Patents

Literature

33results about How to "High Tg value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High dirt resistance exterior wall latex paint capable of degrading haze and production process thereof

InactiveCN105462410AHigh stain resistanceEfficient degradationAntifouling/underwater paintsPaints with biocidesRaw materialChemistry

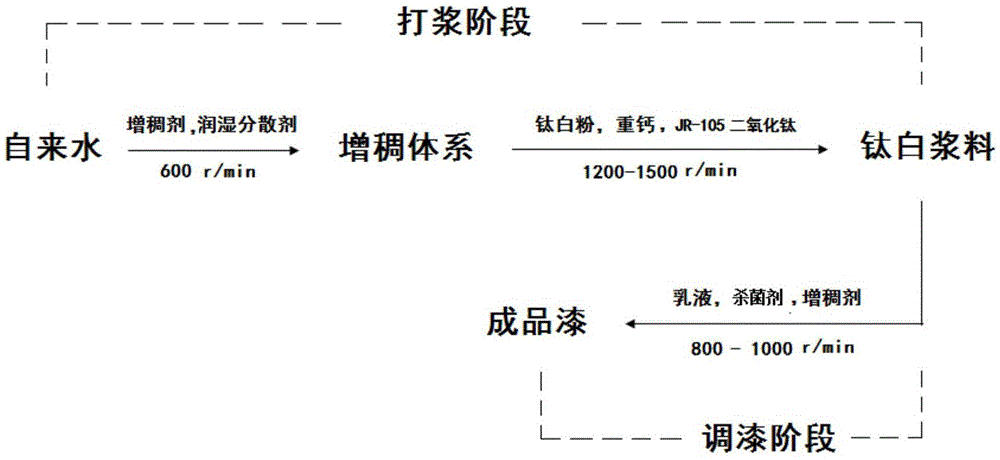

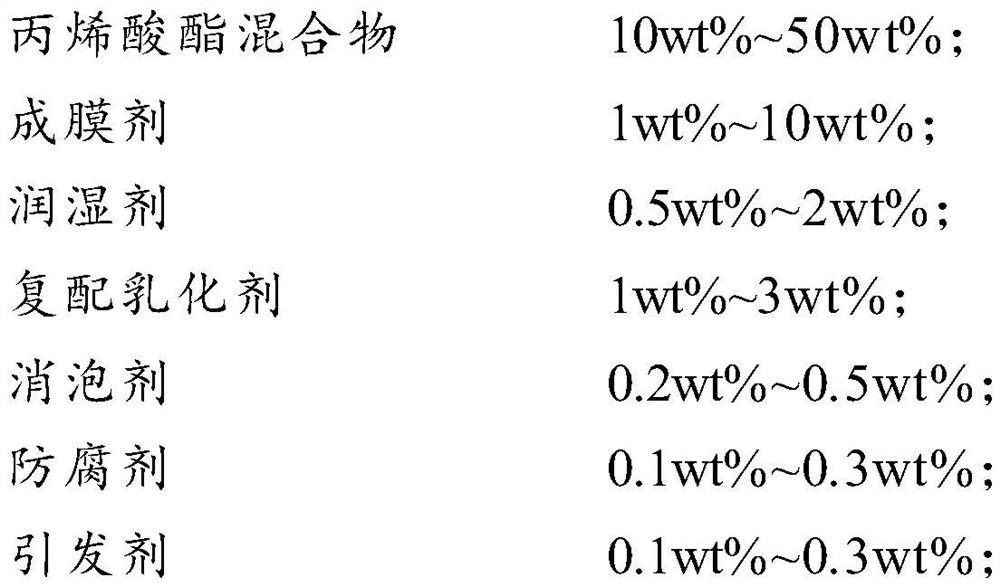

The invention discloses a high dirt resistance exterior wall latex paint capable of degrading haze and a production process thereof. The high dirt resistance exterior wall latex paint capable of degrading the haze comprises raw materials with percentage by weight: water 15.0-25.0%, alkali swelling thickening agents 0.5-1.0%, potential of hydrogen (pH) adjusting agents 0.1-0.2%, antifoaming agents 0.2-0.5%, wetting agents 0.1-0.3%, dispersing agents 0.3-0.6%, ethylene glycol 1.5-2.5%, coalescing agents 1.8-2.5%, titanium dioxide 0-20.0%, ground calcium carbonate 20.0-30.0%, titanium dioxide 0.2-0.6%, silicone modified acrylate emulsion 30.0-40.0%, bactericide 0.2-0.4% and polyurethane thickening agents 0.2-0.5%. The production process of the high dirt resistance exterior wall latex paint capable of degrading the haze comprises two stages of pulping and paint mixing. The high dirt resistance exterior wall latex paint capable of degrading the haze accords with national standard GB / T9755-2014 performance features of exterior wall latexes, and further has the functions of haze degrading and high dirt resistance.

Owner:HUBAO NEW MATERIAL TECH SHANGHAI CO LTD

Composite plating treatment process of electrolytic copper foil copper-based high polymer material

ActiveCN103866366AMeet the development trend of high radiusHigh Tg valueElectrolytic organic material coatingChemical LinkageCopper plating

The invention discloses a composite plating treatment process of an electrolytic copper foil copper-based high polymer material. According to the process, original copper foil posttreatment equipment is adopted, and an auxiliary pulse power supply is additionally arranged. The composite plating treatment process comprises the following steps: (1) carrying out acid cleaning activation by adopting sulfuric acid H2SO4 to remove oxides from the surface of a copper foil; (2) carrying out copper-based composite plating, namely forming a composite plating layer of copper and the high polymer material on the surface of the copper foil and uniformly distributing a polar high polymer organic matter on the surface of the copper foil, wherein the polar end and the crystal structure of the copper plating layer are firmly fused and the non-polar end is exposed out of the surface of the plating layer, and thus a favorable binding force is formed between the copper foil and non-metal materials such as resin in a chemical bond manner; and (3) washing with water to remove a residual solution from the surface of the copper foil so as to prevent copper foil oxidation, and then entering into the subsequent processing procedure. According to the process disclosed by the invention, the roughness of the surface of the copper foil can be adjusted at will according to the development demands of the electronic industry, the copper foil with double smooth surfaces is produced, and the development trends of exquisite lines, high Tg value and high flexibility of a printed circuit board are met.

Owner:JIANGSU MINGFENG ELECTRONIC MATERIALS CO LTD

Resin composition and semi-flexible copper-clad plate made from resin composition

ActiveCN103571157AHigh bonding strengthHigh peel strengthLaminationLamination apparatusDimer acidCopper

The invention provides a resin composition and a semi-flexible copper-clad plate prepared from the resin composition. The resin composition comprises the following components in parts by weight of: 60-70 parts of phosphorus-containing epoxy resin, 5-10 parts of novolac epoxy resin, 10-20 parts of bisphenol A epoxy resin modified through dimer acid addition, 10-20 parts of polyurethane modified epoxy resin and 2-4 parts of dicyandiamide. The resin composition is characterized in that the polyurethane modified epoxy resin and the bisphenol A epoxy resin modified through dimer acid addition are introduced so that the tenacity of the system is enhanced and the influence on the Tg of the system is low; as a result, the system is capable of achieving the balance between flexibility and Tg; the semi-flexible copper-clad plate made from resin composition has more excellent flexibility than common FR-4, and is capable of keeping a high Tg value.

