Patents

Literature

85results about How to "Avoid sorting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

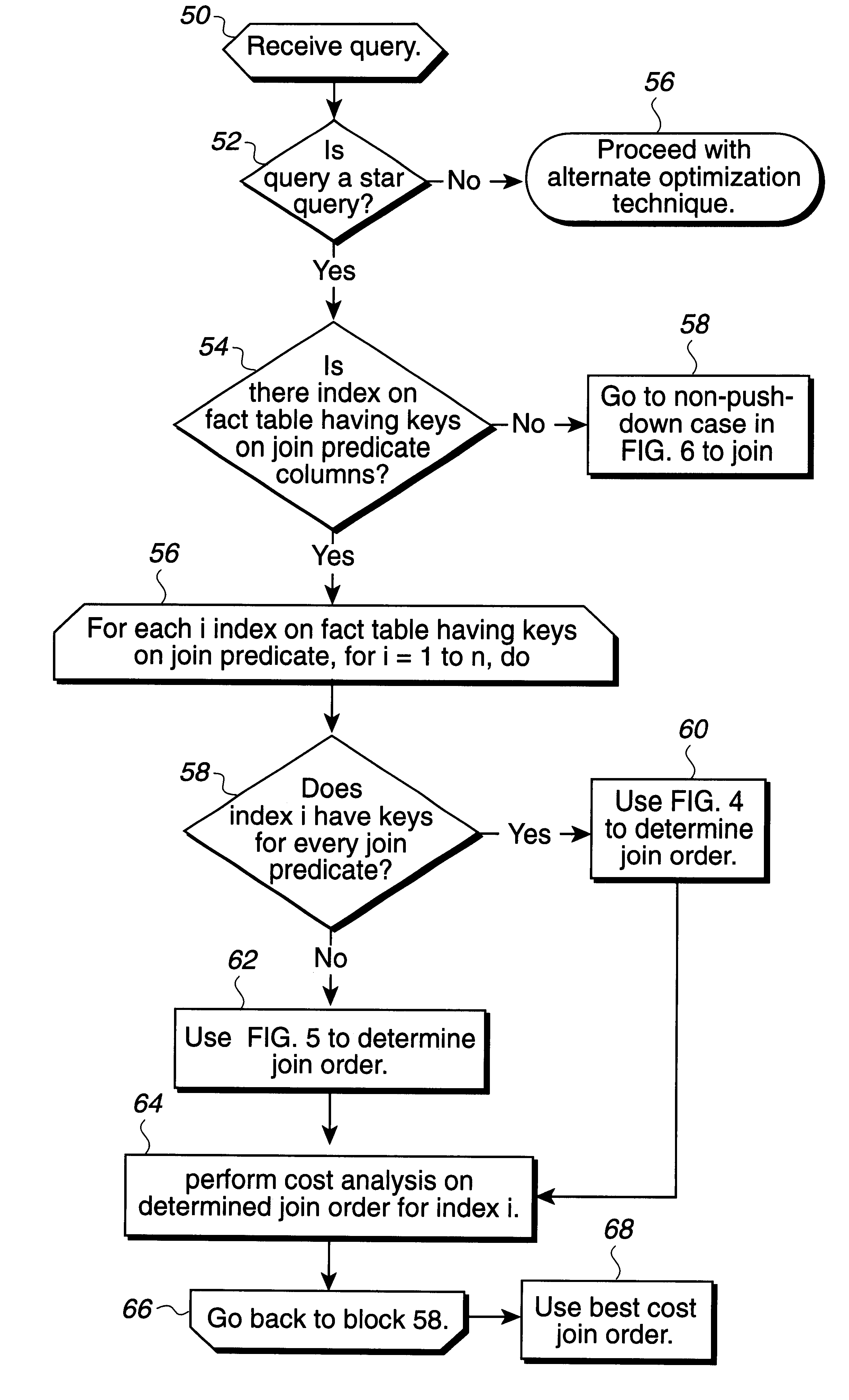

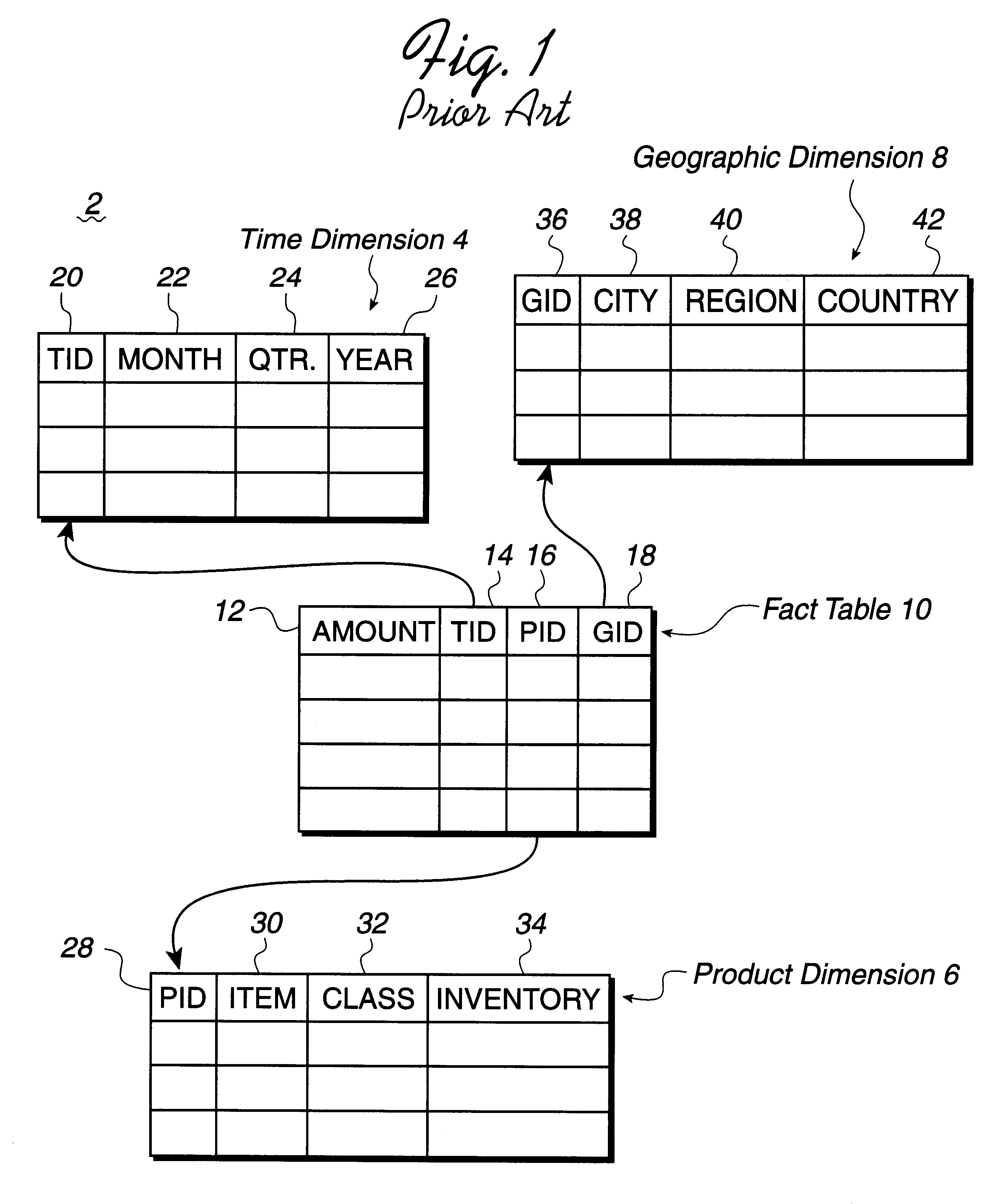

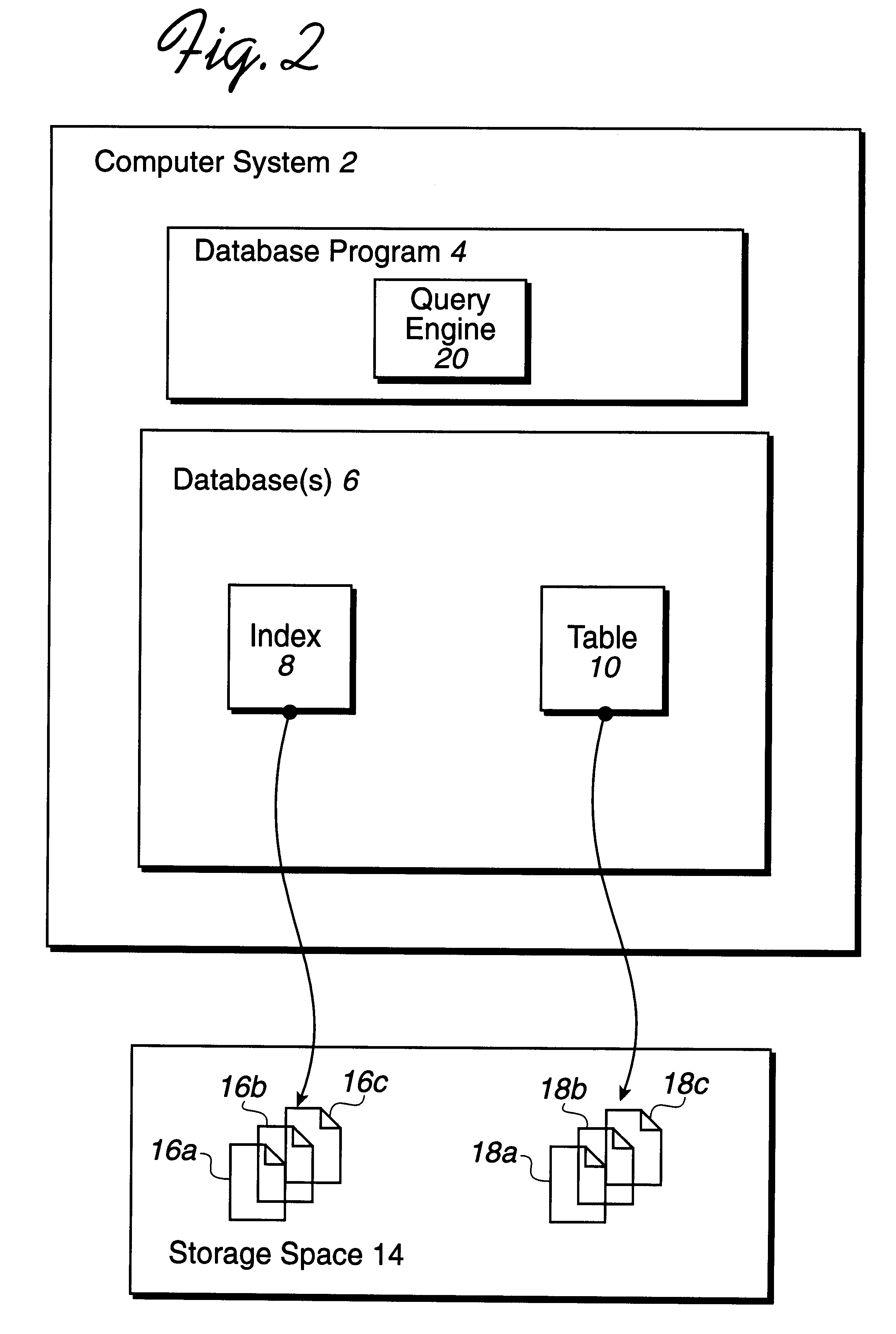

Method, system, and program for determining the join ordering of tables in a join query

InactiveUS6397204B1Significant processing timeReduce usageData processing applicationsDigital data information retrievalData miningSatellite

Disclosed is a system, method, and program for joining a multi-column table and at least two satellite tables. Each satellite table is comprised of multiple rows and at least one join column and each multi-column table is comprised of multiple rows and join columns corresponding to the join columns in the satellite tables. A query including predicates is received. A join predicate column comprises the satellite table and multi-column table join column to which at least one query predicate applies. A determination is then made as to whether there is at least one index on the multi-column table including at least one column for one join predicate column. One index is selected. The ordering of the join predicate columns in the selected index is used to determine the join order of the satellite tables and the multi-column table. The satellite tables and multi-column tables are then joined in the determined join order.

