Organic thin-film transistor and manufacturing method thereof

A technology of organic thin film and transistor, which is applied in the field of organic thin film transistor and its manufacturing, can solve the problem of difficult interconnection of the upper and lower electrode layers, and achieve the effect of simple and easy to realize, low cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] In order to solve the technical defect in the existing thin film transistors that it is difficult to interconnect the upper and lower electrode layers through the via holes formed from the patterned insulating layer, the embodiment of the present invention provides an organic thin film transistor with via holes interconnection.

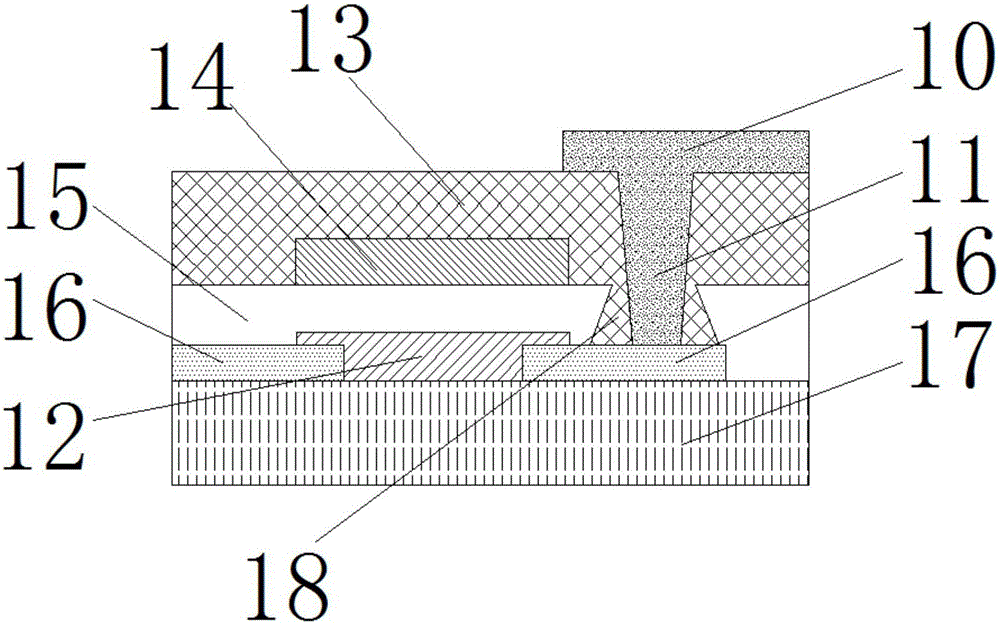

[0063] The via interconnected organic thin film transistor provided in the embodiment of the present invention is a top-gate thin film transistor.

[0064] figure 2 A schematic structural diagram of an organic thin film transistor according to Embodiment 1 of the present invention is shown. Such as figure 2 As shown, the organic thin film transistor of the present embodiment includes:

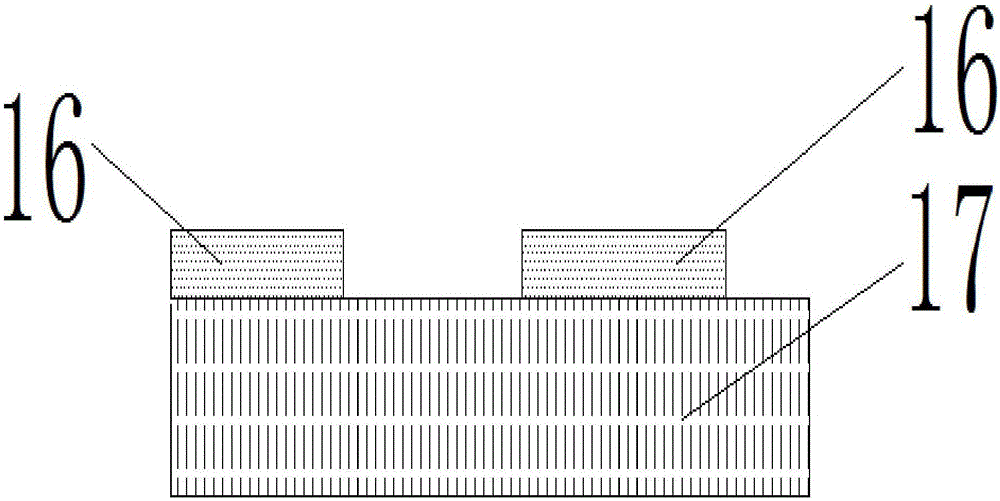

[0065] insulating substrate 17;

[0066] a source-drain electrode layer 16 formed on the insulating substrate 17;

[0067] an organic semiconductor layer 12 formed on the source-drain electrode layer 16;

[0068] A self-patterned organic gate insulating l...