Owner:GUANGDONG SHENGYI SCI TECH

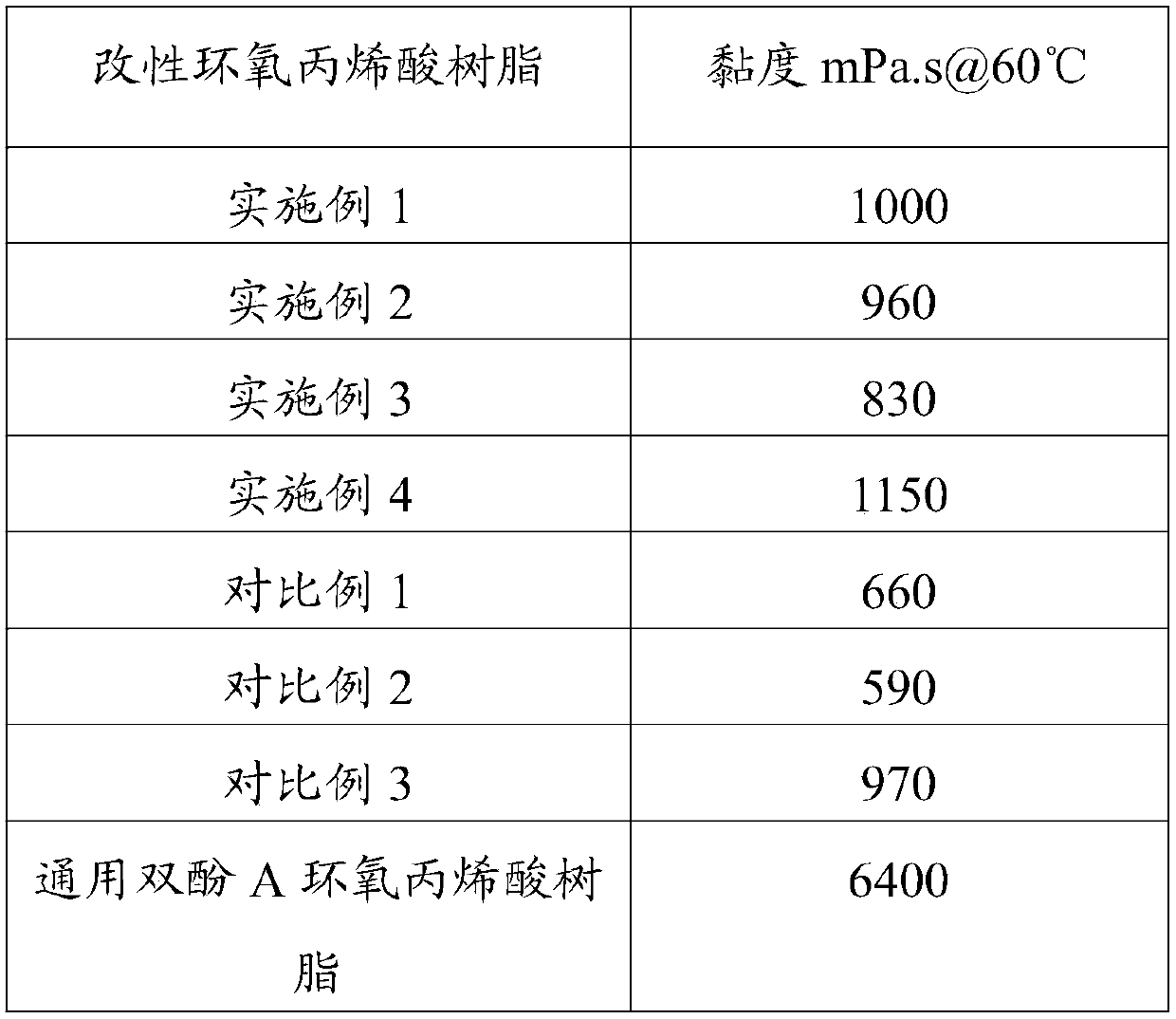

Modified epoxy acrylic resin and preparation method thereof

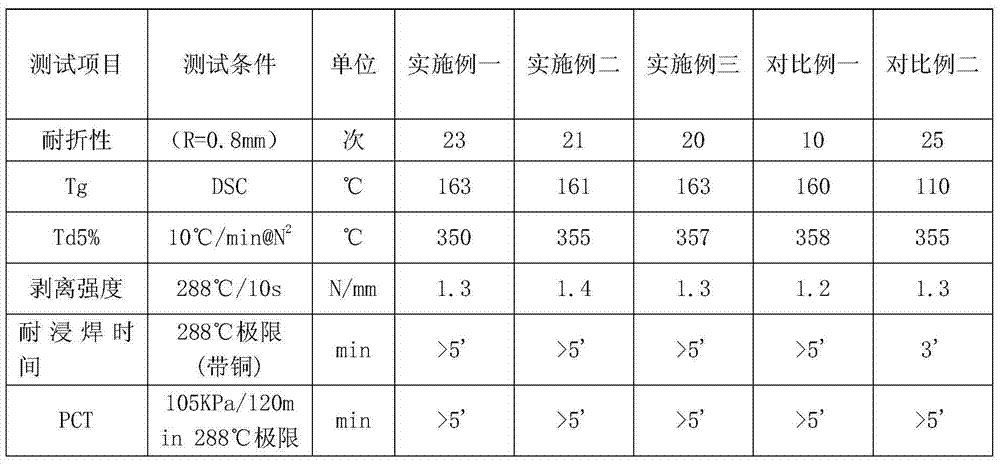

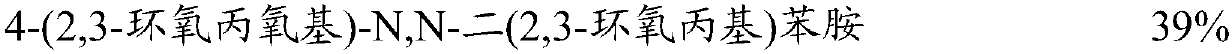

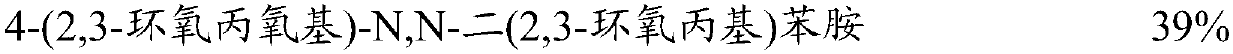

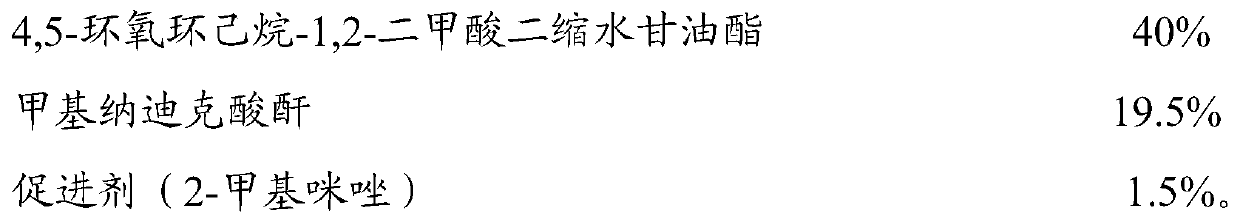

The invention relates to modified epoxy acrylic resin and a preparation method thereof. The modified epoxy acrylic resin is mainly prepared from modified cycloaliphatic epoxy resin, acrylic monomers,a catalyst and a polymerization inhibitor, wherein the modified cycloaliphatic epoxy resin is prepared from raw materials in percentage by weight as follows: 65%-85% of polyfunctional cycloaliphatic epoxy resin, 14%-34% of methyl nadic anhydride and 0.1%-3% of a promoter, wherein the mole ratio of epoxy groups to acrylic monomers in the modified cycloaliphatic epoxy resin is 1:(0.7-1.5). The modified epoxy acrylic resin has good heat resistance, can reduce curing shrinkage and has lower viscosity. With addition of the modified epoxy acrylic resin, the Tg value of a UV curing product can be greatly increased, and the modified epoxy acrylic resin has better market prospects.

Owner:广州日高新材料科技有限公司

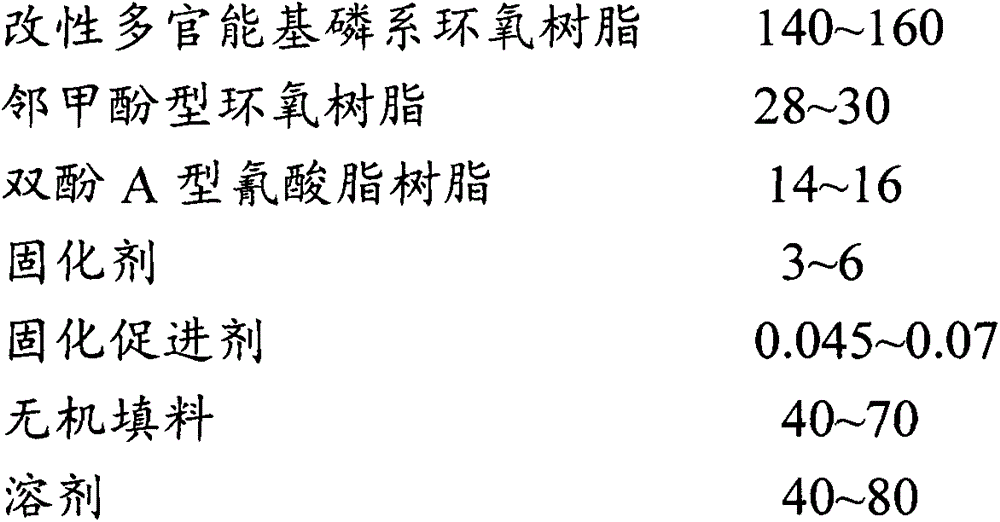

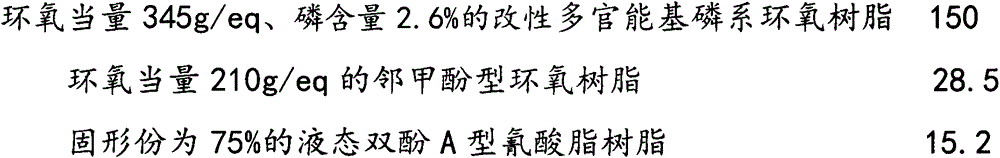

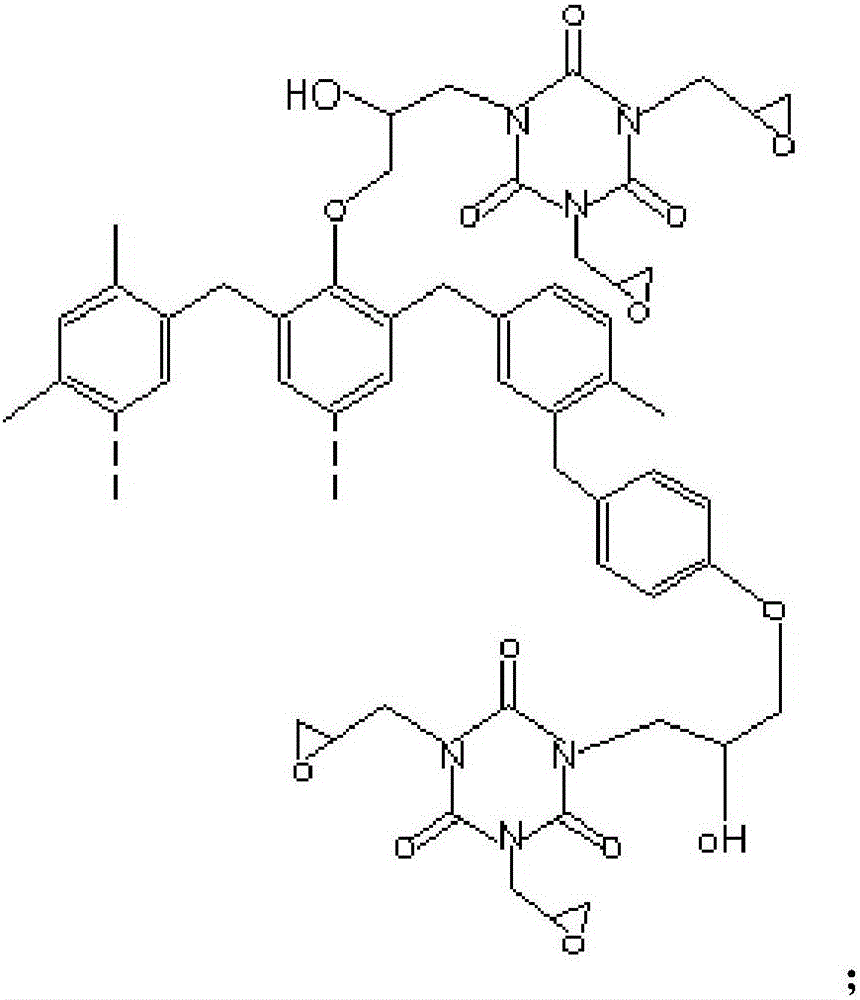

Making method for high TG halogen-free LOW Dk/Df copper-clad plate

InactiveCN104002525AHigh glass transition temperatureImprove insulation performanceLamination ancillary operationsSynthetic resin layered productsDecompositionBisphenol A

The invention discloses a making method for a high TG halogen-free LOW Dk / Df copper-clad plate. The method comprises the steps of: 1. glue solution preparation: adopting a modified multifunctional phosphorous series epoxy resin / amine curing system, adding o-cresol epoxy resin and bisphenol A cyanate ester resin, then adding a curing agent, a curing accelerator and an inorganic filler; taking any one of or a composition of over one of acetone, propylene glycol methyl ether acetate and butanone as the solvent to prepare the glue solution; 2. cementing: using an NE glass fiber cloth with a low dielectric constant as a reinforcing material and conducting soaking in the prepared glue solution, and making a B stage prepreg by a vertical cementing machine; and 3. superimposition and hot pressing: superimposing the well cemented prepreg, and carrying out compression moulding by a vacuum hot pressing machine. The halogen-free copper-clad plate prepared by the method provided by the invention has a TG value over 170DEG C, and also has a low dielectric constant and dielectric loss special performance, a Df value lower than 3.8 and a Df value lower than 0.07, thus fully meeting the requirements for making high frequency and high speed circuit boards. At the same time, the high TG halogen-free LOW Dk / Df copper-clad plate also has excellent heat resistance, hot cracking decomposition temperature and other excellent performance, etc.

Owner:NANTONG RODA ELECTRON

Technology for producing high-frequency microwave copper-clad plate with dielectric constant of 3.4

InactiveCN103818054ASatisfy high frequency communicationFulfil requirementsSynthetic resin layered productsLaminationCopper foilPolymer chemistry

The invention discloses a technology for producing a high-frequency microwave copper-clad plate with a dielectric constant of 3.4. The technology comprises the following steps: dissolving modifying polyphenyl ether resin, dip-coating a glass fabric, stacking with a copper foil, laminating at high temperature and high pressure, testing performance and cutting packages, wherein a crosslinked body with an appropriate molecular weight is formed by the allylation modification of the polyphenyl ether resin, then the glass fiber fabric is dipped in the crosslinked body to form a prepreg, and the prepreg is laminated together with the copper foil to produce the high-frequency copper-clad plate.

