Automatic battery cell gluing device and method

A gluing device and gluing technology are applied to devices and coatings that apply liquid to the surface, which can solve the problems of low production efficiency and labor consumption, and achieve the effect of improving production efficiency and avoiding manual grasping of battery cells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

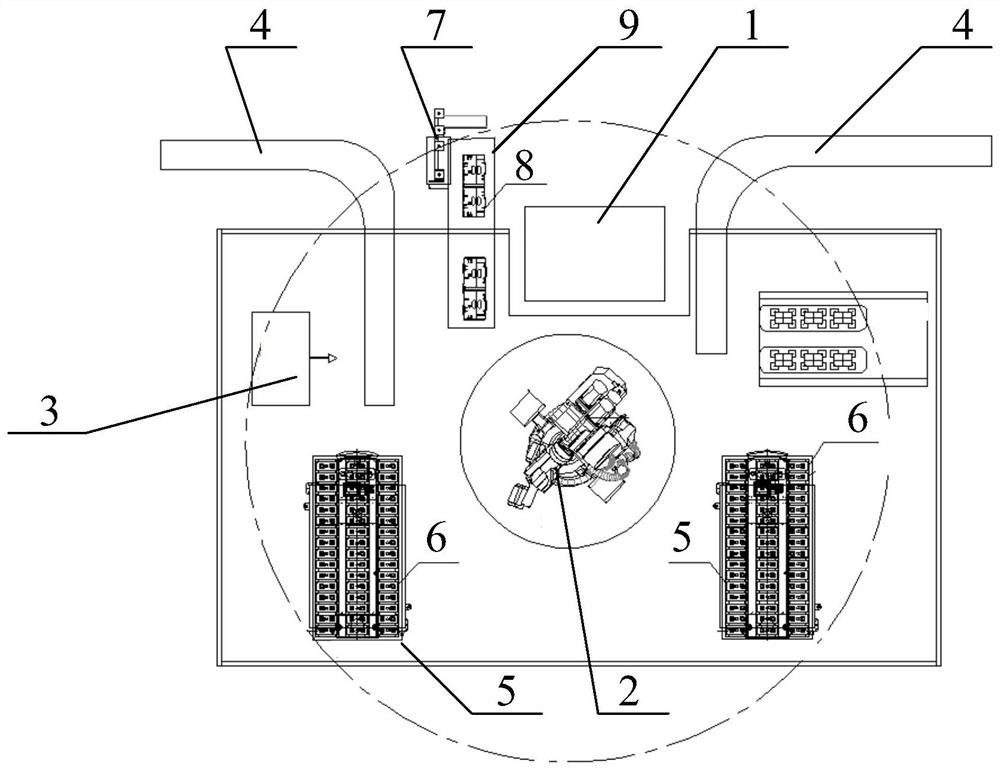

[0050] The invention discloses an automatic glue coating device for battery cells, wherein the automatic glue coating device for battery cells includes a controller 1 , a manipulator 2 , a glue gun assembly 3 and a conveyor 4 .

[0051] The controller 1 is respectively connected to the manipulator 2, the glue gun assembly 3 and the conveyor 4 in signal connection. Specifically, the controller 1 is placed in the console, and various action control buttons are arranged on the console.

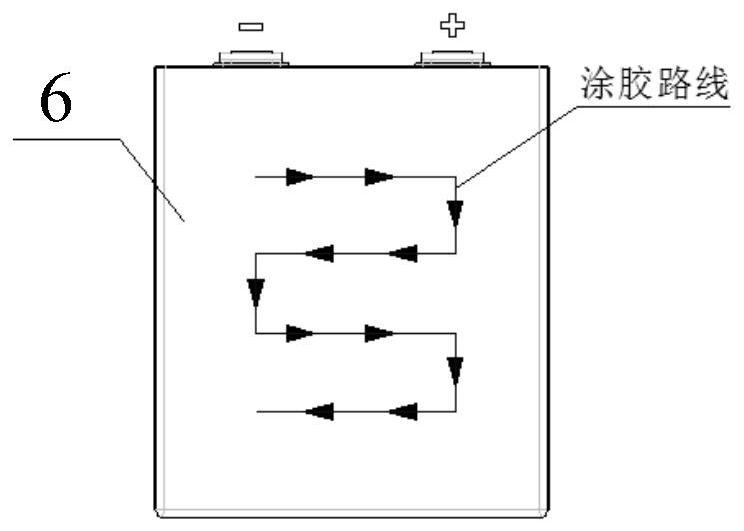

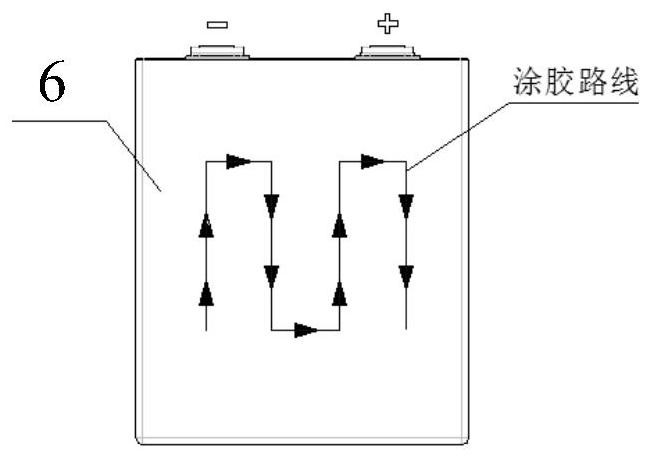

[0052] Under the control of the controller 1, the manipulator 2 can grab the cell 6 to be glued at the cell loading station 5, and place the cell 6 to be glued under the glue outlet of the glue gun assembly 3, so that the cell to be coated The surface to be glued of the glue cell 6 faces the glue outlet, and the glue gun assembly 3 can spray a preset amount of glue onto the surface to be glued under the control of the controller 1 to complete the glueing of the battery cell 6 to be glued. glued. ...

Embodiment 2

[0056] In the second embodiment provided by the present invention, the structure of the battery automatic gluing device in this embodiment is similar to the structure of the battery automatic gluing device in Embodiment 1, and the similarities will not be repeated, only the introduction the difference.

[0057] In this embodiment, the invention discloses that the battery automatic gluing device also includes detection equipment, which is installed on the manipulator 2 and is connected to the controller 1 with a signal. When the detection equipment detects that the battery cell 6 to be glued When the surface to be glued is downward, the controller 1 controls the manipulator 2 to turn over the cell 6 to be glued so that the surface to be glued is upward.

[0058] Specifically, the present invention discloses that the detection device is a cell OCV detection device. It should be noted that the detection device is not limited to the cell OCV detection device, and may also be other...

Embodiment 3

[0068] The invention provides a battery automatic glue coating method, comprising the following steps:

[0069] Step S1: Control the manipulator 2 to grab the battery cell 6 to be glued.

[0070] The cell 6 to be glued is placed in the cell feeding station 5, and the number of the cell feeding station 5 is at least 2, so as to save the waiting time for refilling at the cell feeding station 5 and improve work efficiency. The battery loading tooling truck is transported to each battery loading station 5 according to the requirements, and the battery cells 6 to be glued are placed according to the agreed placement requirements, and the battery loading tooling vehicle is limited and locked.

[0071] Further, the present invention discloses that before the manipulator 2 grabs the battery cells 6 to be glued, it also includes: judging whether the row of battery cells 6 to be glued near the manipulator 2 on the battery loading station is empty, and if so, prompting an alarm , if no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com