A kind of thin salt-spray resistant automobile anti-rust epoxy primer and preparation method thereof

An epoxy primer and salt spray resistance technology, applied in epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve the problem of expensive imported products, less than ideal salt spray resistance of anti-rust primers, and low-end vehicles. It is difficult to accept and use problems, so as to achieve the effect of being conducive to salt spray resistance, improving salt spray resistance, and low crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

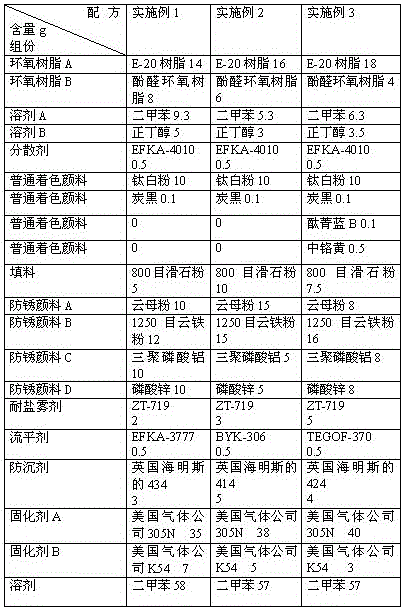

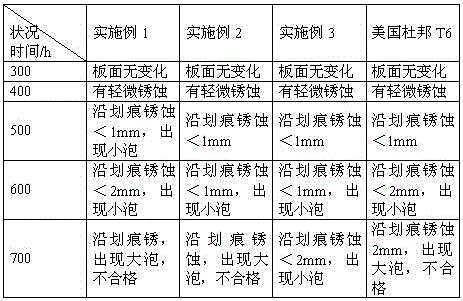

Embodiment 1-3

[0027] Embodiment 1-3 comprises the following steps during the preparation of thin-type salt-spray-resistant automobile rust-proof epoxy primer:

[0028] (1) Take each raw material in proportion, mix and dissolve epoxy resin A, epoxy resin B, solvent A, and solvent B, add dispersant to disperse evenly, and add the following powders in sequence: ordinary coloring pigment, filler, antirust pigment A, anti-rust pigment B, anti-rust pigment C, anti-rust pigment D, anti-sedimentation agent, each powder needs to be dispersed evenly, then add salt spray agent, grind at 30-45°C, and finally add auxiliary The agent is dispersed until the fineness is not greater than 50 μm, and component A is obtained;

[0029] (2) Mix curing agent A, curing agent B, and solvent to obtain component B. Passed the inspection, component A and component B are packaged separately.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com