High dirt resistance exterior wall latex paint capable of degrading haze and production process thereof

A stain-resistant and degradable technology, applied in biocide-containing paints, anti-fouling/underwater coatings, coatings, etc., can solve the problems of low weather resistance, low weather resistance and low sticking and stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In the embodiment of the present invention, a kind of highly anti-adhesive and stain-resistant exterior wall latex paint that can degrade smog, the raw materials according to the mass percentage include:

[0027] Water 15.0%

[0028] Alkali swelling thickener 1.0%

[0029] pH regulator 0.2%

[0030] Defoamer 0.5%

[0031] Wetting agent 0.3%

[0032] Dispersant 0.6%

[0033] Ethylene glycol 2.5%

[0034] Coalescent 2.5%

[0035] Titanium dioxide 16.8%

[0036] Heavy Calcium 30.0%

[0037] Nano Titanium Dioxide 0.6%

[0038] Silicone modified acrylic emulsion 30.0%

[0039] Fungicide 0.4%

[0040] Polyurethane thickener 0.5%.

Embodiment 2

[0042] In the embodiment of the present invention, a kind of highly anti-adhesive and stain-resistant exterior wall latex paint that can degrade smog, the raw materials according to the mass percentage include:

[0043] Water 25.0%

[0044] Alkali swelling thickener 0.5%

[0045] pH regulator 0.1%

[0046] Defoamer 0.2%

[0047] Wetting agent 0.1%

[0048] Dispersant 0.3%

[0049] Ethylene glycol 1.5%

[0050] Coalescent 1.8%

[0051] Titanium dioxide 9.9%

[0052] Heavy Calcium 20.0%

[0053] Nano Titanium Dioxide 0.2%

[0054] Silicone modified acrylic emulsion 40.0%

[0055] Fungicide 0.2%

[0056] Polyurethane thickener 0.2%.

Embodiment 3

[0058] In the embodiment of the present invention, a kind of highly anti-adhesive and stain-resistant exterior wall latex paint that can degrade smog, the raw materials according to the mass percentage include:

[0059] water 20%

[0060] Alkali swelling thickener 0.8%

[0061] pH regulator 0.2%

[0062] Defoamer 0.5%

[0063] Wetting agent 0.2%

[0064] Dispersant 0.5%

[0065] Ethylene glycol 2%

[0066] Coalescing aid 2%

[0067] Titanium dioxide 12.6%

[0068] Heavy Calcium 25%

[0069] Nano Titanium Dioxide 0.4%

[0070] Silicone Modified Acrylic Emulsion 35%

[0071] Fungicide 0.3%

[0072] Polyurethane thickener 0.5%.

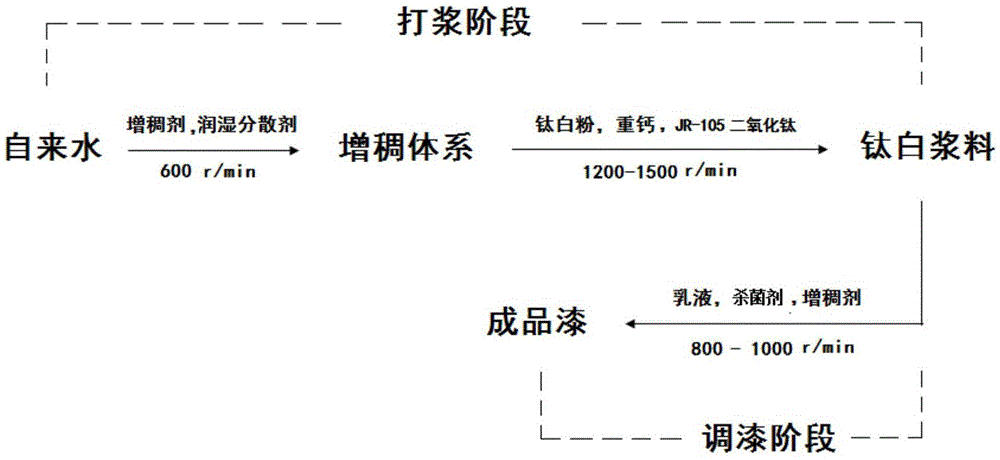

[0073] 1. Production process

[0074] The production process of the highly sticky and stain-resistant exterior wall latex paint capable of degrading smog is divided into two stages: beating and mixing. The specific steps are as follows:

[0075]1) Beating stage: first add water to the stirring tank, and at a speed of 600r / min, add defoamer, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com