Owner:TONGLING HAORONG ELECTRONICS TECH

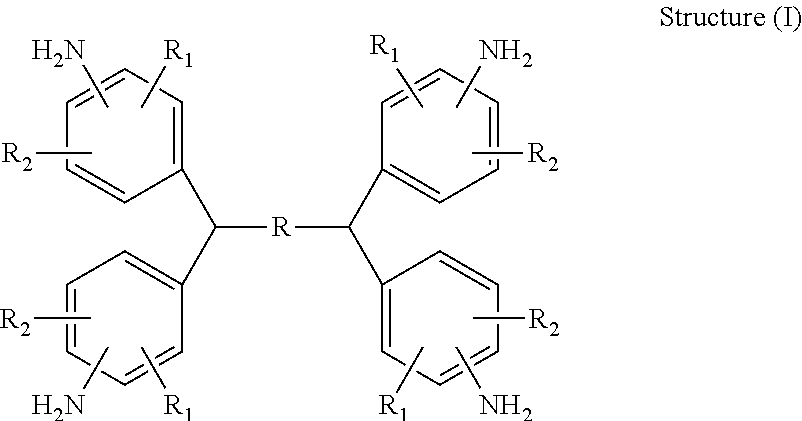

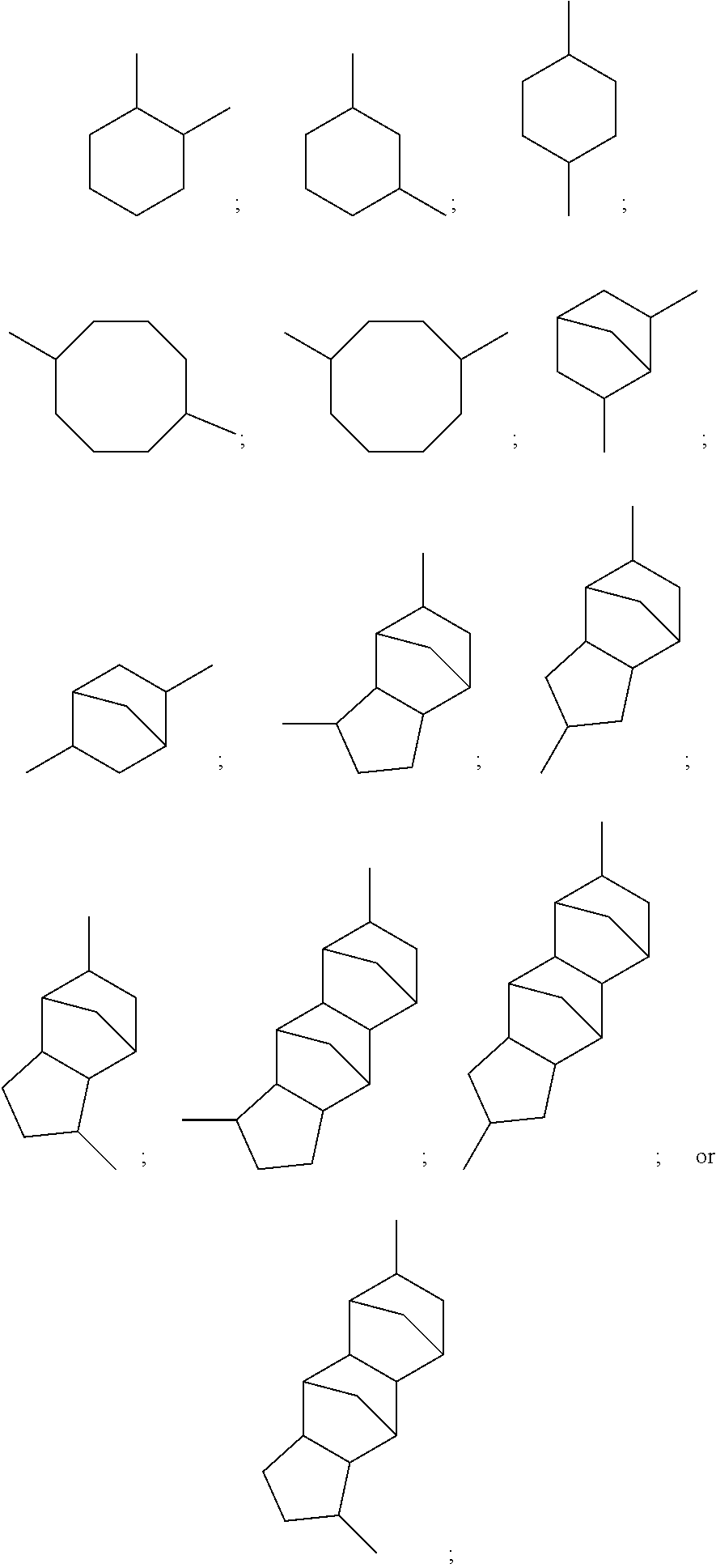

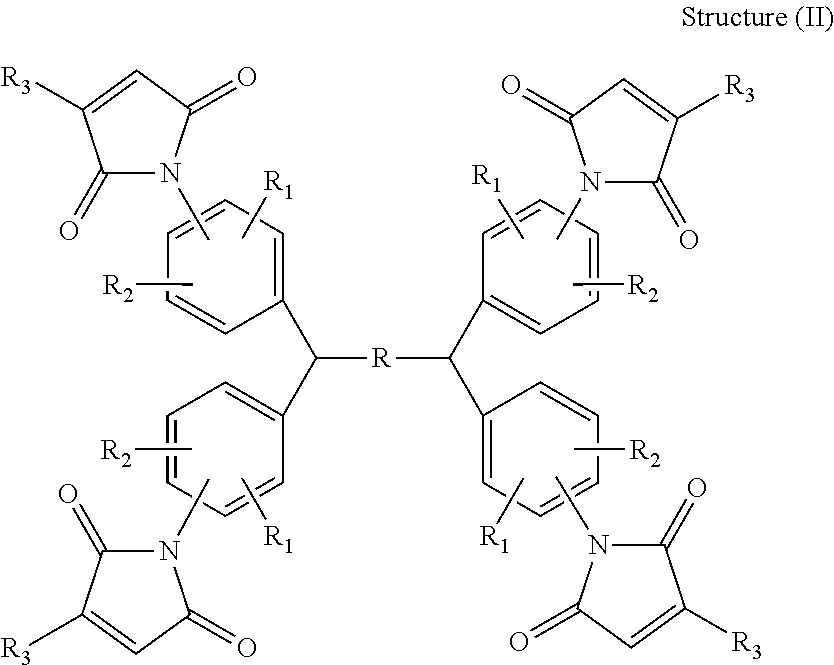

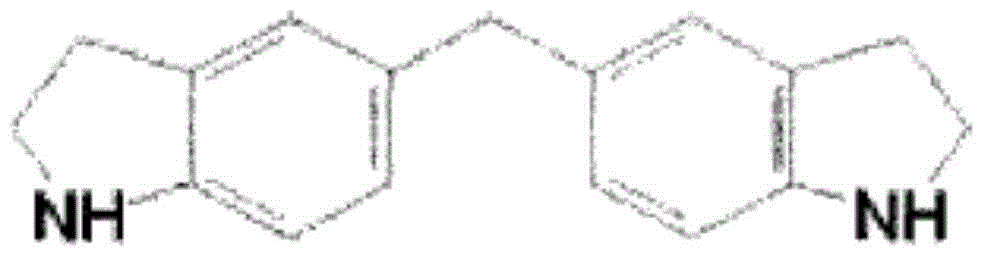

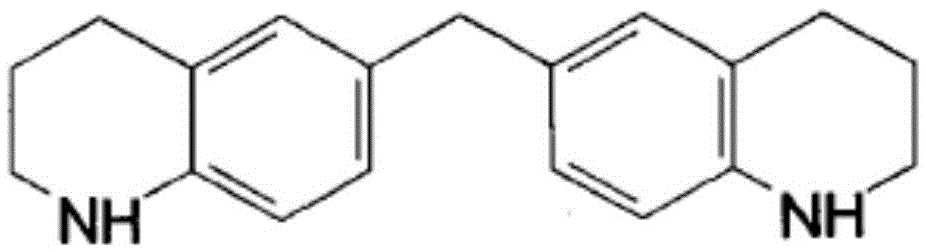

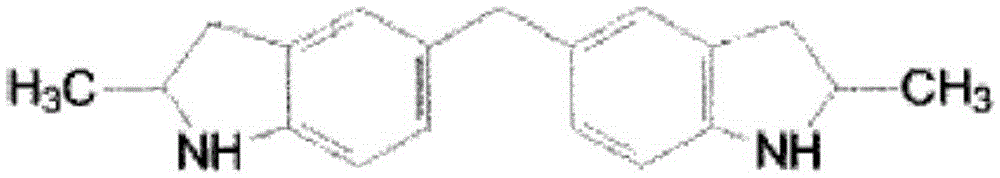

Hardeners for thermosettable resin compositions

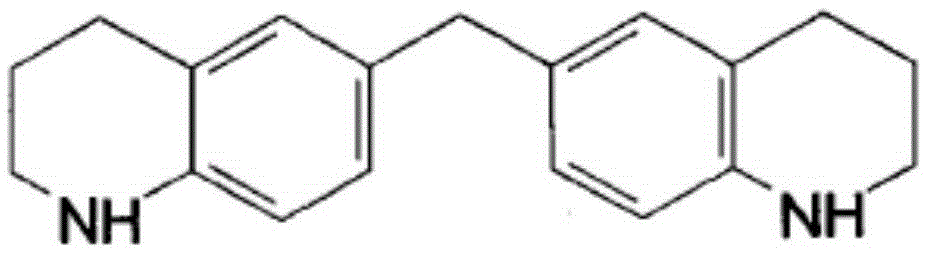

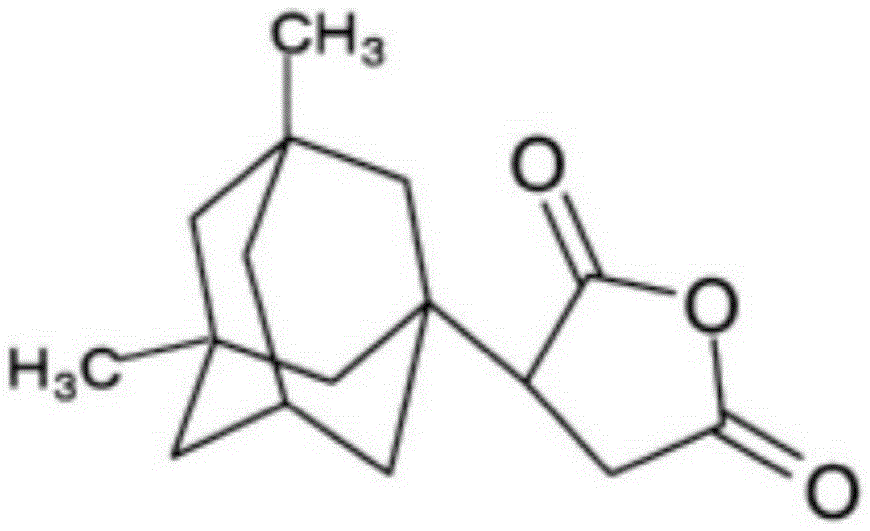

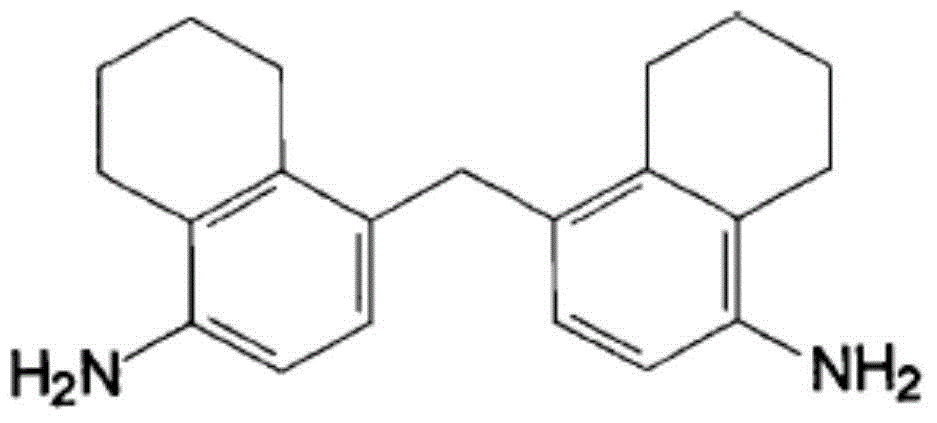

ActiveUS20130066026A1Improved thermo-mechanical behaviorHigh Tg valueOrganic chemistryOrganic compound preparationPolymer scienceAniline

A multifunctional aromatic amine hardener composition including the reaction condensation product of (a) at least one aniline and (b) at least one non-aromatic cyclic dicarboxaldehyde; and a reactive thermosettable resin composition including (i) at least one multifunctional aromatic amine hardener composition curing agent, (ii) at least one thermoset resin, and optionally (c) at least one catalyst; and a process for preparing a thermoset product from the thermosettable composition. The hardener composition above and a thermoset resin may be used to prepare a thermoset product with improved thermo-mechanical behavior.

Owner:BLUE CUBE IP

Making method of halogen-free flame retardant copper clad laminate

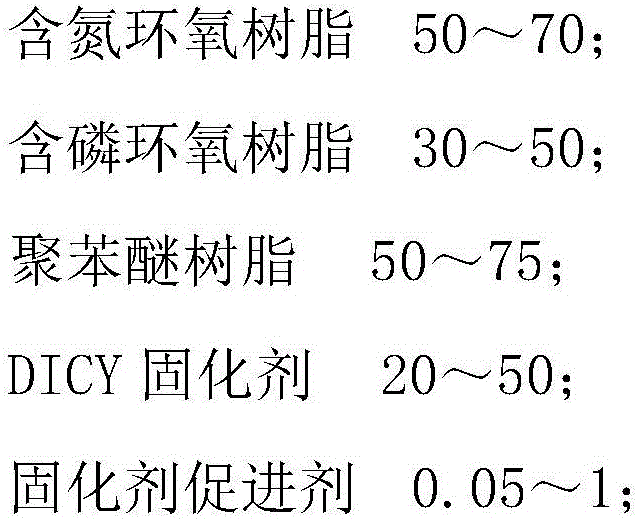

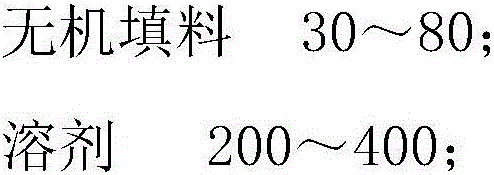

InactiveCN106240127AImprove heat resistanceHigh Tg valueNon-macromolecular adhesive additivesLayered product treatmentEpoxySolvent

The invention discloses a making method of a halogen-free flame retardant copper clad laminate. The steps include: glue preparation: mixing 50-70 parts by weight of nitrogen-containing epoxy resin, 30-50 parts by weight of phosphorus-containing epoxy resin, 50-75 parts by weight of polyphenylene ether resin, 20-50 parts by weight of a DICY curing agent, 0.05-1 part by weight of a curing agent accelerator, 30-80 parts by weight of inorganic filler, and 200-400 parts by weight of a solvent evenly to prepare a glue solution; gluing; superposition and pressing. The method provided by the invention adopts halogen-free nitrogen-containing epoxy resin and phosphorus-containing epoxy resin as the matrix resin, adds polyphenylene ether resin with high heat resistance and excellent electrical properties, then adds the DICY curing agent, the curing agent accelerator, the inorganic filler and the solvent, and carries out baking, superposition and pressing molding. The pressing molded copper clad laminate has a high Tg value and good electrical properties, and has flame retardant performance up to the V-0 level (UL94 standard).