Owner:IBM CORP

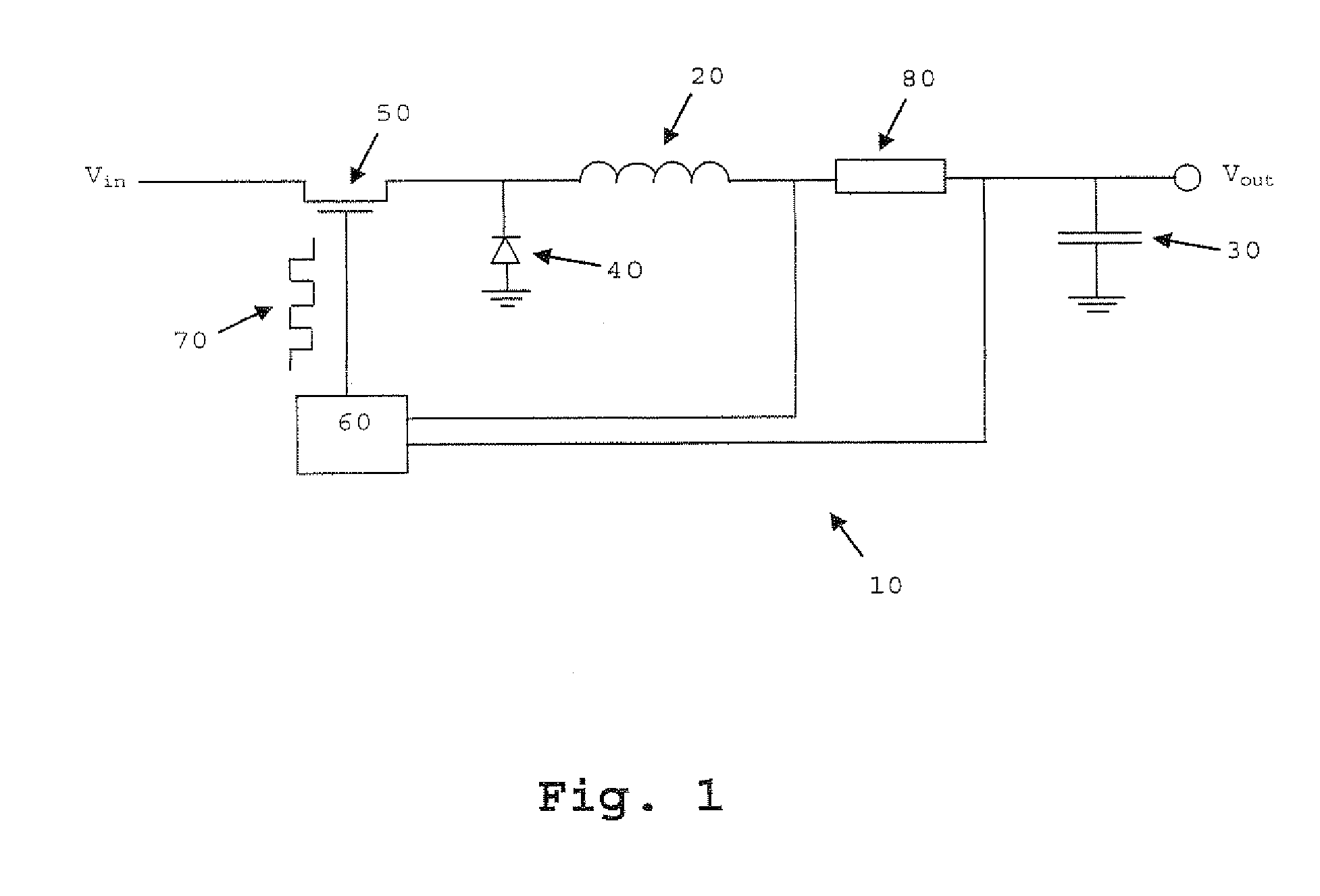

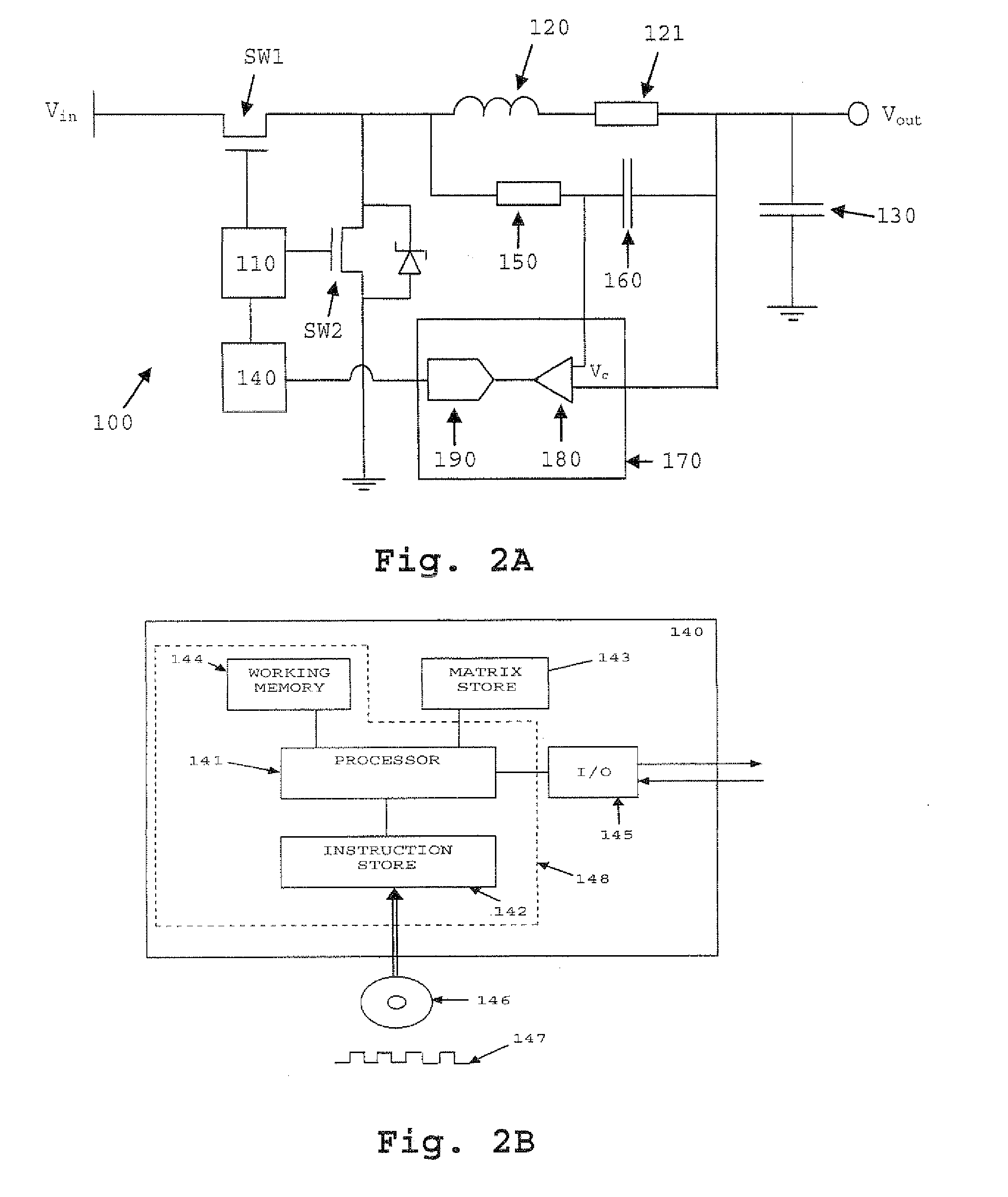

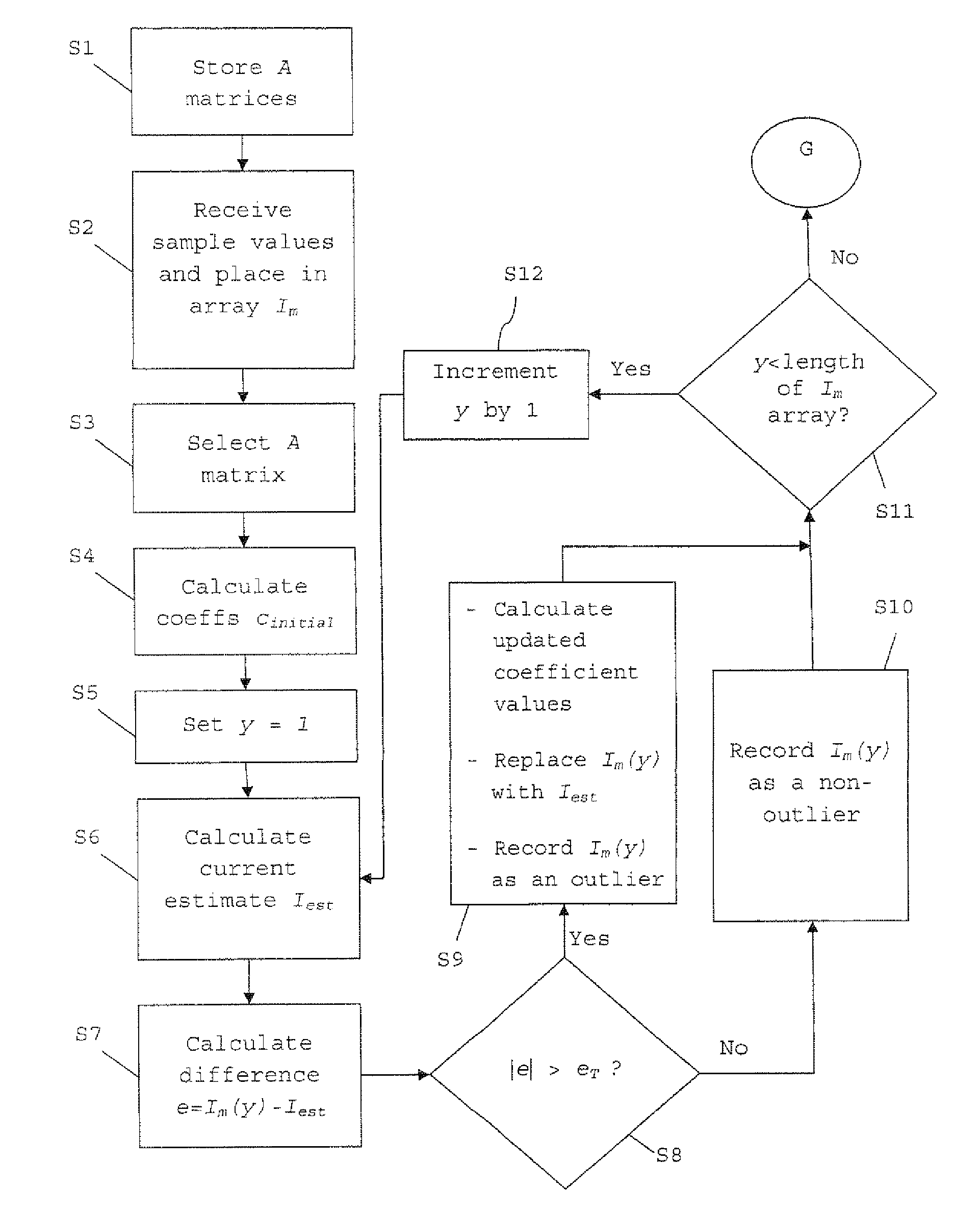

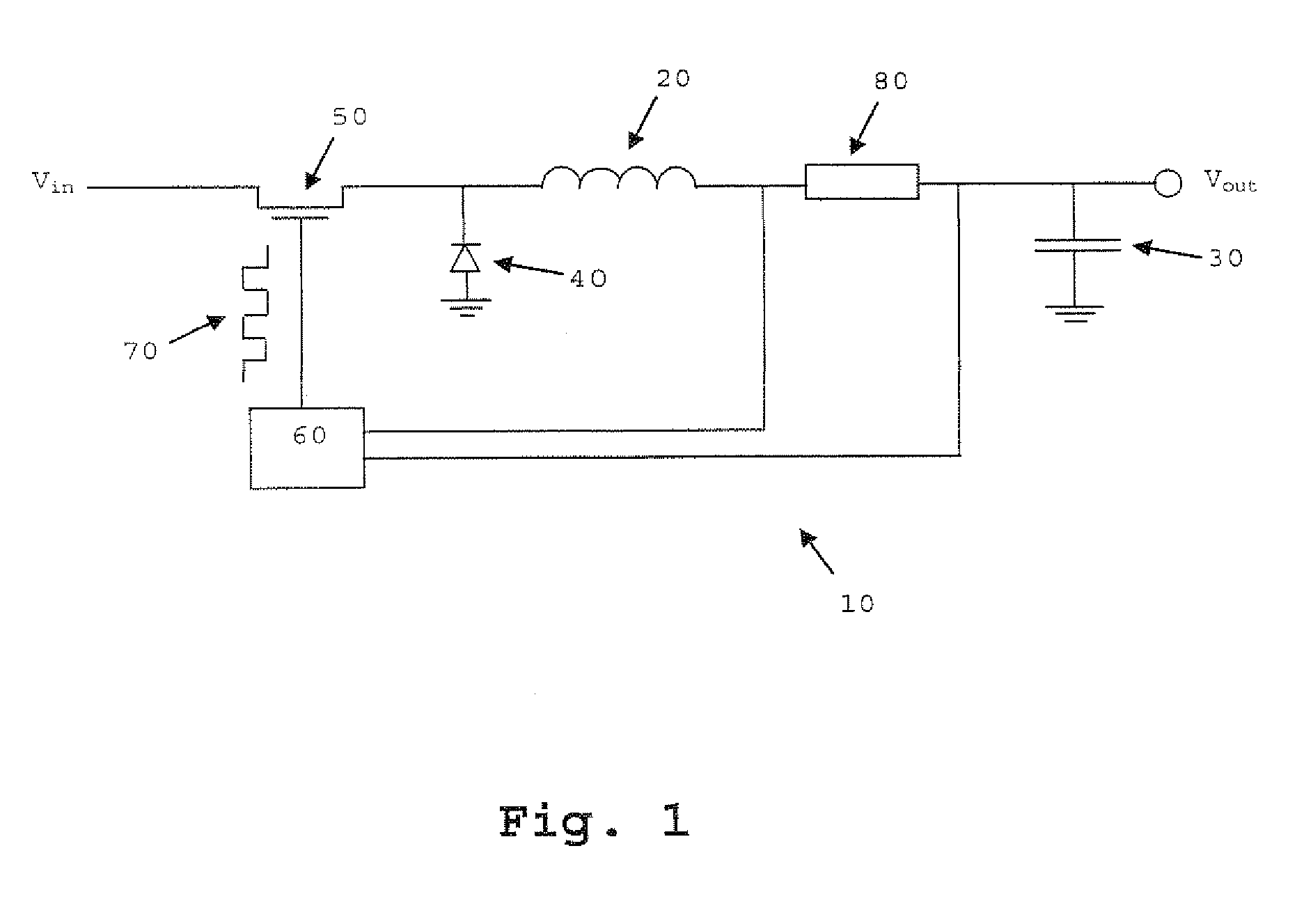

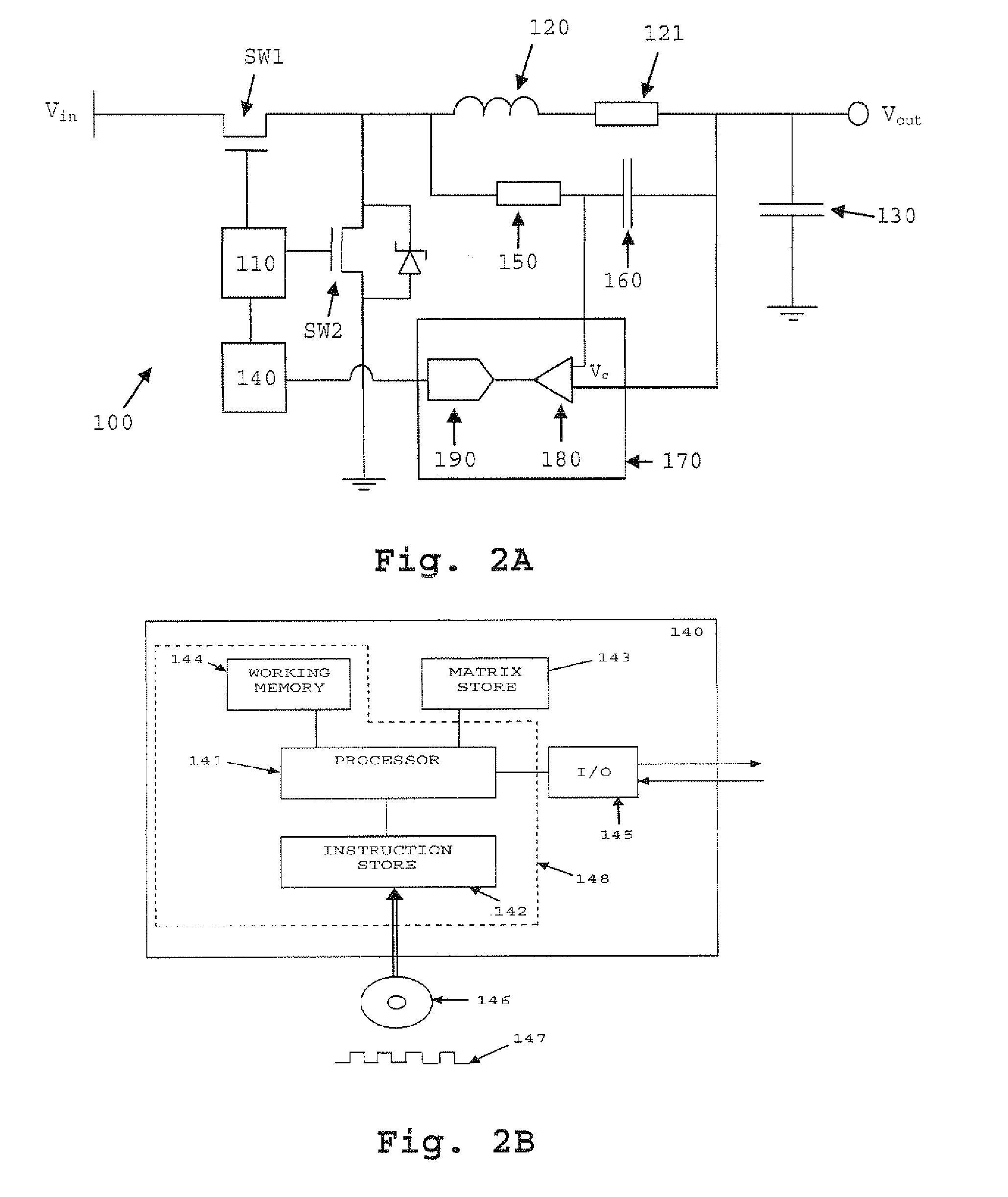

Current measurement in switched mode power supply

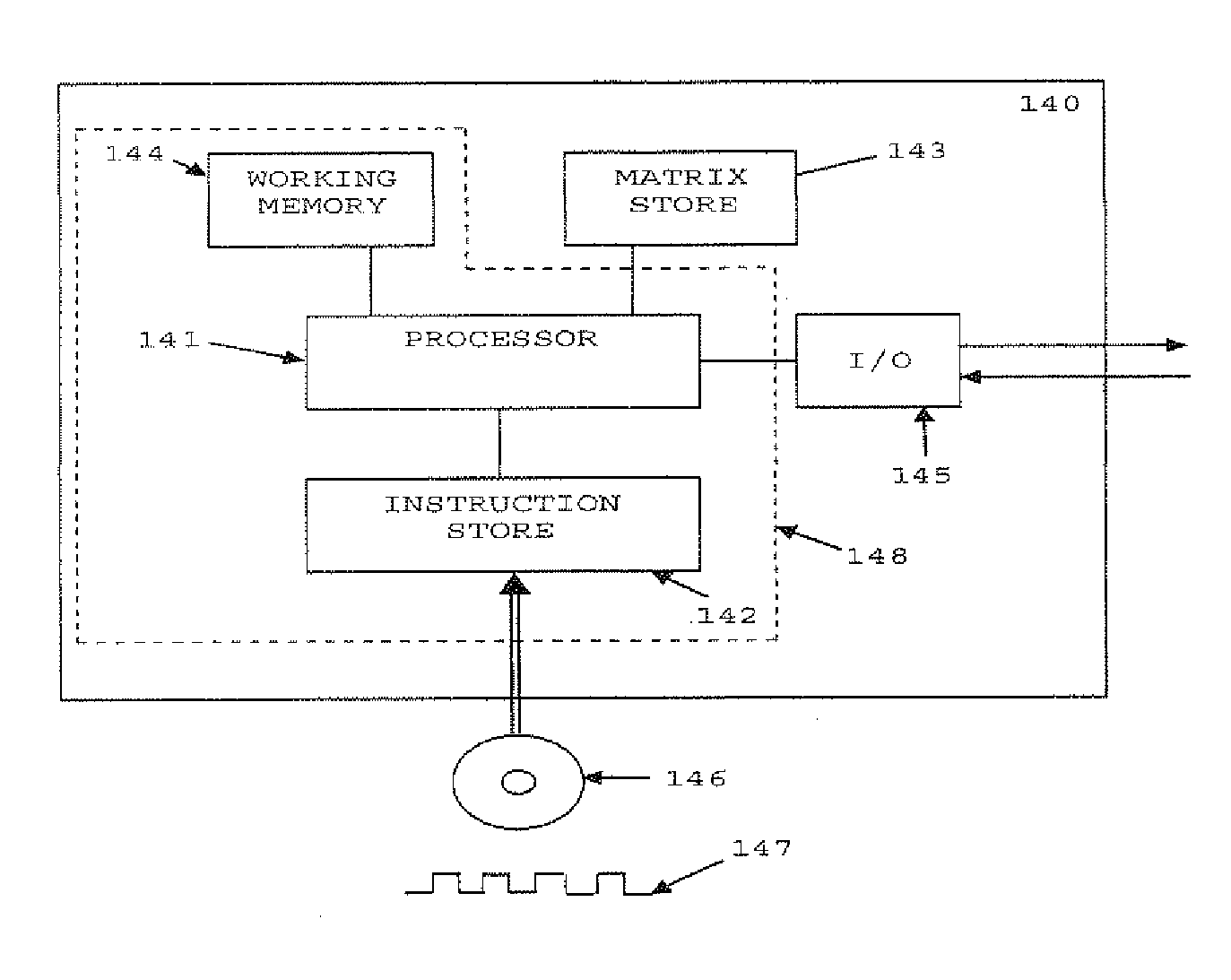

ActiveUS20120078556A1Improve accuracyComputationally efficientDc-dc conversionSpecial data processing applicationsSwitched-mode power supplyElectric current

A method of determining a current in a switched mode power supply. The method comprises: storing values representing at least one pre-calculated matrix A; receiving measured current values; and using the stored values representing the matrix A and the received current values to calculate a respective initial value for each of the coefficients of the line and for each measured current value: calculating an estimated current using the equation of the line and the calculated initial values of the coefficients; determining a difference between the measured current value and the estimated current value to generate a difference value, and comparing the difference value against a threshold and, if the difference value is greater than the threshold, calculating updated values of the coefficients using stored values representing matrix A and difference value. A value for the current in the switched mode power supply is determined using the updated values of the coefficients

Owner:TELEFON AB LM ERICSSON (PUBL)

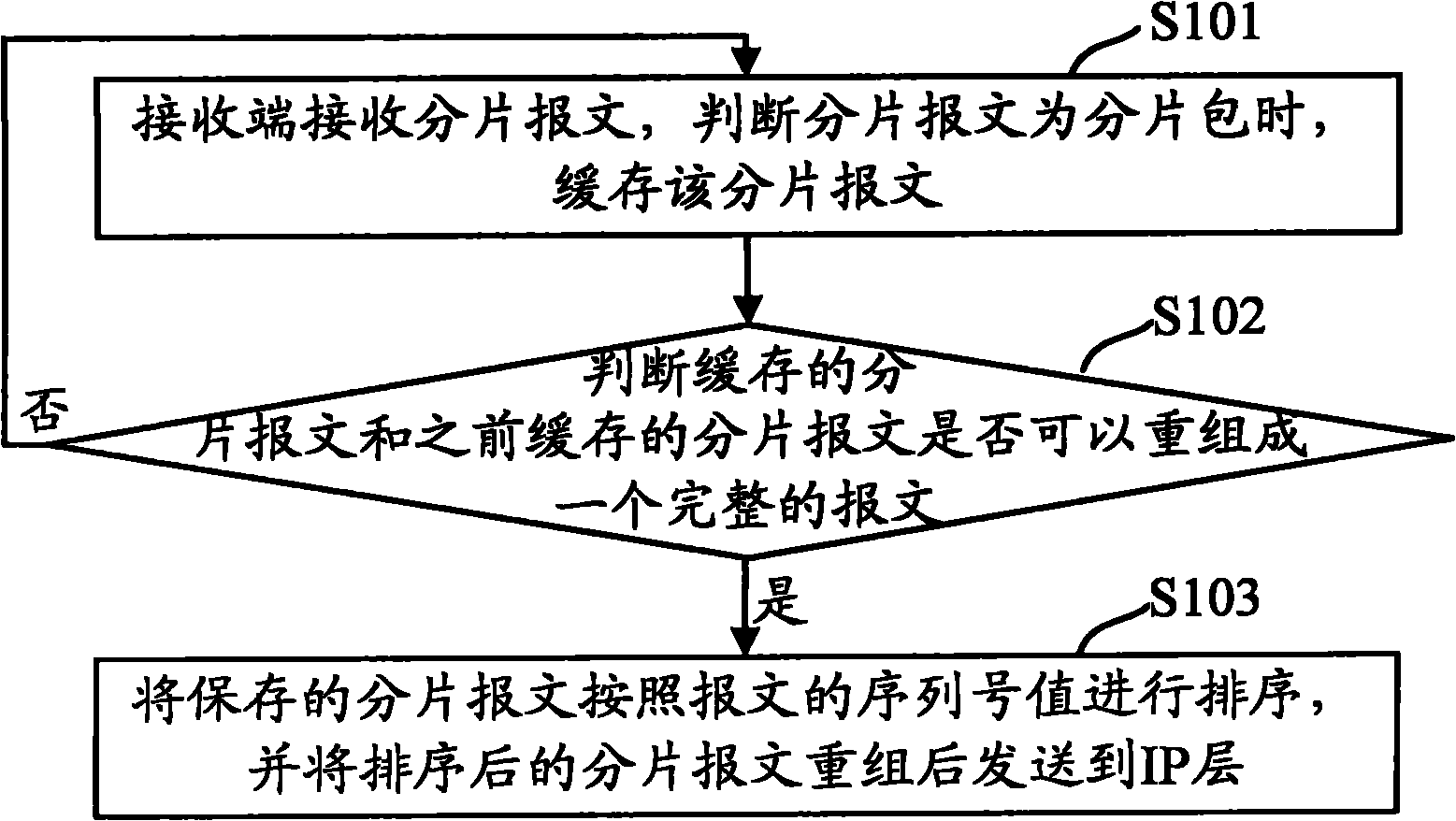

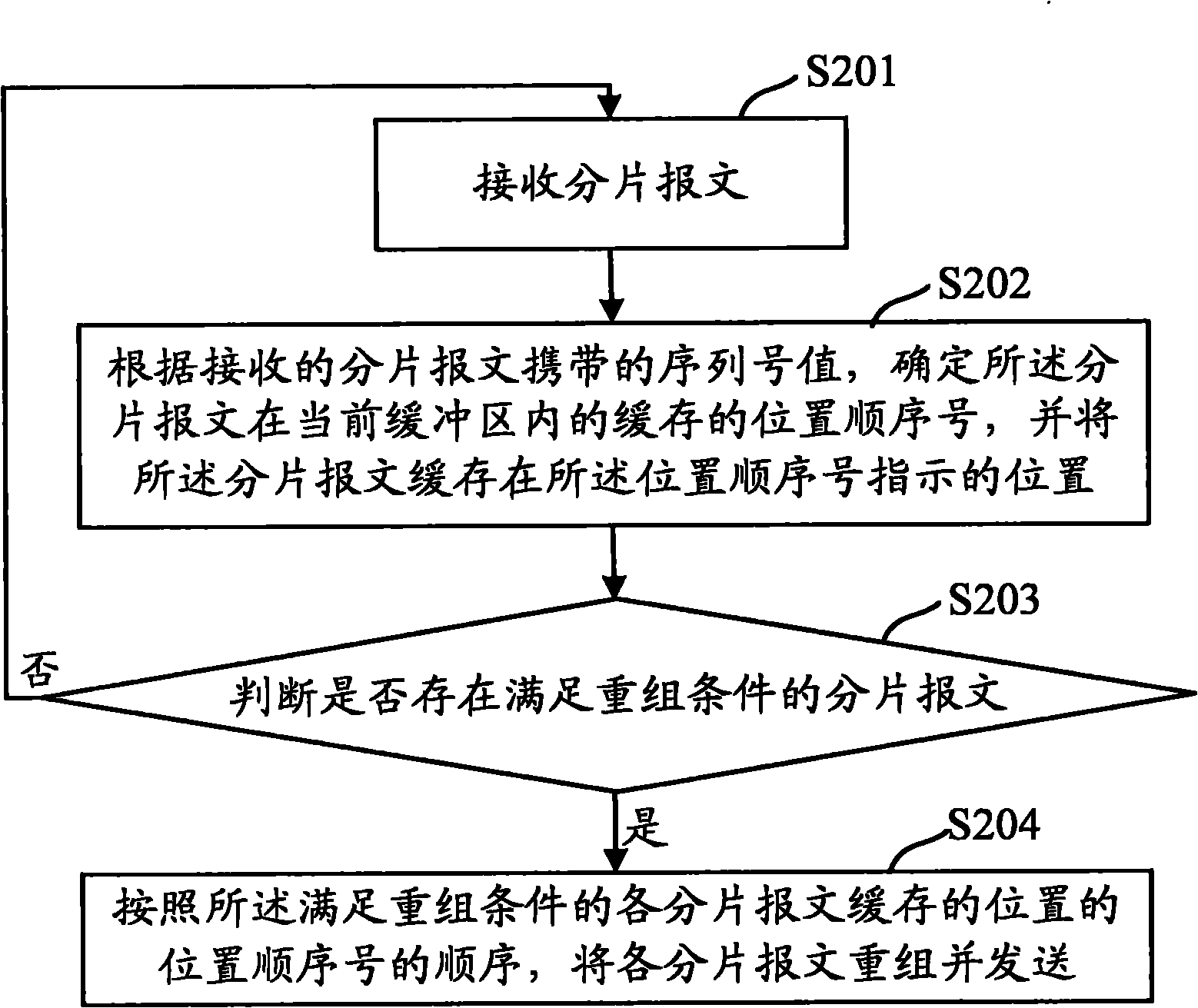

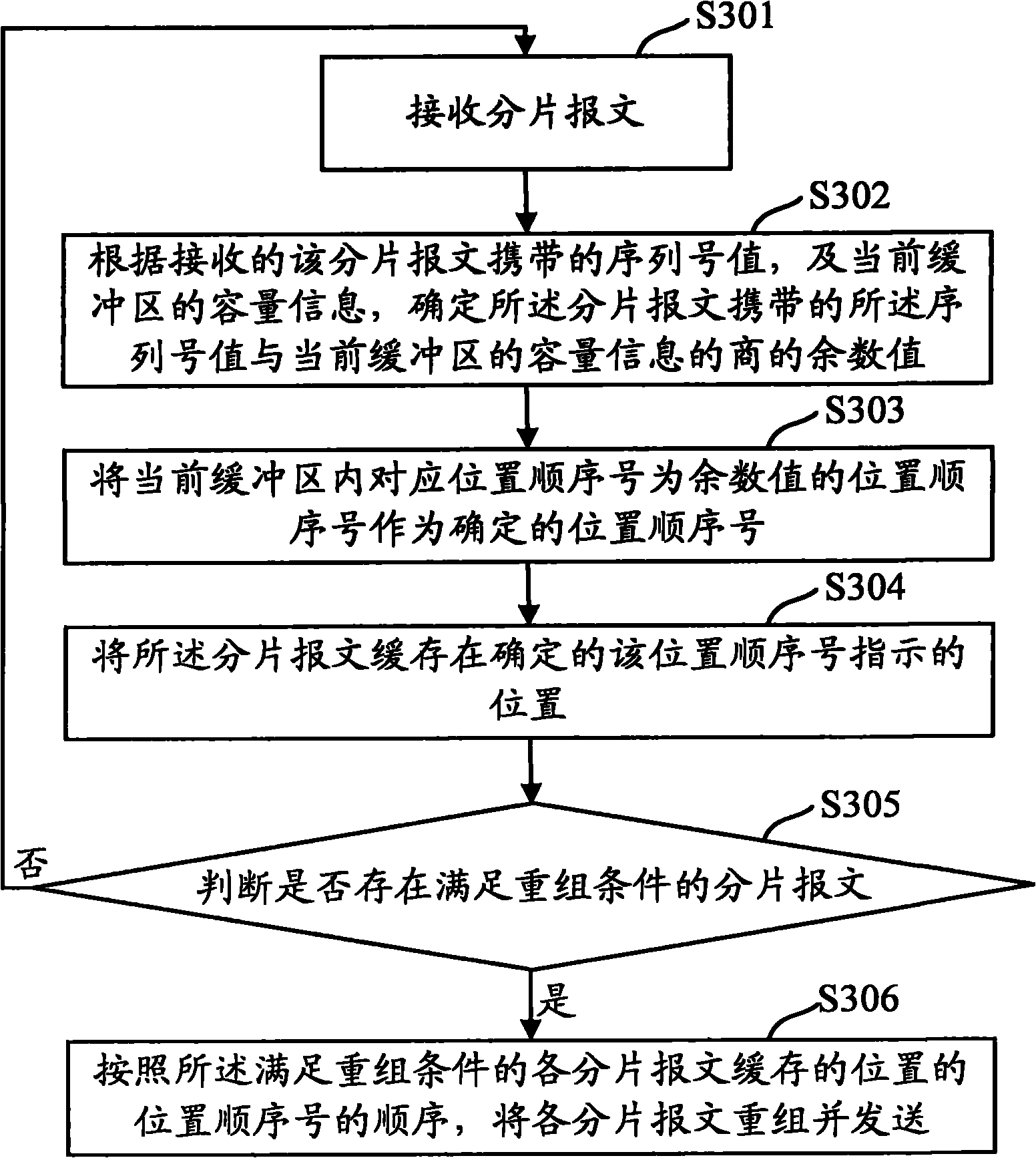

Method, device and equipment for recombining multi-link messages

InactiveCN101917472ASave reorganization timeIncrease transfer rateData switching networksMulti linkData transmission

The invention discloses a method, a device and equipment for combining multi-link messages, which are used for solving the problem that the recombination of the multi-link messages influences the efficiency of message data transmission. The method comprises the following steps of: determining the sequence number of cache position of a fragment message in the current buffer zone according to the serial number value of the received fragment message, and caching the fragment message; judging whether fragment message meeting the recombining condition exist or not; and recombining and transmittingeach fragment message according to the sequence of the position sequence number of the cache position of each fragment message meeting the recombining condition if the fragment message meeting the recombining condition indeed exists. By adopting the scheme, the fragment message is directly recombined according to the sequence of the cache position of each fragment message meeting the recombining condition, and is transmitted to save the time for recombining the fragment messages, so that the efficiency of transmitting the message data is improved, and the real-time of the message data is improved.

Owner:BEIJING XINWANG RUIJIE NETWORK TECH CO LTD

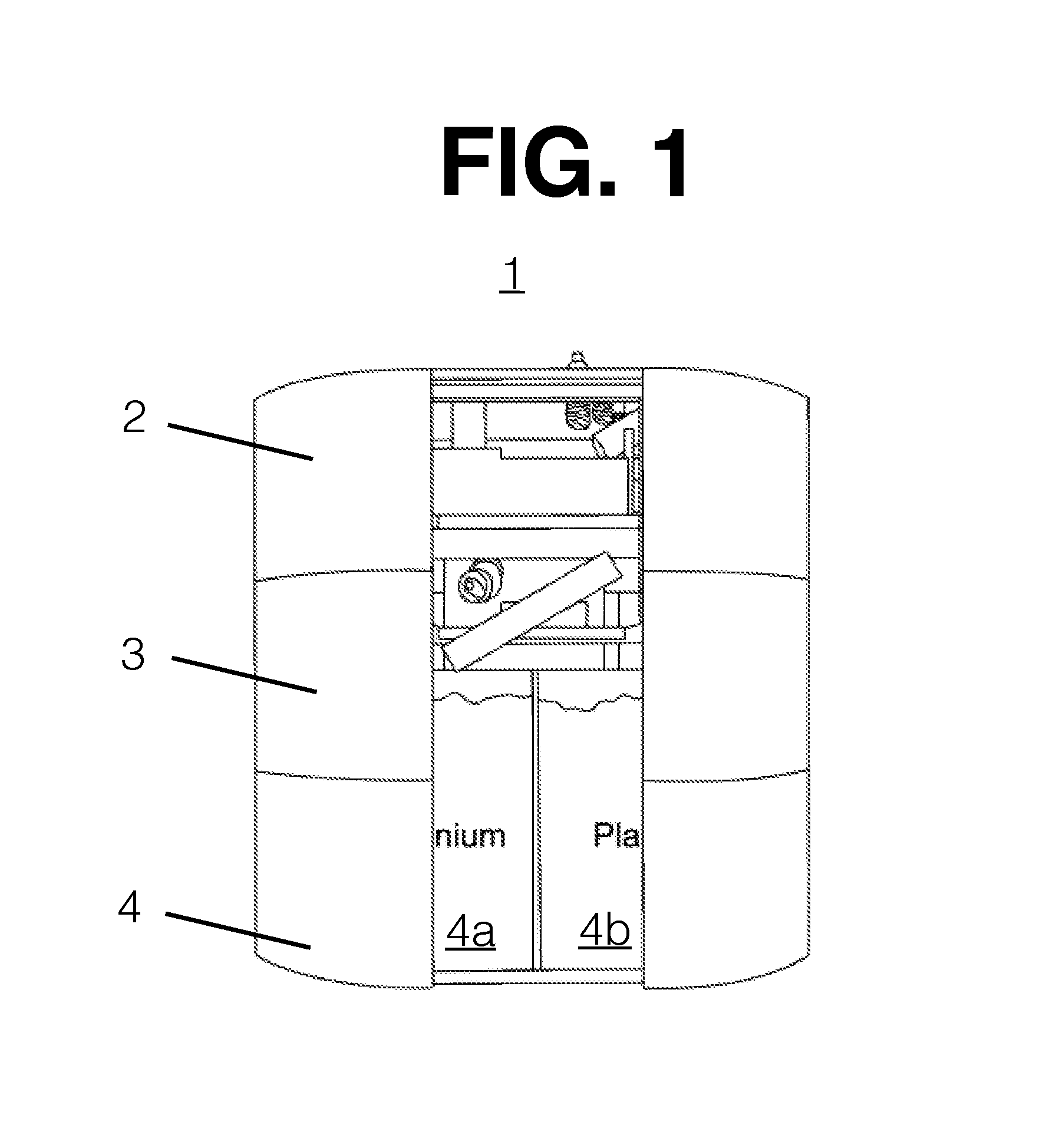

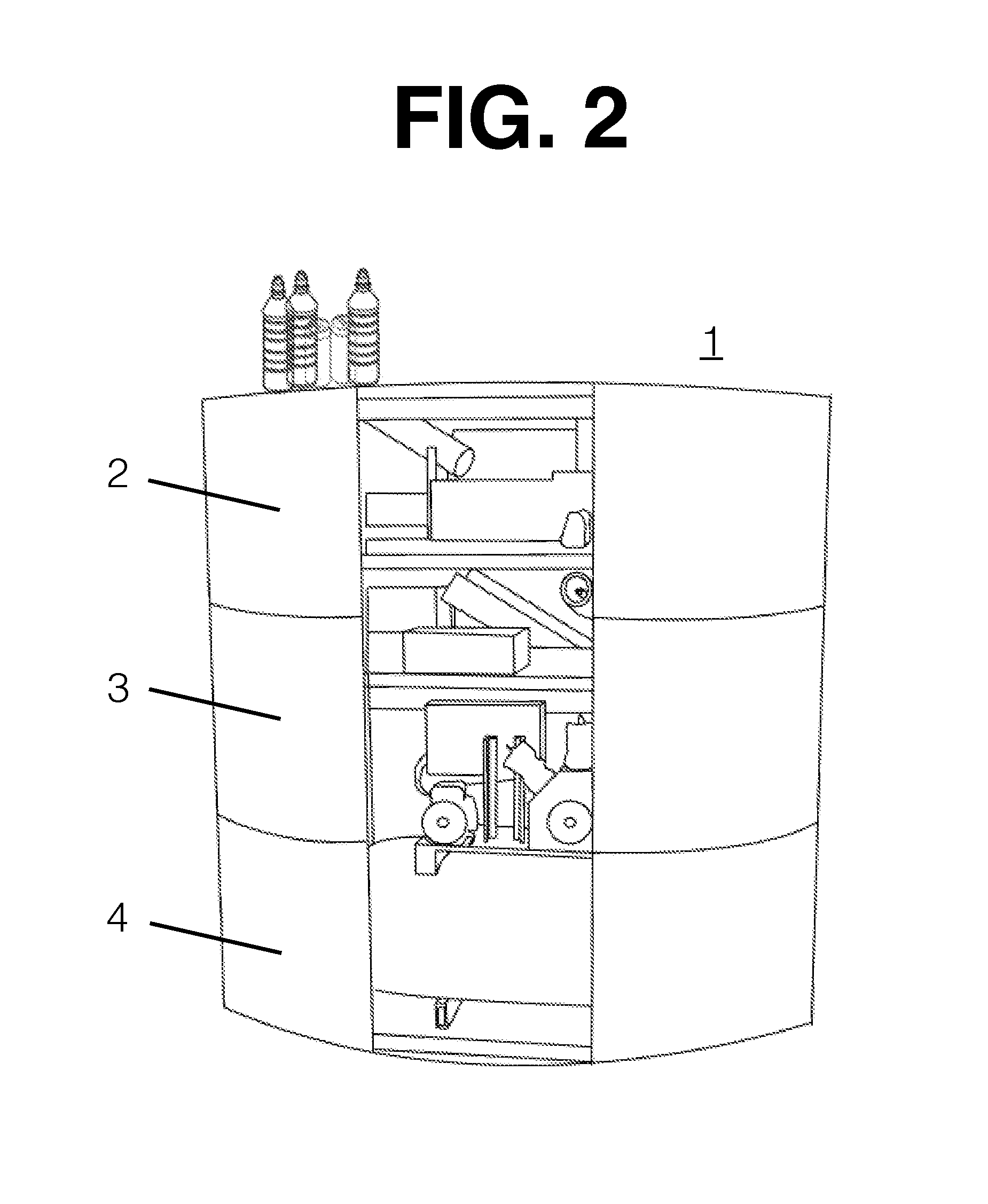

Modular garbage collection apparatus

ActiveUS9272842B1Easy to processEasy to replaceWaste collection and transferRefuse receptaclesLitterAluminum can

