Vacuum glue pouring method for permanent magnetism motor rotors

A permanent magnet motor and glue filling technology, which is applied in the manufacture of motor generators, stator/rotor bodies, electrical components, etc., can solve the problems of excessive glue loss, high labor intensity, difficulty in ensuring sufficient filling and glue filling quality, etc. , to achieve the effect of preventing tooth tension and glue loss, increasing the flow rate of glue injection, and shortening the time required for gelation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

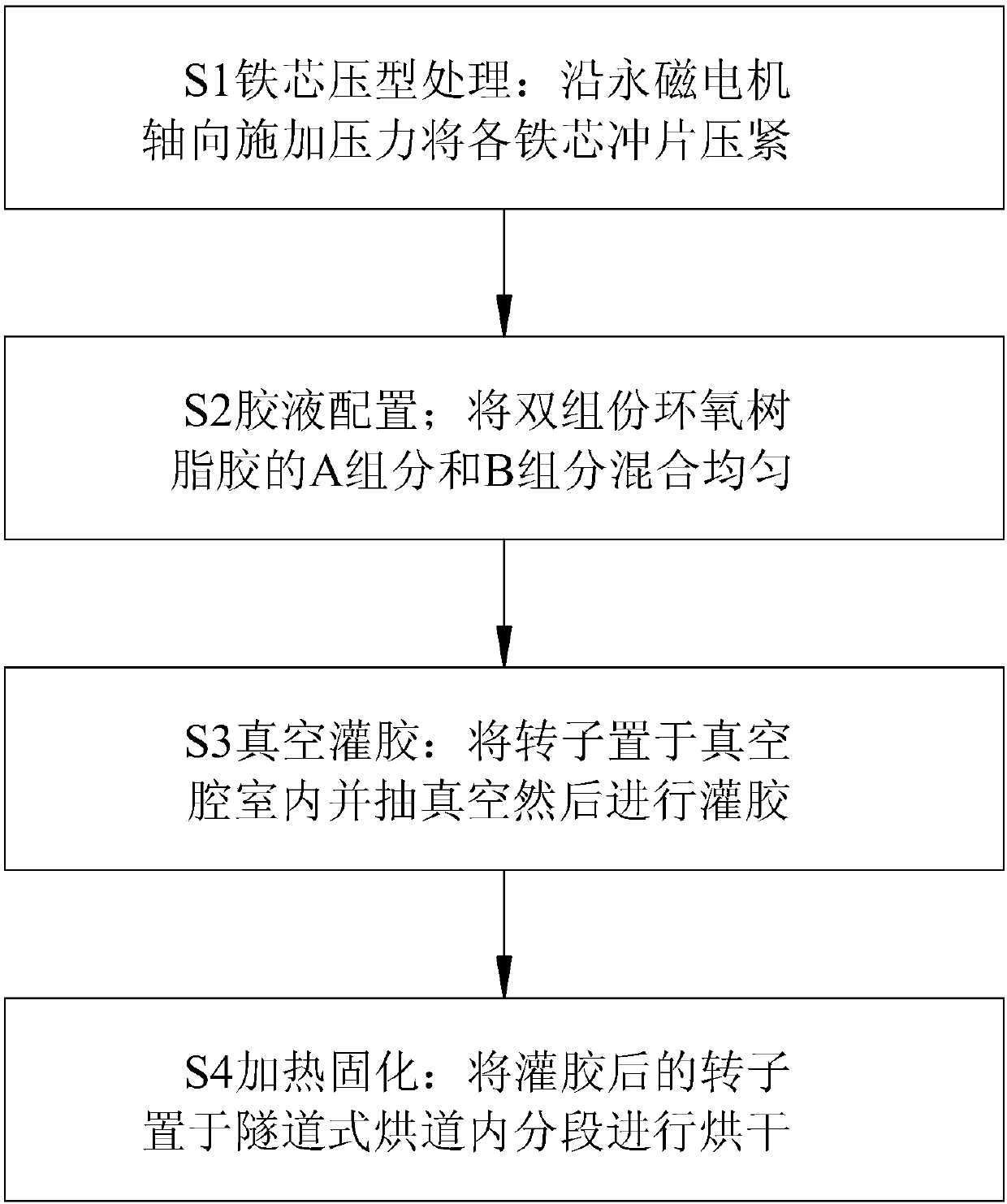

[0036] Figure 2 to Figure 5 , Figure 8 and Figure 9 An embodiment of the present invention is shown. The permanent magnet motor rotor vacuum filling method of this embodiment includes the following steps:

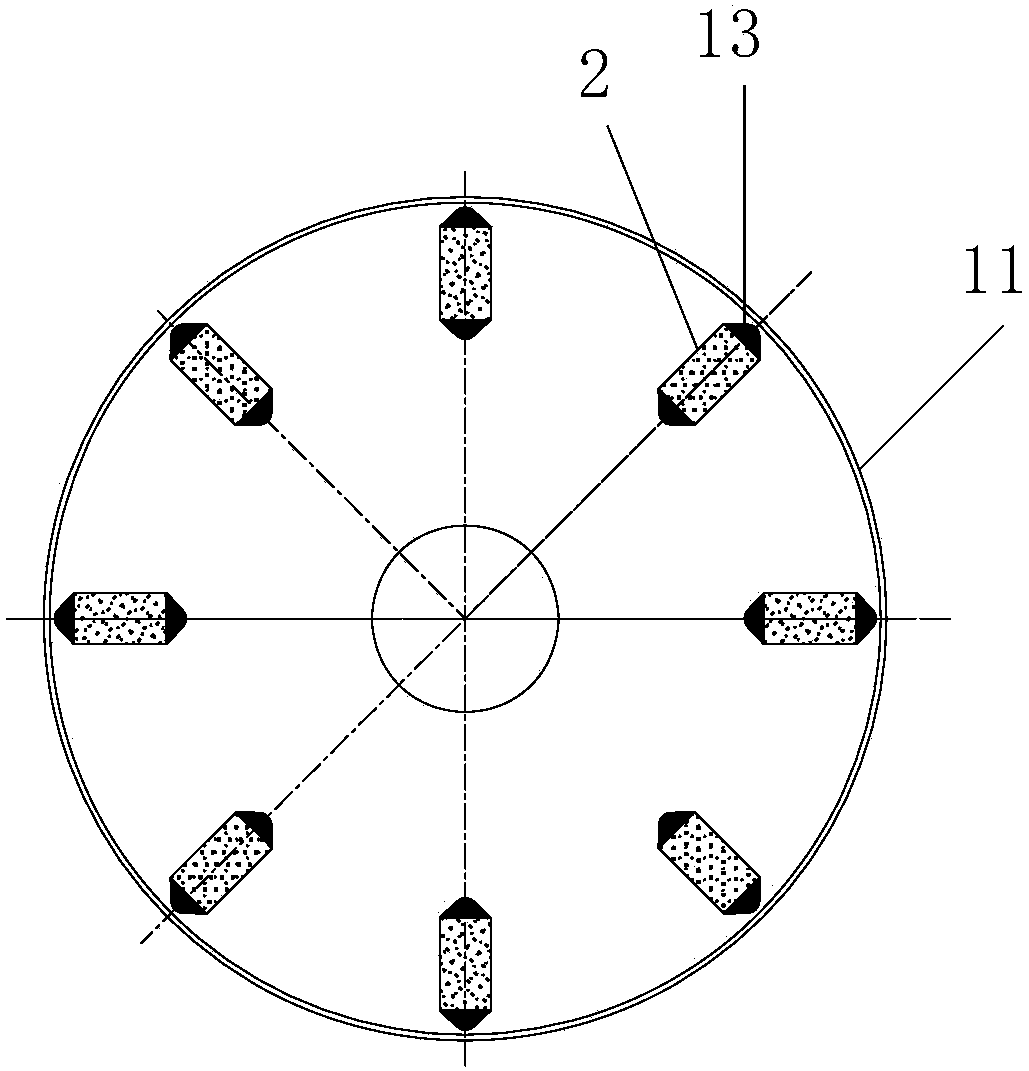

[0037] S1 rotor core 1 pressing process: apply pressure along the axial direction of the permanent magnet motor to compress each iron core punching piece 11;

[0038] S2 glue solution configuration; mix the A component and B component of the two-component epoxy resin glue evenly;

[0039] S3 Vacuum Glue Filling: Put the rotor in the vacuum chamber and evacuate and then glue the glue;

[0040] S4 Heating and curing: Place the filled rotor in a tunnel-type drying tunnel for drying in sections.

[0041]In the permanent magnet motor rotor vacuum glue filling method, the iron core 1 is molded before the glue is glued, and the iron core punches 11 are pressed tightly through the mold pressure to reduce the gap between the iron core punches 11, which is beneficial to preven...