Owner:重庆德凯实业股份有限公司

Triphenyl-based organic compound, organic electroluminescent material and device

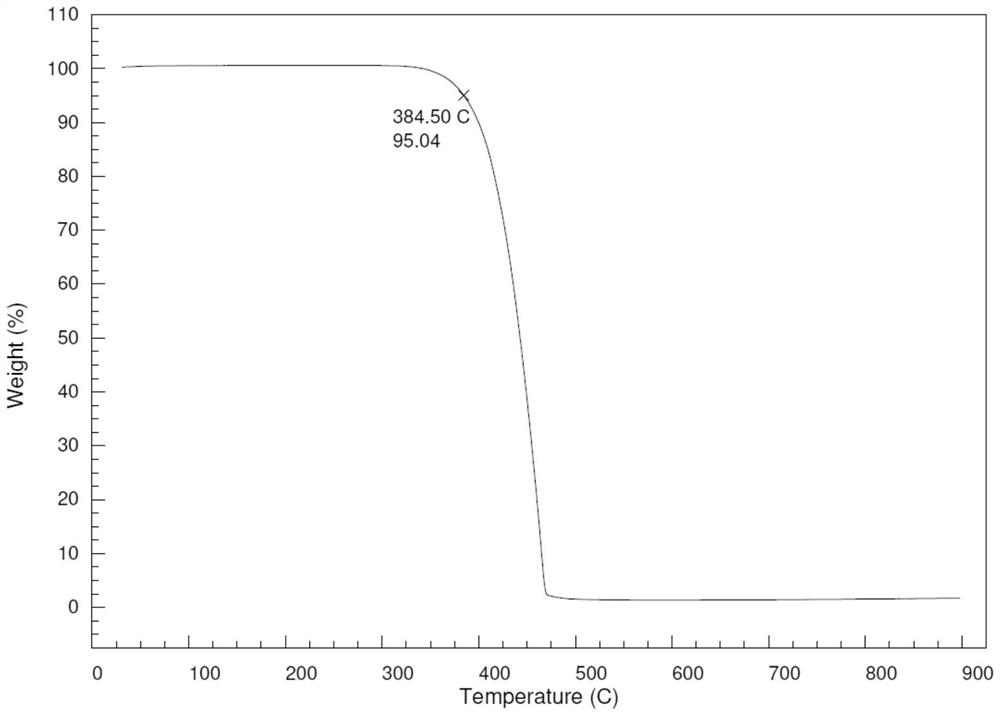

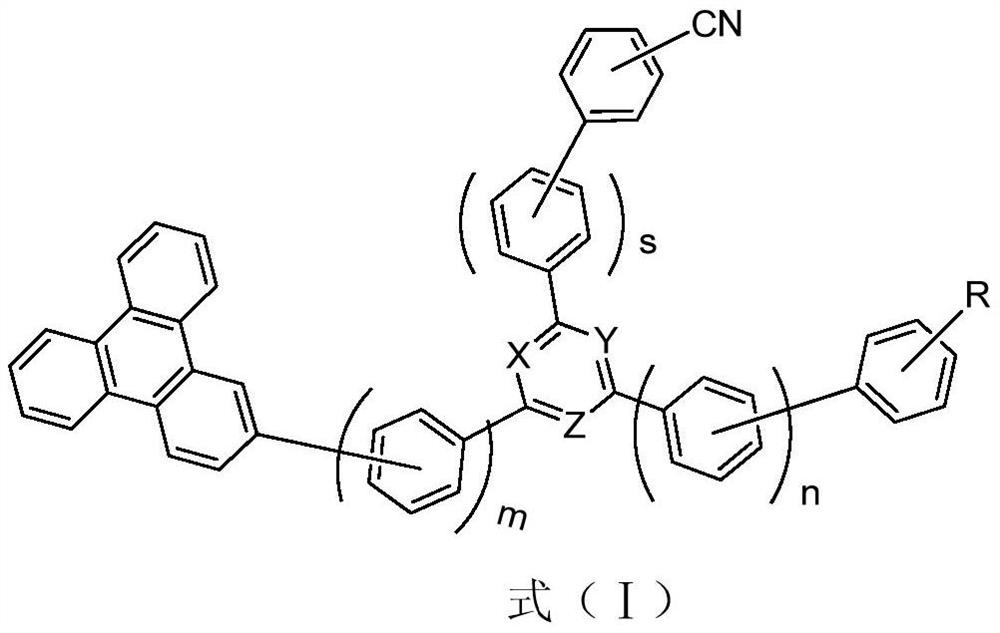

ActiveCN112851591AHigh electron mobilityImprove thermal stabilityOrganic chemistrySolid-state devicesSimple Organic CompoundsElectron transporting layer

The invention discloses a triphenyl-based organic compound, an organic electroluminescent material and a device, the structural formula of the triphenyl-based organic compound is shown in the following formula (I): R is any one of hydrogen, deuterium, halogen atom, cyano, substituted or unsubstituted C1-C5 alkyl, substituted or unsubstituted C6-C30 aromatic group, and substituted or unsubstituted C5-C30 heteroaromatic group; X, Y and Z are respectively and independently CH or N, and at least one of X, Y and Z is N; m, s and n are respectively and independently 0 or 1; the organic compound is used as the electron transport layer so that the driving voltage of the device can be greatly reduced, the consumption of electric energy is greatly reduced, the luminous efficiency is remarkably improved, and in addition, the service life of the organic light-emitting device is remarkably prolonged by reducing the driving voltage.