Owner:UNIVERSITY OF PUERTO RICO

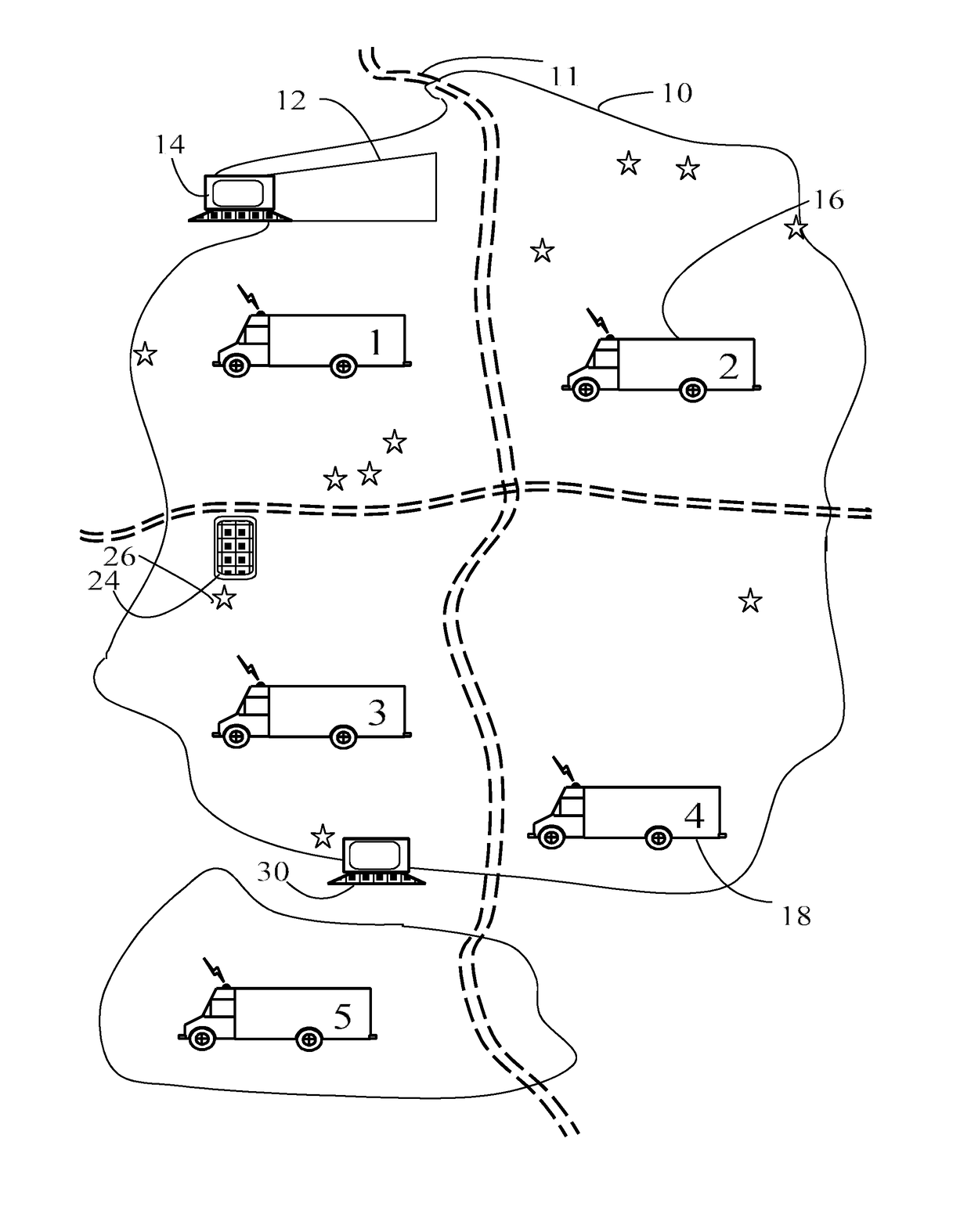

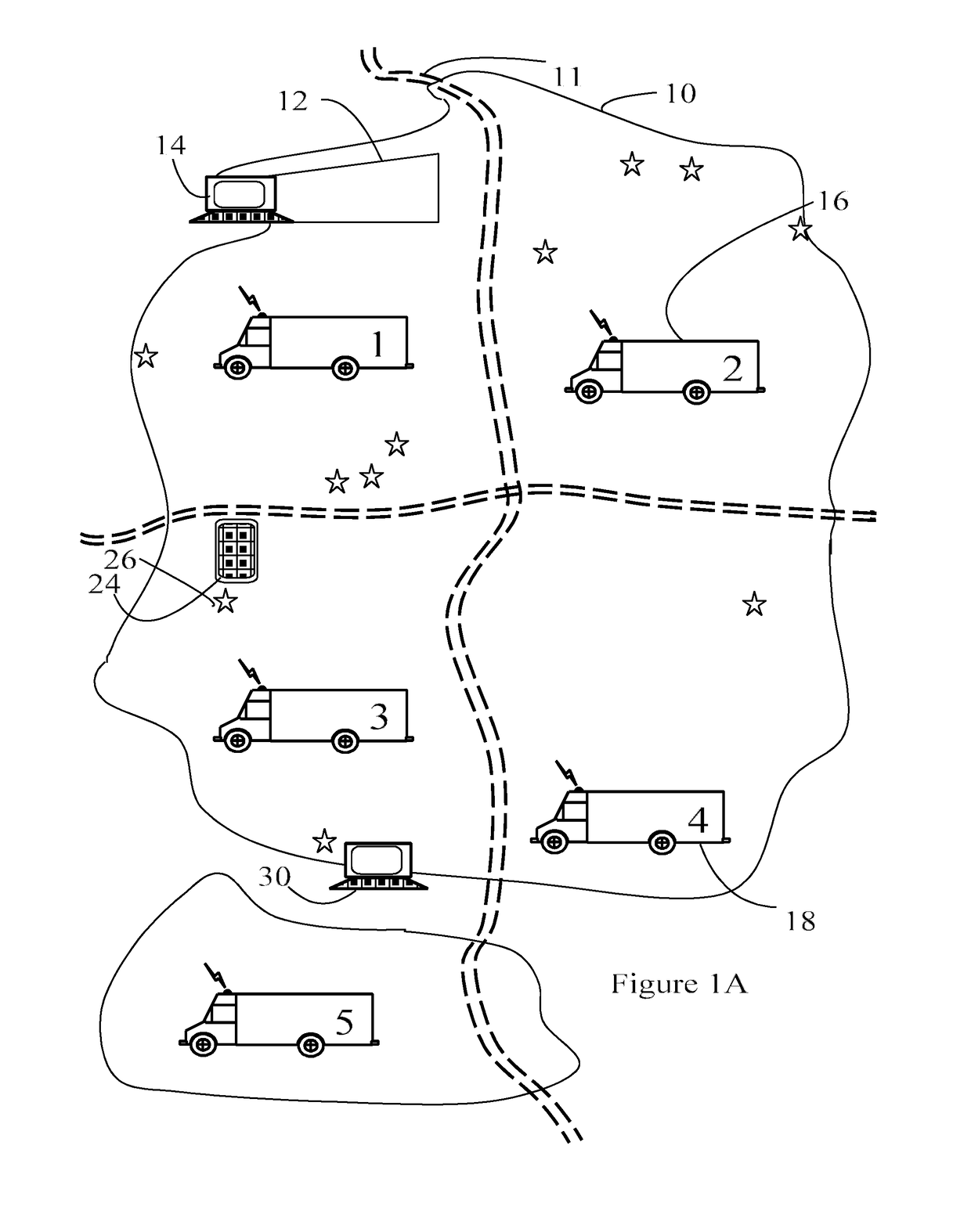

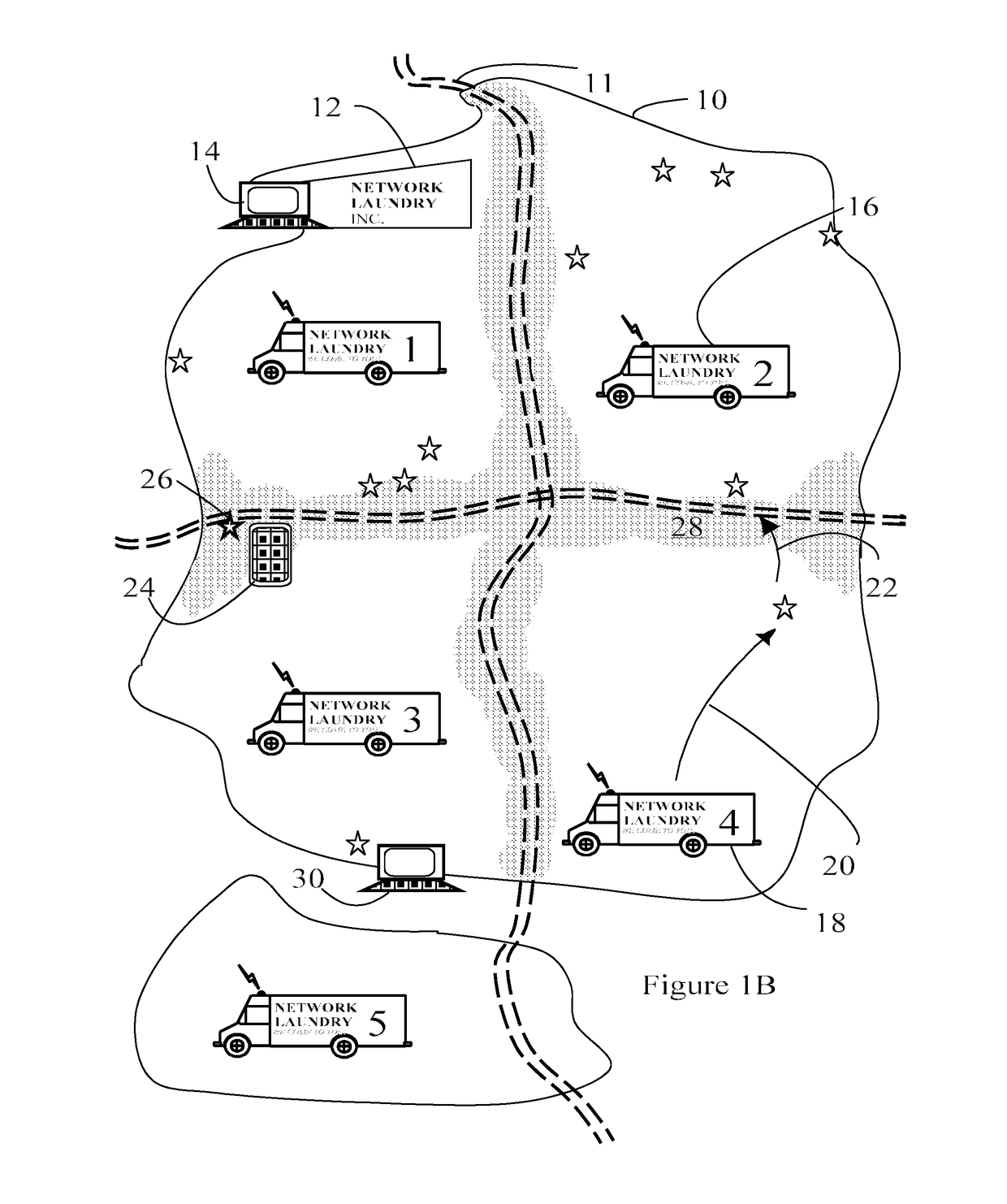

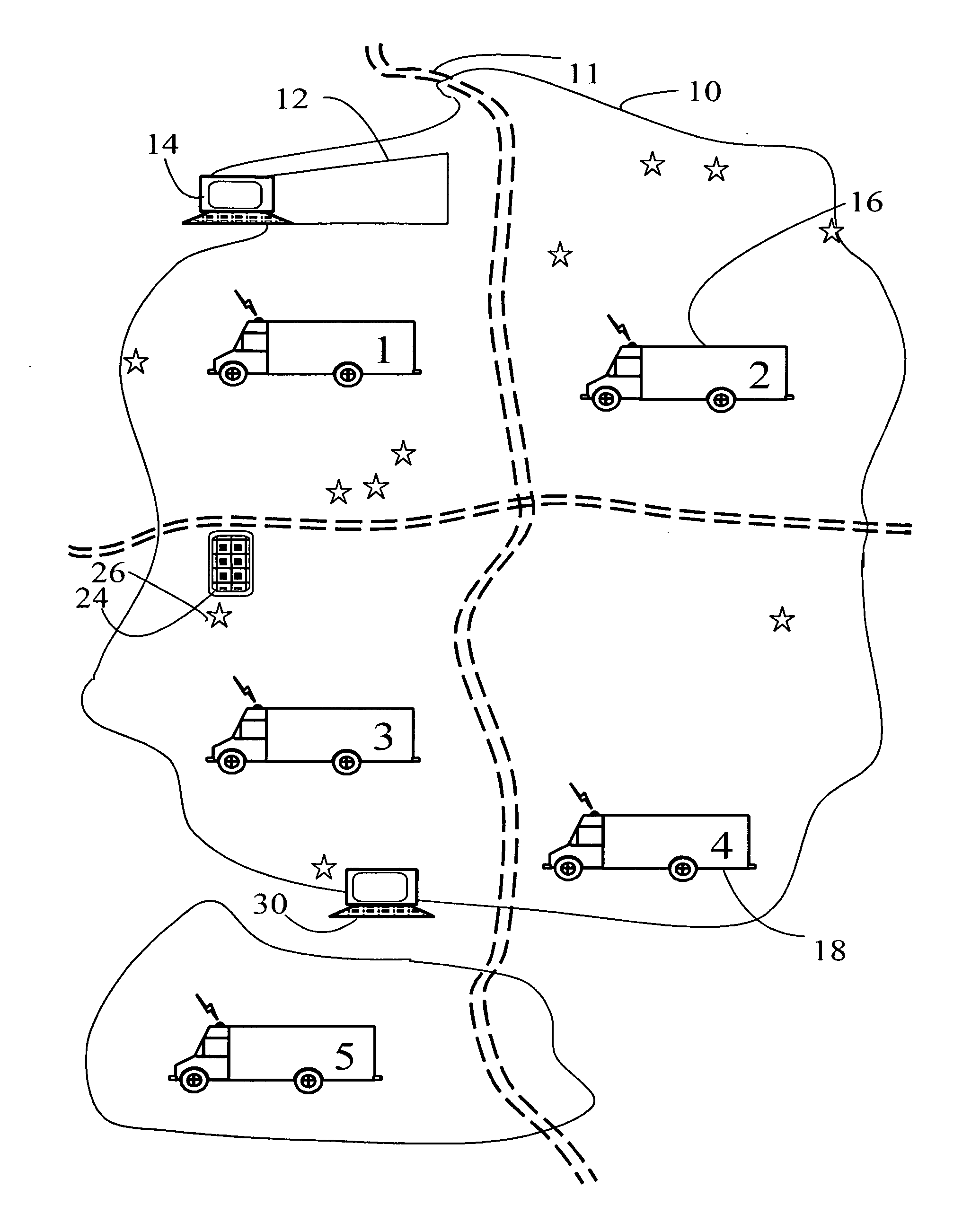

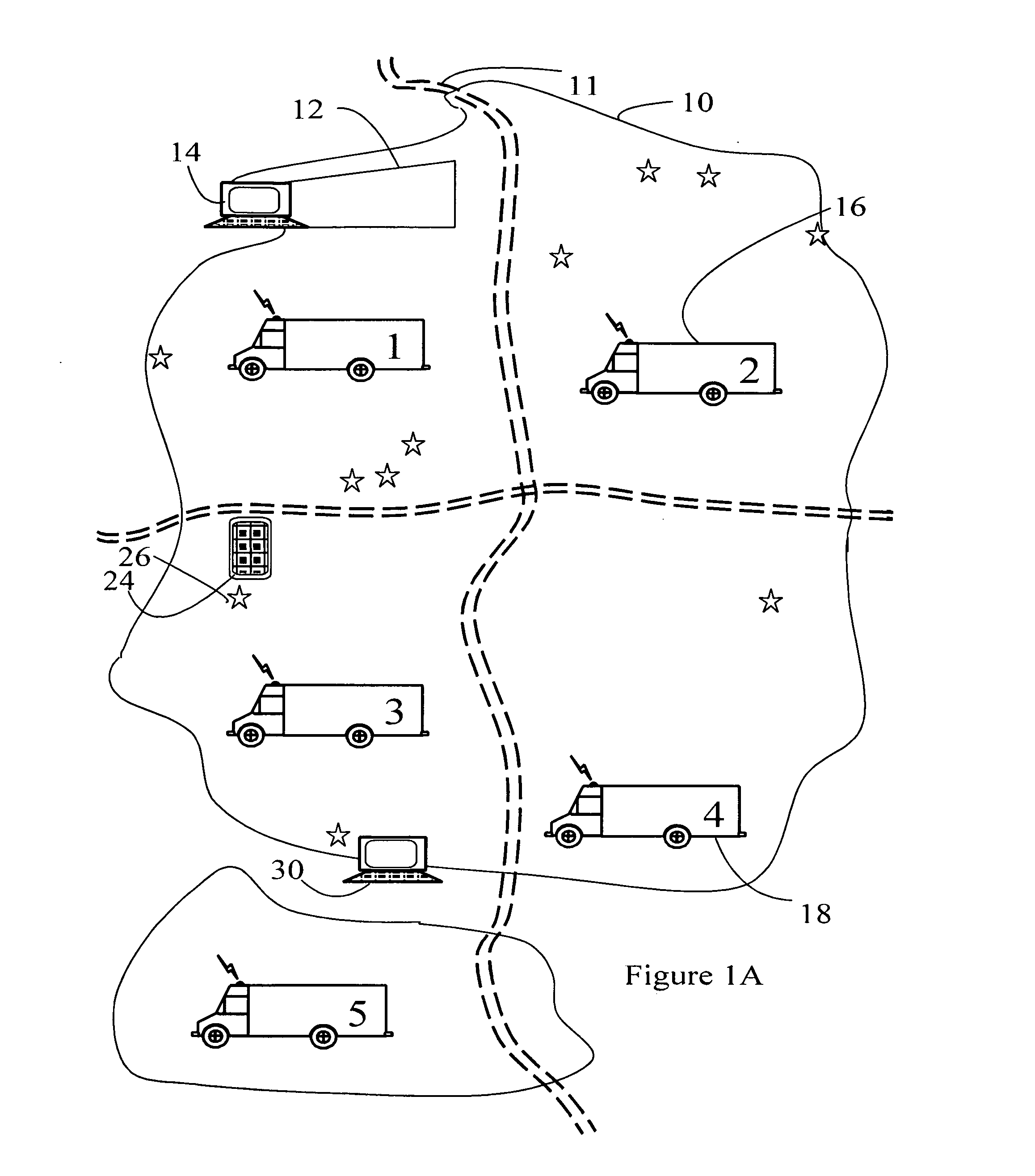

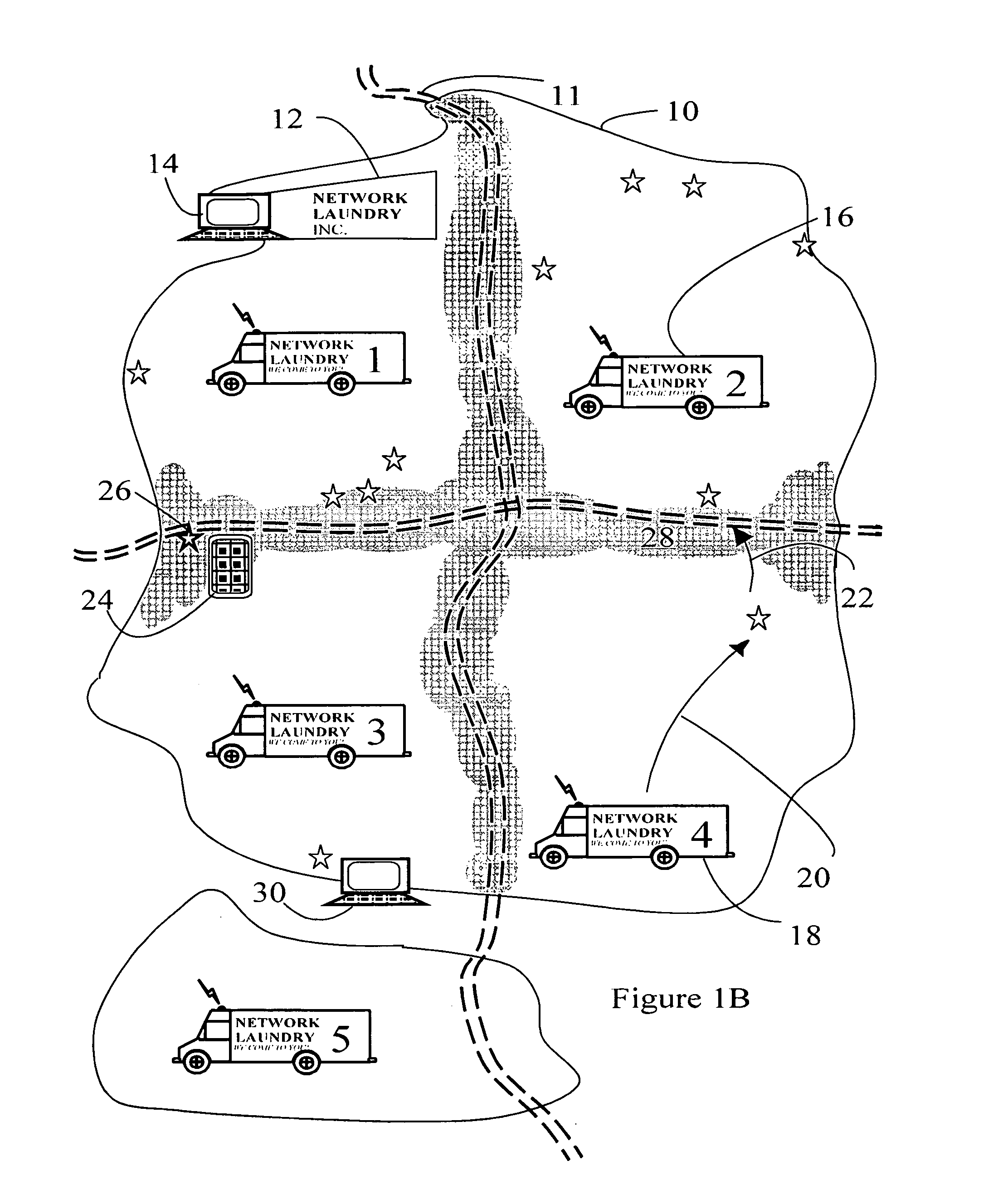

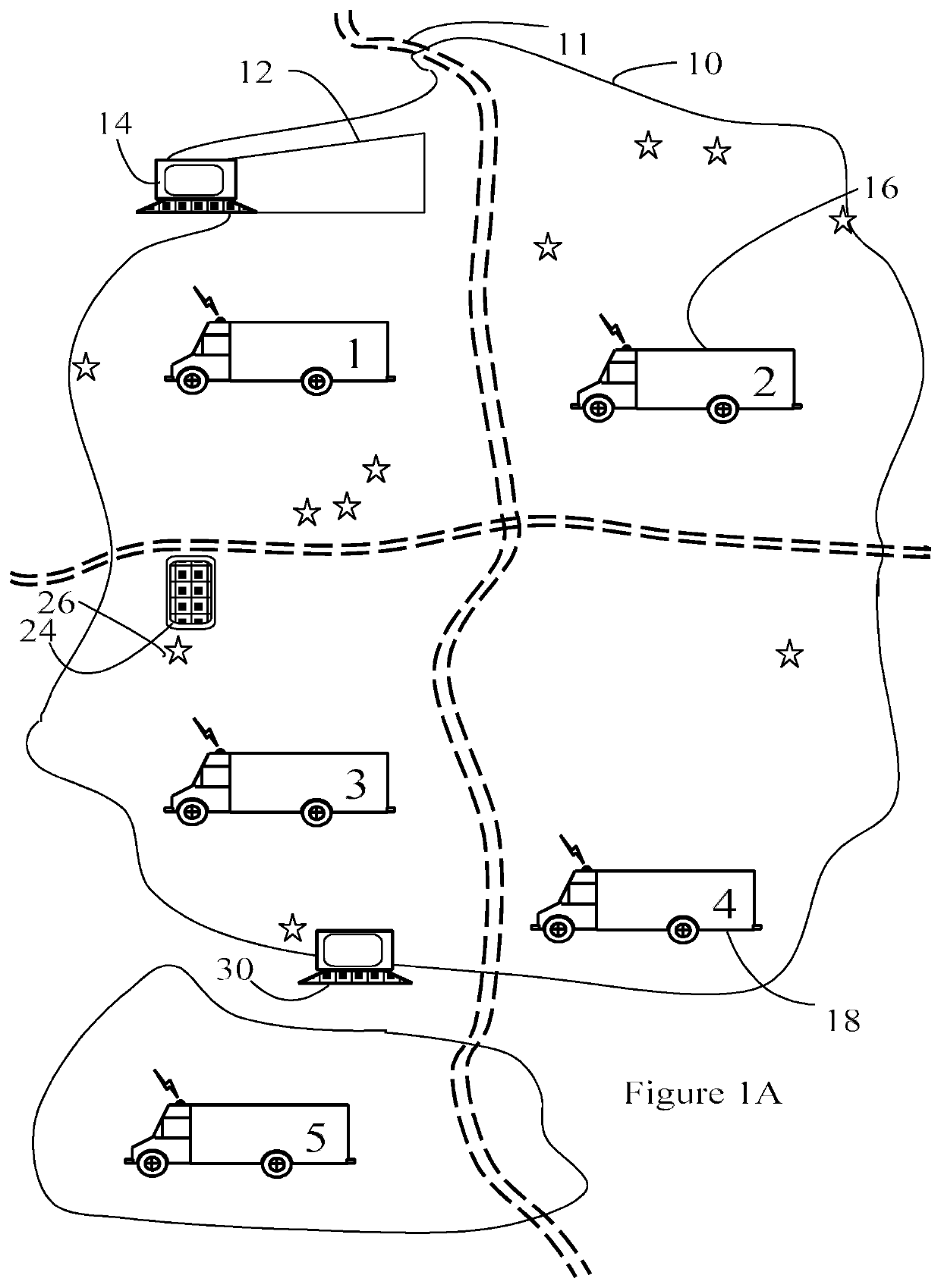

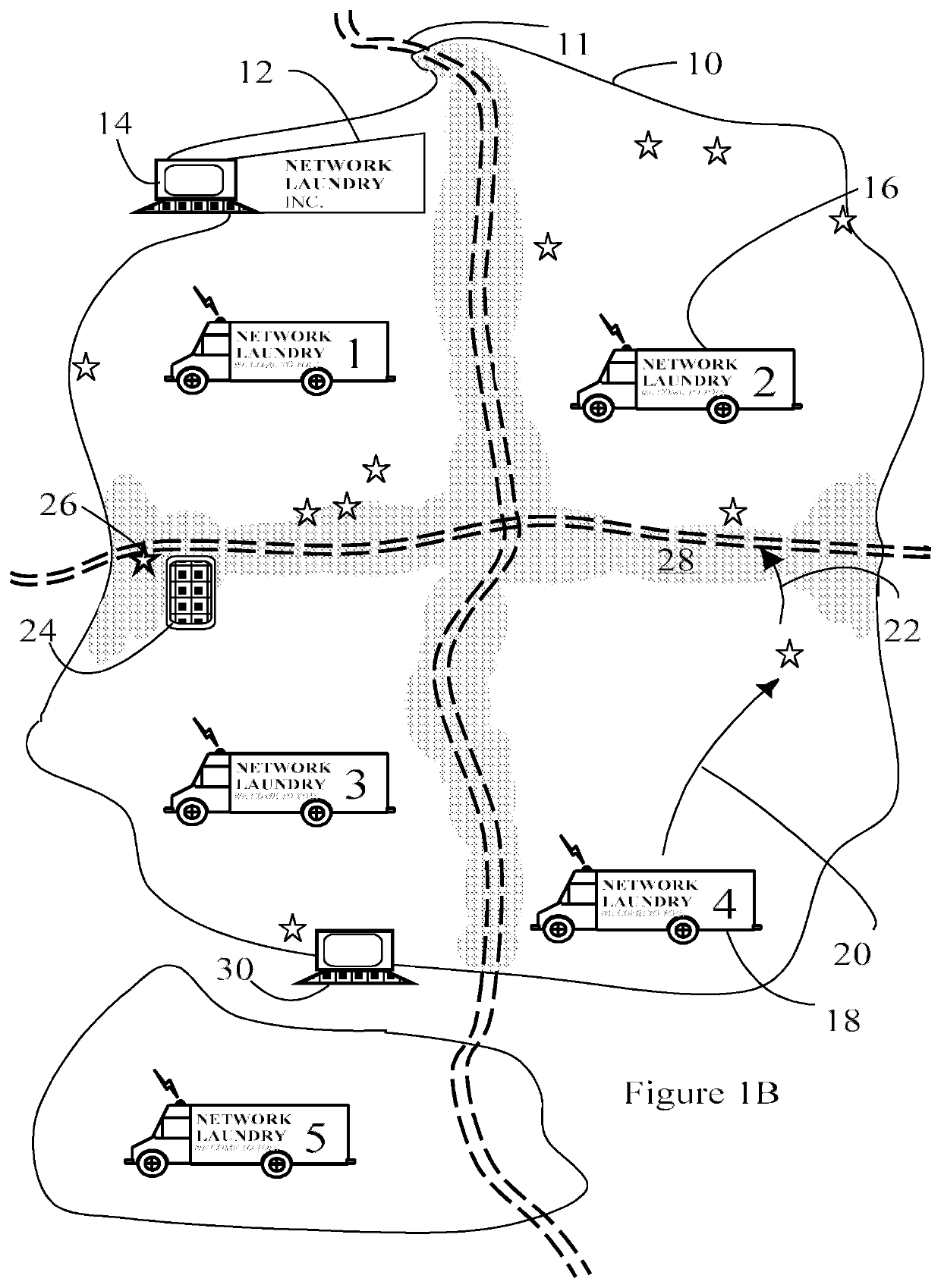

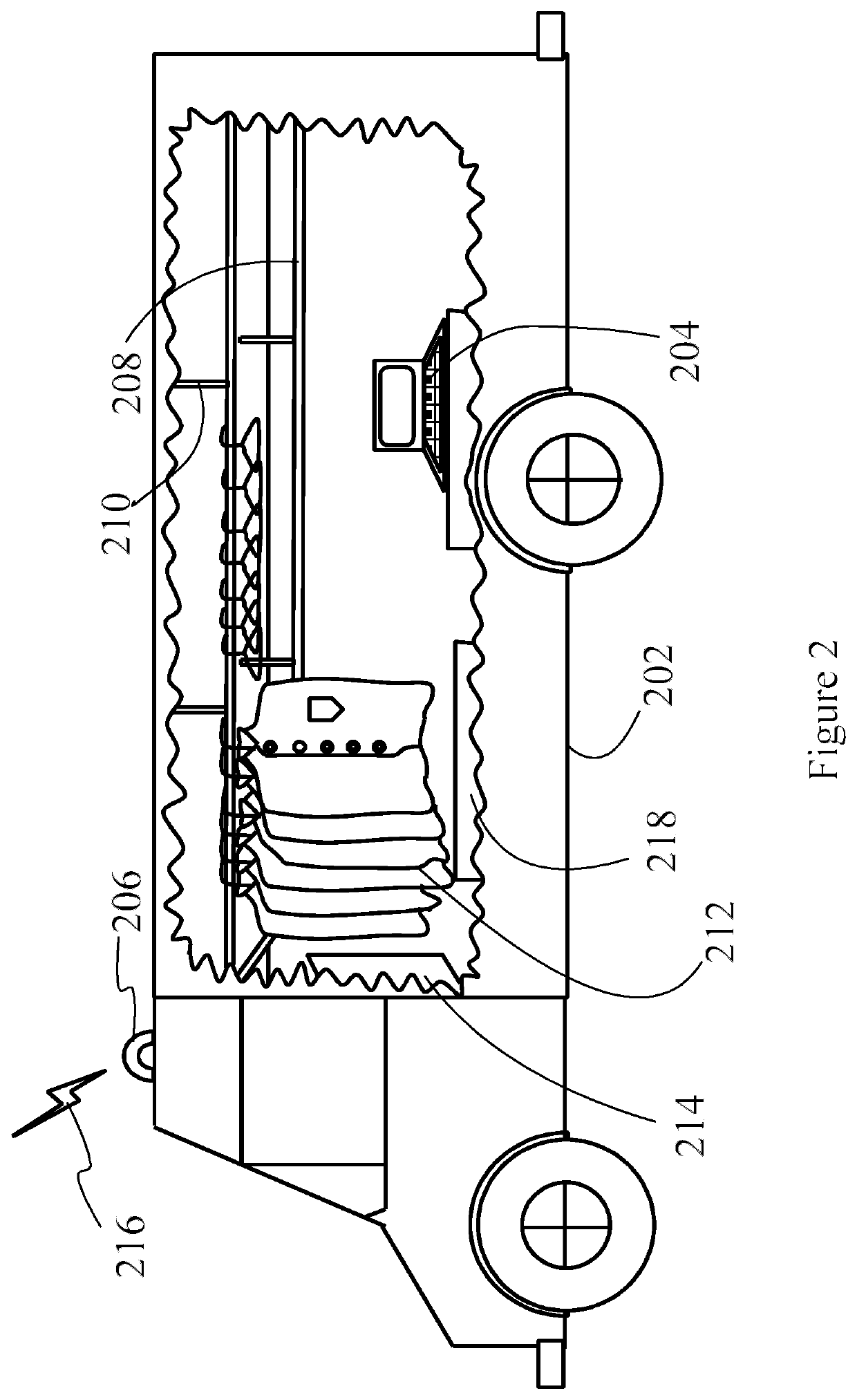

Mobilized laundry service system

A distributed laundry system having mobilized laundry vehicles, including true laundry conveyors in the vehicles, and including a specialized distributed computer network in the vehicles to handle the circumstances of mobile laundry operations, such as special laundry instructions. In addition, procedures and operations which allow the vehicles to cooperate to provide efficient pickup and drop off services at locations of the customers' choices (such as at home or work), including flexible territories for the trucks, customer user interfaces on mobile devices such as cell phones, mobile computing devices and the like, and precise time estimates of pick-up and drop-off times.

