Modified epoxy acrylic resin and preparation method thereof

A technology of epoxy acrylic acid and epoxy resin, which is applied in the field of polymers and resins, can solve the problems of fracture and decomposition of cross-linked network structure, affect the service life of products, and high viscosity of finished adhesives, so as to facilitate large-scale production, improve Tg value, Effect of reducing cure shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

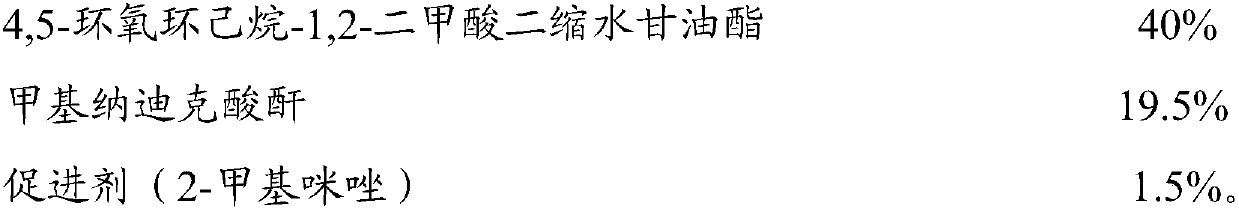

Examples

Embodiment 1

[0039] (1) Preparation of modified cycloaliphatic epoxy resin

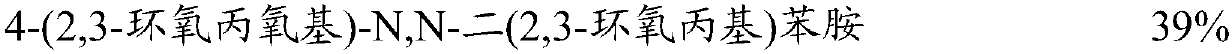

[0040] The modified cycloaliphatic epoxy resin of the present embodiment is prepared from following raw materials:

[0041] Diglycidyl 4,5-epoxycyclohexane-1,2-dicarboxylate 75%

[0042] Nadic Methyl Anhydride 24%

[0043] Accelerator (2-methylimidazole) 1%.

[0044] Its preparation method is as follows:

[0045] Add diglycidyl 4,5-epoxycyclohexane-1,2-dicarboxylate and accelerator into the reactor, stir and raise the temperature to 100±2°C, add methylnadic anhydride dropwise (with constant pressure drop funnel for dropwise addition), after 0.8h, the dropwise addition is completed (it is best to control the dropwise addition within 0.5-1.0h); The temperature is lowered to below 50°C, and the material is discharged to obtain the modified cycloaliphatic epoxy resin.

[0046] (2) Preparation of modified epoxy acrylic resin

[0047] Put 1.02mol of the modified cycloaliphatic epoxy resin prepared in step (1) (in ...

Embodiment 2

[0049] (1) Preparation of modified cycloaliphatic epoxy resin

[0050] The modified cycloaliphatic epoxy resin of the present embodiment is prepared from following raw materials:

[0051] 4-(2,3-epoxypropyloxy)-N,N-bis(2,3-epoxypropyl)aniline 75%

[0052] Nadic Methyl Anhydride 24%

[0053] Accelerator (1-cyanoethyl-2-phenylimidazole) 1%.

[0054] Its preparation method is with embodiment 1.

[0055] (2) Preparation of modified epoxy acrylic resin

[0056] Put 1.02mol of the modified cycloaliphatic epoxy resin prepared in step (1) (calculated as epoxy group) into the reactor, stir and heat up to 85±2°C, then add the catalyst (in this example, triphenylphosphine , consumption is 0.1% of modified cycloaliphatic epoxy resin and acrylic acid monomer gross weight), then dress acrylic monomer 0.96mol (methacrylic acid in the present embodiment) and polymerization inhibitor with constant pressure dropping funnel agent (in this embodiment, it is p-methoxyphenol, and the consumpti...

Embodiment 3

[0058] (1) Preparation of modified cycloaliphatic epoxy resin

[0059] The modified cycloaliphatic epoxy resin of the present embodiment is prepared from following raw materials:

[0060] 4-(2,3-epoxypropyloxy)-N,N-bis(2,3-epoxypropyl)aniline 71%

[0061] Nadic Methyl Anhydride 28%

[0062] Accelerator (2-methylimidazole) 1%.

[0063] Its preparation method is with embodiment 1.

[0064] (2) The preparation of modified epoxy acrylic resin is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com