Owner:NANJING TOPTO MATERIALS CO LTD

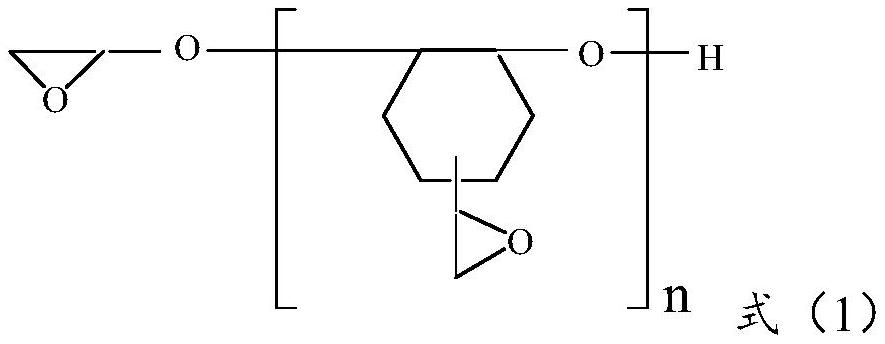

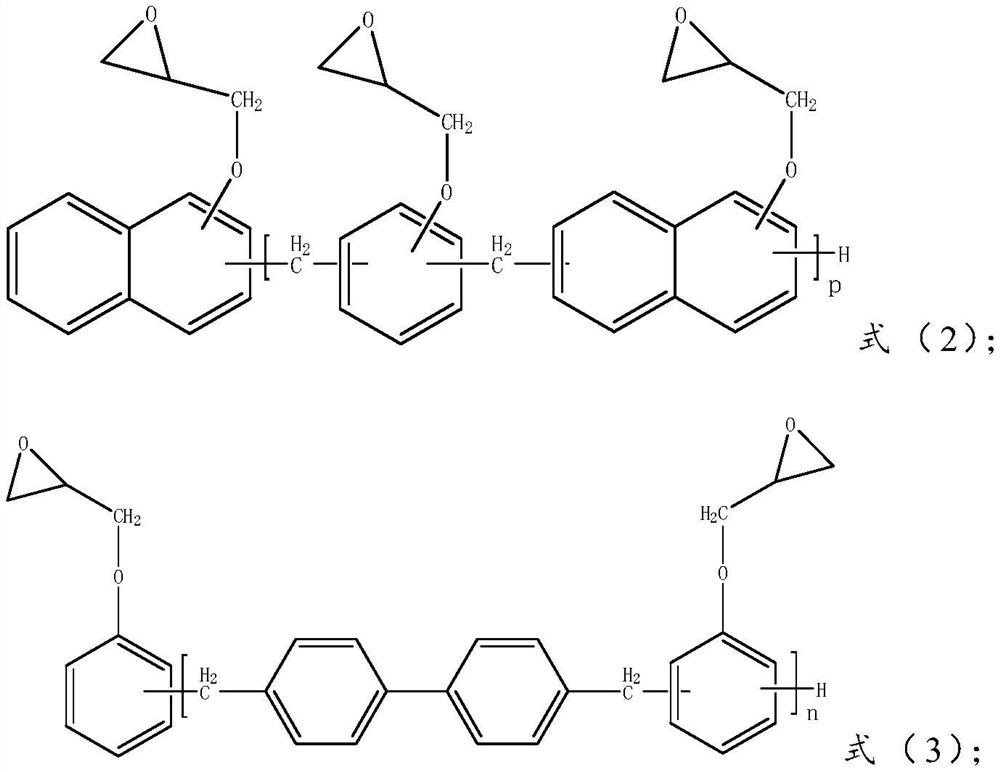

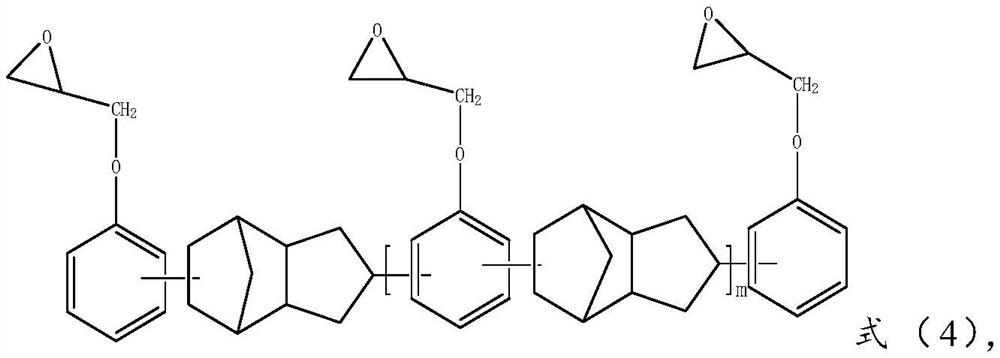

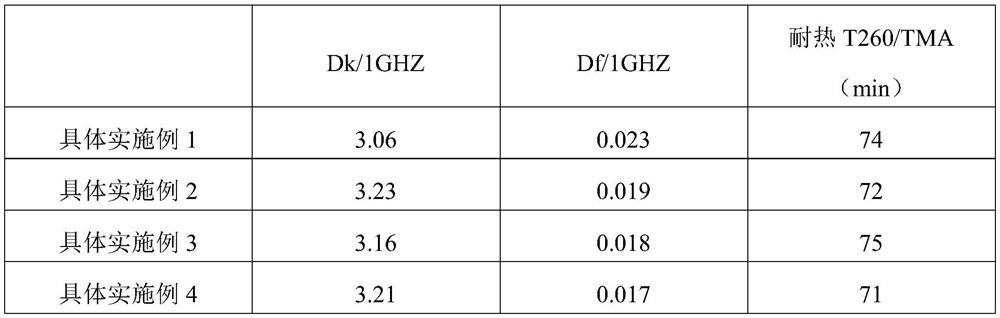

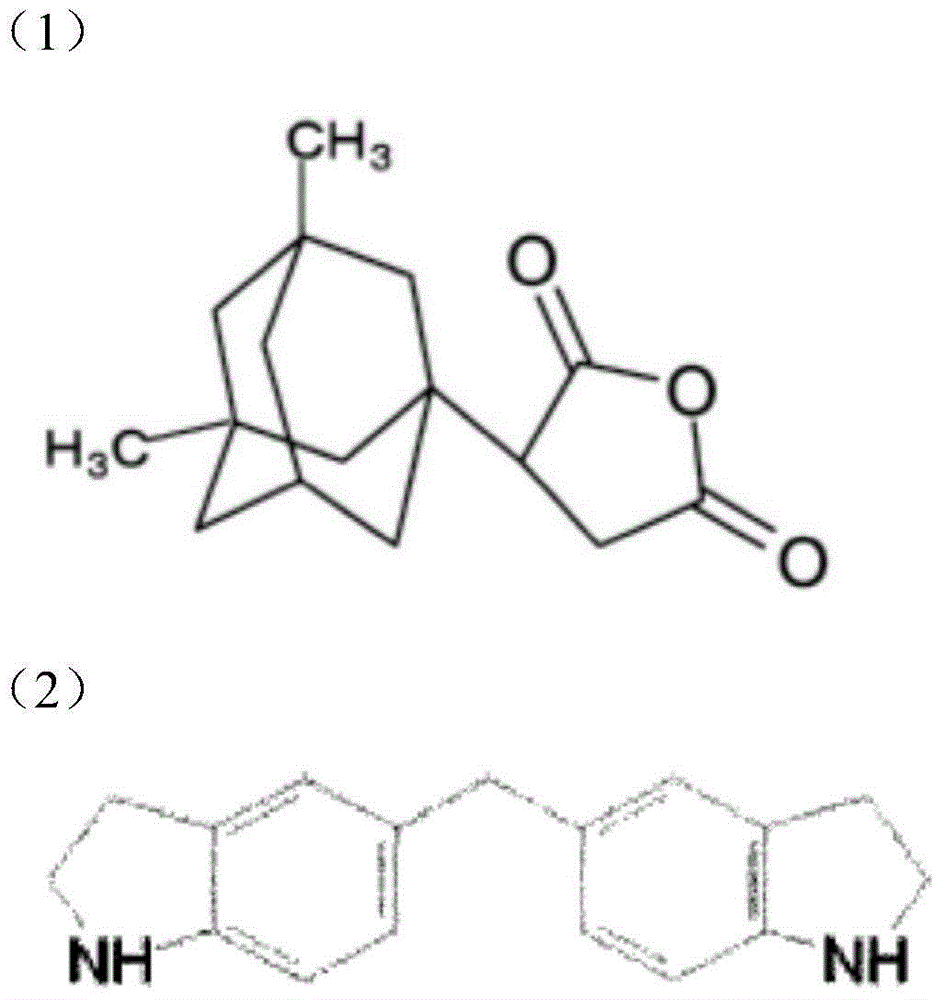

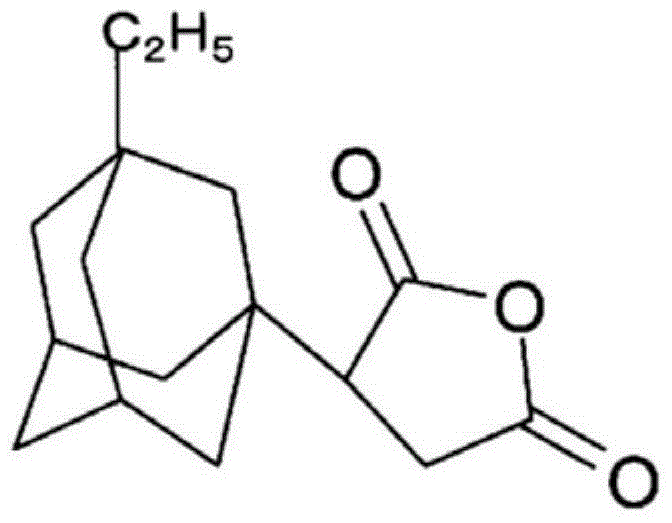

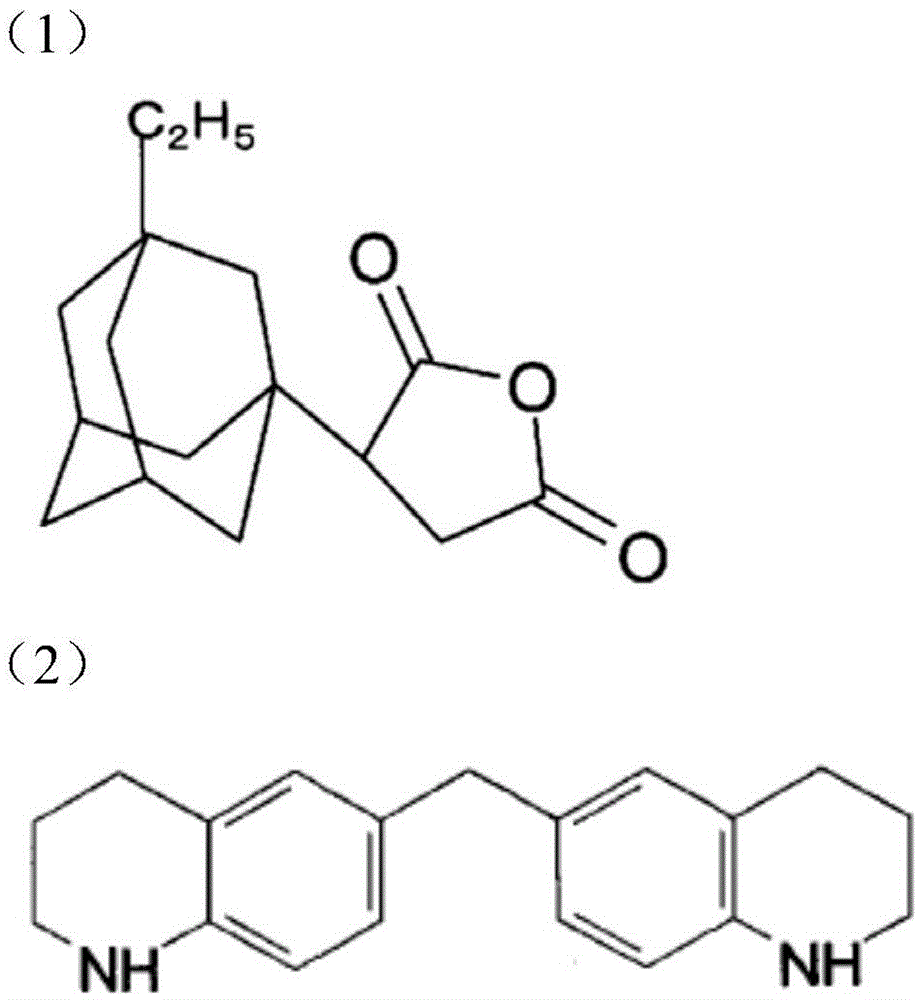

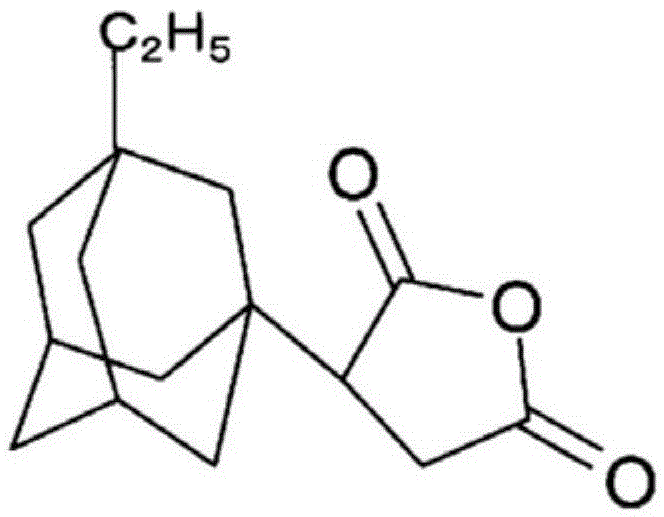

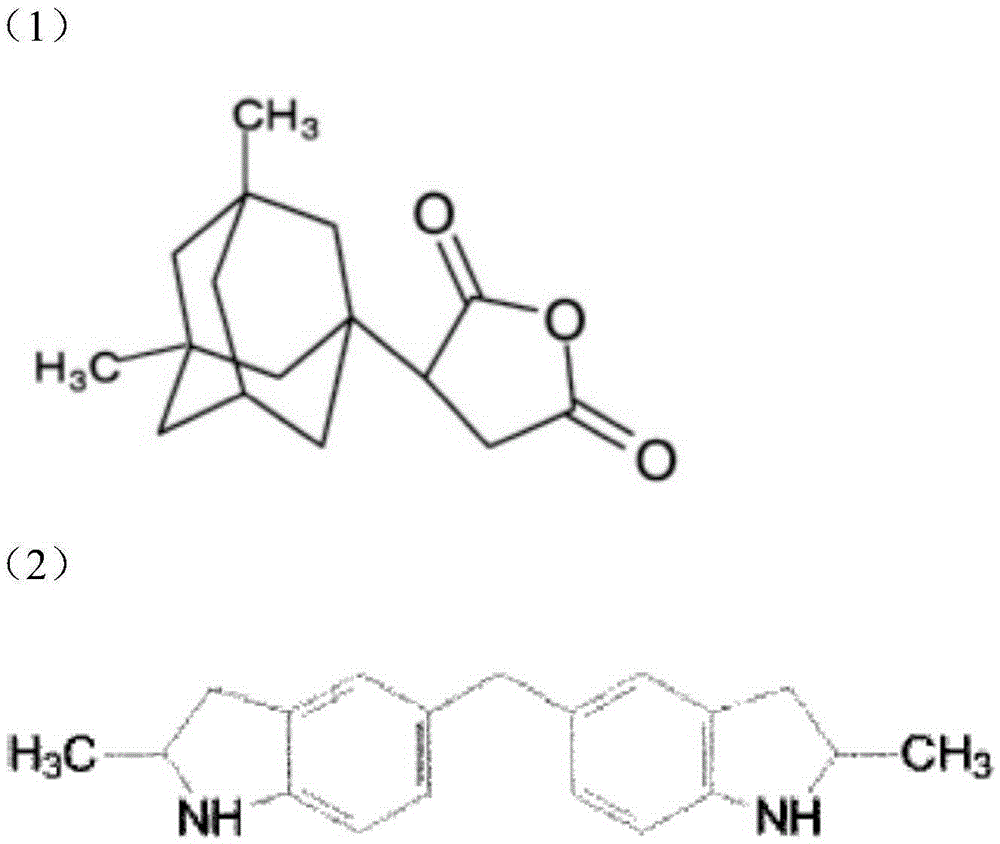

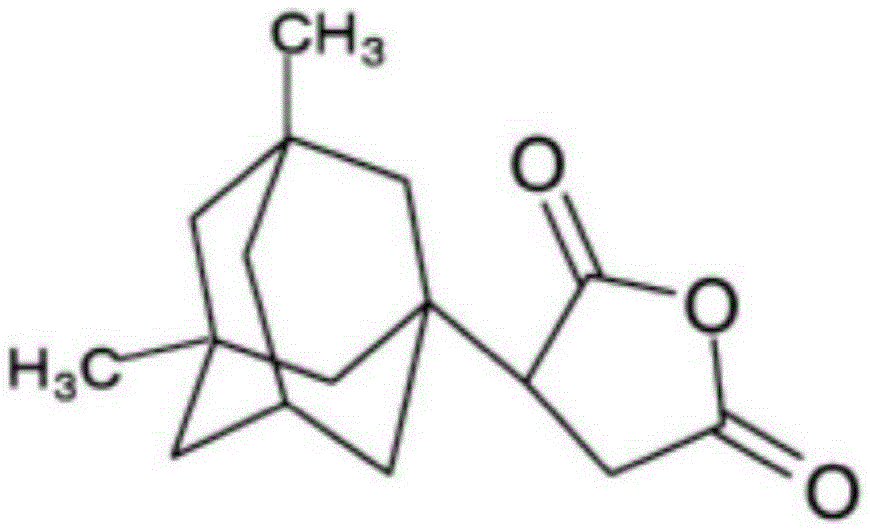

Resin composition and application

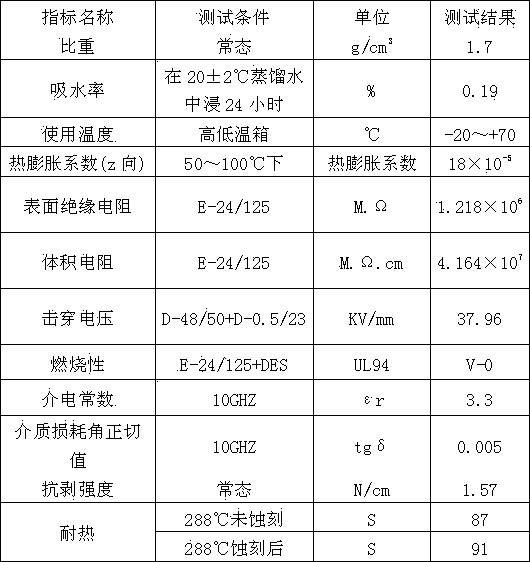

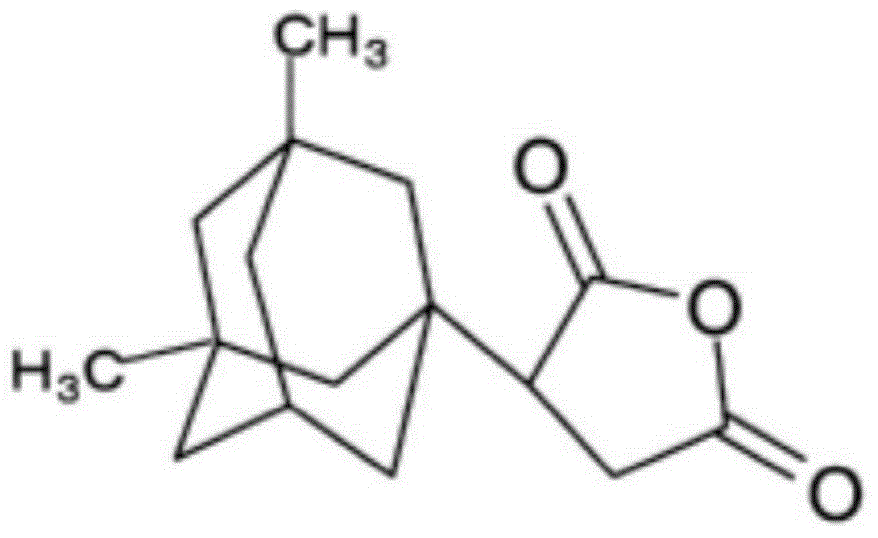

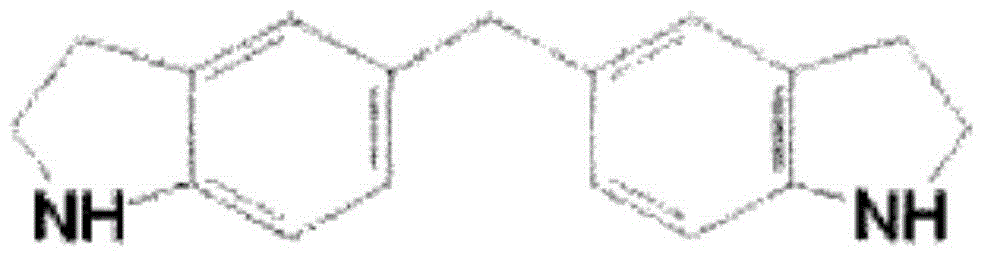

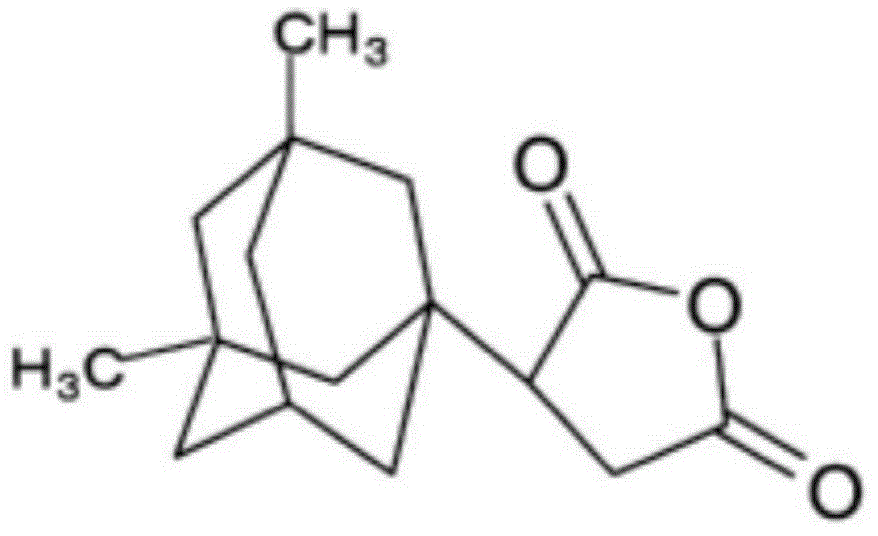

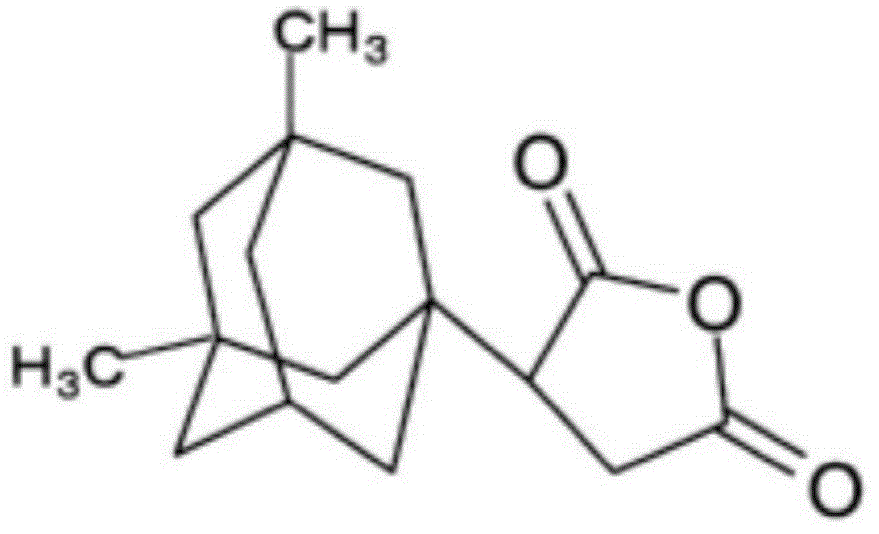

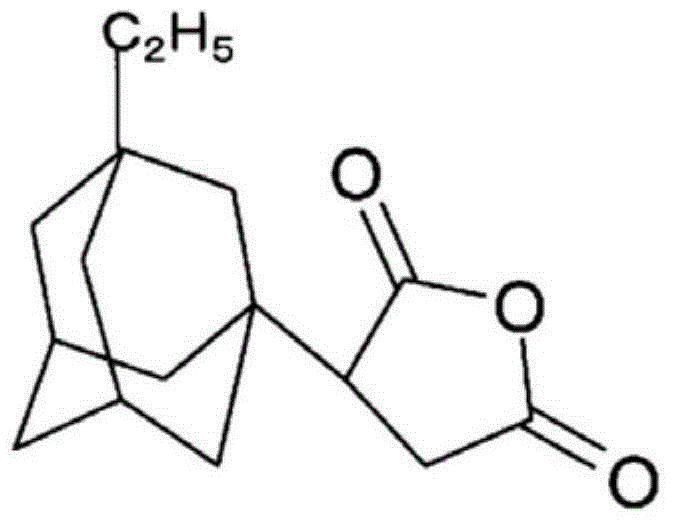

PendingCN114292492AHigh CTI valueHigh Tg valueSynthetic resin layered productsCircuit susbtrate materialsEpoxyImide

The invention provides a resin composition, which comprises the following components in parts by weight: 5 to 30 parts of alicyclic epoxy resin; 10-60 parts by weight of aromatic epoxy resin; 5 to 60 parts by weight of bismaleimide resin; wherein the molecular structural formula of the alicyclic epoxy resin is shown as a formula (1); in the formula (1), n is an integer of 1-10. The resin composition contains aliphatic epoxy resin and bismaleimide resin with specific structures, and prepregs and laminated boards prepared from the resin composition have the characteristics of high CTI value and Tg value, excellent humidity and heat resistance, low water absorption, excellent flame retardance and the like.

Owner:常熟生益科技有限公司

Halogen-free phosphorus-containing low-dielectric copper-clad plate and preparation method thereof

PendingCN112248577AHigh Tg valueImprove heat resistanceLamination ancillary operationsLaminationHigh heatCorrosion

The invention discloses a halogen-free phosphorus-containing low-dielectric copper-clad plate and a preparation method thereof, and belongs to the technical field of electronic materials and preparation thereof. According to the invention, by selecting the components and proportion of the resin glue solution and selecting the glass fiber cloth, the copper-clad plate has excellent properties such as high heat resistance, high flame resistance, low dielectric constant, low dielectric loss and the like, so that the overall safety coefficient of the product is greatly improved, and the troubles and hidden dangers caused by poor electrical insulativity in the PCB processing process are avoided; meanwhile, the requirements of the halogen-free process of high-order products can be comprehensivelymet in the aspects of halogen-free flame retardance, expansion coefficient, CAF resistance, corrosion resistance and the like, and the halogen-free process can be completely suitable for the halogen-free process of high-order multilayer boards with 20 layers or even more than 30 layers. According to the invention, the issues in the aspects of practical application and processing of downstream PCBs are researched in a targeted mode, performance balance is fully considered, and performance application of the board in the aspects is brought into full play to the best.