Embodiment 2

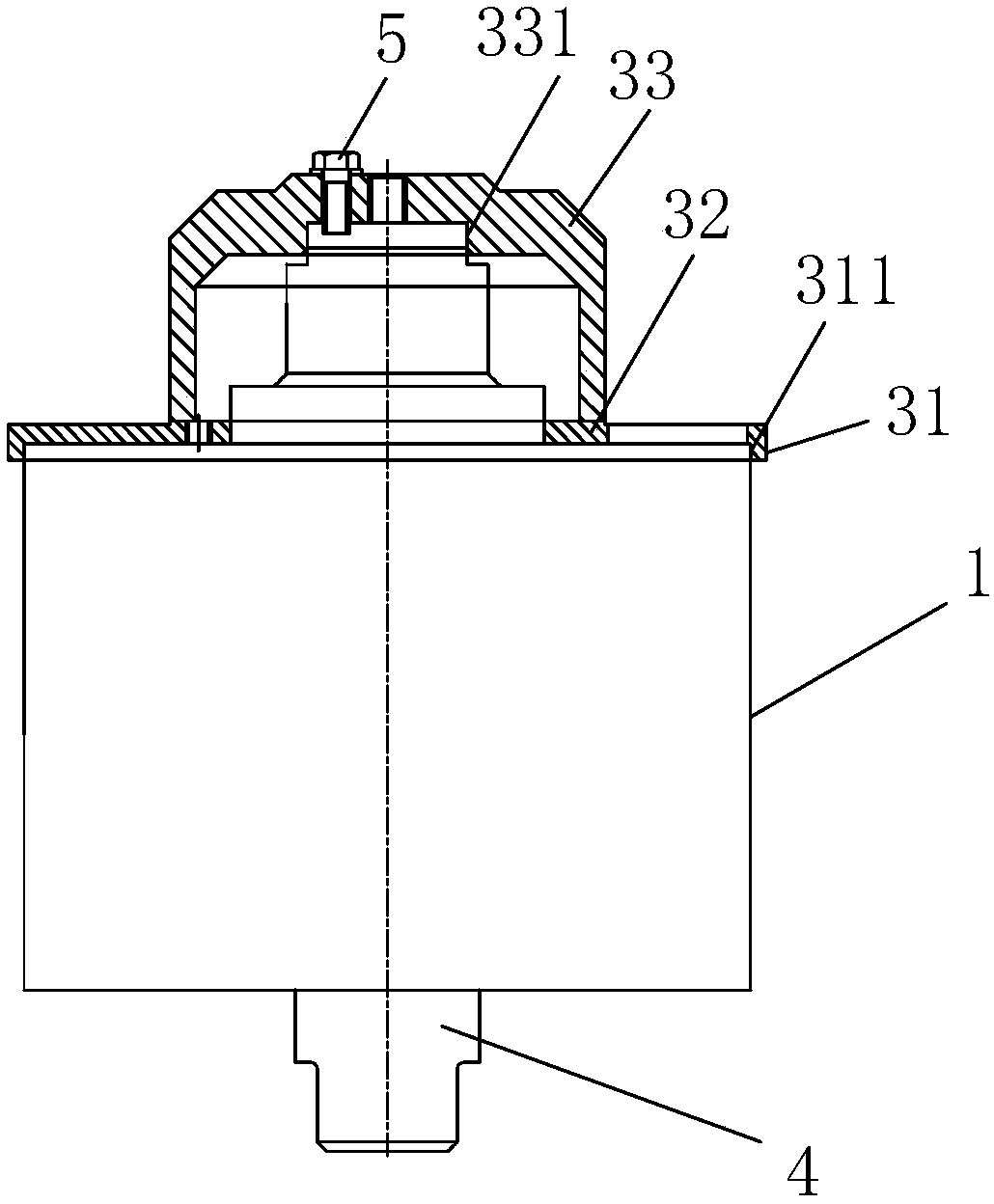

[0050] Image 6 and Figure 7 An embodiment of the present invention is shown. The glue filling scheme of this embodiment is basically the same as that of Embodiment 1, the difference is that in this embodiment, the iron core forming device includes an upper pressing plate 71, a lower pressing plate 72, and The tensioning assembly 73 used to tighten the upper pressing plate 71 and the lower pressing plate 72, the upper pressing plate 71 is provided with a stepped hole and is set on the stepped surface between the iron core 1 and the upper end of the rotor pressing ring 12, and the lower pressing plate 72 is provided with It has a stepped hole and is set on the stepped surface between the iron core 1 and the rotor pressure ring 12 at the lower end. Wherein, the tensioning assembly 73 can adopt tensioning screw rods and supporting lock nuts, and the tensioning assemblies 73 are arranged in four groups and distributed at the four corners. After locking the tensioning assembly 73...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com