Resin composition and application

A resin composition, epoxy resin technology, applied in the direction of synthetic resin layered products, layered products, metal layered products, etc., can solve the problem of poor heat and humidity resistance, flame retardancy can not reach UL94V-0, insulating substrates Deterioration of adhesion with copper foil, etc., to achieve the effects of excellent processing performance, excellent moisture and heat resistance, and improvement of insufficient flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] The preparation steps of the laminate are as follows: one side or both sides of one above-mentioned prepreg is covered with metal foil, or after at least two above-mentioned prepregs are stacked, one side or two sides of the above-mentioned prepreg are covered with metal foil, and hot-pressed, that is Metal foil laminates are available. The pressing conditions of the above-mentioned laminated board are: pressing at a pressure of 0.2-2 MPa and a temperature of 150-250° C. for 2-4 hours.

[0074] Specifically, the number of prepregs can be determined according to the required thickness of the laminate, and one or more prepregs can be used.

[0075] The metal foil can be copper foil or aluminum foil, and its material is not limited; the thickness of the metal foil is also not particularly limited, such as 5 microns, 8 microns, 12 microns, 18 microns, 35 microns or 70 microns.

[0076] The present invention also provides an application of a prepreg in an insulating board, ...

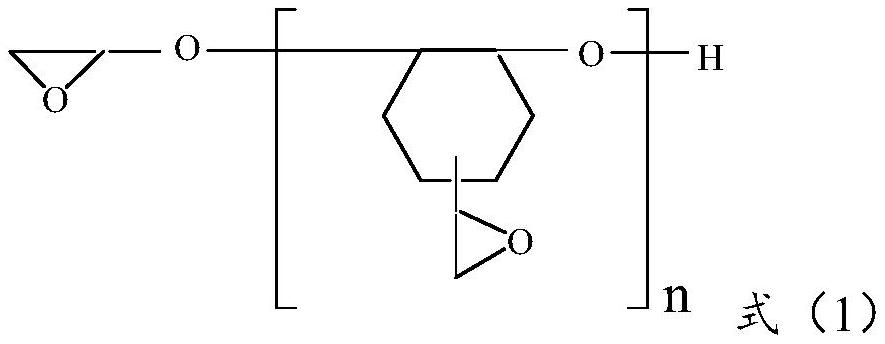

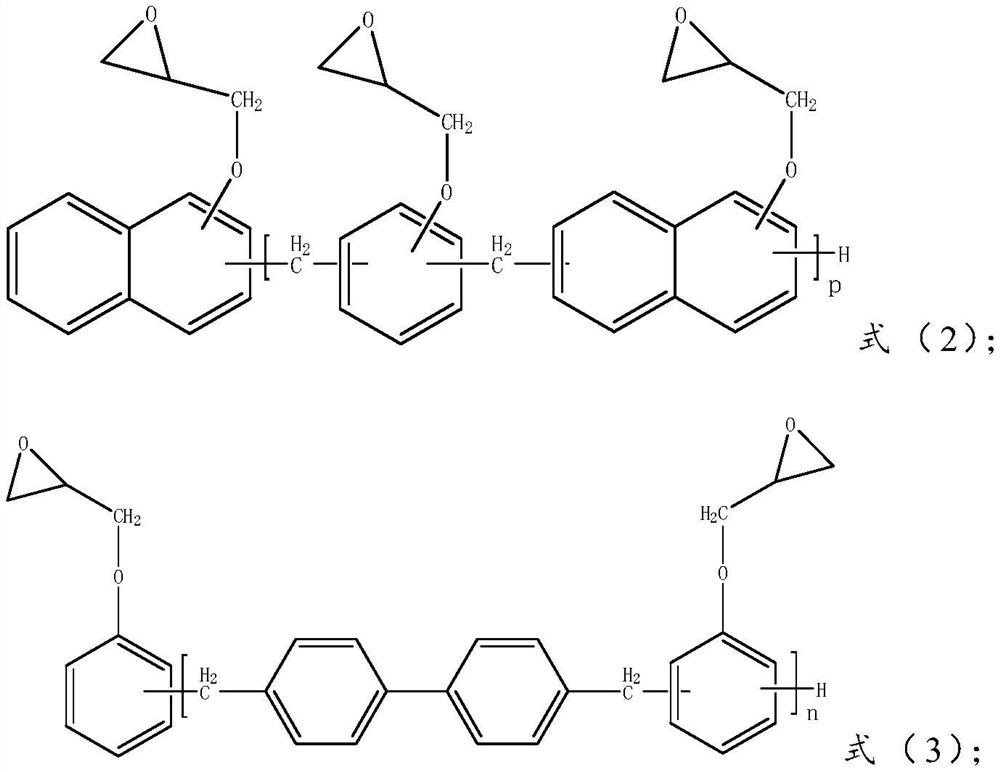

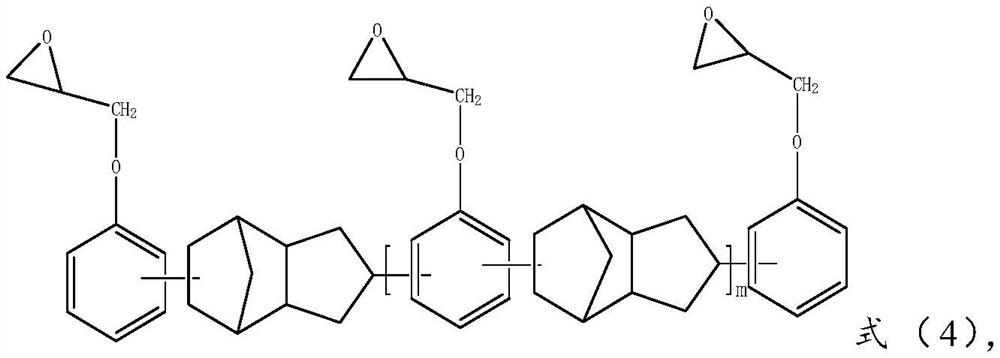

Embodiment 1