Owner:江苏联鑫电子工业有限公司

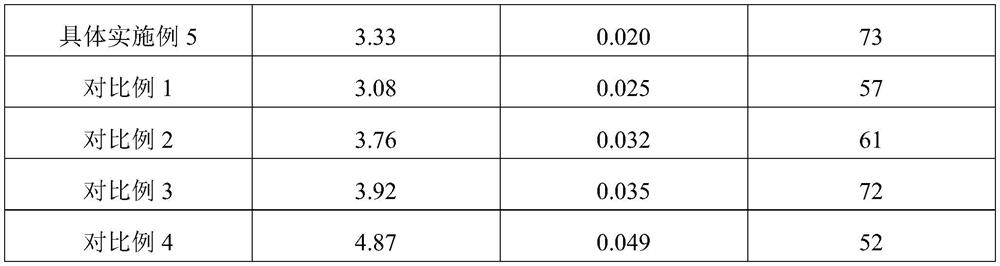

High-barrier and high-water-resistance water-based acrylic emulsion and preparation method thereof

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

Modified epoxy acrylic resin and preparation method thereof

The invention relates to modified epoxy acrylic resin and a preparation method thereof. The modified epoxy acrylic resin is mainly prepared from modified cycloaliphatic epoxy resin, acrylic monomers,a catalyst and a polymerization inhibitor, wherein the modified cycloaliphatic epoxy resin is prepared from raw materials in percentage by weight as follows: 65%-85% of polyfunctional cycloaliphatic epoxy resin, 14%-34% of methyl nadic anhydride and 0.1%-3% of a promoter, wherein the mole ratio of epoxy groups to acrylic monomers in the modified cycloaliphatic epoxy resin is 1:(0.7-1.5). The modified epoxy acrylic resin has good heat resistance, can reduce curing shrinkage and has lower viscosity. With addition of the modified epoxy acrylic resin, the Tg value of a UV curing product can be greatly increased, and the modified epoxy acrylic resin has better market prospects.

Owner:广州日高新材料科技有限公司

Electrolytic Copper Foil Copper-Based Polymer Material Composite Plating Process

ActiveCN103866366BMeet the development trend of high radiusHigh Tg valueElectrolytic organic material coatingChemical LinkageCopper plating

The invention discloses a composite plating treatment process of an electrolytic copper foil copper-based high polymer material. According to the process, original copper foil posttreatment equipment is adopted, and an auxiliary pulse power supply is additionally arranged. The composite plating treatment process comprises the following steps: (1) carrying out acid cleaning activation by adopting sulfuric acid H2SO4 to remove oxides from the surface of a copper foil; (2) carrying out copper-based composite plating, namely forming a composite plating layer of copper and the high polymer material on the surface of the copper foil and uniformly distributing a polar high polymer organic matter on the surface of the copper foil, wherein the polar end and the crystal structure of the copper plating layer are firmly fused and the non-polar end is exposed out of the surface of the plating layer, and thus a favorable binding force is formed between the copper foil and non-metal materials such as resin in a chemical bond manner; and (3) washing with water to remove a residual solution from the surface of the copper foil so as to prevent copper foil oxidation, and then entering into the subsequent processing procedure. According to the process disclosed by the invention, the roughness of the surface of the copper foil can be adjusted at will according to the development demands of the electronic industry, the copper foil with double smooth surfaces is produced, and the development trends of exquisite lines, high Tg value and high flexibility of a printed circuit board are met.

