Angle lifter base

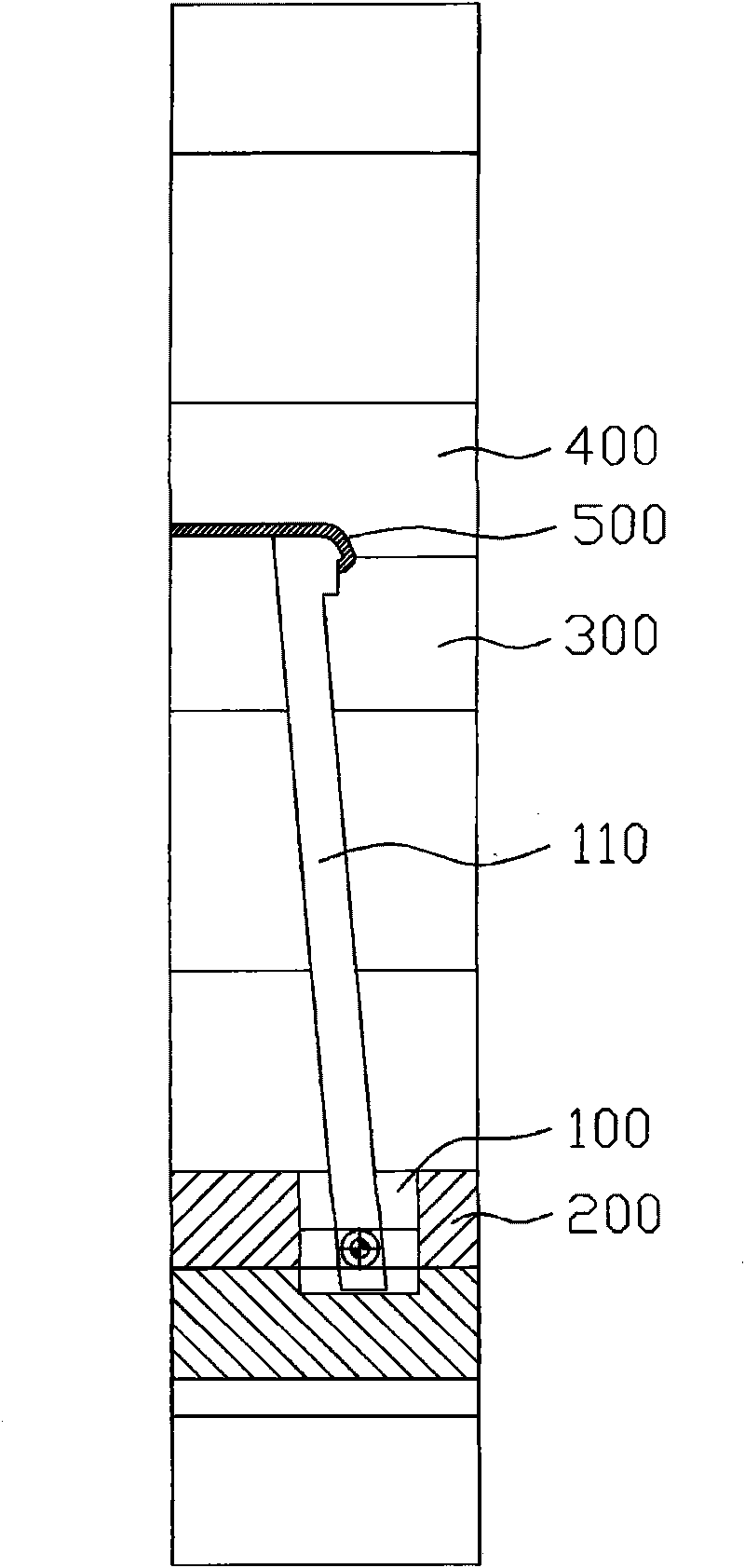

A technology of oblique pin seat and oblique pin, which is applied in the field of new type oblique pin seat, can solve the problems of product 500 that are prone to burrs or excess glue, and the strength is reduced, so as to achieve the best practical value and avoid the effect of burrs or excess glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

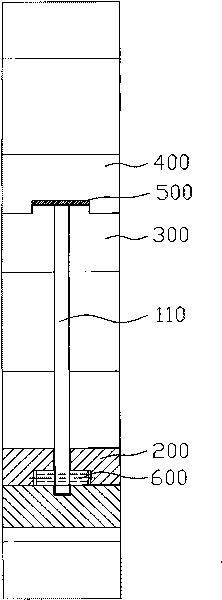

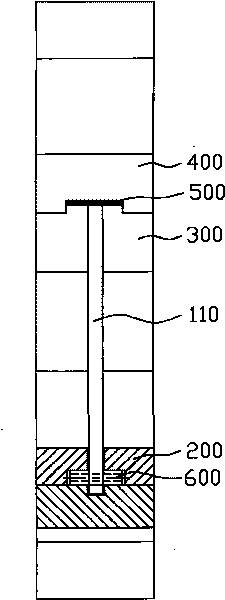

[0010] In order to make the above and other objects, features, and advantages of the present invention more comprehensible, some embodiments are specifically cited below and described in detail in conjunction with the accompanying drawings.

[0011] see figure 2 As shown, the present invention is applied in an injection mold, which includes a sliding block 600. In this embodiment, one end of the mold oblique pin 110 is fixed on the sliding block 600, and the other end is matched with the male and female mold cores 300, 400 molded product 500, the top plate 200 of the mold is provided with an inverted T-shaped slot, and one end of the oblique pin 110 and the sliding block are movably arranged in the inverted T-shaped slot.

[0012] When the mold is opened, the upper top plate 200 rises, thereby driving the sliding block 600 to rise, and the sliding block 600 drives the inclined pin 110 to rise, and then the inclined pin 110 can eject the product 500; The female mold core 400 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com