Owner:LEE CHANG SHIN +1

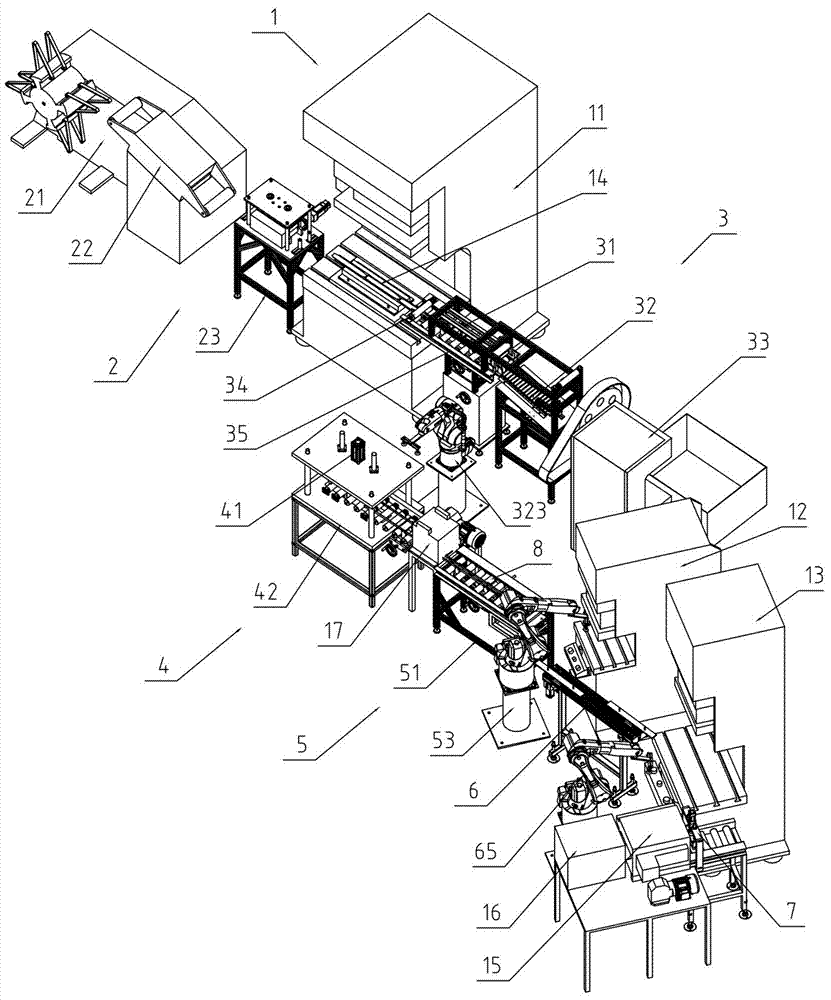

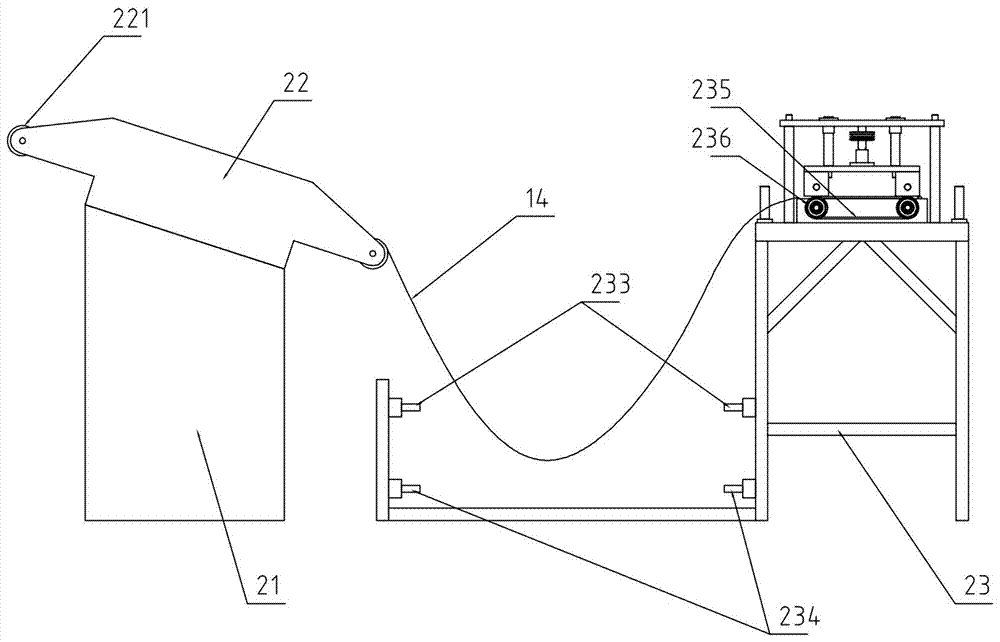

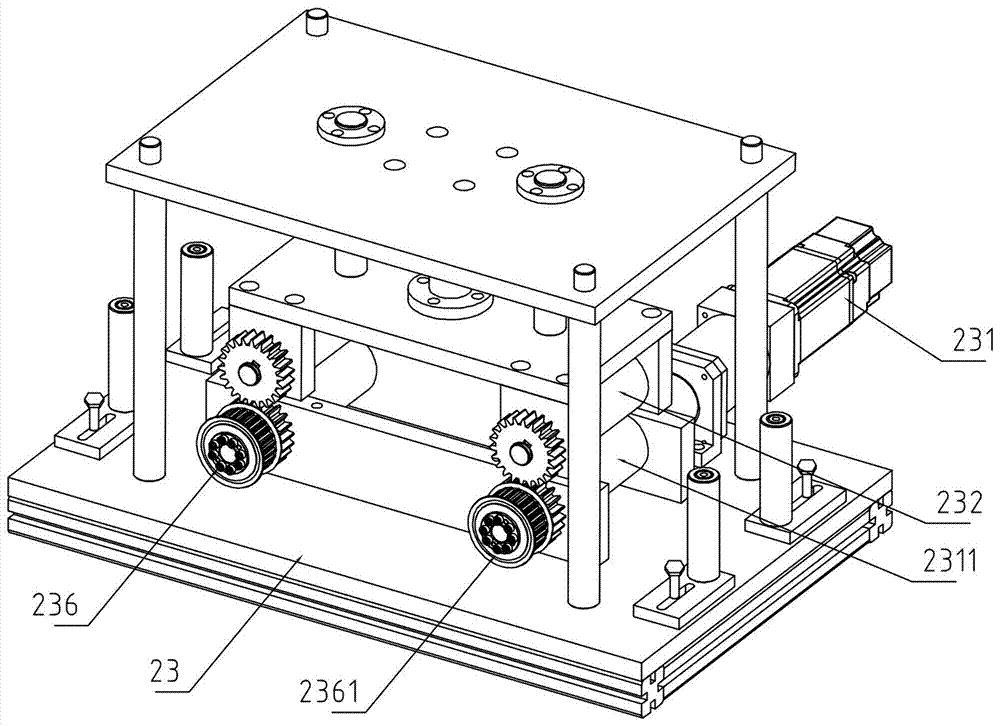

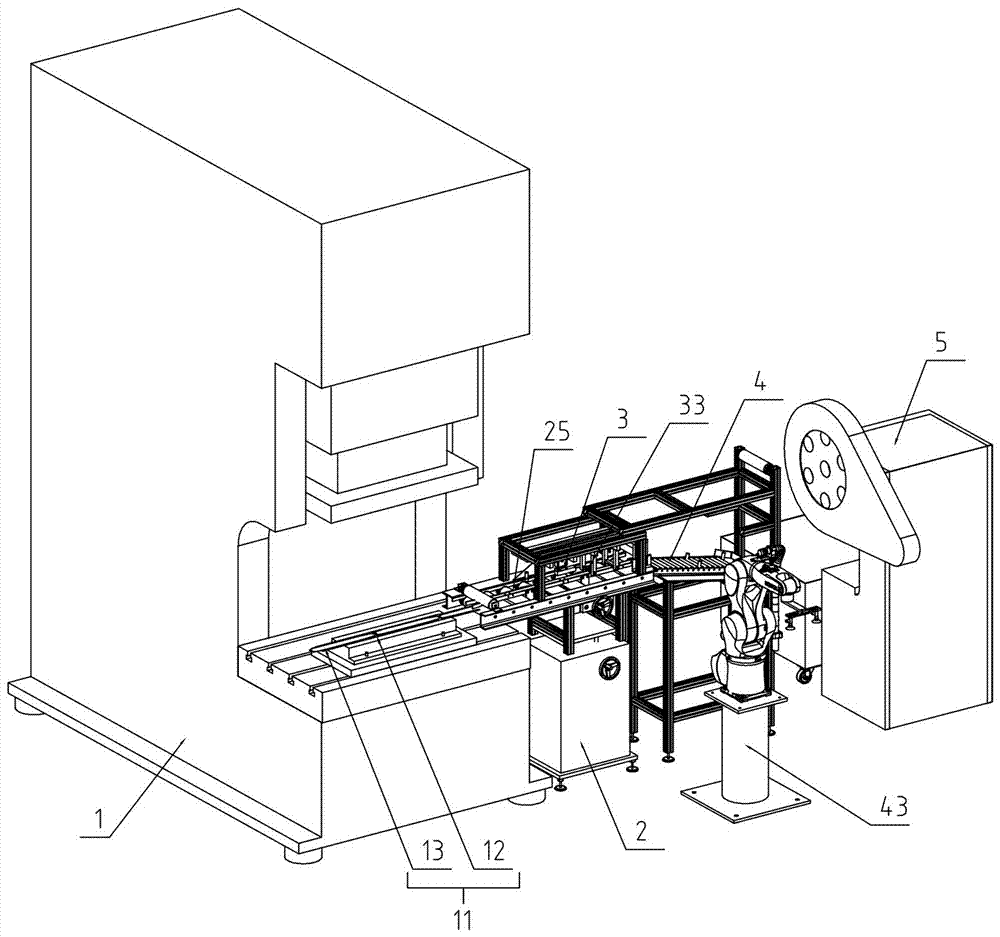

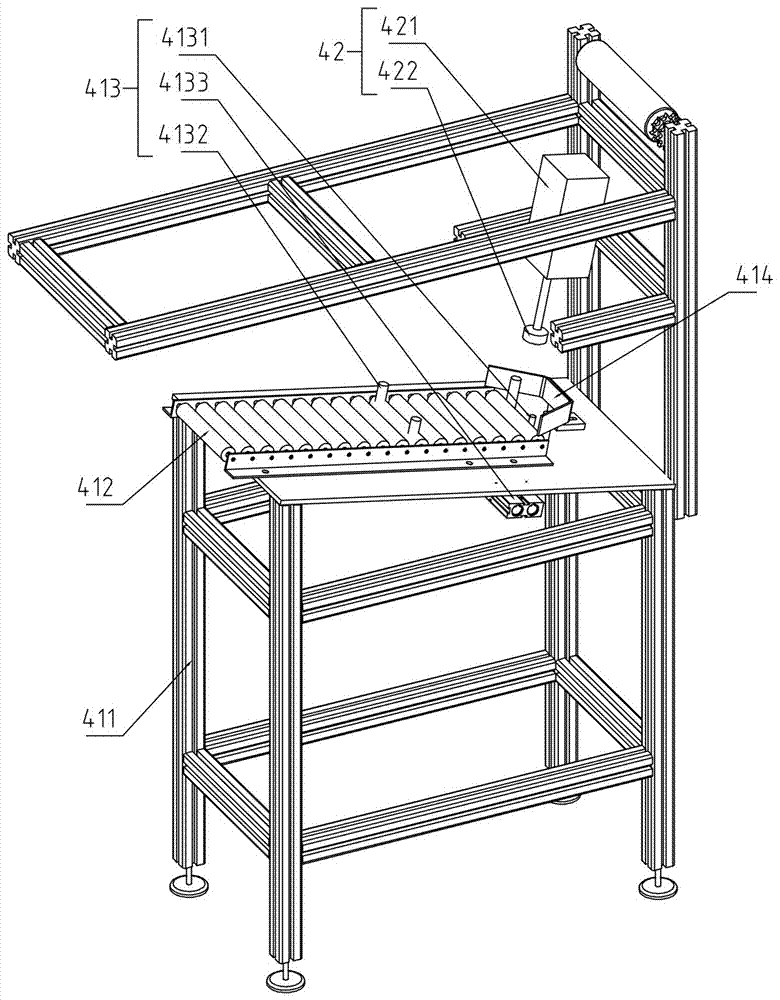

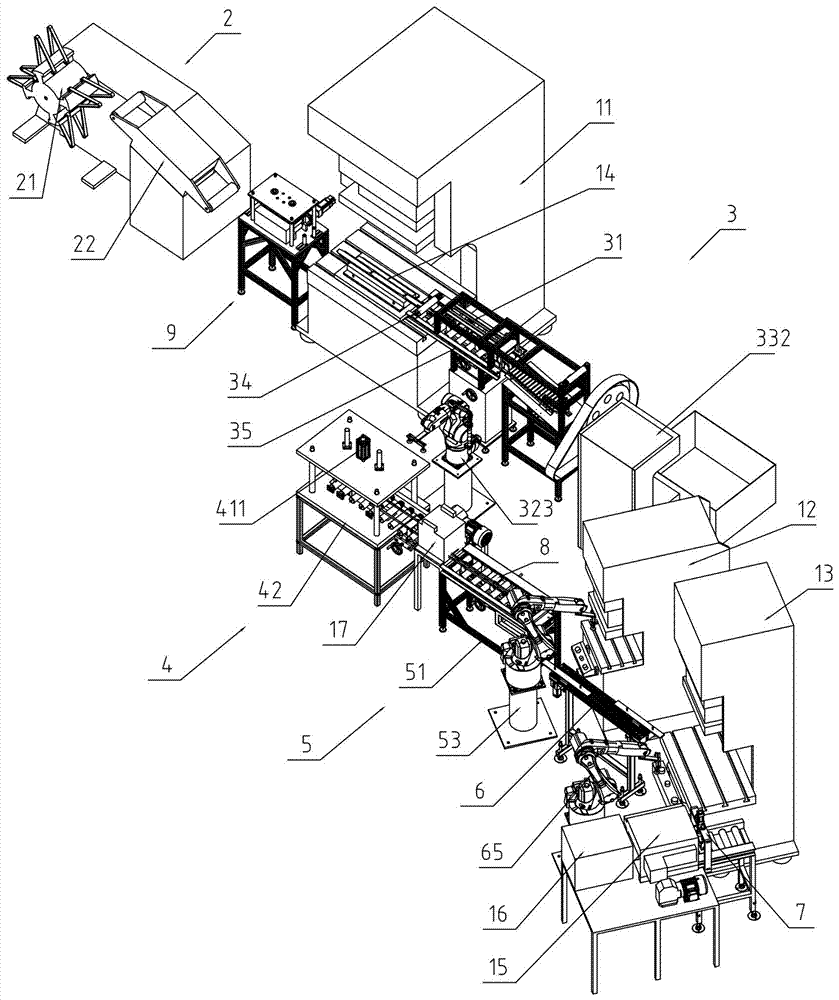

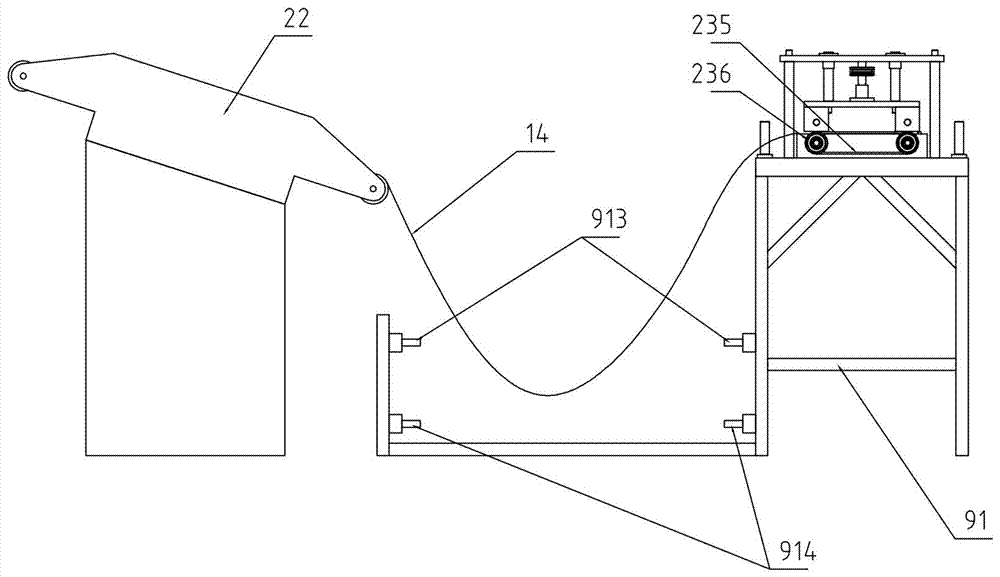

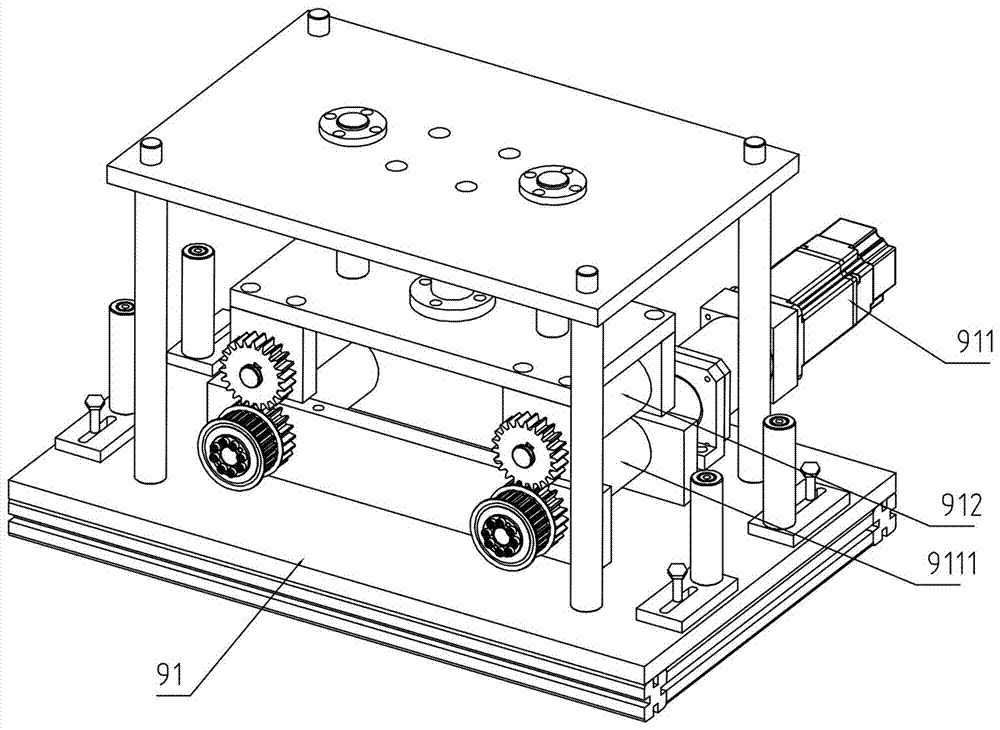

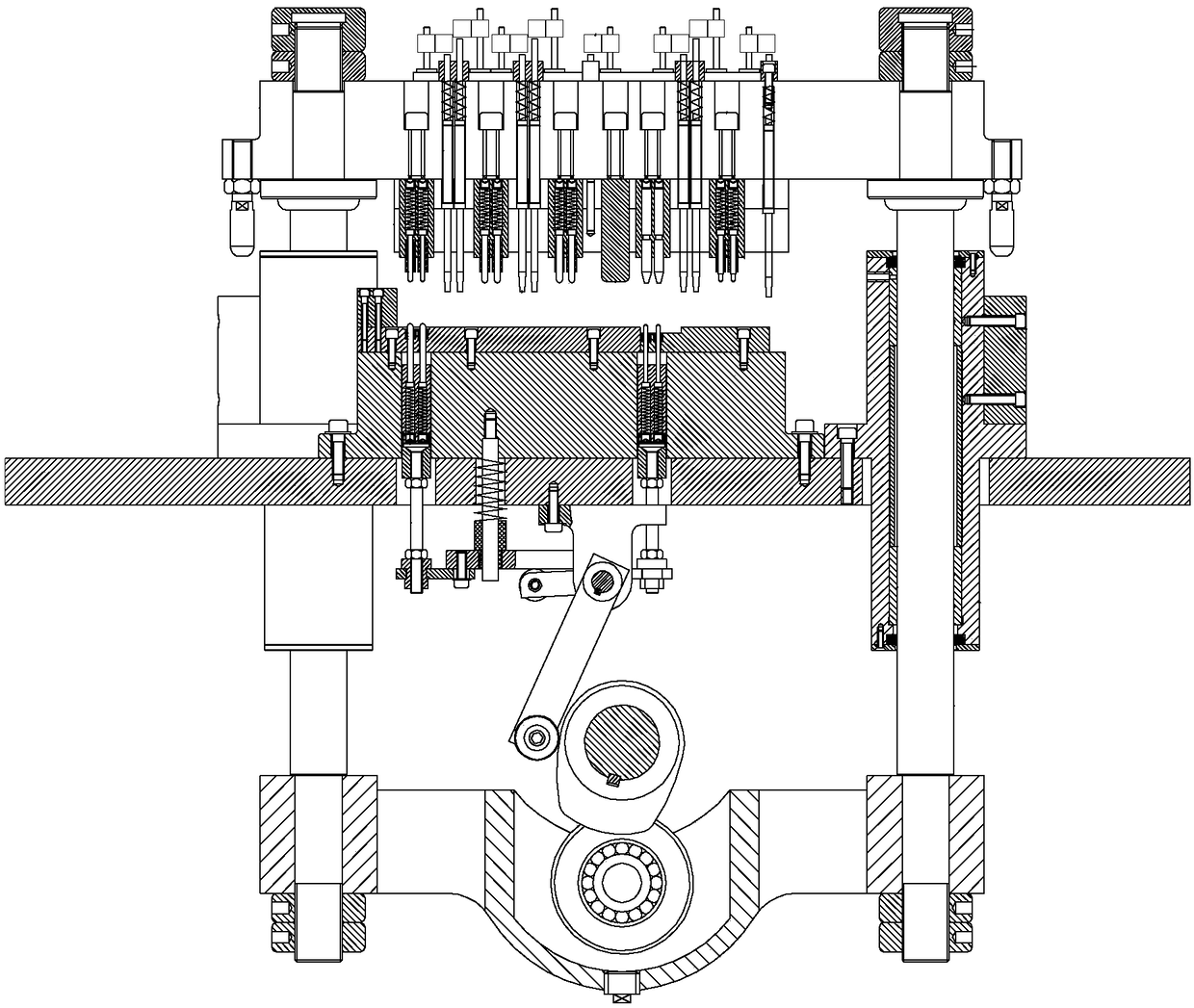

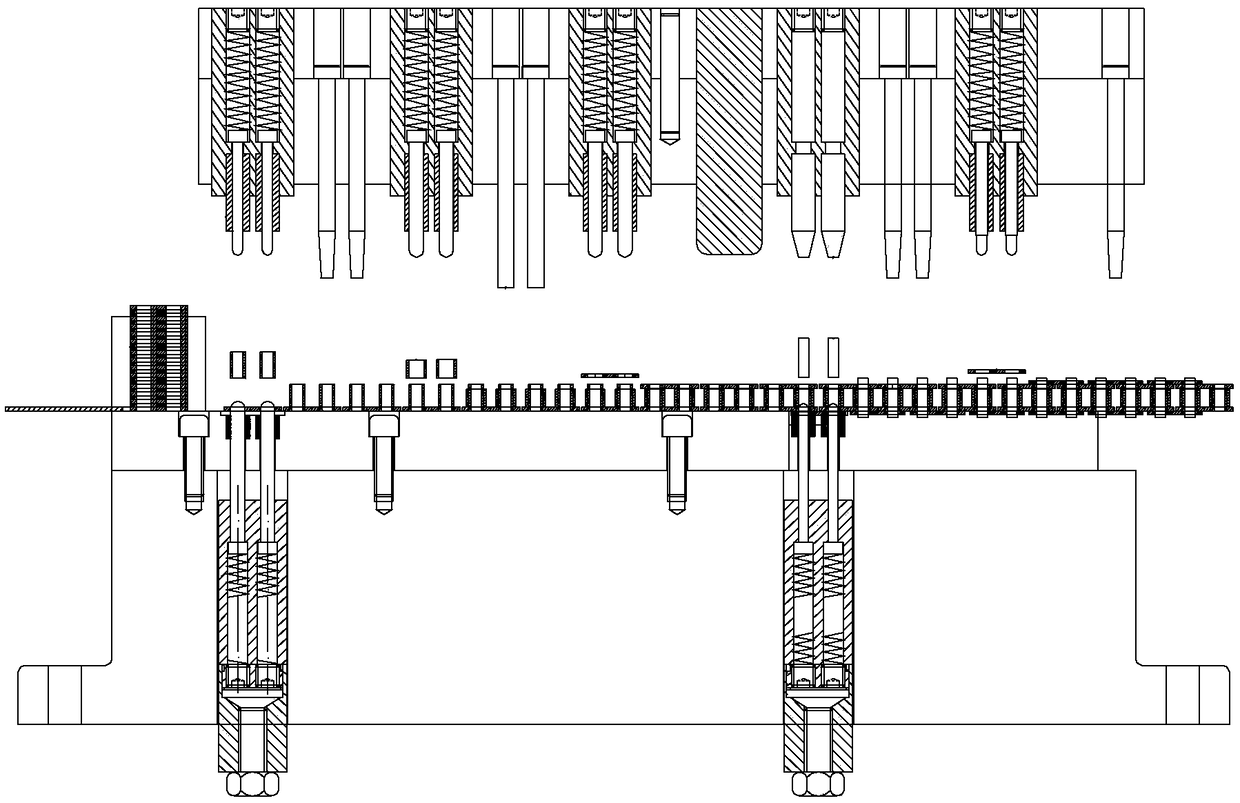

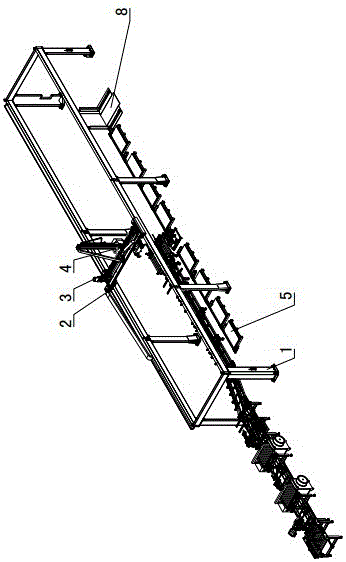

Guide plate stamping production line

ActiveCN106925665AHigh degree of automationAvoid sortingMetal-working feeding devicesMetal working apparatusProduction linePunch press

The invention discloses a guide plate stamping production line. According to the key points of the technical scheme, the guide plate stamping production line comprises a controller, a feeding mechanism used for pushing strip-shaped coil materials to a first punch, a first conveying mechanism used for conveying the strip-shaped coil materials which pass the first punch, a separation mechanism used for separating a finished plate from strip-shaped waste, a turning-over mechanism used for turning over the finished plate, a cutting and collecting mechanism used for cutting and collecting the strip-shaped waste, a discharging mechanism used for ejecting out waste in technological holes, a deburring machine used for removing burrs on the finished plate, a second conveying mechanism connected between the discharging mechanism and the input end of the deburring machine, a third conveying mechanism connected between a second punch and the output end of the deburring machine, a fourth conveying mechanism connected between the second punch and a third punch, and a pushing mechanism used for pushing the finished plate punched and machined by the third punch into a flattening machine. Synchronous feeding can be achieved, the machining efficiency can be improved, the machining labor intensity is lowered, and the machining automation degree is improved.

Owner:浙江辉煌三联实业股份有限公司

Mobilized laundry service system

A distributed laundry system having mobilized laundry vehicles, including true laundry conveyors in the vehicles, and including a specialized distributed computer network in the vehicles to handle the circumstances of mobile laundry operations, such as special laundry instructions. In addition, procedures and operations which allow the vehicles to cooperate to provide efficient pickup and drop off services at locations of the customers' choices (such as at home or work), including flexible territories for the trucks, customer user interfaces on mobile devices such as cell phones, mobile computing devices and the like, and precise time estimates of pick-up and drop-off times.