Owner:JIANGSU MINGFENG ELECTRONIC MATERIALS CO LTD

A kind of resin composition and semi-flexible copper-clad laminate made of the same

ActiveCN103571157BHigh bonding strengthHigh peel strengthLaminationLamination apparatusCopperDimer acid

The invention provides a resin composition and a semi-flexible copper-clad plate prepared from the resin composition. The resin composition comprises the following components in parts by weight of: 60-70 parts of phosphorus-containing epoxy resin, 5-10 parts of novolac epoxy resin, 10-20 parts of bisphenol A epoxy resin modified through dimer acid addition, 10-20 parts of polyurethane modified epoxy resin and 2-4 parts of dicyandiamide. The resin composition is characterized in that the polyurethane modified epoxy resin and the bisphenol A epoxy resin modified through dimer acid addition are introduced so that the tenacity of the system is enhanced and the influence on the Tg of the system is low; as a result, the system is capable of achieving the balance between flexibility and Tg; the semi-flexible copper-clad plate made from resin composition has more excellent flexibility than common FR-4, and is capable of keeping a high Tg value.

Owner:GUANGDONG SHENGYI SCI TECH

Curing agent composition

Owner:华玉叶

Lead-free copper clad laminate with high toughness and high tg and preparation method thereof

ActiveCN109719967BIncrease crosslink densityImprove heat resistanceDomestic articlesFlat articlesGlass fiberPolymer science

The invention discloses a lead-free copper clad laminate with high toughness and high Tg and a preparation method thereof. The aliphatic or alicyclic diisocyanate is used to modify a liquid bisphenol A epoxy resin to obtain an isocyanate modified epoxy resin. Epichlorohydrin epoxidizes bisphenol A phenolic resin to obtain bisphenol A phenolic epoxy resin, which has the characteristics of high crosslinking density and good heat resistance. Phenol A and silica are prepared to form resin glue for glass fiber cloth impregnation, the resin glue is coated on glass fiber cloth and then dried, and then a plurality of glass fiber cloth impregnated sheets are stacked on one side of the glass fiber cloth. Or double-sided clad copper foil, and finally get high toughness and high Tg lead-free copper clad laminate after hot pressing and cooling. Performance is very good.

Owner:江苏联鑫电子工业有限公司

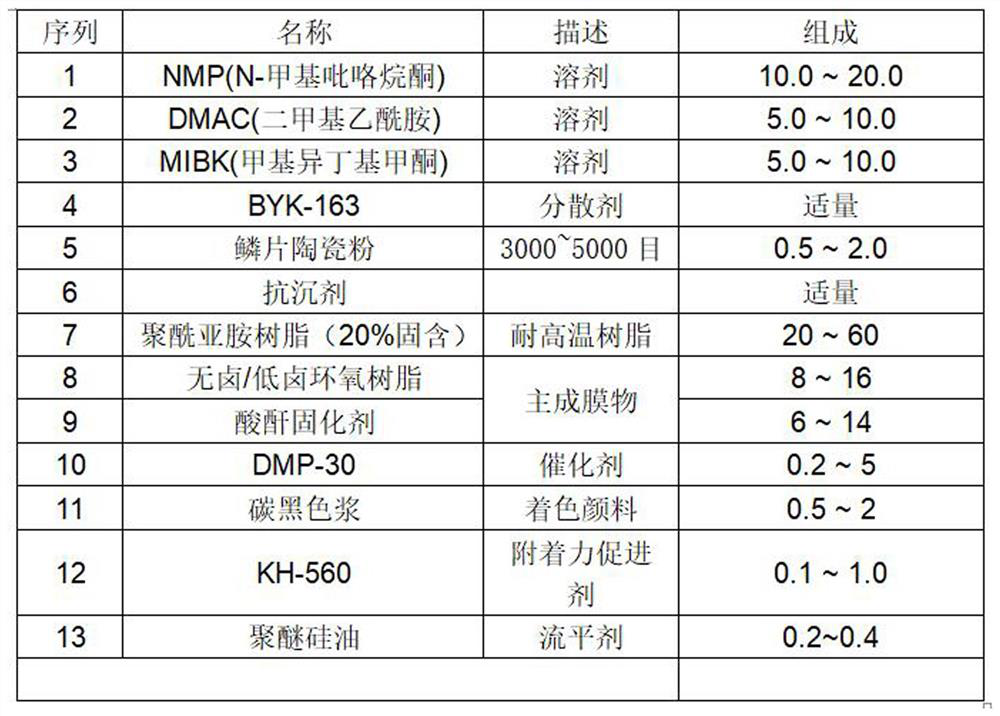

A high-temperature, high-humidity, high-pressure, acid-alkali-resistant, high-adhesion roll-spray coating

ActiveCN112831270BHigh Tg valueVolatile fastFireproof paintsEpoxy resin coatingsSpray coatingFirming agent

Owner:上海创林新材料技术有限公司

Curing agent composition

Owner:华玉叶

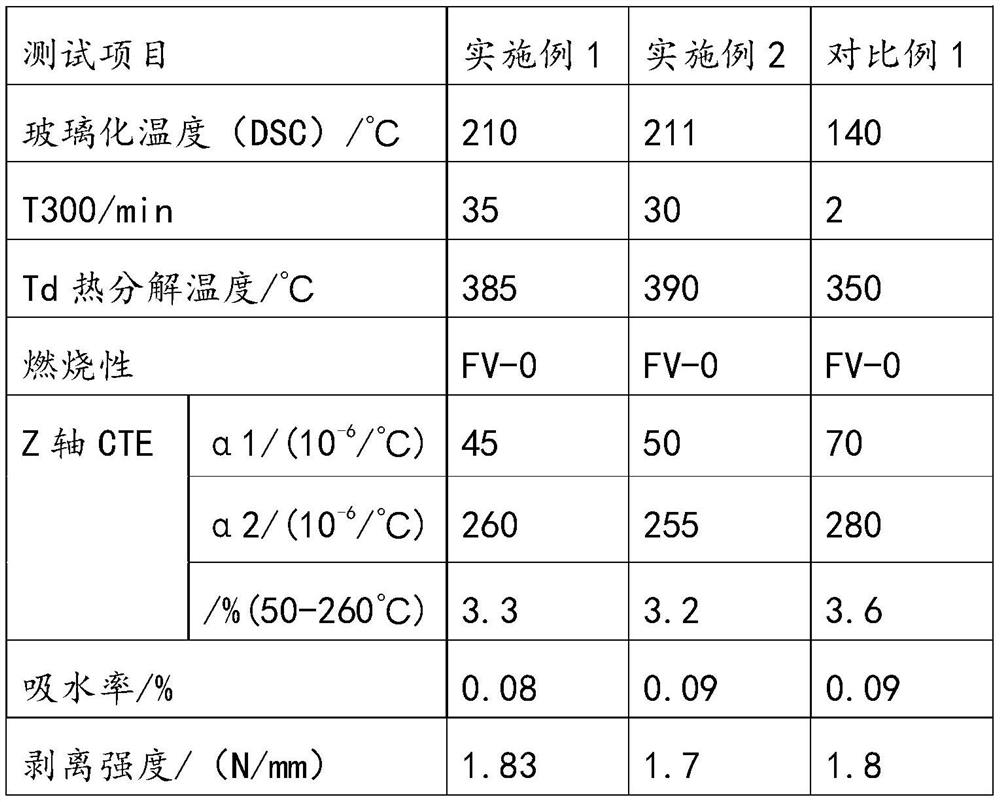

A kind of preparation method of high tg copper clad laminate

ActiveCN109094166BImprove wettabilityHigh Tg valueLaminationLamination apparatusHeat resistanceHemt circuits

The invention belongs to the technical field of copper-clad plate preparation and in particular relates to a method for preparing a high Tg copper-clad plate. According to the method, by virtue of combination of raw materials of different molecular weights, the wettability of glass cloth can be improved, the Tg value can be further increased as special rigid molecule segments are introduced, the purpose of improving properties can be achieved together with other auxiliary materials and solvents, the Tg value of the copper-clad plate can be up to 210 degrees or greater, and the thermal stratification time T300 DEG C / minute is greater than 30; by increasing the Tg value of the copper-clad plate, the thermal resistance, the wet resistance, the chemical resistance and the stability of a circuit board can be improved, the problem that a circuit board is broken in the lead-free hot air solder level process of a circuit can be solved, and meanwhile, the circuit board manufacturing efficiencycan be also improved.

Owner:SHANDONG JINBAO ELECTRONICS

Curing agent composition

Owner:华玉叶

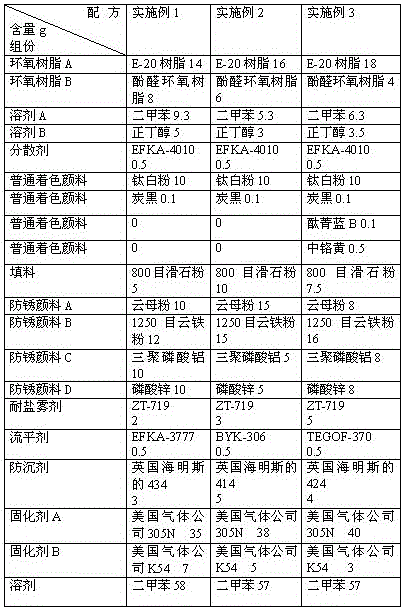

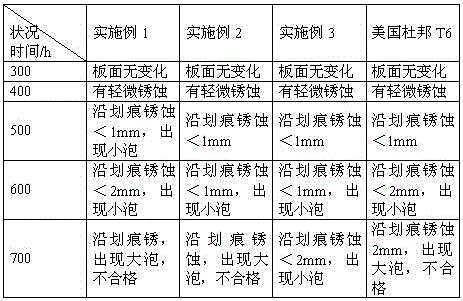

A kind of thin salt-spray resistant automobile anti-rust epoxy primer and preparation method thereof

InactiveCN104194561BHigh Tg valueReduce drying speedAnti-corrosive paintsEpoxy resin coatingsFirming agent

The invention belongs to the technical field of automotive primers, and in particular relates to a thin salt-spray-resistant automotive rust-proof epoxy primer, which consists of component A and component B, and the weight part of component A is composed of: epoxy resin A13-18 4-8 parts of epoxy resin, 18-26 parts of solvent A, 9-13 parts of solvent B, 0.1-0.5 parts of dispersant, 8-15 parts of ordinary coloring pigments, 5-15 parts of fillers, 6-15 parts of antirust pigments , anti-rust pigment B12-18 parts, anti-rust pigment C5-10 parts, anti-rust pigment D5-10 parts, salt spray resistance 2-8 parts, anti-sedimentation agent 2-5 parts, additives 0.2-1 part; Part B consists of: 35-40 parts of curing agent A, 2-10 parts of curing agent B, and 40-60 parts of solvent. The primer prepared by the invention can improve the salt spray resistance of the product when the coating thickness is relatively thin.

Owner:河南三元科技化工有限公司

Curing agent composition

Owner:华玉叶

Curing agent composition

Owner:华玉叶

White-light adhesive capable of reducing light attenuation speed of LED lamp beads

InactiveCN105505272AHigh Tg valueGood resistance to yellowing and weatheringNon-macromolecular adhesive additivesEpoxy resin adhesivesAntioxidantAdhesive

The invention relates to a white-light adhesive capable of reducing the light attenuation speed of LED lamp beads. The molecular formula of the white-light adhesive is A(5-X)B(5-X)O(1-X), wherein A is at least one of elements Si, N and C; B is at least one of elements H and F; O is the oxygen element; X is 1-20; A is prepared from the following components in parts by weight: 30-50 parts of cycloaliphatic epoxy resin, 30-50 parts of solid-state special epoxy resin and 30-40 parts of toughening epoxy resin; and B is prepared from the following components in parts by weight: 60-90 parts of anhydride polymer curing agent, 1-5 parts of oxanilide absorbent, 1-5 parts of hindered amine light stabilizer, 5-10 parts of phosphite antioxidant and 10-20 parts of urea modified accelerator. The finished product of an encapsulated white-light adhesive provided by the invention has the advantages of high Tg value and good resistance to yellowing and weather; and the service life is prolonged by reducing the LED light attenuation.

