Automatic cleaning and glue pouring platform for capillary array

A capillary array and automatic cleaning technology, applied in the field of biological analysis, can solve the problems of long working process, low automation procedures, unstable cleaning effect, etc., and achieve a compact structure, high degree of automation, and high cleaning and glue filling efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

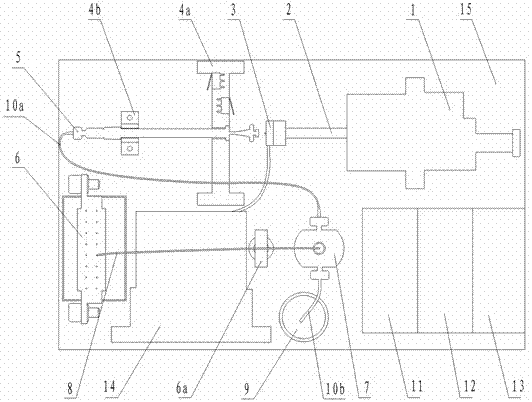

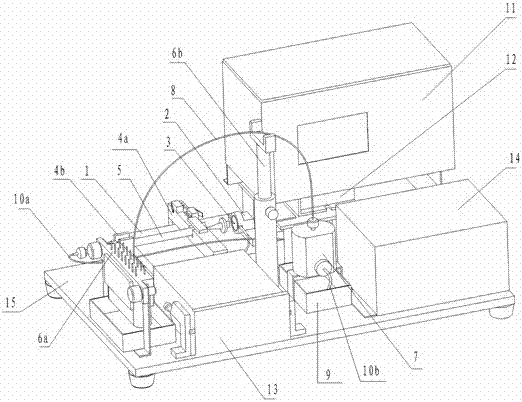

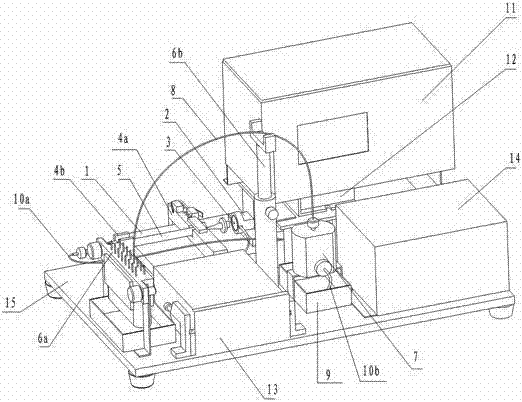

[0016] Such as figure 1 , figure 2 As shown, the present invention includes an electric translation stage 1, a push rod 2, a pressure sensor 3, a micro-sampler support, a tail end support 4a, a head support 4b, a micro-sampler 5, a capillary support 6, a capillary head base 6a, Capillary middle bracket 6b, tee 7, capillary array 8, waste liquid tank 9, sampling conduit 10a, waste discharge conduit 10b, instrument controller with panel 11, stepper motor driver 12, DC power supply 13, pressure sensor display instrument 14 and platform base 15; Electric translation platform 1, stepper motor and DC power supply 13 are installed on platform base 15 side, instrument controller 11 with panel and stepper motor driver 12 are connected with DC power supply 13, electric translation platform 1 One end of the electric translation stage 1 is connected with one end of the push rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com