Owner:LEE SUNG OK +1

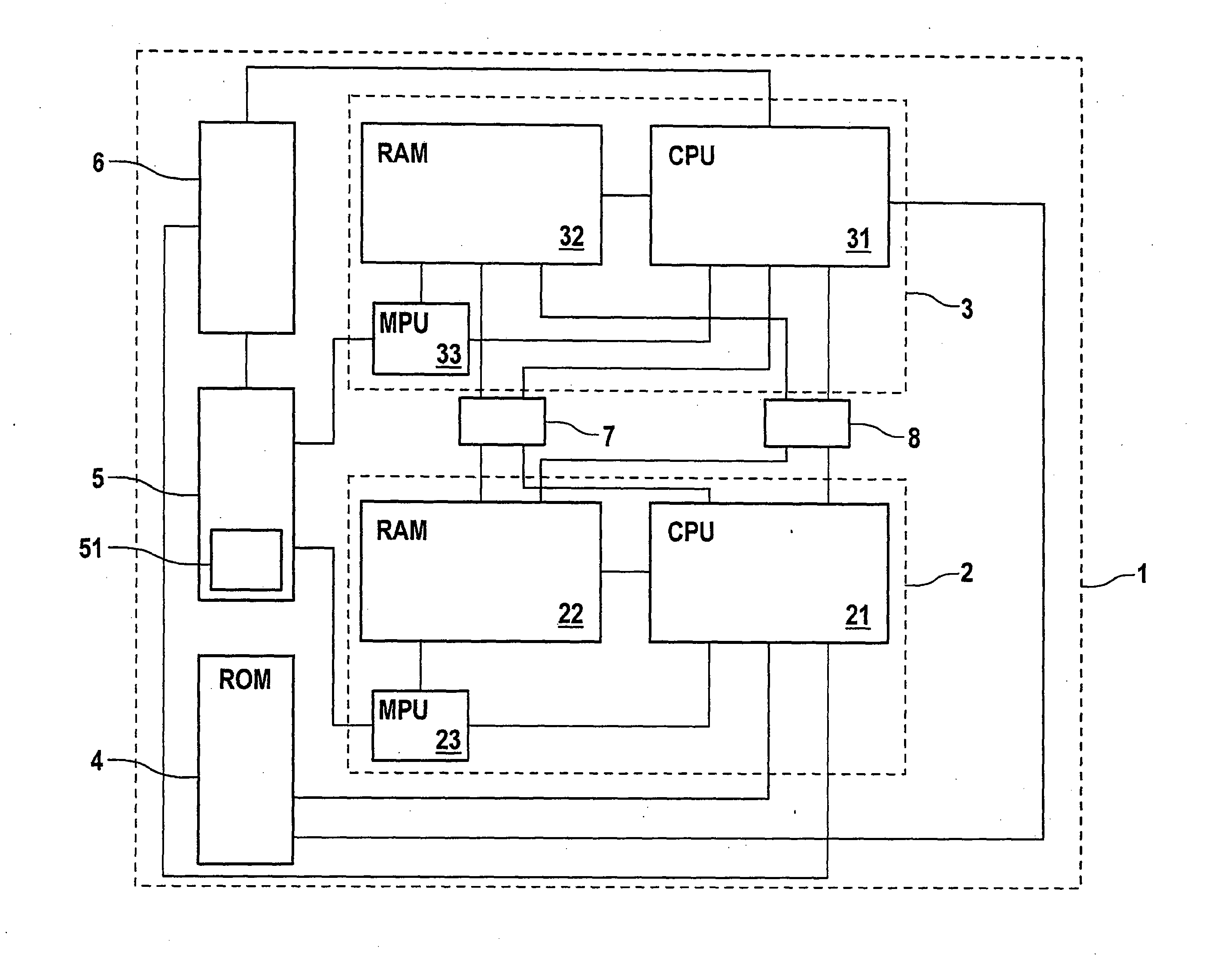

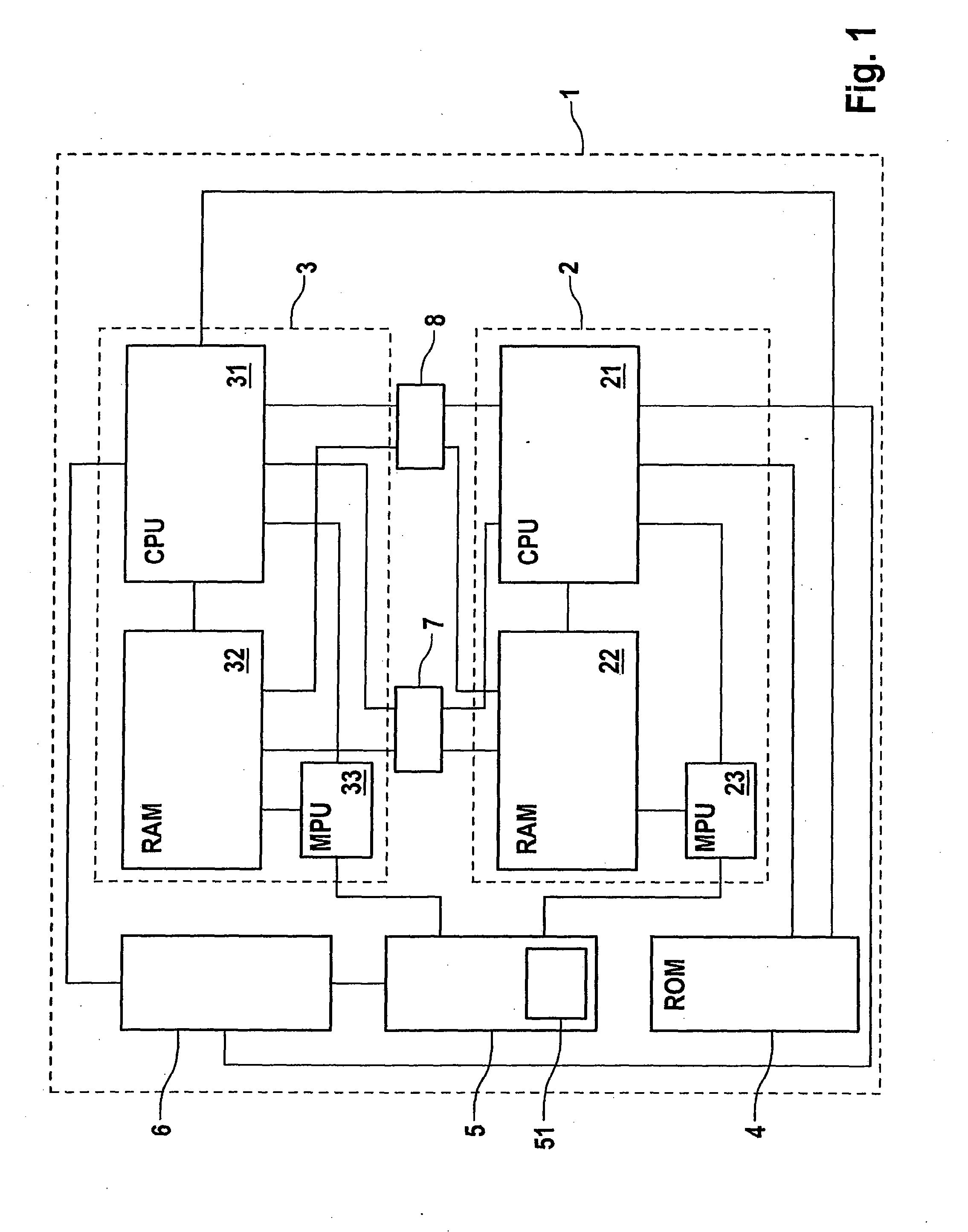

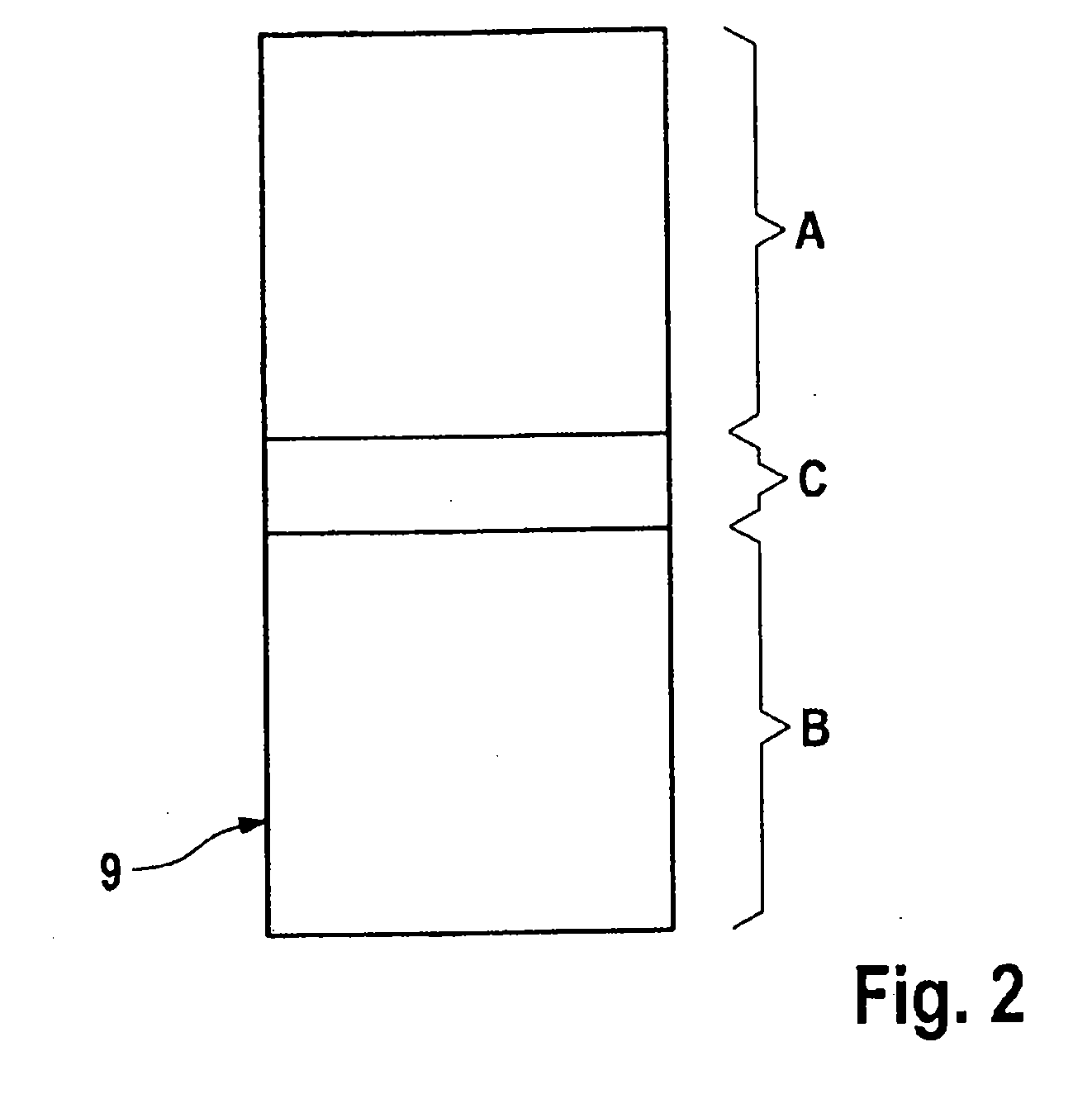

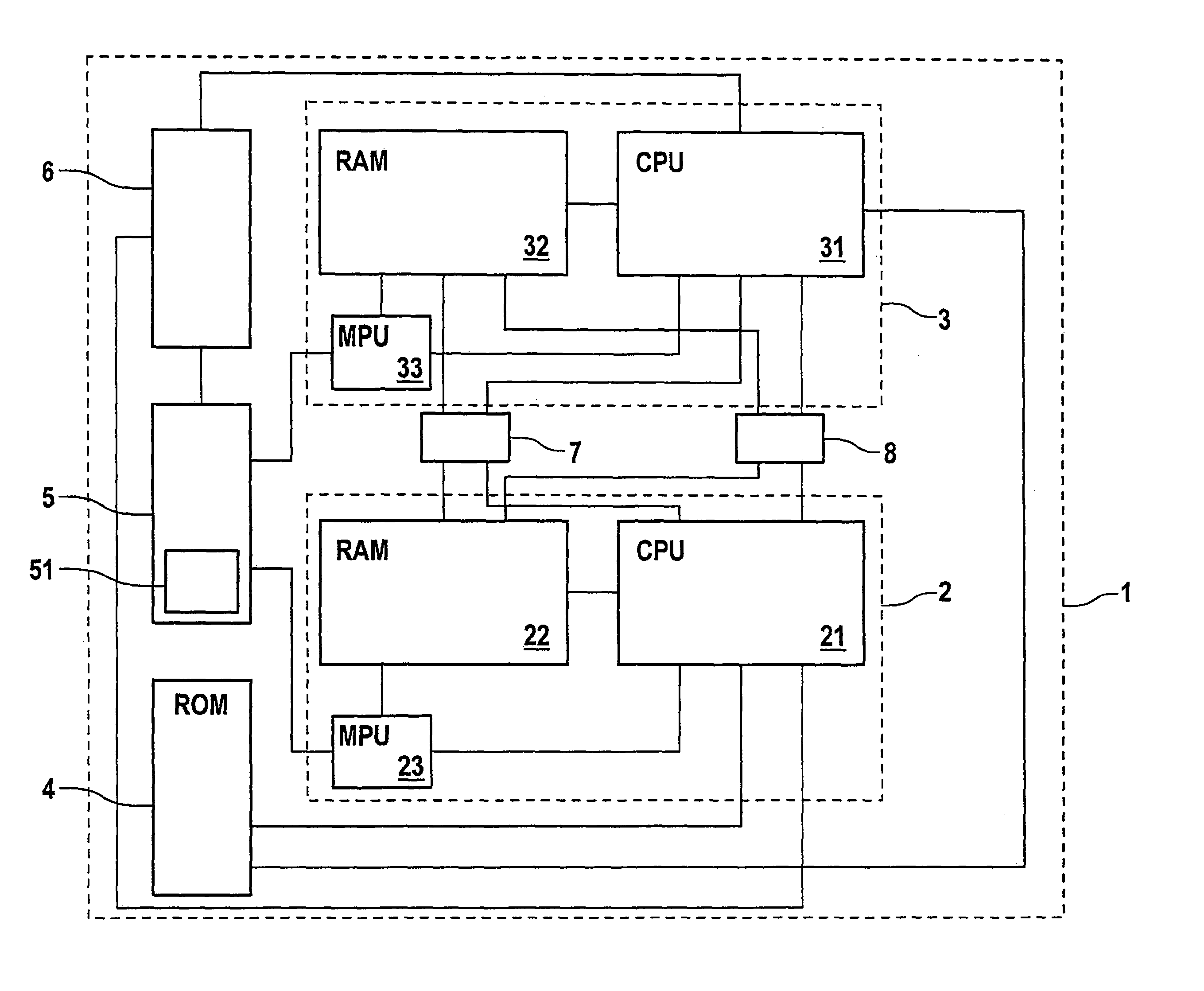

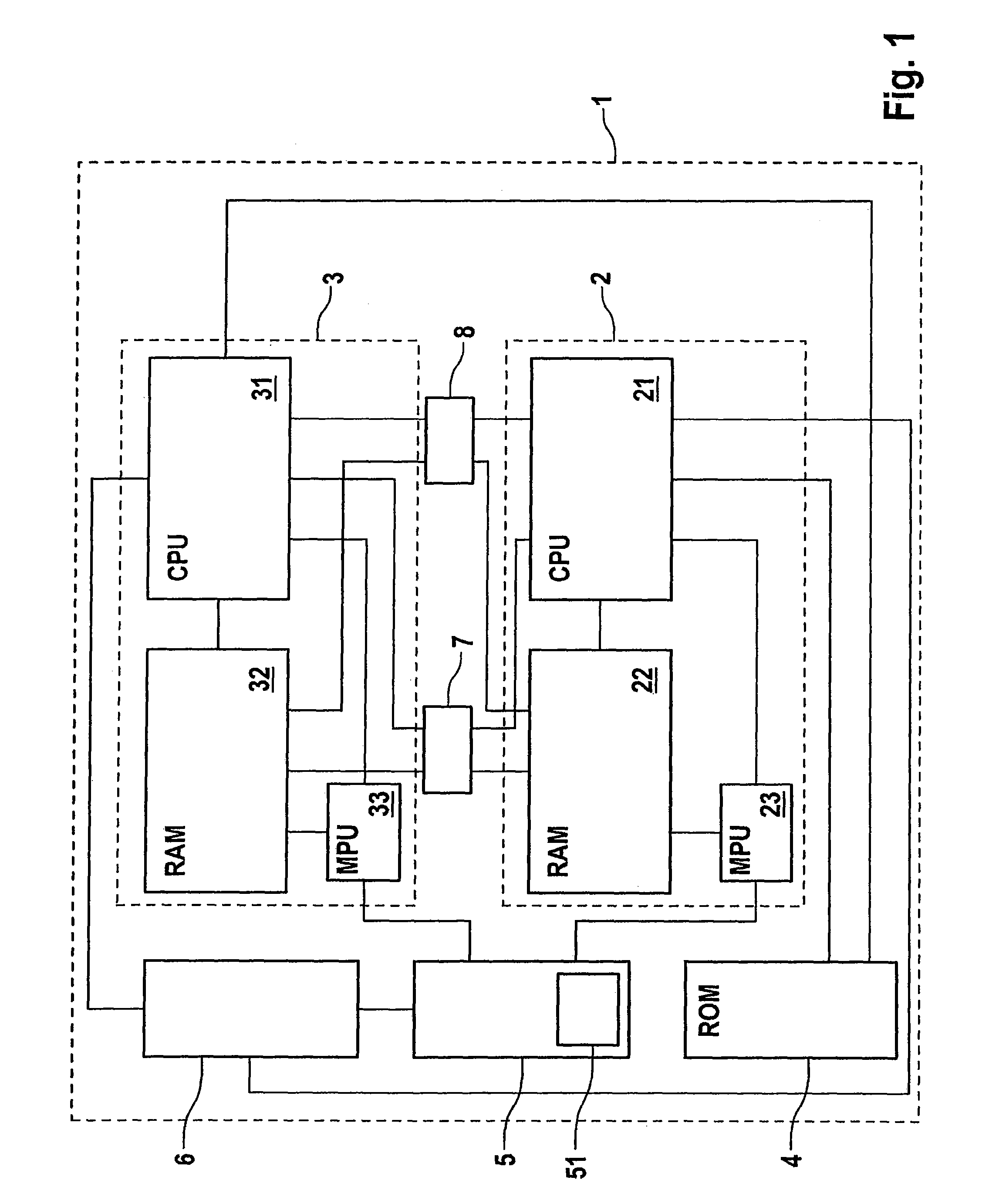

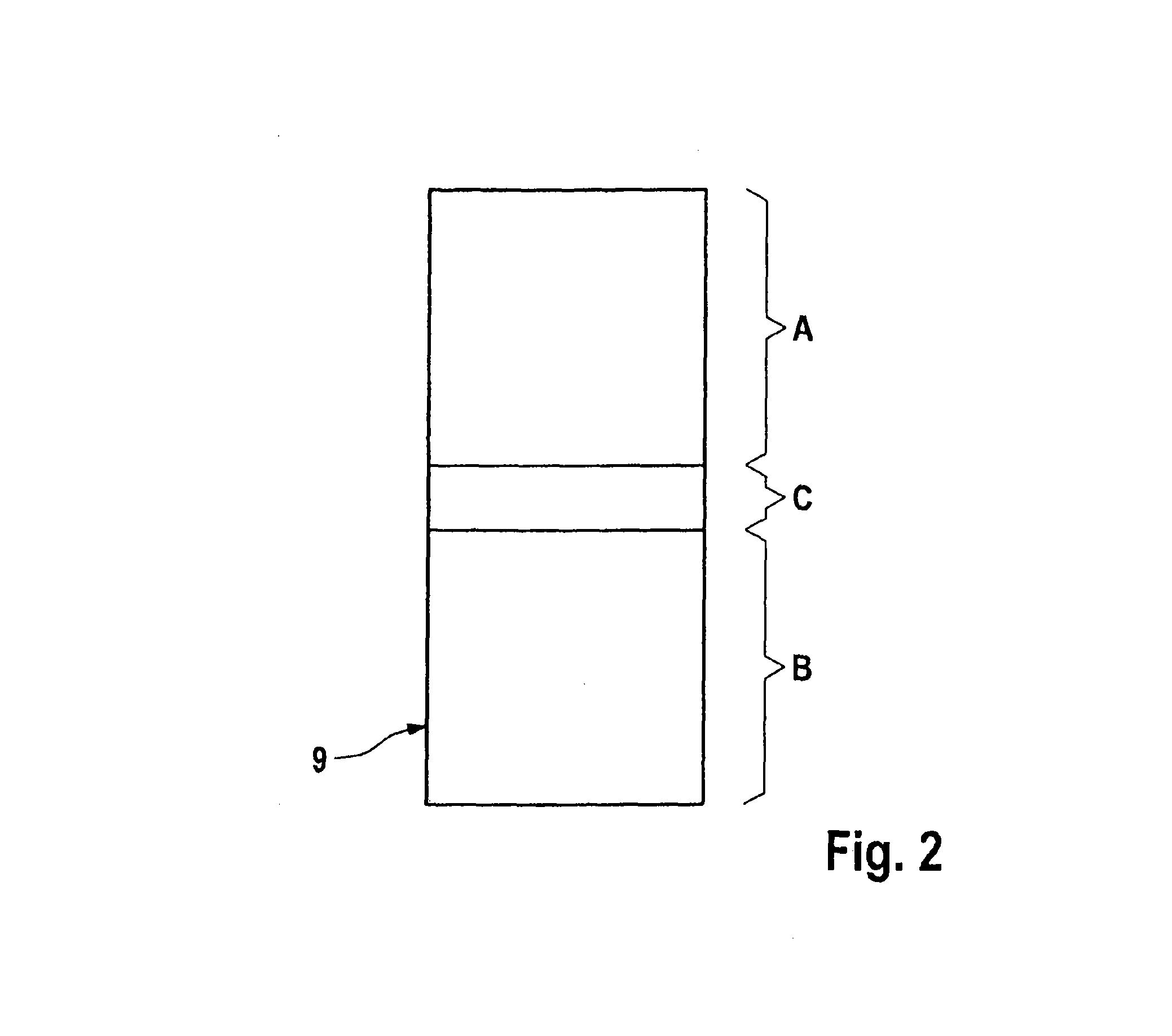

Integrated microprocessor system for safety-critical control systems

ActiveUS20100306601A1Strict requirementsCost-effectiveProgramme controlUnauthorized memory use protectionControl systemRead-only memory

An integrated microprocessor system for safety-critical control systems, comprising at least two microprocessor system modules each comprising at least one processor core, a read / write memory and a memory protection unit, and a read-only memory which is jointly assigned to the processor cores of the microprocessor system modules. Each of the microprocessor system modules executes a main program and a monitoring program which may comprise a plurality of subprograms. If the memory protection unit detects unauthorized operations by one of the programs for accessing a separate address area (A, B) of another program, then the respective memory protection unit assigns a separate address area (A, B) of the read / write memory to the main program and to the monitoring program.

Owner:CONTINENTAL TEVES AG & CO OHG

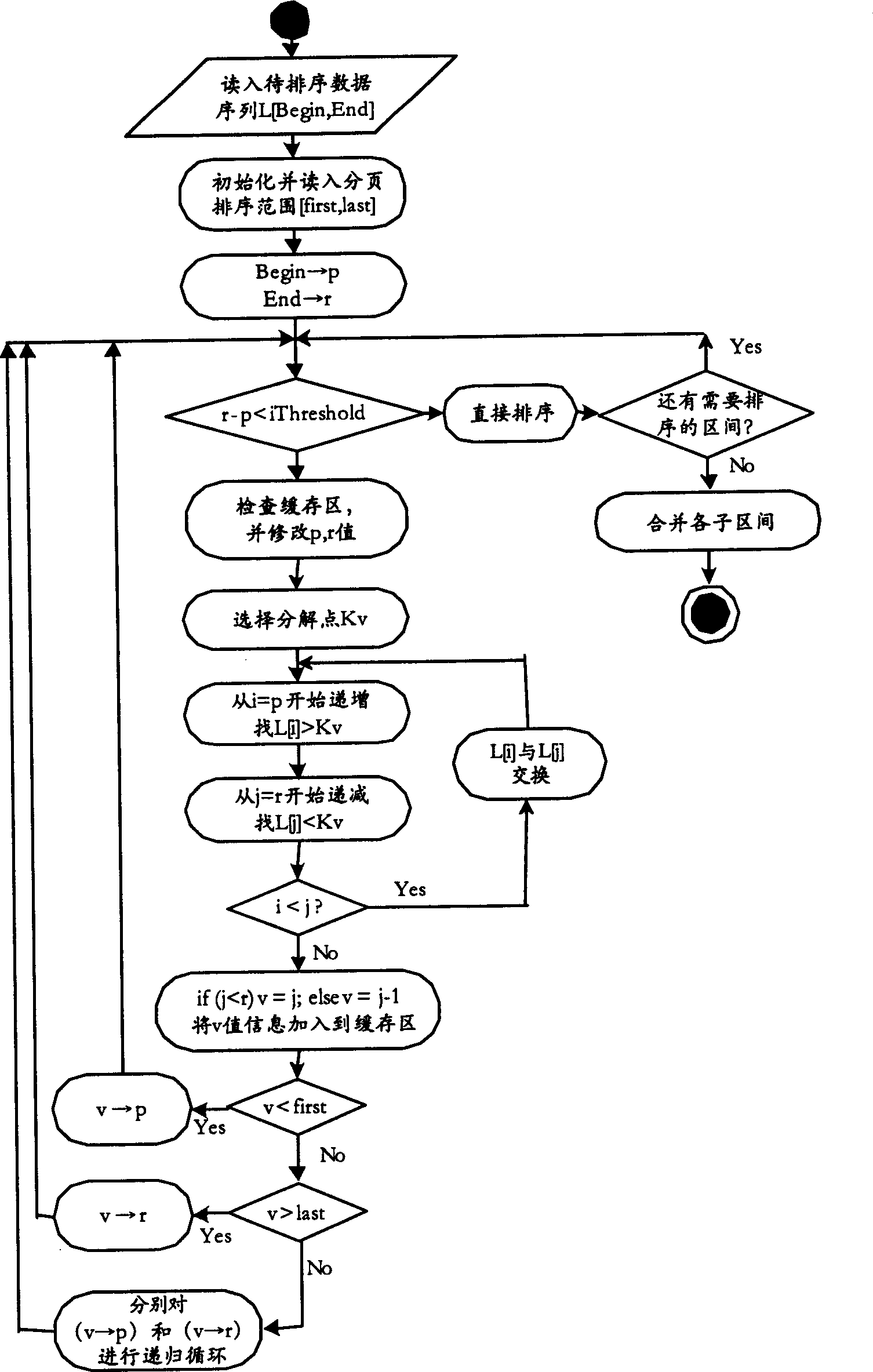

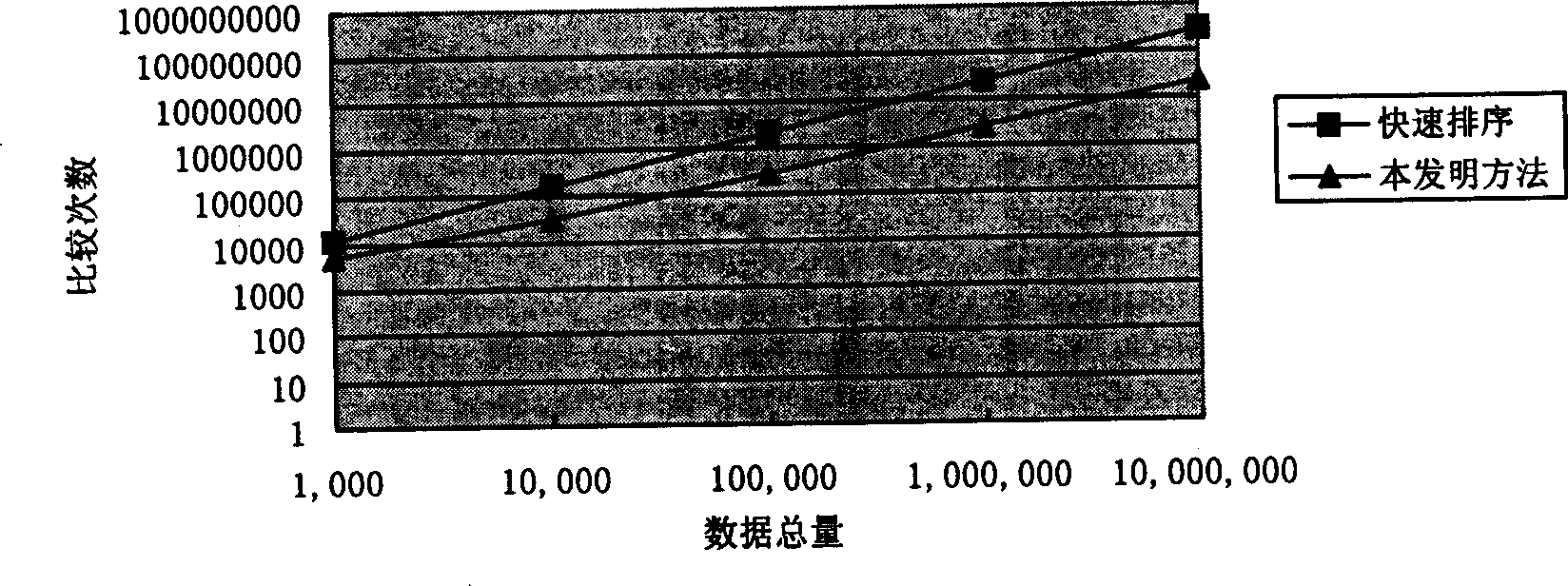

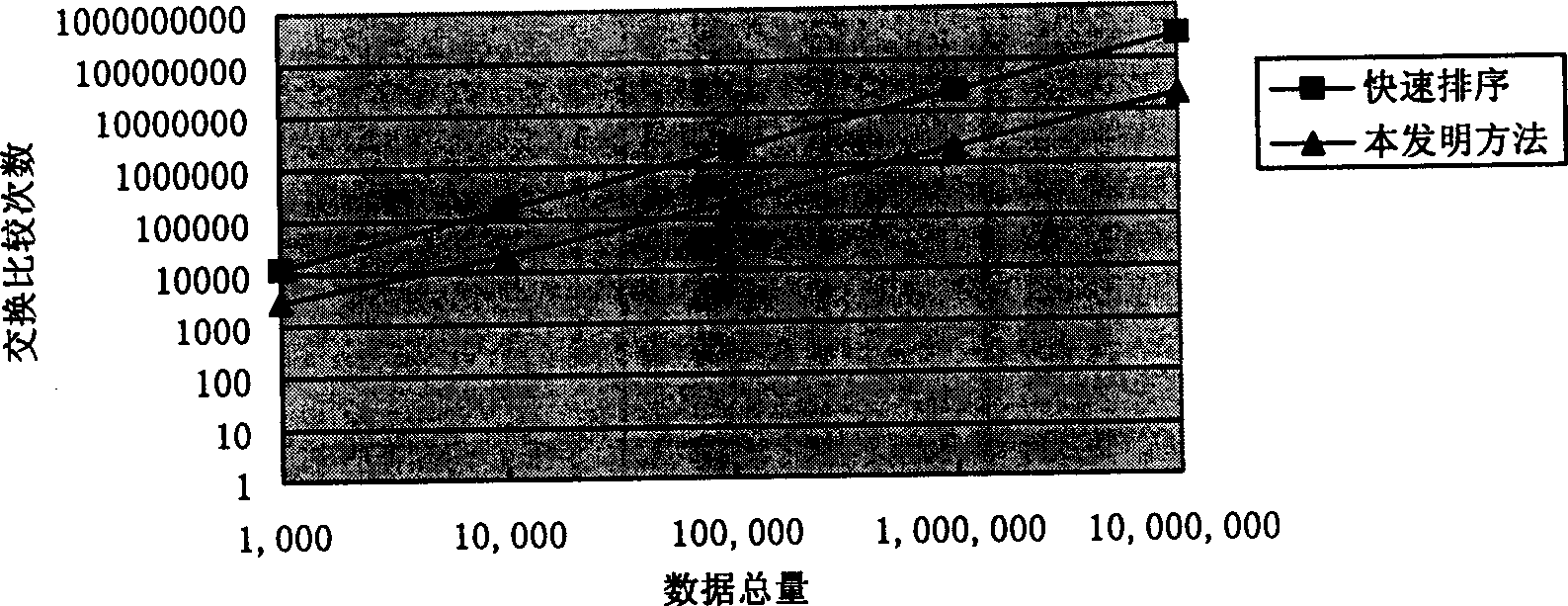

Quick-sorting in page method based on quick sorting computation

ActiveCN1581162AQuick responseSolve the paging sorting problemSpecial data processing applicationsSorting algorithmAlgorithm

The present invention relates to a quick paging sorting method based on quick serting algorithm. It is characterized by that it adopts a divide-and-conquer strategy similar to quick sorting algorithm, utilizes buffer storage mechansm to continuously remove the elements which are not belonged to the defined range, and progressively sort and position the data which are belonged to the defined range so as to can resolve the problem of quick paging sorting process.

