Crown-shaped composite material honeycomb interlayer antenna housing and forming tool and method thereof

A technology of composite material and honeycomb interlayer, which is applied in the direction of antenna, antenna parts, radiating unit cover, etc., to achieve the effect of reducing weight, improving wave transmittance and high electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

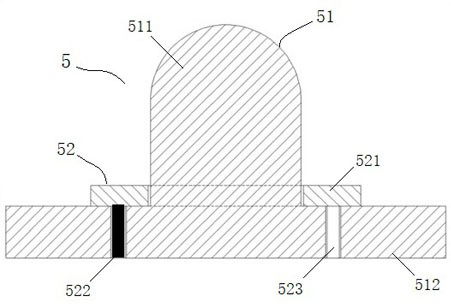

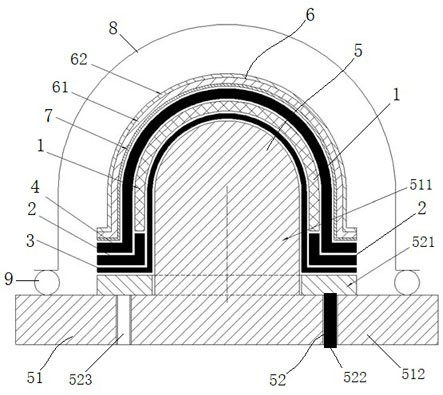

[0033] This embodiment is a crown-shaped composite material honeycomb sandwich radome and its forming process.

[0034] The radome described in this embodiment is made of composite material and honeycomb sandwich, which includes a casing part and a cover edge; and the casing part is provided with a honeycomb sandwich layer 1, and the cover edge is provided with glass fiber reinforcement Layer 2. That is, the material of the radome wall is made of wave-transparent composite material glass fiber, and the middle and crown parts are designed with a honeycomb sandwich. The two materials have low dielectric constants, and the reflection of electromagnetic waves on the radome wall is small. The high wave rate can ensure the required mechanical strength without affecting the wave transmittance, and at the same time greatly reduce the weight of the radome, which is beneficial to the lightweight design of aircraft and other aerospace vehicles. Specifically, the cover part includes the ...

Embodiment 2

[0045] The radome made in Example 1 was tested for electrical properties (wave transmittance), weight, etc., and the radome prepared in the same molding method as the radome in Example 1 did not have a honeycomb layer (that is, all three layers were made of glass). Fiber material) radome as a comparative example for comparison. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com