Three-axis linked glue pouring machine

A technology of three-axis linkage and glue filling machine, which is applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of inability to realize automation, difficulty in grasping the dosage, and waste of time, so as to reduce labor costs and achieve accurate dosage , mixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in combination with specific embodiments.

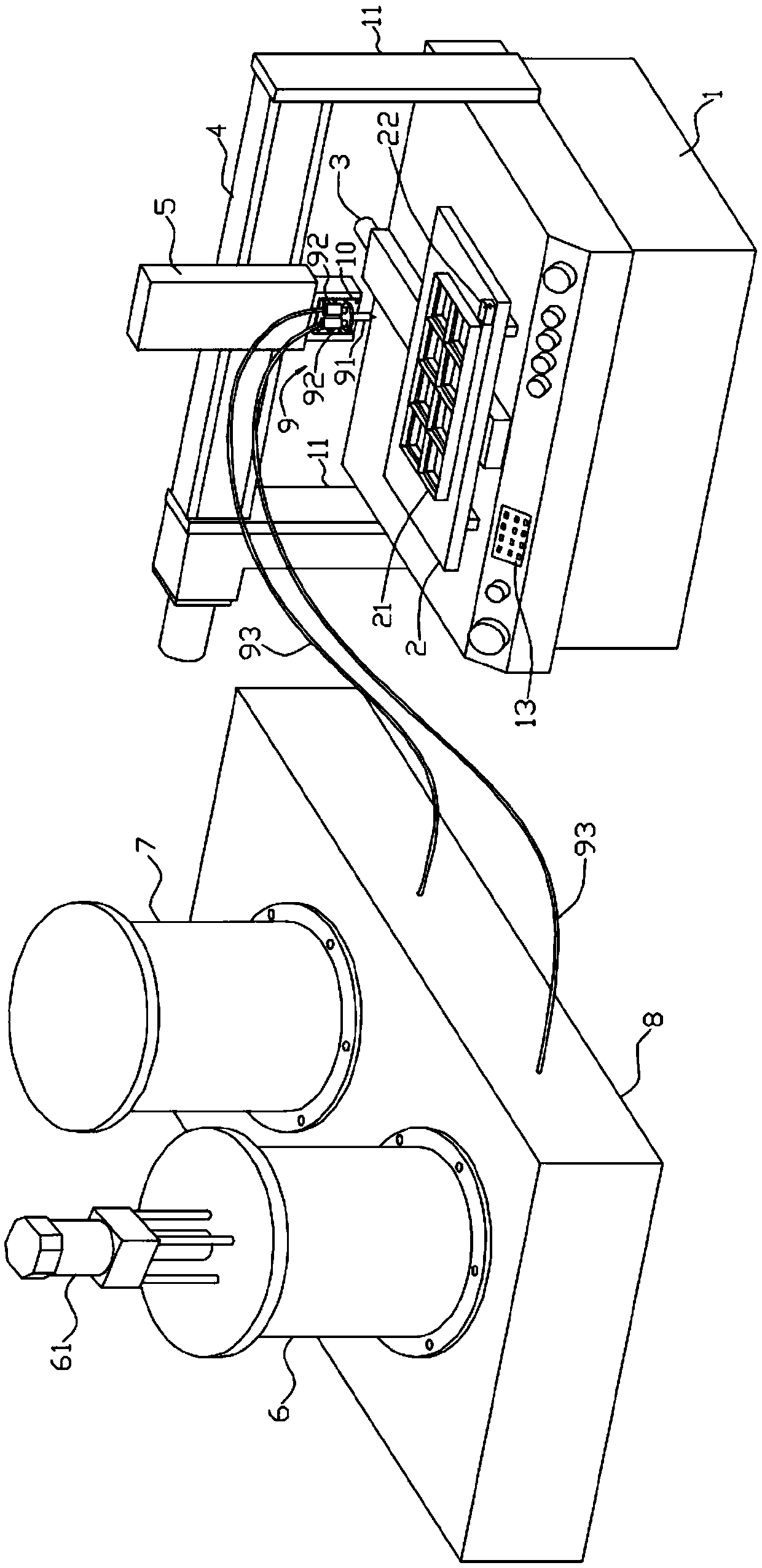

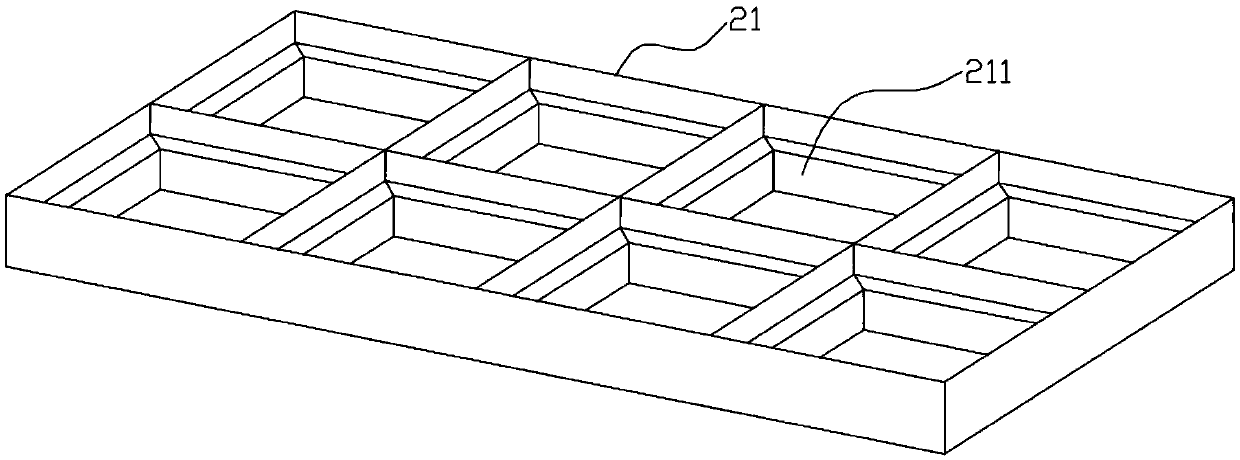

[0014] Such as figure 1 and 2 As shown, the three-axis linkage glue filling machine according to an embodiment of the present invention includes a cabinet 1, a workbench 2, an X-axis motion mechanism 3, a Y-axis motion mechanism 4, a Z-axis motion mechanism 5, a glue barrel 6, a curing Dosage cartridge 7, control box 8 and mixing device 9.

[0015] The X-axis motion mechanism 3 is fixedly installed on the cabinet 1 by bolts, the workbench 2 is slidably arranged on the X-axis motion mechanism 3, the support frame 11 is installed on both sides of the cabinet 1, and the Y-axis motion mechanism 4 is fixed on the support frame 11. The Z-axis motion mechanism 5 is slidably arranged on the Y-axis motion mechanism 4 , and the mixing device 9 is installed on the Z-axis motion mechanism 5 through the fixing plate 10 . The X-axis motion mechanism 3, the Y-axis motion mechanism 4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com