High-barrier and high-water-resistance water-based acrylic emulsion and preparation method thereof

A water-based acrylic, high-barrier technology, applied in coatings and other directions, can solve the problems of poor water resistance of emulsion film formation, affecting aesthetics, and being unacceptable to the market.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The application also provides a preparation method for the aqueous acrylic emulsion, comprising the following steps:

[0040] a) According to the proportion, mix 95wt% of the total amount of methyl methacrylate, methyl acrylate, methacrylic acid and N-aminoacrylamide, and then add 70wt% of the total amount of compound emulsifier to obtain the first mixed solution ; Mix 20wt% of the total amount of soft water and 60wt% of the total amount of initiator to obtain the second mixed solution;

[0041] b) mixing the remaining soft water, methyl methacrylate, compound emulsifier, initiator and pH regulator, and reacting to obtain a reaction solution;

[0042] c) mixing the first mixed solution, the second mixed solution and the reaction solution, and reacting;

[0043] d) The reaction solution obtained in step c) is mixed with the defoamer, then vacuumized, and then an antiseptic, a wetting agent and a film-forming agent are added to obtain a water-based acrylic emulsion.

[00...

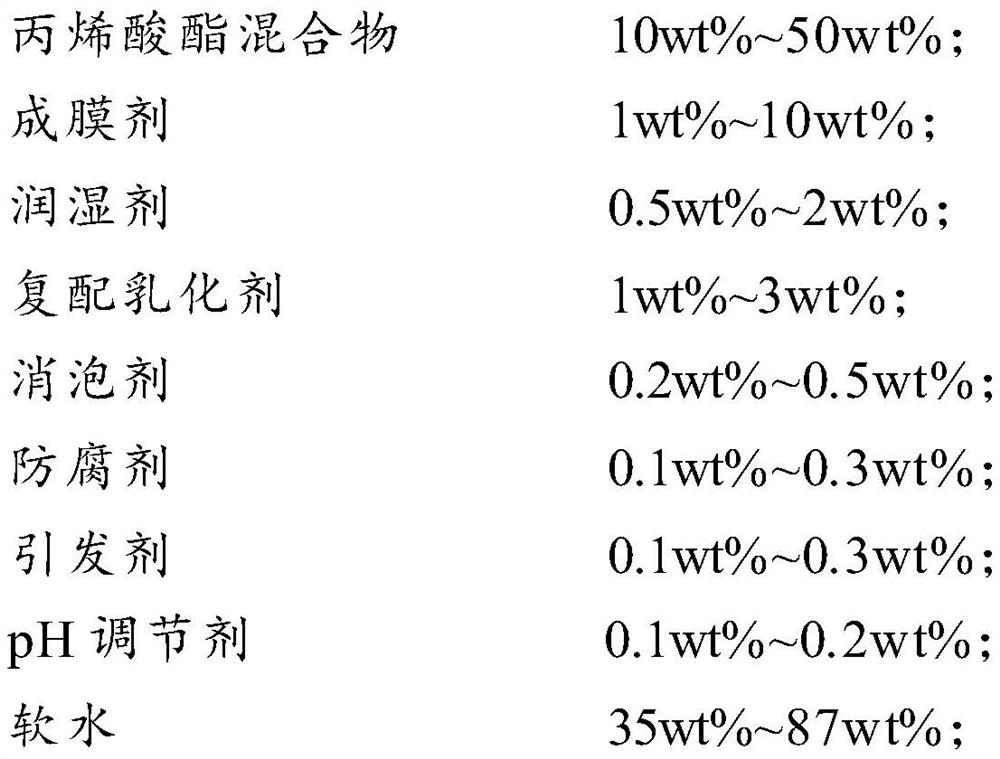

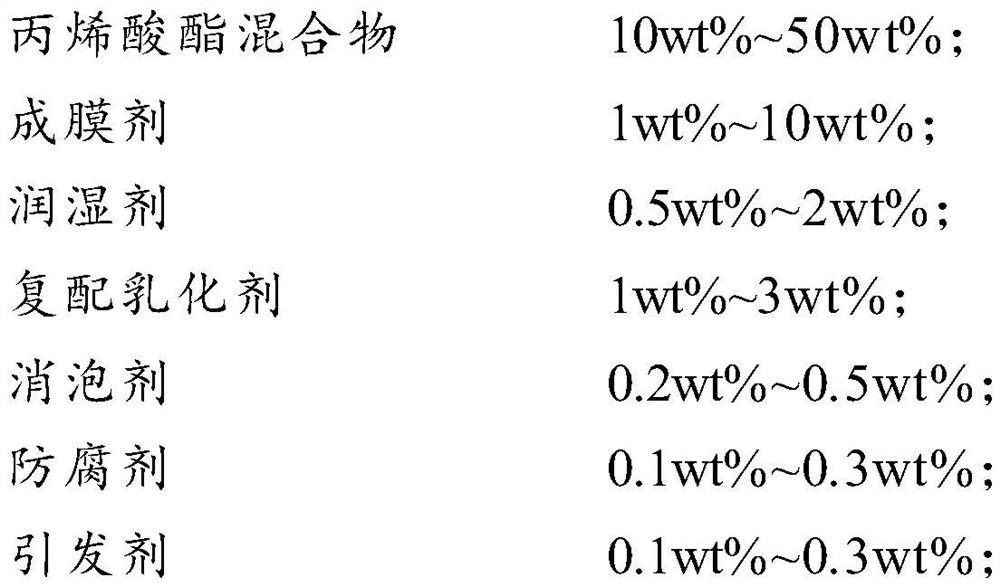

Embodiment 1

[0051] A water-based acrylic emulsion with high barrier and high water resistance, which is prepared from the following raw materials by weight: 10% acrylate mixture, 1% film forming agent, 0.5% wetting agent, 1% compound emulsifier, defoamer 0.2%, preservative 0.1%, initiator 0.1%, pH regulator 0.1%, soft water 87%; acrylate mixture consists of methyl methacrylate, ethyl methacrylate, methyl acrylate, ethyl acrylate, methacrylic acid , N-aminoacrylamide mixed, wherein the mixing ratio of methyl acrylate and methyl methacrylate is 1:1; the compound emulsifier is a compound of reactive emulsifier SR-10 and sodium lauryl sulfate , the compounding ratio is 10:1; the film forming agent is triethylene glycol diisocaprylate; the wetting agent is macromolecular polyether modified polyester; the defoaming agent is mineral oil; the preservative is sodium benzoate; The pH regulator is sodium bicarbonate; the initiator is potassium persulfate.

[0052] A method for preparing a high-barr...

Embodiment 2

[0059] A water-based acrylic emulsion with high barrier and high water resistance, which is prepared from the following raw materials by weight: acrylate mixture 50%, film forming agent 9%, wetting agent 2%, compound emulsifier 3%, defoamer 0.3%, preservative 0.3%, initiator 0.3%, pH regulator 0.1%, soft water 35%; acrylate mixture consists of methyl methacrylate, ethyl methacrylate, methyl acrylate, ethyl acrylate, methacrylic acid , N-aminoacrylamide mixed, wherein the mixing ratio of methyl acrylate and methyl methacrylate is 1:5; the compound emulsifier is a compound of reactive emulsifier SR-10 and sodium lauryl sulfate , the compounding ratio is 10:4; the film forming agent is triethylene glycol diisocaprylate; the wetting agent is macromolecular polyether modified polyester; the defoaming agent is a mixture of mineral oil and silicone; The preservative is Cathone; the pH regulator is sodium bicarbonate; the initiator is potassium persulfate.

[0060] A method for prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com