[0081] 15g cycloaliphatic epoxy resin (formula 1), 30g biphenyl epoxy resin (product name: NC3000H, manufacturer: Nippon Kayaku), 25g bismaleimide (product name: BMI-70, manufacturer: Japan KI ), 15g phosphorus-containing phenolic resin (product name: XZ92741), 5g diaminodiphenyl sulfone (abbreviation: DDS), acid anhydride (product name: SMAEF-1000, manufacturer, Kray Power) 10g, 0.05g 2-methyl-4 - Ethylimidazole, 30g barium sulfate (product name: HC600, manufacturer: Suzhou Beijiamei Electronic Materials), 15g boehmite (product name: BG403-H6, manufacturer: Anhui Yishitong New Materials), 0.5g BYK903 ( Product name) dispersant, and add a certain amount of butanone, stir and mix to obtain the glue solution 1 with a solid content of 65%.

[0082]

[0083] The glue solution 1 is dipped and coated on E glass fiber cloth (2116, unit weight is 104g / m 2 ) and baked in an oven at 160° C. for 5 minutes to obtain a prepreg 1 with a resin content of 50%.

[0084] The prepared prepr...

Embodiment 2

[0087] 27g cycloaliphatic epoxy resin (formula 1), 20g biphenyl epoxy resin (product name: NC3000H, manufacturer: Nippon Kayaku), 15g bismaleimide (product name: BMI-70, manufacturer: Japan KI ), 15g phosphorus-containing phenolic resin (product name: XZ92741), 3g diaminodiphenyl sulfone (DDS), 20g anhydride (product name: SMAEF-1000, manufacturer: Clay Power), 0.05g 2-methyl-4- Ethyl imidazole, 10g barium sulfate (product name: HC600, manufacturer: Suzhou Beijiamei Electronic Materials), 35g boehmite (product name: BG403-H630g, manufacturer: Anhui Yishitong New Materials), 0.5g BYK903 (product Name) dispersant, and add a certain amount of butanone, stir and mix evenly to obtain glue solution 2 with a solid content of 65%.

[0088] The glue solution 2 is dipped and coated on E glass fiber cloth (2116, unit weight is 104g / m 2 ) and baked in an oven at 160°C for 5 minutes to obtain a prepreg 2 with a resin content of 50%.

[0089] The prepared prepreg 2 with a resin content of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com