Owner:蒋柱明

Curing agent composition

Owner:华玉叶

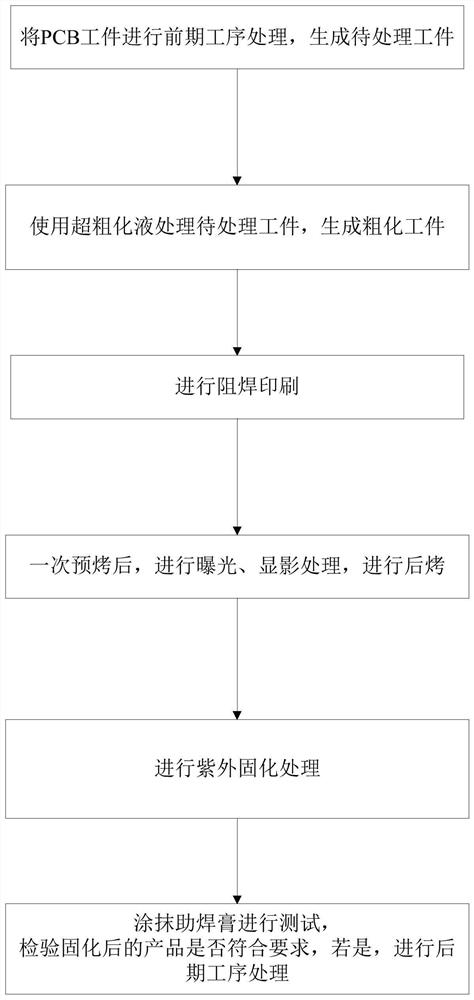

Method for preventing solder resist paste from stripping in test

PendingCN113411985AHigh Tg valueImprove stabilityPrinted circuit assemblingInsulating substrate metal adhesion improvementCrystal structurePrinting ink

The invention discloses a method for preventing test stripping of solder resist paste flux, and the method comprises the following steps: carrying out the early-stage processing of a PCB workpiece, and generating a to-be-processed workpiece; treating the to-be-treated workpiece with the super-roughening liquid, and generating a roughened workpiece; carrying out the solder resist printing; after primary pre-baking, carrying out the exposure and development treatment, and carrying out the post-baking; coating flux paste for testing, and carrying out ultraviolet curing treatment; and checking whether the cured product meets the requirements or not: if so, carrying out later process treatment. The Tg value of printing ink can be increased after solder resist high-temperature curing, the stability, the reliability, the heat resistance and the chemical resistance of a finished PCB are improved, and the thermal expansion coefficient is reduced; meanwhile, the physical shape of the copper surface can be improved through super roughening, the crystal structure can be changed microcosmically, the copper surface can be activated, the super roughened copper surface and a solder resist film can form chemical bonds more easily, the solder paste test solder resist stripping risk is reduced, and the problems of solder resist test stripping and bubbling are solved.

Owner:GUANGZHOU MEADVILLE ELECTRONICS

Curing agent composition

The invention discloses a curing agent combination. Through compounding of two different types of curing agents, a Tg value is improved under this premise of no change of a use amount.

Owner:华玉叶

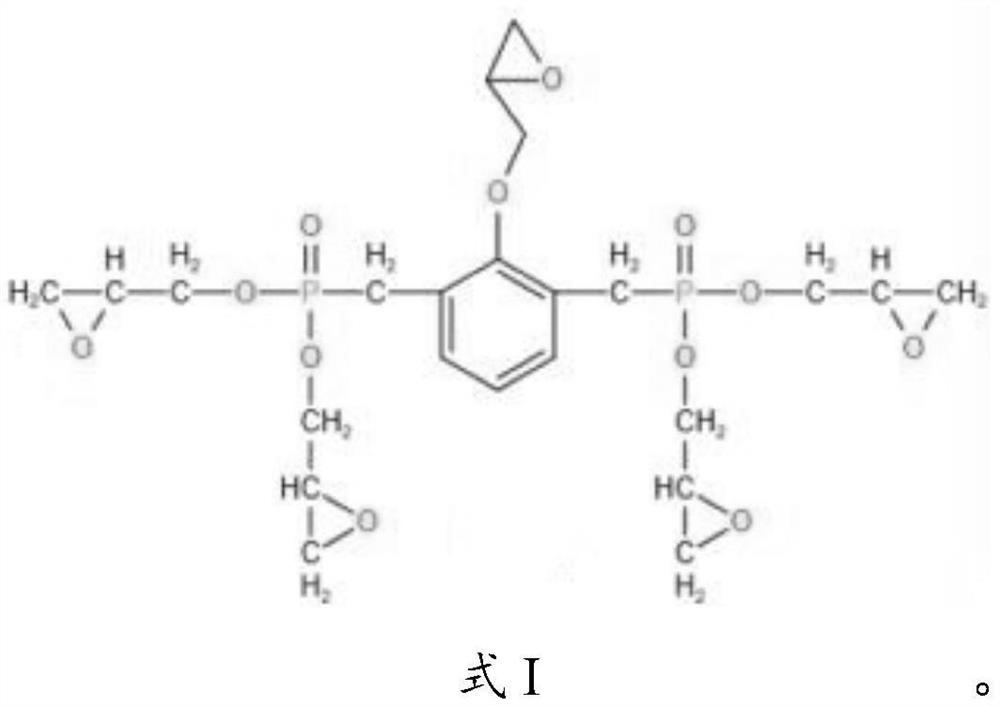

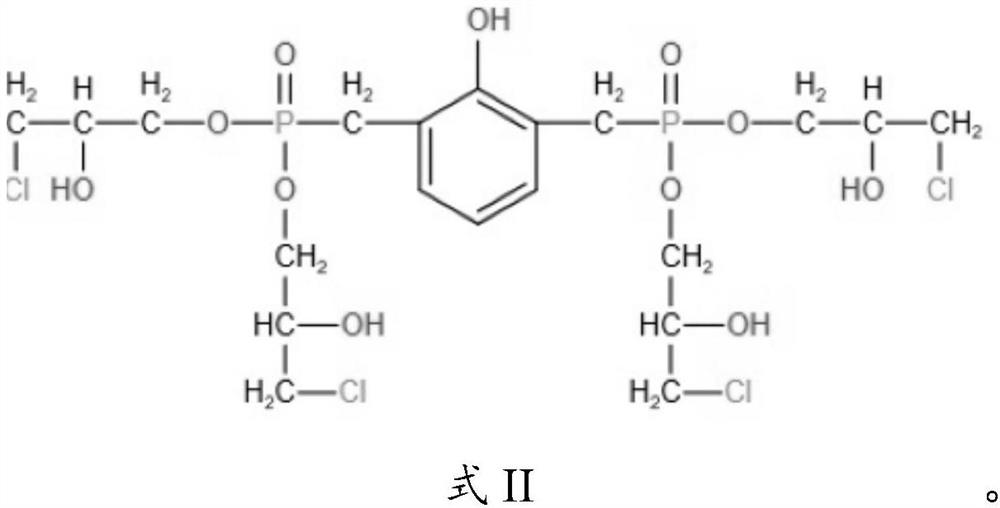

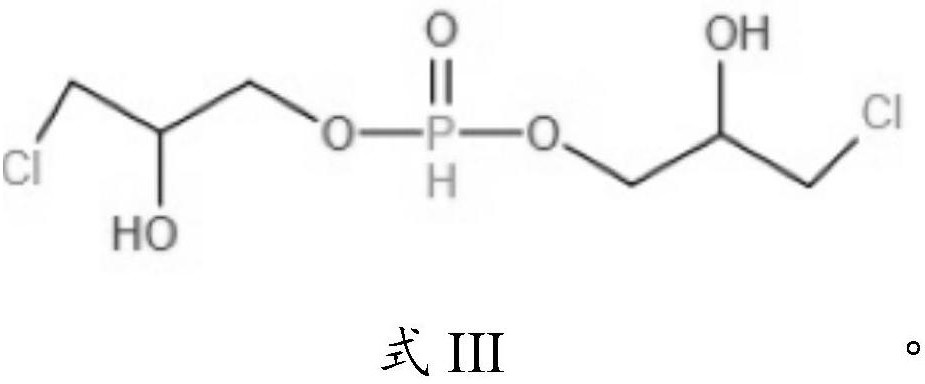

Flame retardant and preparation method thereof

PendingCN114031640AHigh Tg valueImprove flame retardant performanceGroup 5/15 element organic compoundsPhosphoric Acid EstersPhosphate

The invention discloses a flame retardant which is polyfunctional epoxy phosphate and has a structure shown in a formula I. The invention also provides a preparation method of the flame retardant, the preparation method comprises the following steps: (1) dehydrating chloropropanediol, dropwise adding a mixed solution of phosphorus trichloride and toluene for reaction, and controlling the reaction temperature to be 25-35 DEG C; raising the temperature to 135 DEG C and vacuumizing to obtain chlorohydrin ether phosphate; (2) adding phenol into the product of the step (1), controlling the temperature to be 80-90 DEG C, adding formaldehyde in batches, and keeping the temperature for 2 hours to obtain chlorohydrin ether phenolic phosphate; and (3) adding epichlorohydrin into the product obtained in the step (2), cooling to 65 DEG C, carrying out reduced pressure reflux, dropwise adding NaOH, adding a proper amount of water and toluene, layering, taking out the upper layer, and removing toluene to obtain the polyfunctional epoxy phosphate. The flame retardant property of the epoxy resin can be improved, the raw materials for synthesizing the epoxy phosphate are easy to obtain and low in cost, the process is simple, and the cost is low.

Owner:烟台东化新材料有限公司

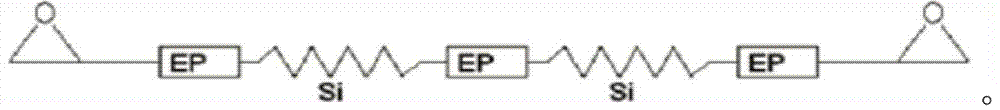

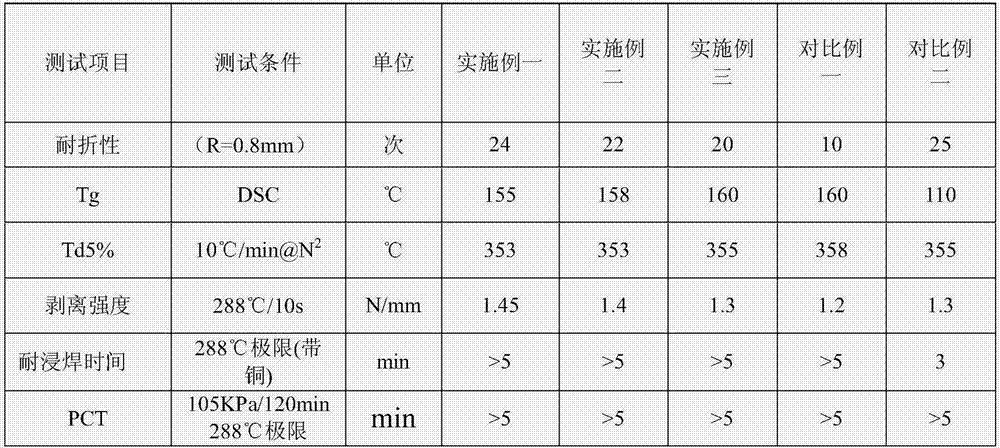

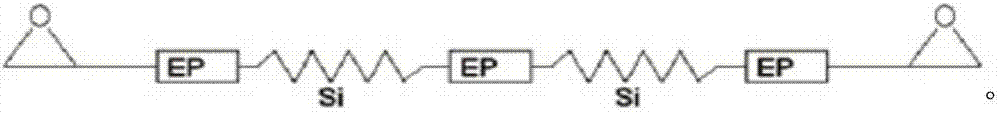

A kind of resin composition and the copper clad board made thereof

The invention provides a resin composition and a copper-clad plate manufactured from the same. The resin composition comprises the following components in parts by weight: 50-70 parts of phosphorus-containing epoxy resin, 5-10 parts of phenolic epoxy resin, 10-20 parts of modified epoxy resin with a silicone rubber core-shell structure, 10-20 parts of an organic silicon-epoxy block copolymer and 2-4 parts of dicyandiamide. The resin composition can not only strengthen the toughness of a system, but also ensure little influence on Tg of the system by introducing the modified epoxy resin with the silicone rubber core-shell structure and the organic silicon-epoxy block copolymer; compared with ordinary FR-4, the copper-clad plate manufactured by using the resin composition has better flexural property and can keep a higher Tg value.

Owner:GUANGDONG SHENGYI SCI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com