Owner:PEKING UNIV +1

Integrated microprocessor system for safety-critical control systems including a main program and a monitoring program stored in a memory device

ActiveUS8549352B2Cost-effectiveStrict requirementsProgramme controlRedundant hardware error correctionControl systemComputer module

An integrated microprocessor system for safety-critical control systems, comprising at least two microprocessor system modules each comprising at least one processor core, a read / write memory and a memory protection unit, and a read-only memory which is jointly assigned to the processor cores of the microprocessor system modules. Each of the microprocessor system modules executes a main program and a monitoring program which may comprise a plurality of subprograms. If the memory protection unit detects unauthorized operations by one of the programs for accessing a separate address area (A, B) of another program, then the respective memory protection unit assigns a separate address area (A, B) of the read / write memory to the main program and to the monitoring program.

Owner:CONTINENTAL TEVES AG & CO OHG

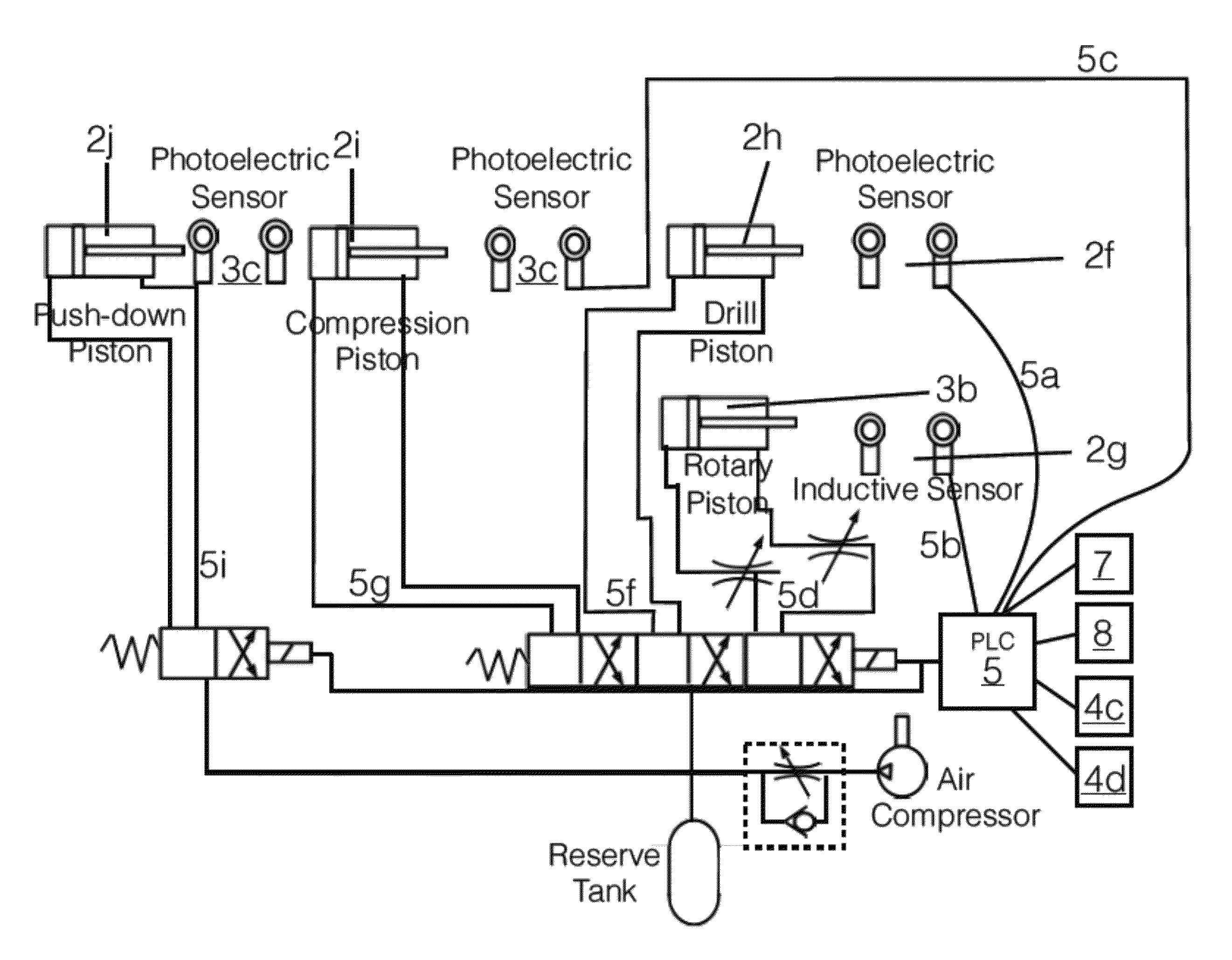

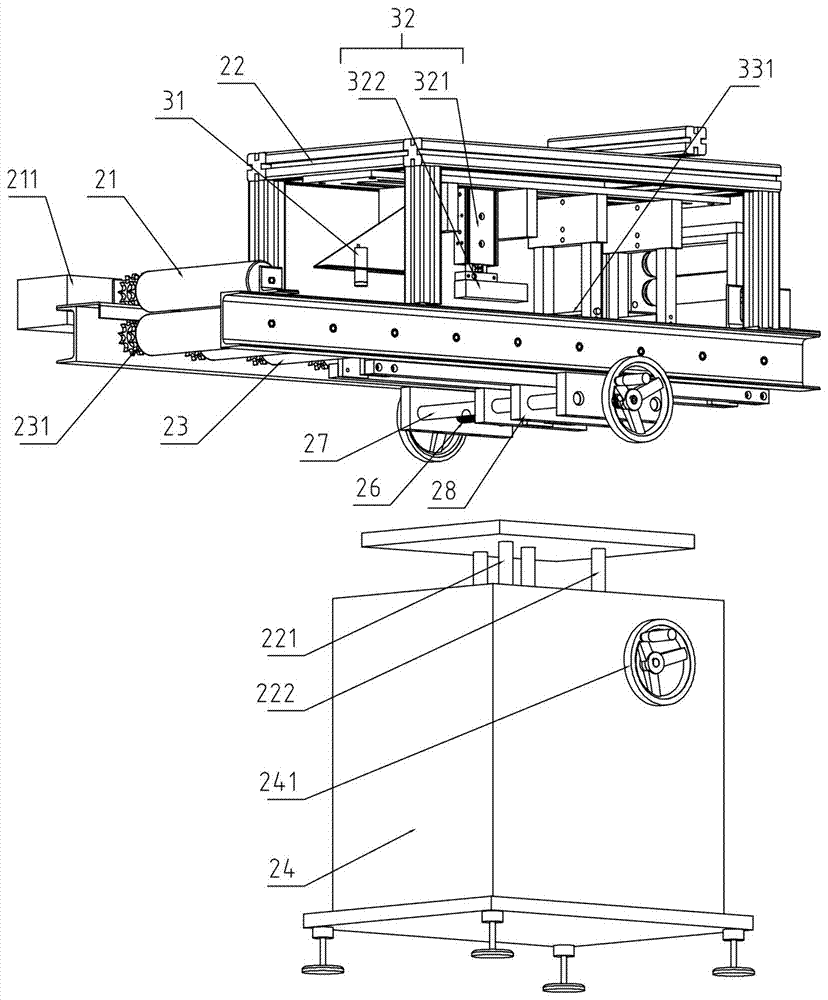

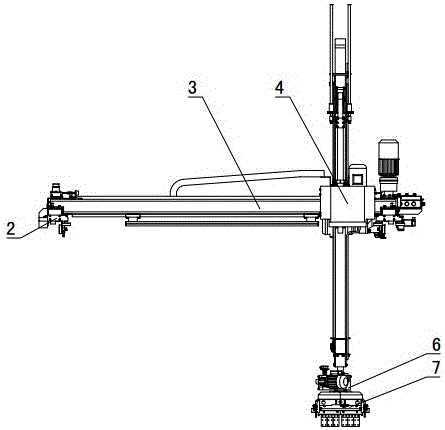

Guide plate detection separation, turnover and pre-material-cutting device

ActiveCN106862411AAvoid sortingReduce labor intensityMetal-working feeding devicesStripping-off devicesManipulatorEngineering

The invention discloses a guide plate detection separation, turnover and pre-material-cutting device. According to the technical scheme, the guide plate detection separation, turnover and pre-material-cutting device is characterized in that a punching machine and a belt-shaped coiled material are included, and the belt-shaped coiled material comprises a belt-shaped waste material and a finished product plate material; the device further comprises a controller, a feeding mechanism used for conveying the belt-shaped coiled material, a separation mechanism used for separating the finished product plate material and the belt-shaped waste material, a turnover mechanism used for overturning the finished product plate material, and a cutting and collecting mechanism used for cutting and collecting the belt-shaped waste material; the feeding mechanism comprises a first belt material mechanism, the cutting and collecting mechanism comprises a second belt material mechanism, and the first belt material mechanism and the second belt material mechanism operate synchronously; the separation mechanism comprises a first sensor, a falling assembly and a material lifting assembly; the turnover mechanism comprises a material movement assembly, a first mechanical arm and a second mechanical arm; and the cutting and collecting mechanism comprises a cutting machine and a collecting box. By means of the device, the automation degree of punching machine machining is easily improved.

Owner:浙江辉煌三联实业股份有限公司

Current measurement in switched mode power supply

ActiveUS8676525B2Improve accuracyComputationally efficientElectric devicesComputer controlElectrical currentSwitched-mode power supply

A method of determining a current in a switched mode power supply. The method comprises: storing values representing at least one pre-calculated matrix A; receiving measured current values; and using the stored values representing the matrix A and the received current values to calculate a respective initial value for each of the coefficients of the line and for each measured current value: calculating an estimated current using the equation of the line and the calculated initial values of the coefficients; determining a difference between the measured current value and the estimated current value to generate a difference value, and comparing the difference value against a threshold and, if the difference value is greater than the threshold, calculating updated values of the coefficients using stored values representing matrix A and difference value. A value for the current in the switched mode power supply is determined using the updated values of the coefficients

Owner:TELEFON AB LM ERICSSON (PUBL)

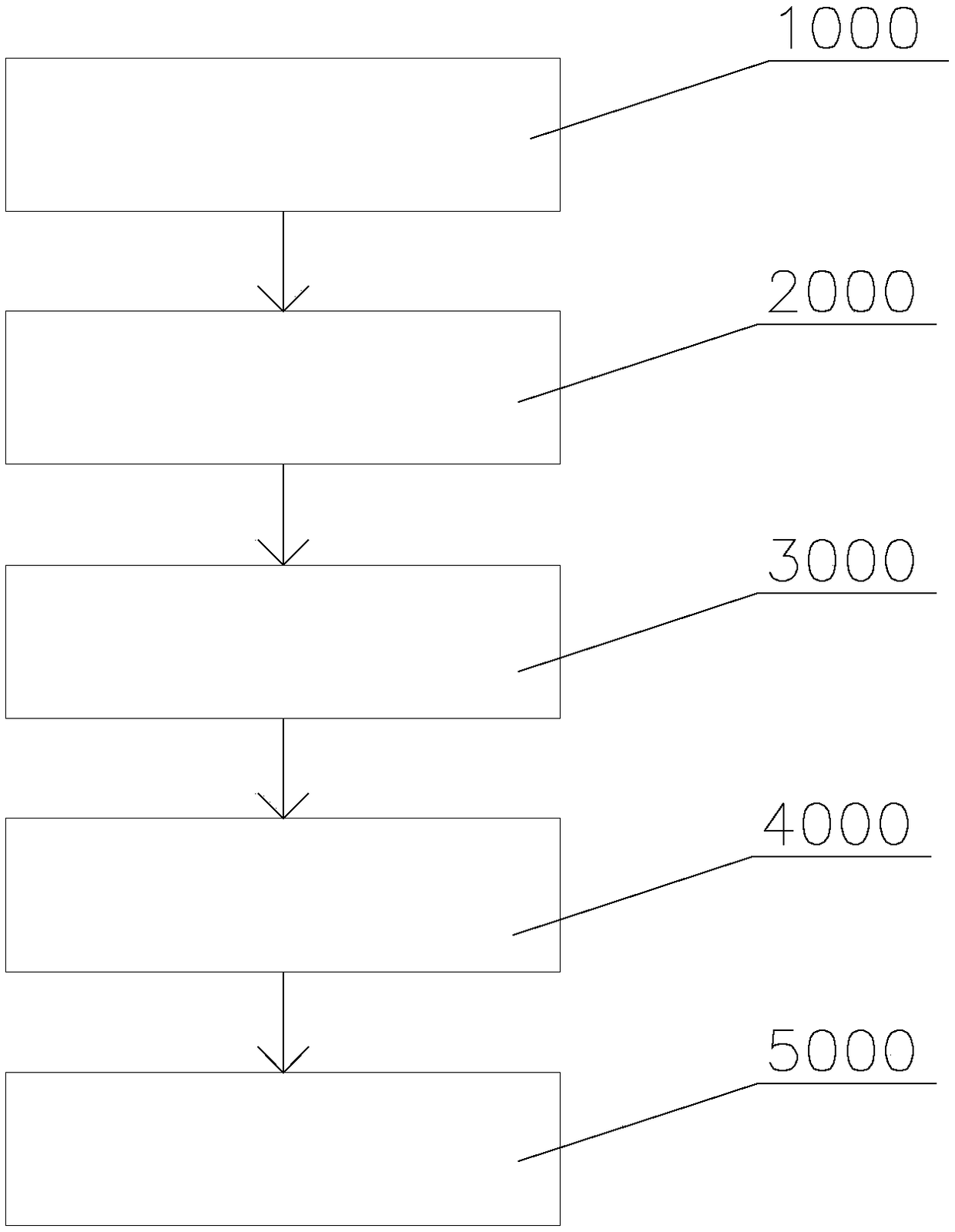

Guide plate stamping process

ActiveCN106984725AHigh degree of automationUniform feedingMetal-working feeding devicesStripping-off devicesPunch pressEngineering

The invention discloses a guide plate stamping process. According to the technical scheme, the guide plate stamping process is mainly characterized by comprising the steps of (1), feeding; (2), stamping; (3), blanking; (4), material cutting and collecting; (5), turning; (6), jacking of waste materials; (7), deburring; (8), positioning hole stamping; (9), process hole stamping; (10), flattening and cleaning. By means of the process, synchronous feeding can be performed on a stamping machine, the machining efficiency of the stamping machine is improved, labor intensity of part machining is lowered, and the automated degree of stamping machine machining is increased.

Owner:ZHEJIANG SEOKHO ROBOT TECH CO LTD

Automatic chain production line

ActiveCN108994250AMake sure to tune inAvoid sortingMetal chainsProduction lineManufacturing engineering

The invention relates to the field of chain production, and discloses an automatic chain production line. The automatic chain production line comprises a chain assembling machine, a chain automatic detecting machine, a chain automatic jump riveting machine, a chain automatic running and closing oiling machine and a chain pre-pulling and disassembling joint machine which are sequentially arranged according to the procedure. According to the automatic chain production line, the assembly, the detection, the jump riveting, the running and closing oiling and the pre-pulling and dissembling joint ofthe chain can be realized, and the production efficiency is high.

Owner:浙江东亿自动化科技有限公司

Sorting technology for radioactive pollution soil

InactiveCN104043600AAvoid sortingRealize on-site quantitative measurementSortingPollution soilRadioactive contamination

The invention relates to a treatment method of a solid radioactive pollution material. The invention aims to solve a problem of being incapable of effectively sorting radioactive pollution soil in a sorting method for the radioactive pollution soil in the prior art and provides a sorting technology for the radioactive pollution soil. The technology includes following steps: (1) analyzing source items; (2) determining sorting targets and analyzing sorting values; (3) selecting a sorting method and a model of a sorting device; (4) determining sorting experimental calibrations: establishing a Monte Carlo simulative calculation model of the radioactive pollution soil, carrying out an experimental verification process and determining sorting conditions according to a calculated result and an effective center of a detector; (5) carrying out a sorting process: preparing a sorting site, formulating an on-site implementation standard and designing a sorting container to achieve an on-site quantitative measurement and an on-site quantitative sorting process. An on-site sorting method of the experimental calibrations is employed in the sorting technology for the radioactive pollution soil so that the on-site quantitative measurement of the radioactive pollution soil is achieved and the problem of sorting the radioactive pollution soil is effectively solved.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Mobilized laundry service system

A distributed laundry system having mobilized laundry vehicles, including true laundry conveyors in the vehicles, and including a specialized distributed computer network in the vehicles to handle the circumstances of mobile laundry operations, such as special laundry instructions. In addition, procedures and operations which allow the vehicles to cooperate to provide efficient pickup and drop off services at locations of the customers' choices (such as at home or work), including flexible territories for the trucks, customer user interfaces on mobile devices such as cell phones, mobile computing devices and the like, and precise time estimates of pick-up and drop-off times.

Owner:LEE CHANG SHIN +1

Method for partitioning mobile object base on a plurality of gaussian distribution

ActiveCN101231694AEfficient extractionSimple logicImage enhancementImage analysisPattern recognitionData acquisition

Aiming at the problems existing in the prior background differencing that the practicability is bad, the speed is slow, and the accuracy is bad, the invention discloses an improved moving object segmentation method which uses a plurality of Gaussian distributions to construct the background in a video sequence, so as to further segment the foreground, and the method is based on a plurality of Gaussian distributions. The invention also discloses methods for initialization, data collection, pixel value calculation, etc. The invention has the advantages that the speed is fast and the accuracy is high, and is a moving object segmentation method which has very high practical value.

Owner:南京中新赛克科技有限责任公司

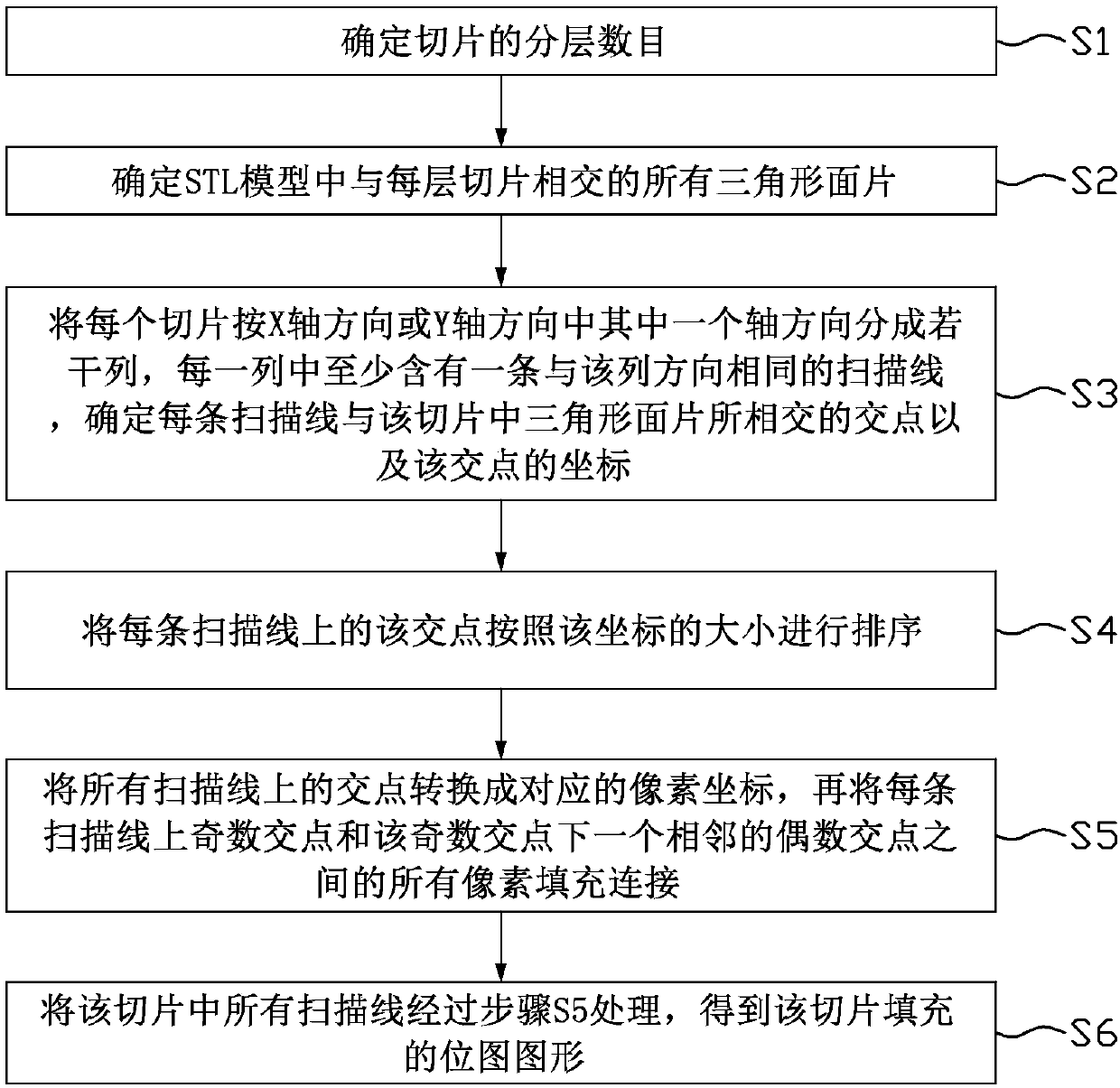

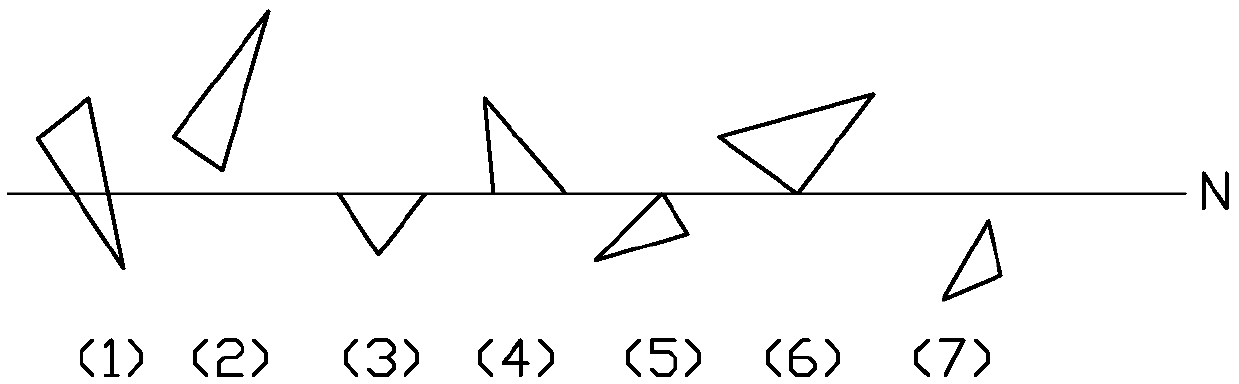

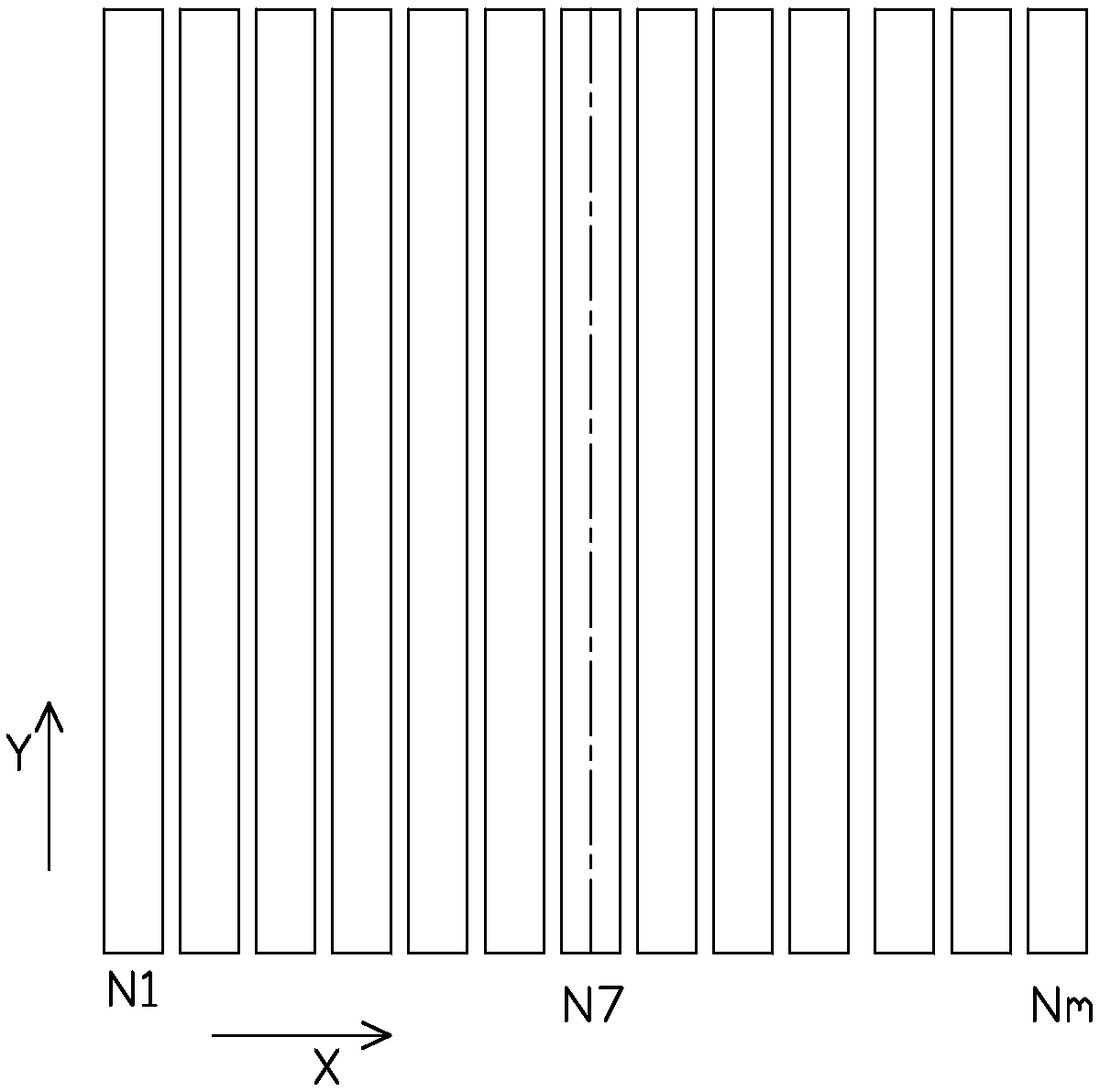

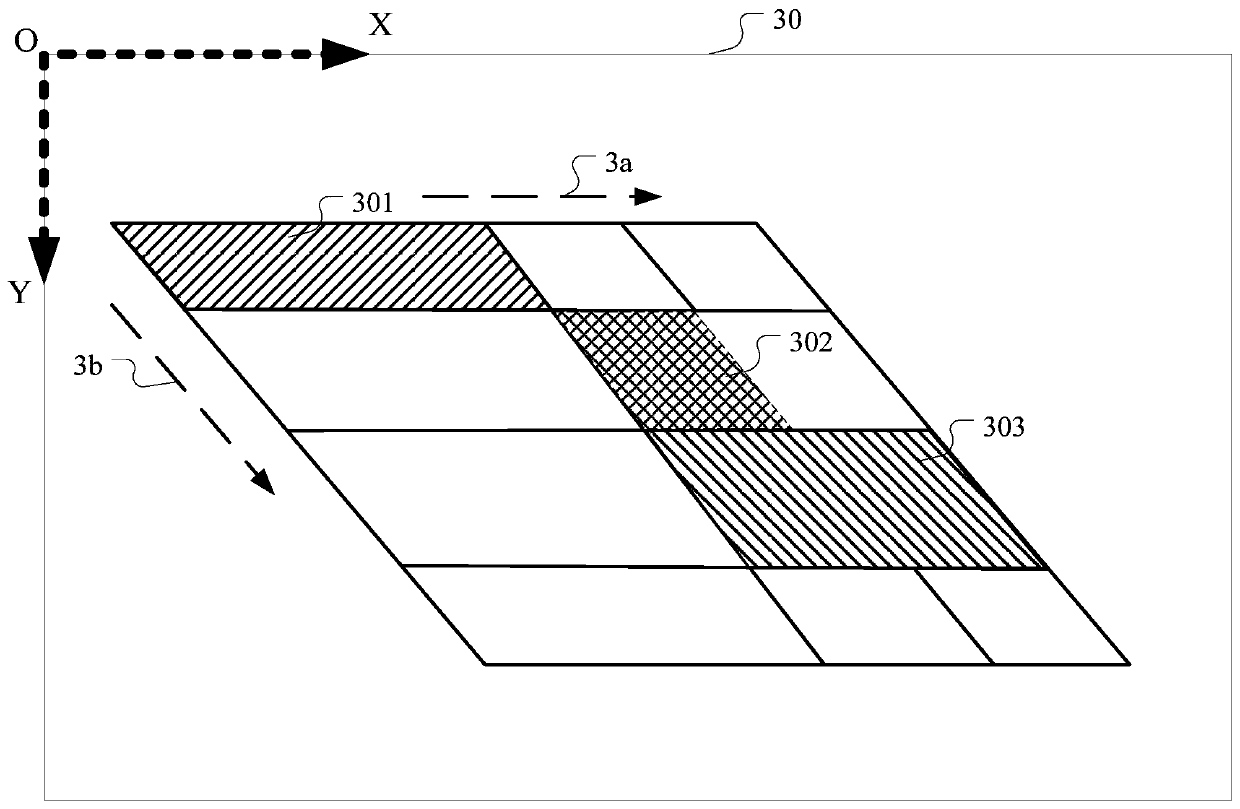

Data processing method applied to 3D printing device and 3D printing device

ActiveCN111319264AImprove processing efficiencyAvoid calculationAdditive manufacturing apparatusManufacturing data aquisition/processingGraphicsTopology information

The invention discloses a data processing method applied to a 3D printing device. The method comprises the steps that the number of layers of slices is determined; all triangular patches intersectingwith all the slices in an STL model are determined; each slice is divided into a plurality of columns in the X-axis direction or the Y-axis direction, each column contains at least one scanning line in the direction identical to the column direction, and intersection points of each scanning line and the triangular patches in the slices and coordinates of the intersection points are determined; theintersection points on each scanning line are sorted according to the values of the coordinates; the intersection points on all the scanning lines are converted into corresponding pixel coordinates,and all pixels between odd intersection points on each scanning line and next even intersection points adjacent to the odd intersection points are in filled connection; all the scanning lines in the slices are processed to obtain a slice-filled bitmap graph. According to the method, topology information does not need to be established for the STL model, so that a large amount of calculation and sorting are avoided, and the data processing efficiency is improved.