Embodiment 2

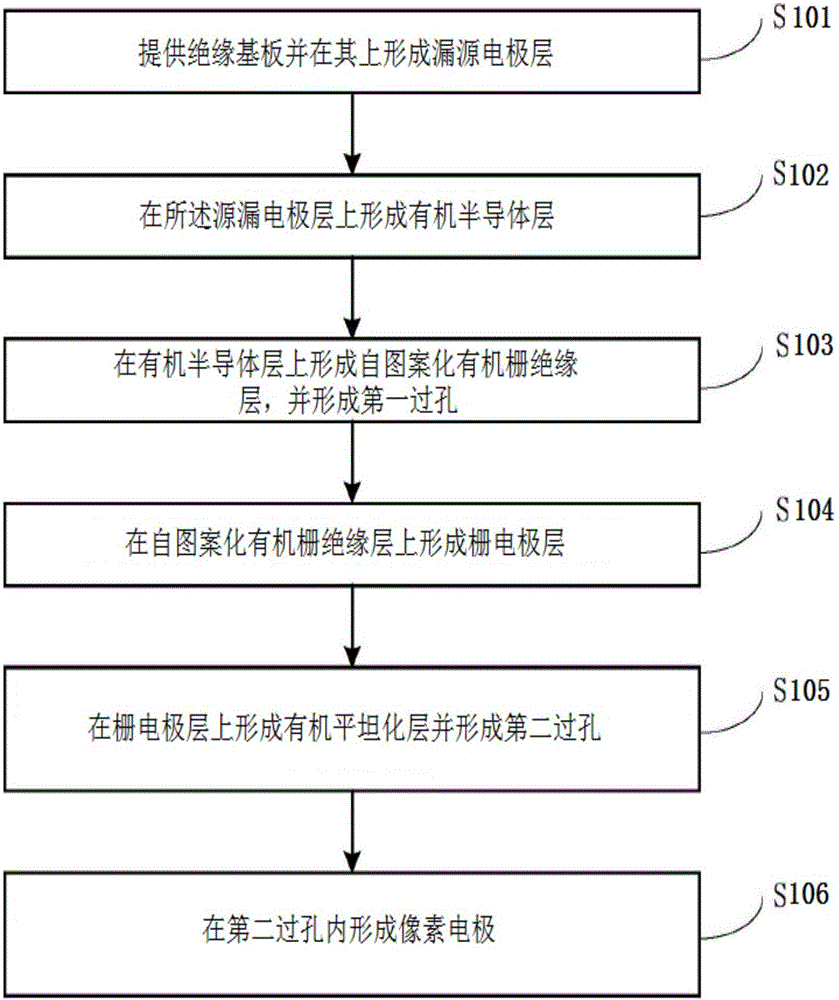

[0083] The embodiment of the present invention also provides a method for manufacturing an organic thin film transistor, which includes:

[0084] Form a multi-layer structure including an insulating substrate 17, a source-drain electrode layer 16, an organic semiconductor layer 12, a self-patterned organic gate insulating layer 15, a gate electrode layer 14, and an organic planarization layer 13; A first via hole 18 is formed in the organic gate insulating layer 15, a second via hole 11 is formed in the organic planarization layer 13, and the second via hole 11 in the organic planarization layer 13 is located in the self-patterned organic and forming the pixel electrode 10 in the second via hole 11 in the organic planarization layer 13 .

[0085] A method for manufacturing an organic thin film transistor, further comprising:

[0086] providing an insulating substrate 17;

[0087] A source-drain electrode layer 16 is formed on the insulating substrate 17; the source-drain ele...

Embodiment 3

[0120] The embodiment of the present invention also provides a method for manufacturing an organic thin film transistor, which includes:

[0121] Form a multi-layer structure including an insulating substrate 17, a source-drain electrode layer 16, an organic semiconductor layer 12, a self-patterned organic gate insulating layer 15, a gate electrode layer 14, and an organic planarization layer 13; A first via hole 18 is formed in the organic gate insulating layer 15, a second via hole 11 is formed in the organic planarization layer 13, and the second via hole 11 in the organic planarization layer 13 is located in the self-patterned organic and forming the pixel electrode 10 in the second via hole 11 in the organic planarization layer 13 .

[0122] A method for manufacturing an organic thin film transistor, further comprising:

[0123] providing an insulating substrate 17;

[0124] A source-drain electrode layer 16 is formed on the insulating substrate 17; the source-drain ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com