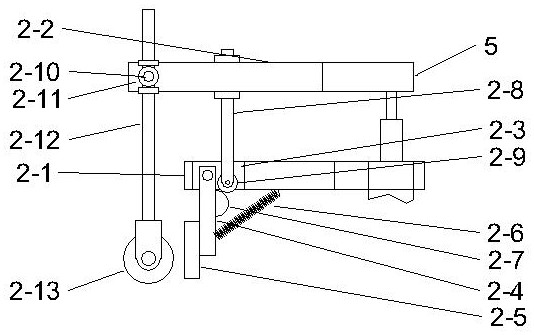

[0012] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 And attached figure 2 A glue pouring and sealing system described in this embodiment includes a glue filling machine turntable 1, a number of glue filling stations are evenly distributed on the edge of the glue filling machine turntable 1, and the center of the glue filling machine turntable 1 is provided with up and down penetrating holes. Sleeve groove, fixed sleeve 2 is installed on the frame below the turntable 1 of the glue filling machine, the top of the fixed sleeve 2 passes through the sleeve groove upwards and is connected with the fixed support plate 3, and the upper part of the inner cavity of the fixed sleeve 2 is fixed with power Cylinder 4, the piston rod of the power cylinder 4 protrudes out of the fixed sleeve 2 and connects with the cylinder support plate 5, the fixed support pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com