Owner:SVG TECH GRP CO LTD +1

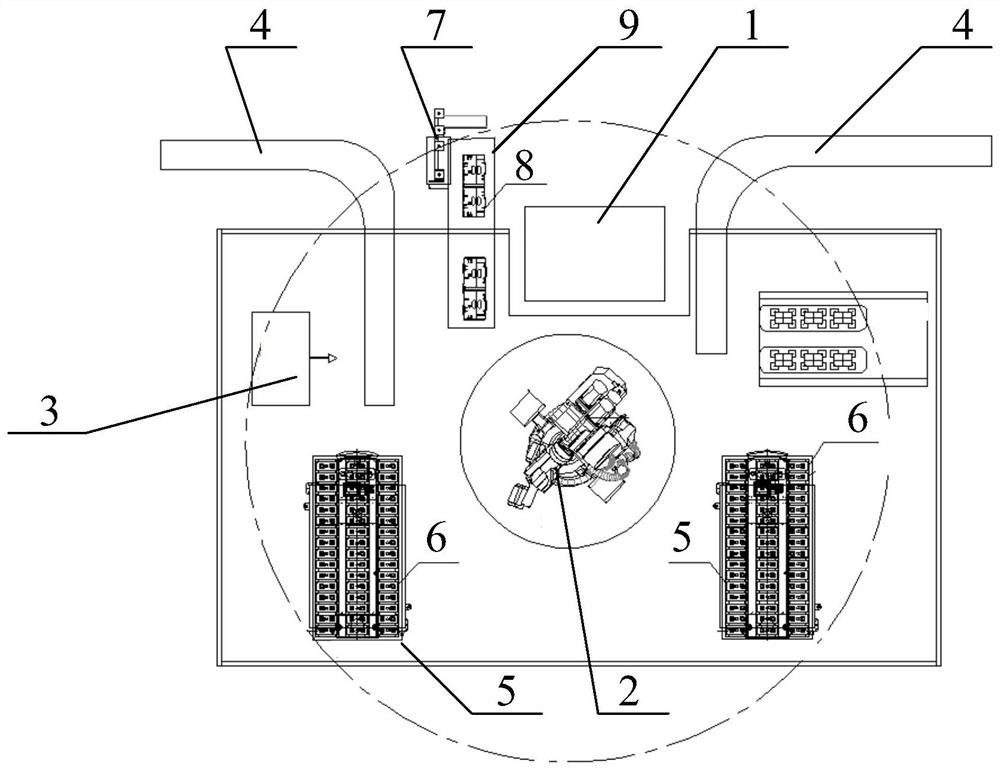

Multi-station stacking device and stacking process thereof

ActiveCN106315241AConvenient storage and loadingImprove work efficiencyStacking articlesDe-stacking articlesCeramic tilesPallet

The invention discloses a multi-station stacking device and a stacking process thereof and belongs to the technical field of ceramic tileproduction equipment. The multi-station stacking device is characterized in that a palletstoreroom (8) and multiple ceramic tile storerooms (5) are arranged at the lower portion of a rack (1), the multiple ceramic tile storerooms (5) are arranged in the ceramic tile conveying direction, and a control device controls a walking mechanism and grabbing mechanism (7) to grab pallets in the palletstoreroom (8) and put the pallets in the ceramic tile storerooms (5). A ceramic tile detection unit is further arranged on the rack (1) and is used for detecting the categories of ceramic tiles and transmitting signals to the control device, the control device controls the walking mechanism and grabbing mechanism (7) toceramic tiles according to category signals of the ceramic tiles and respectively stack different categories of ceramic tiles in different ceramic tile storerooms (5). The multi-station stacking device improves the working efficiency and can also greatly reduce error probability. Manual ceramic tile sorting is avoided by adopting the stacking process of the multi-station stacking device, and the automation degree is greatly improved.

Owner:山东爱而生智能科技有限公司

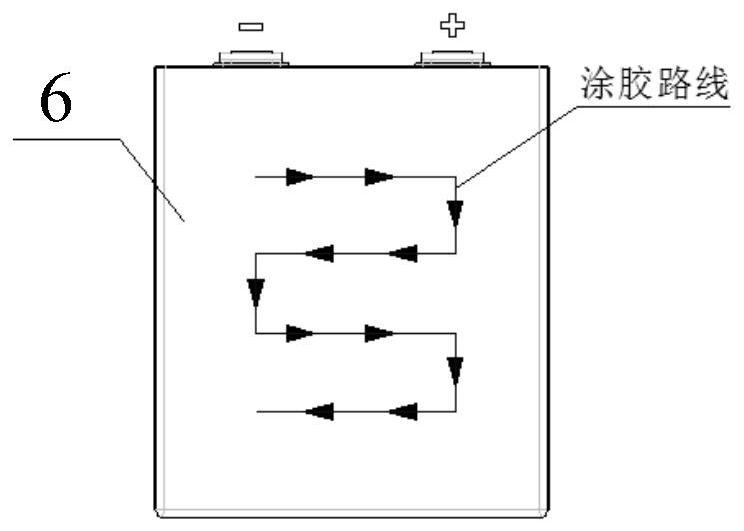

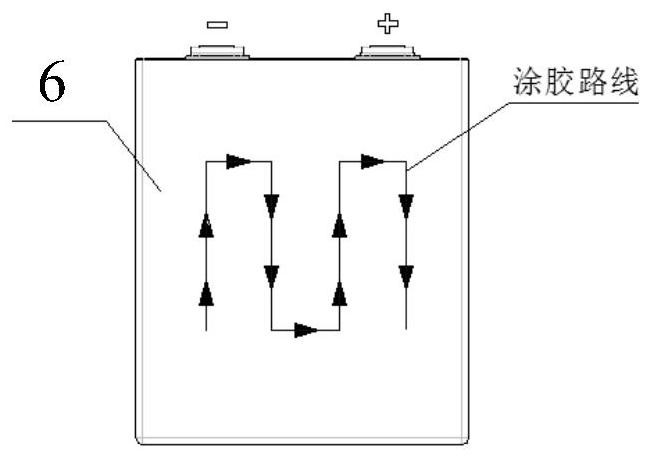

Automatic battery cell gluing device and method

InactiveCN112742661AAvoid manual crawlingAvoid gluingLiquid surface applicatorsCoatingsRobot handControl engineering

The invention discloses an automatic battery cell gluing device and method. The automatic battery cell gluing device comprises a controller, a mechanical hand, a glue gun assembly and conveyors. The controller is in signal connection with the mechanical hand, the glue gun assembly and the conveyors. Under the control of the controller, the mechanical hand can grab to-be-glued battery cells at the battery cell feeding station, place the to-be-glued battery cells below a glue outlet of the glue gun assembly, sort the glued battery cells subjected to gluing and place the battery cells on the conveyors. The glue gun assembly can be controlled by the controller to spray glue to the to-be-glued battery cells. The conveyors are used for conveying the glued battery cells. During use, the mechanical hand is controlled to grab the to-be-glued battery cells and place the to-be-glued battery cells below the glue outlet of the glue gun assembly. Then, the controller controls the glue gun assembly to spray the glue to the to-be-glued battery cells. Then, the mechanical hand is controlled to sort the glued battery cells and place the glued battery cells on the conveyors. Finally, the controller controls the conveyors to output the glued battery cells. By means of the automatic battery cell gluing device and method, manual cell grabbing, gluing and sorting are avoided, and the production efficiency is improved.

Owner:HUNAN CSR TIMES ELECTRIC VEHICLE

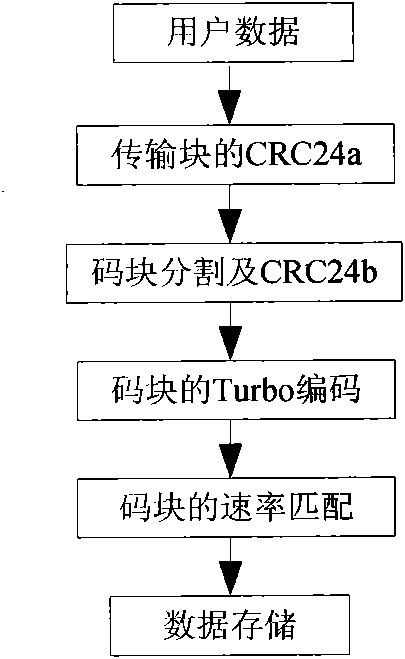

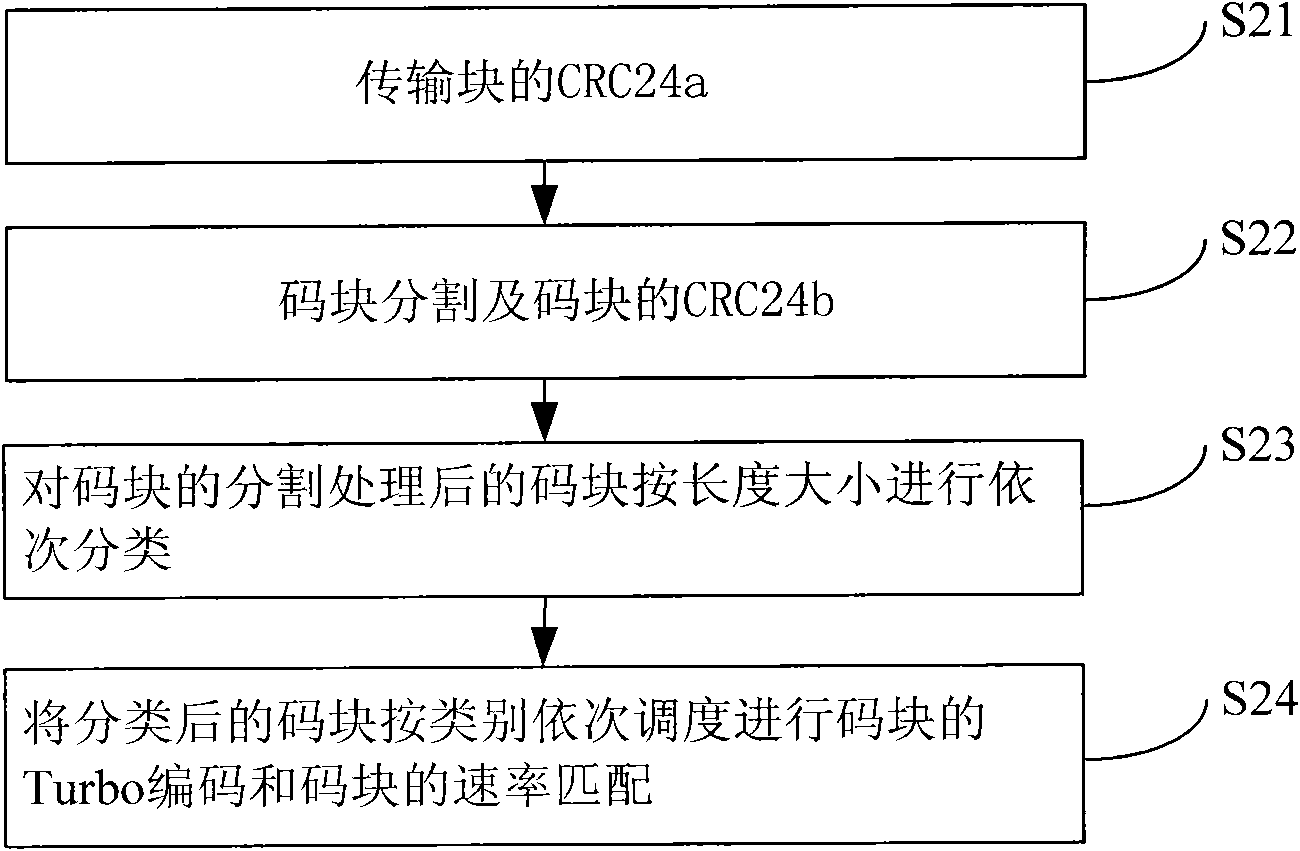

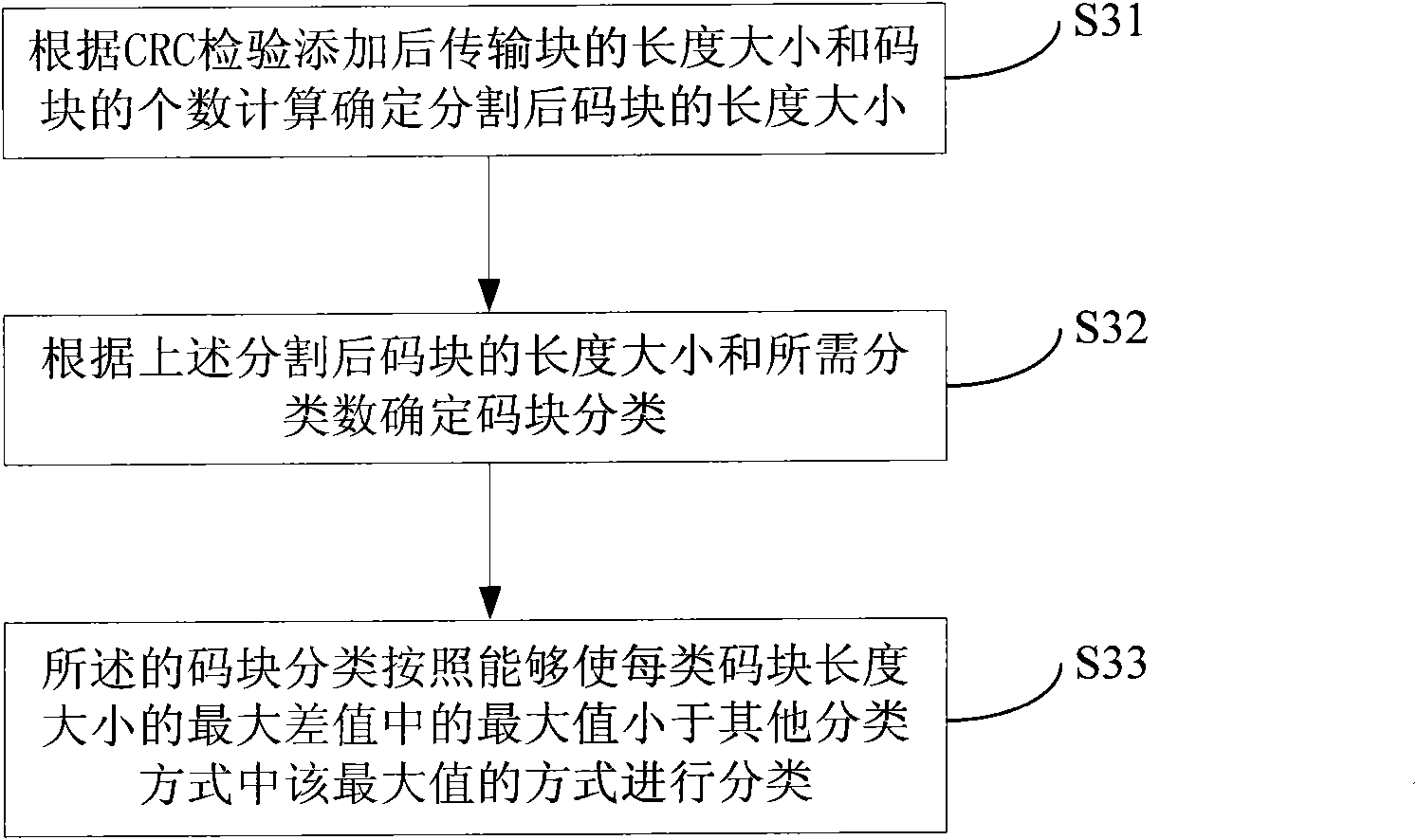

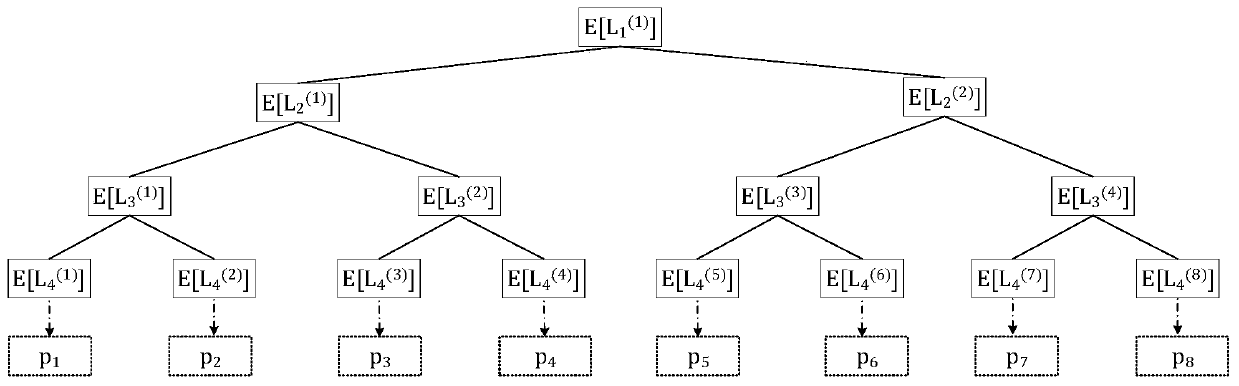

Method and device for increasing bit throughput at transmitting end of LTE (Long Term Evolution) base station

InactiveCN102340372BImprove throughputReduce resource overheadError preventionMulti-frequency code systemsData delayTransmitter

Provided are a method and device for increasing bit-level throughput of transmitter of an LTE Base Station (BS) in the present invention. And the method comprises: adding Transmission Blocks (TB) CRC24a and dividing the Code Blocks (CBs) during the course of the bit-level process in transmitter of an LTE BS. During the course of bit-level process in transmitter of an LTE BS, after dividing the CBs, the method further comprises: assorting, one by one, the divided CBs according to the size; dispatching the assorted CBs in turn of the plurality of categories to perform Turbo coding and rate matching for the CBs. The whole data delay of the BS is able to decreased, so as to increase the whole bit-level throughput of transmitter of the BS.

Owner:ZTE CORP

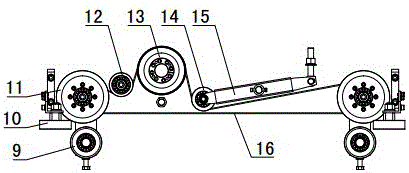

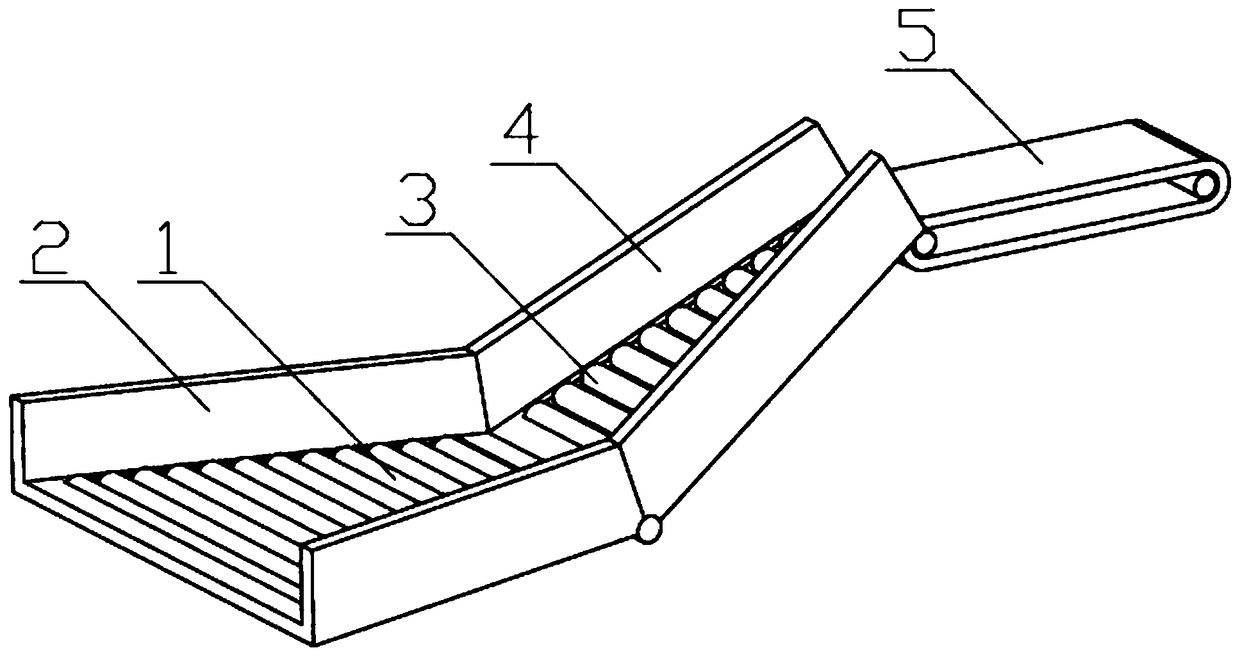

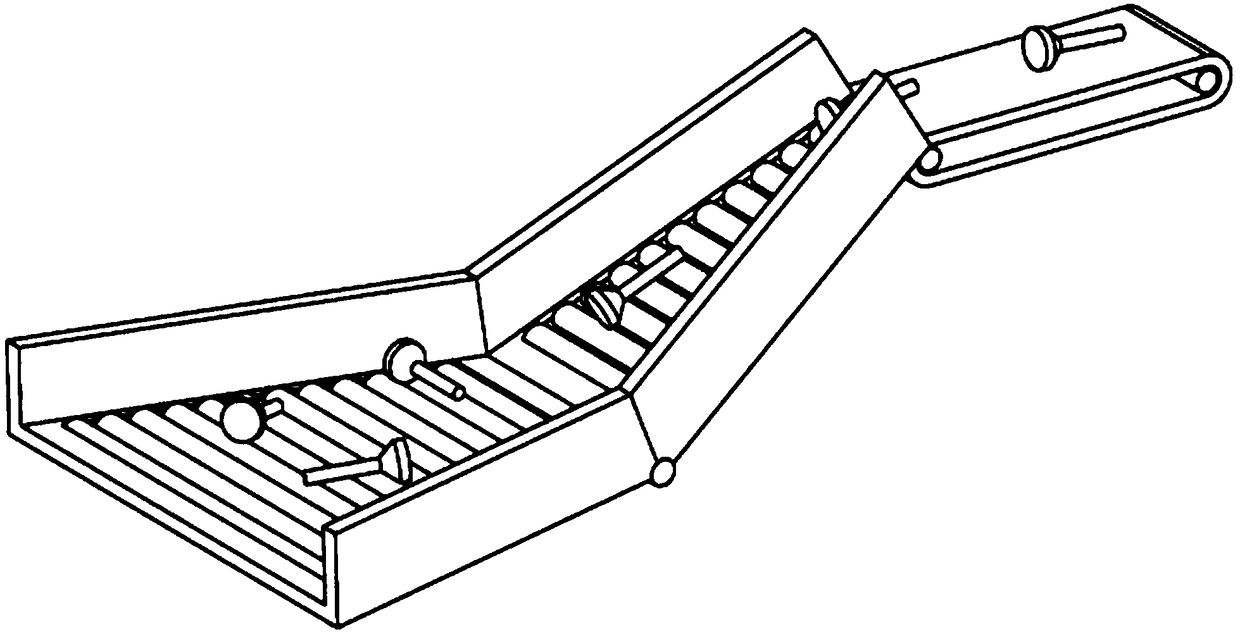

Air valve processing feeding device

InactiveCN108750617AAvoid sortingImprove processing efficiencyConveyorsConveyor partsEngineeringMechanical engineering

The invention discloses an air valve processing feeding device. The conveying face of a first conveying mechanism is horizontally arranged. The feeding end of a second conveying mechanism is connectedwith the discharging end of the first conveying mechanism, the height of the discharging end of the second conveying mechanism is larger than that of the feeding end of the second conveying mechanism, the width of the conveying face of the second conveying mechanism is gradually reduced from the feeding end of the second conveying mechanism to the discharging end of the second conveying mechanism, and the discharging end of the second conveying mechanism only allows one air valve to be processed to pass through at one time. By the adoption of the air valve processing feeding device, in the process that each air valve is conveyed on the second conveying mechanism, the head of each air valve is downward, the rod portion of each air valve is upward, the attitudes of the air valves outputtedby the discharging end of the second conveying mechanism are kept consistent, and the air valves are in the states that the heads are closer to the second conveying mechanism relative to the rod portions, and the rod portions point to the front portion of the conveying direction. In addition, the discharging end of the second conveying mechanism only allows one air valve to pass through at one time, and therefore the air valves can enter the next working procedure one by one, the operation that the air valves are manually sequenced is avoided, and then the processing efficiency is improved.

Owner:ANHUI WODE VALVE MFG

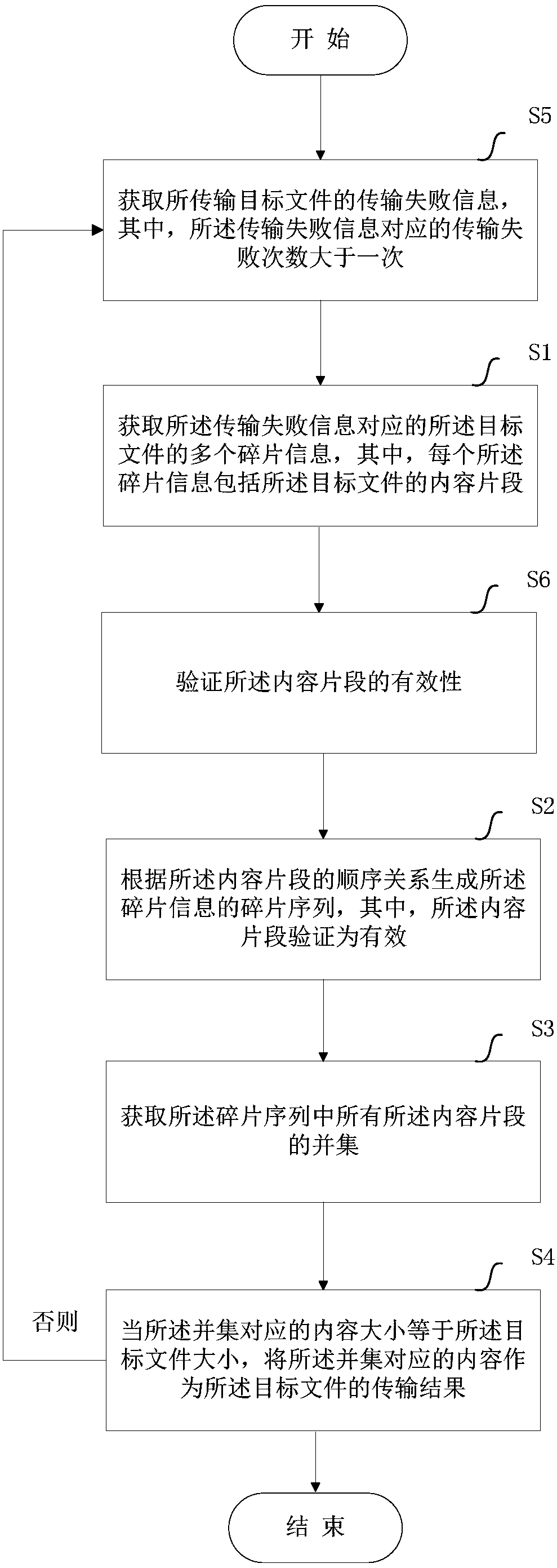

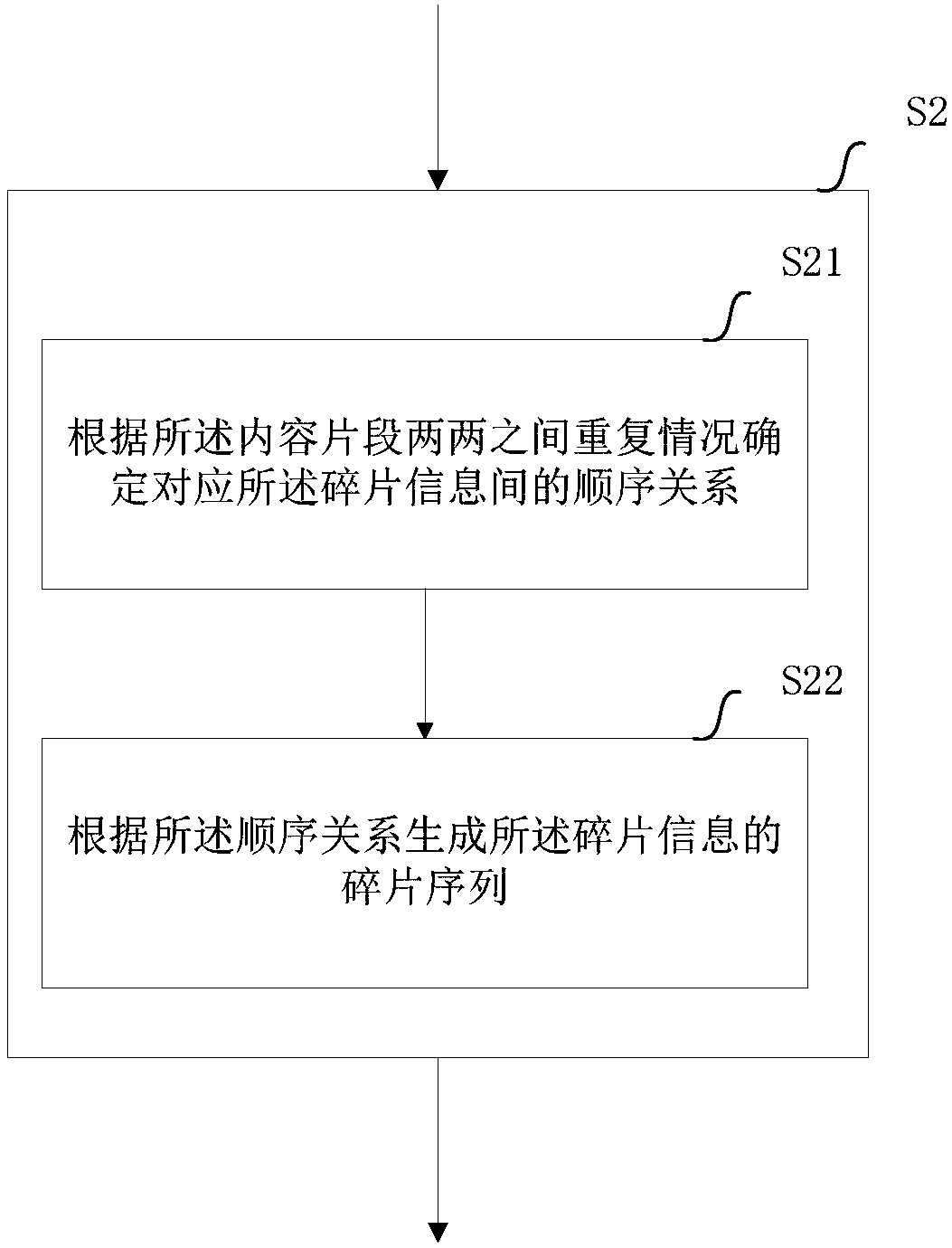

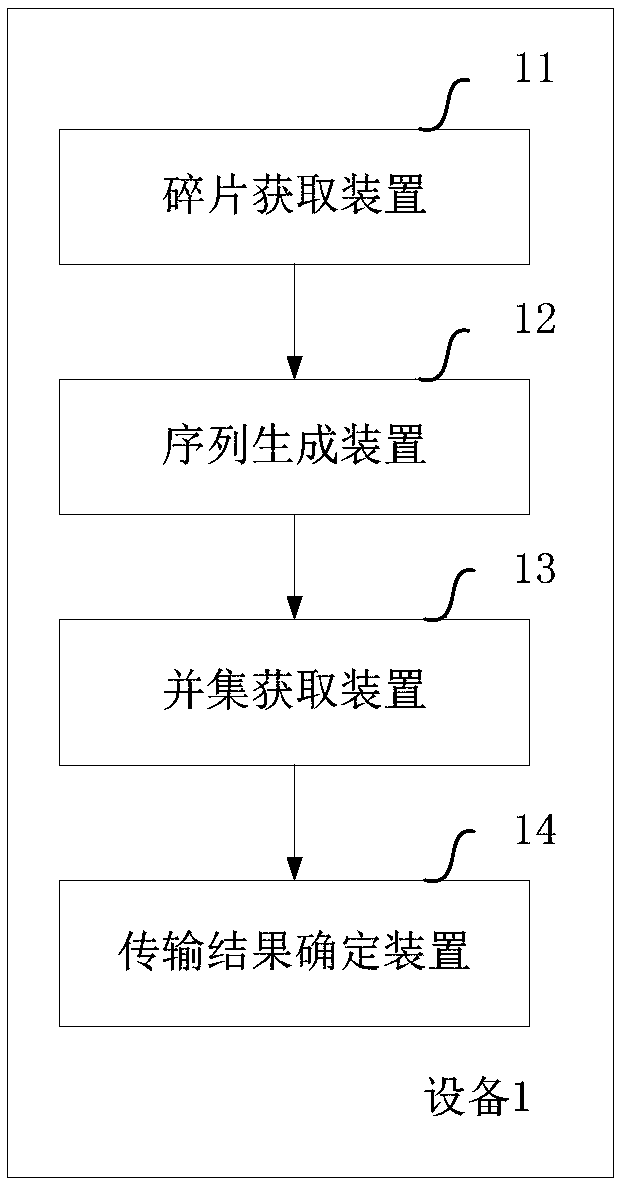

Method and device for acquiring transmitted file

InactiveCN108076109AImprove acquisition efficiencyVerify validityTransmissionSpecial data processing applicationsDatabaseShard

The invention aims at providing a method and device for acquiring a transmitted file. The method particularly comprises the steps that multiple fragment information of a transmitted target file is acquired; a fragment sequence of the fragment information is generated; an union set of all content fragments is acquired; and when the content size of the union set is equal to the target file size, content corresponding to the union set is taken as a transmission result of the target file. Compared with the prior art, the method has the advantages that the multiple fragment information of the transmitted target file is acquired, the fragment sequence of the fragment information is generated according to the order relation of the content fragments, included by the fragment information, of the target file, then the union set of all the content fragments in the fragment sequence is acquired, and when the content size of the union set is equal to the target file size, the content correspondingto the union set is taken as the transmission result of the target file; and accordingly, the complete content of the transmitted target file is obtained on the condition that the target file is transmitted unsuccessfully multiple times to complete transmission.

Owner:ALIBABA GRP HLDG LTD

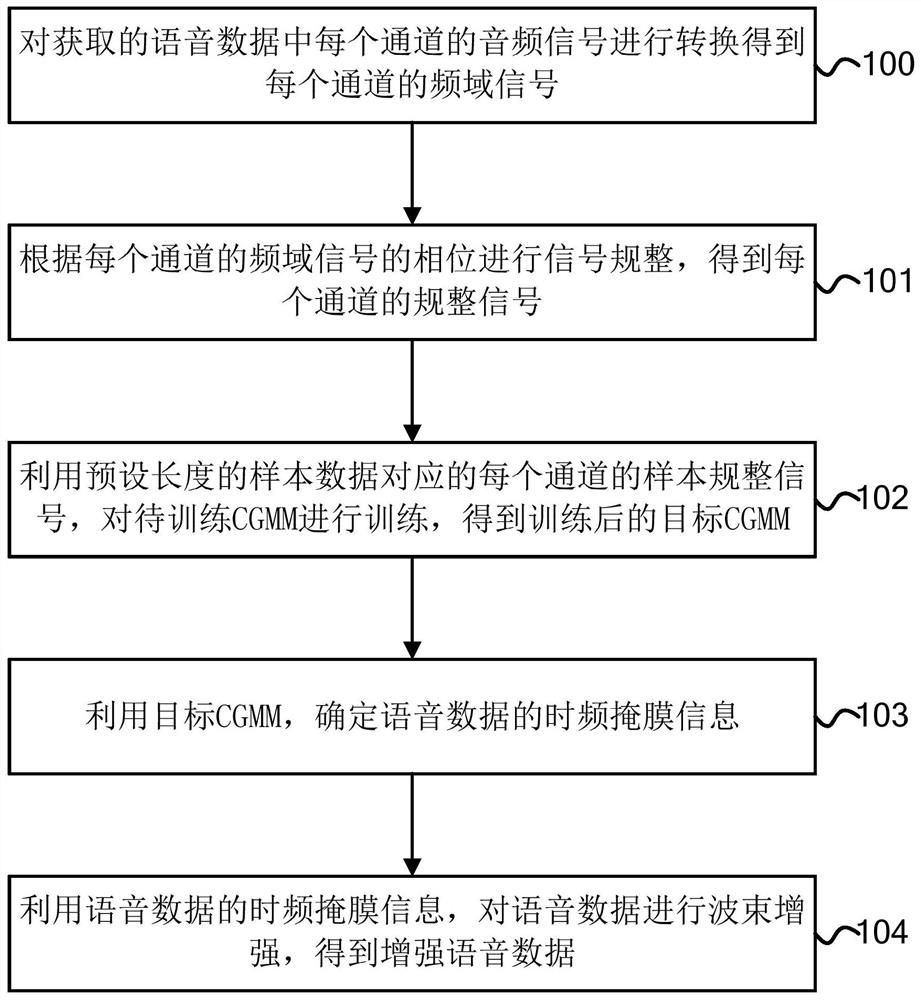

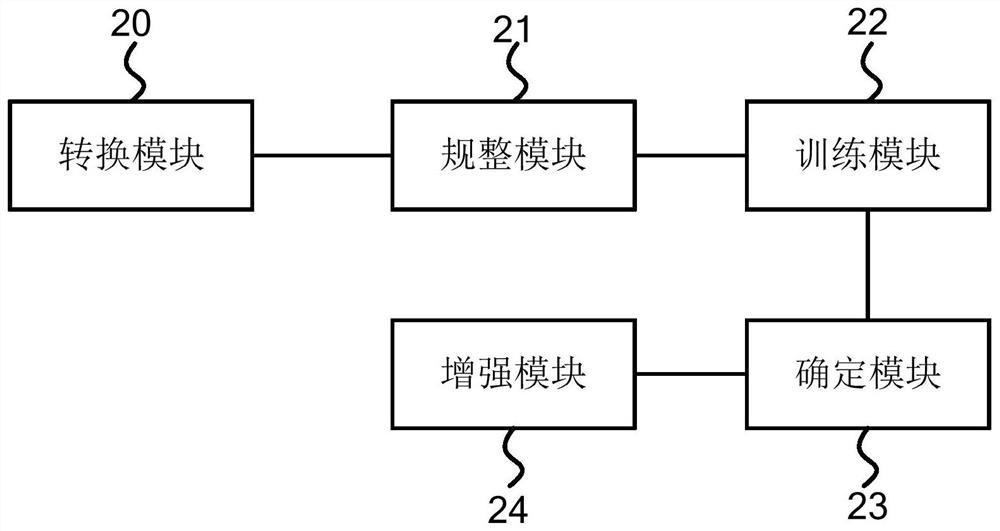

Speech enhancement method and device, equipment and storage medium

The invention relates to a voice enhancement method and device, equipment and a storage medium. The method comprises the steps: converting an audio signal of each channel in obtained voice data to obtain a frequency domain signal of each channel; carrying out the signal normalization according to the phase of the frequency domain signal of each channel so as to obtain a structured signal, only associated with a topological structure of a microphone array, of each channel; training the to-be-trained CGMM by using the sample structured signal, corresponding to the sample data with the preset length, of each channel to obtain target CGMM; and determining the time-frequency mask information of the voice data by using the target CGMM. Therefore, unified modeling of frequency domain signals of all channels is realized, the calculation amount is reduced, the memory occupation amount is small, the resource consumption is further reduced, the sorting problem caused when multiple CGMMs exist is avoided, the accuracy of the obtained mask information is improved, and the reliability of the voice enhancement result is improved.

Owner:BEIJING UNISOUND INFORMATION TECH +1

Tray cleaning, drying and storing assembly line

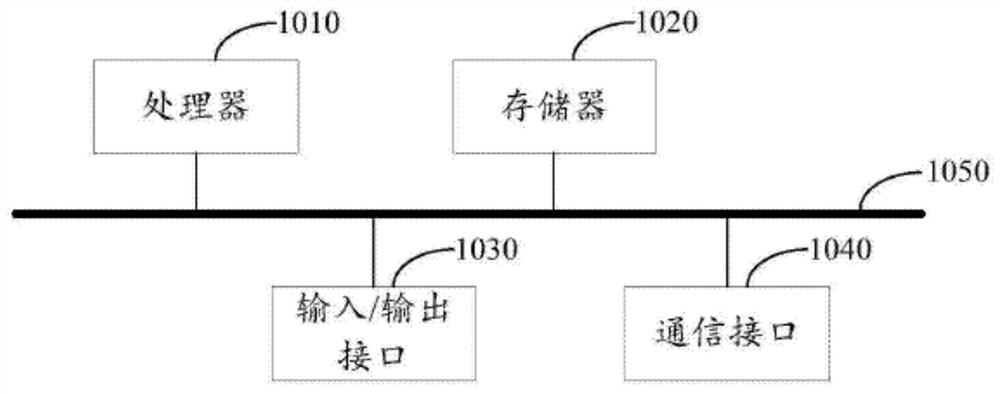

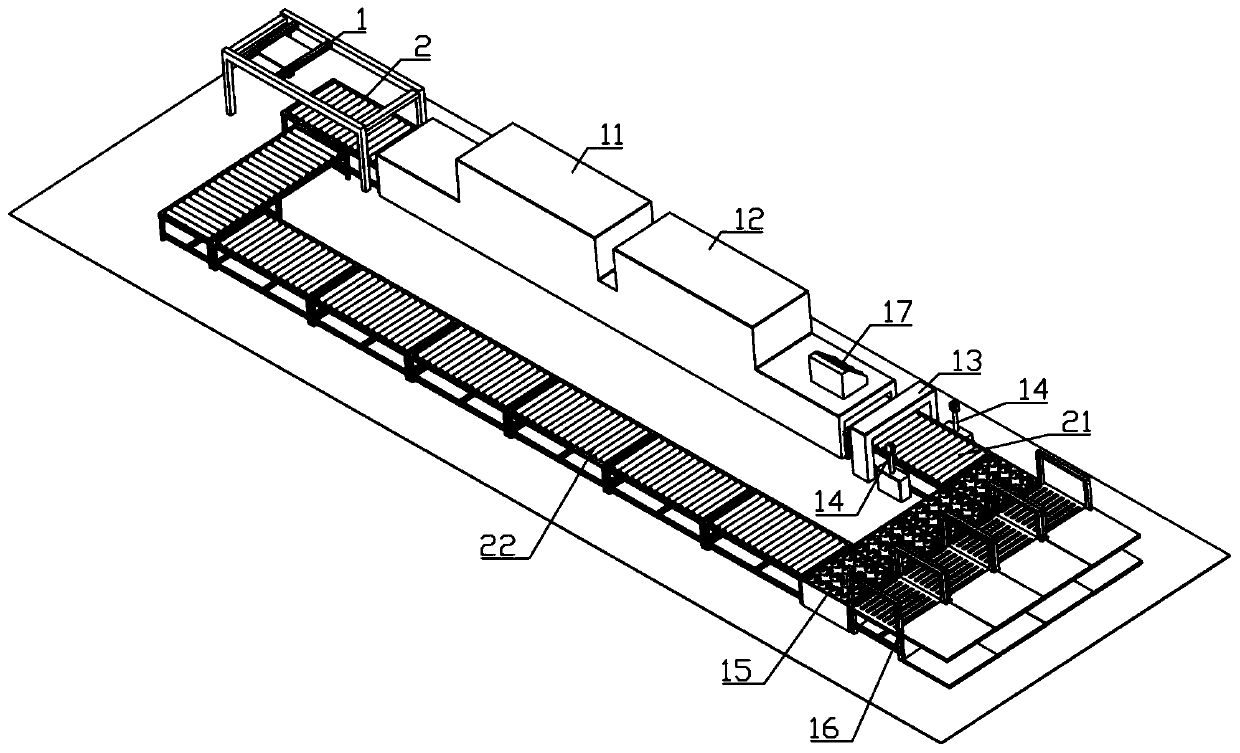

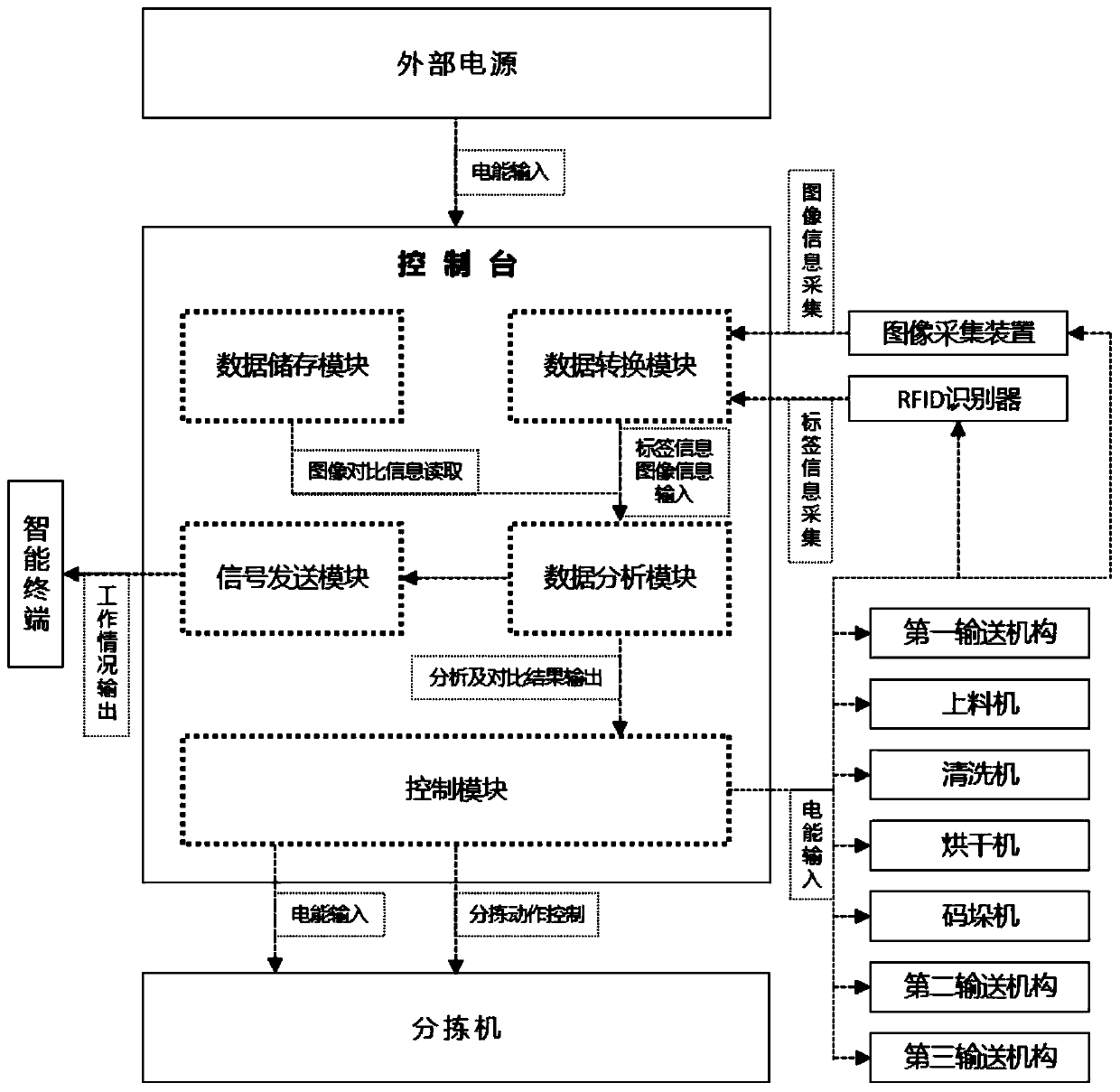

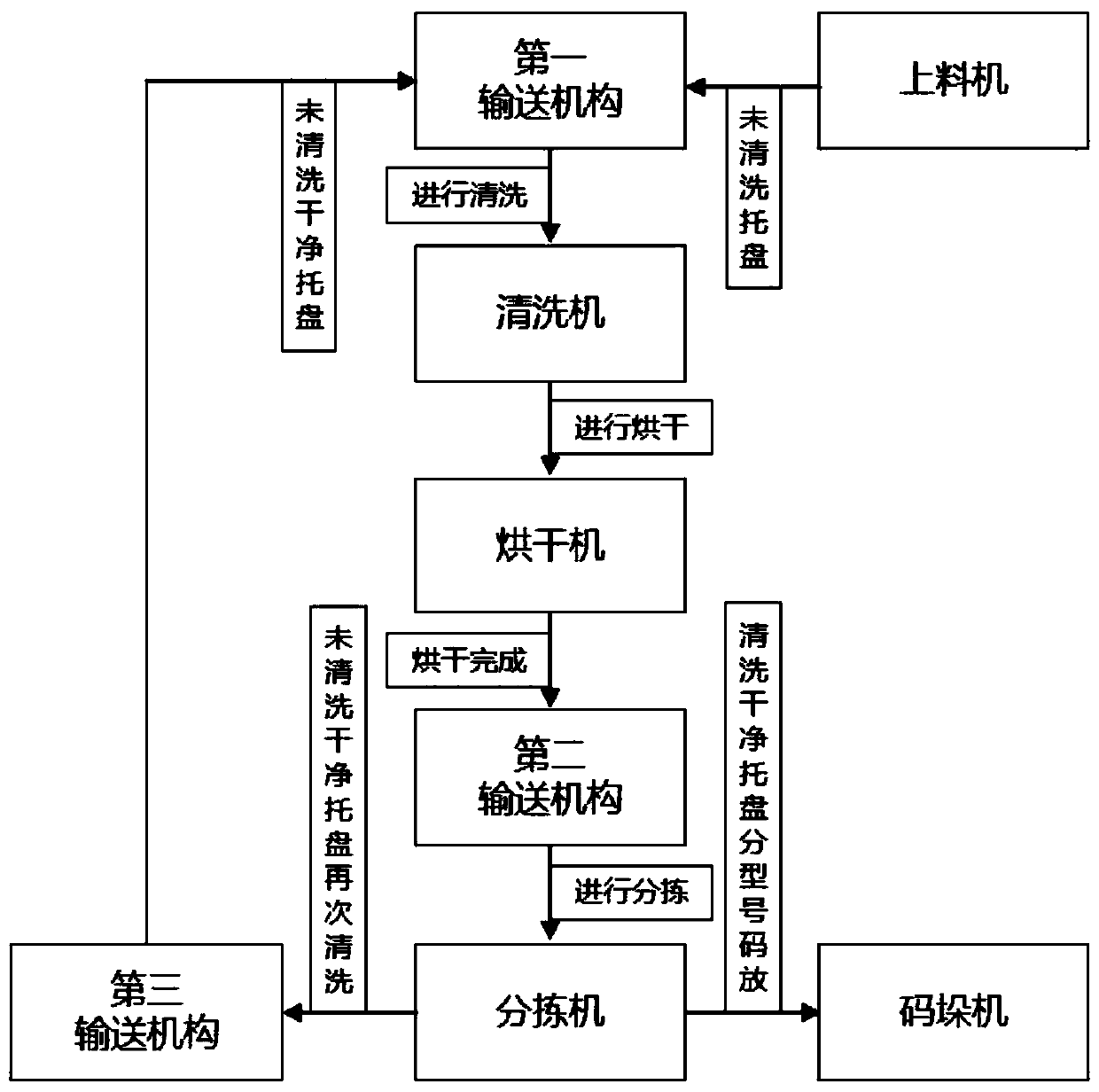

PendingCN111282937AImprove work efficiencyReduce labor costsHollow article cleaningDrying gas arrangementsData transformationPalletizer

The invention belongs to the technical field of tray cleaning, and particularly relates to a tray cleaning, drying and storing assembly line. A feeding machine, a cleaning machine, a drying machine, an RFID recognizer, an image collecting device, a sorting machine, a stacking machine and a control table are included. A first conveying mechanism is arranged between the feeding machine and the cleaning machine. The cleaning machine comprises a plurality of first movable spraying heads and a plurality of second movable spraying heads. The drying machine comprises a plurality of first air knives and a plurality of second air knives. A second conveying mechanism is arranged between the drying machine and the sorting machine. The RFID recognizer is arranged on the side, close to the drying machine, of the second conveying mechanism. The image collecting device comprises two cameras. A third conveying mechanism is arranged between the sorting machine and the first conveying mechanism. The control table comprises a data conversion module, a data analysis module, a data storage module and a control module, the control table is electrically connected with an outer power source, and the datastorage module stores image comparison information.

Owner:江苏乐橘云盘科技有限公司

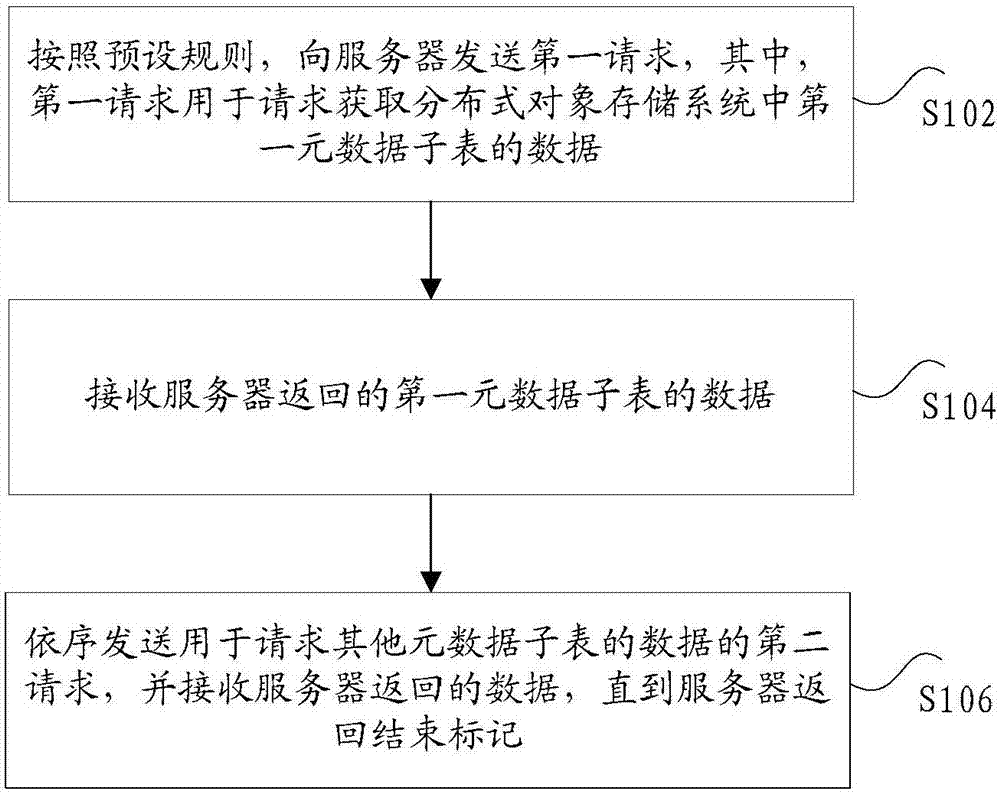

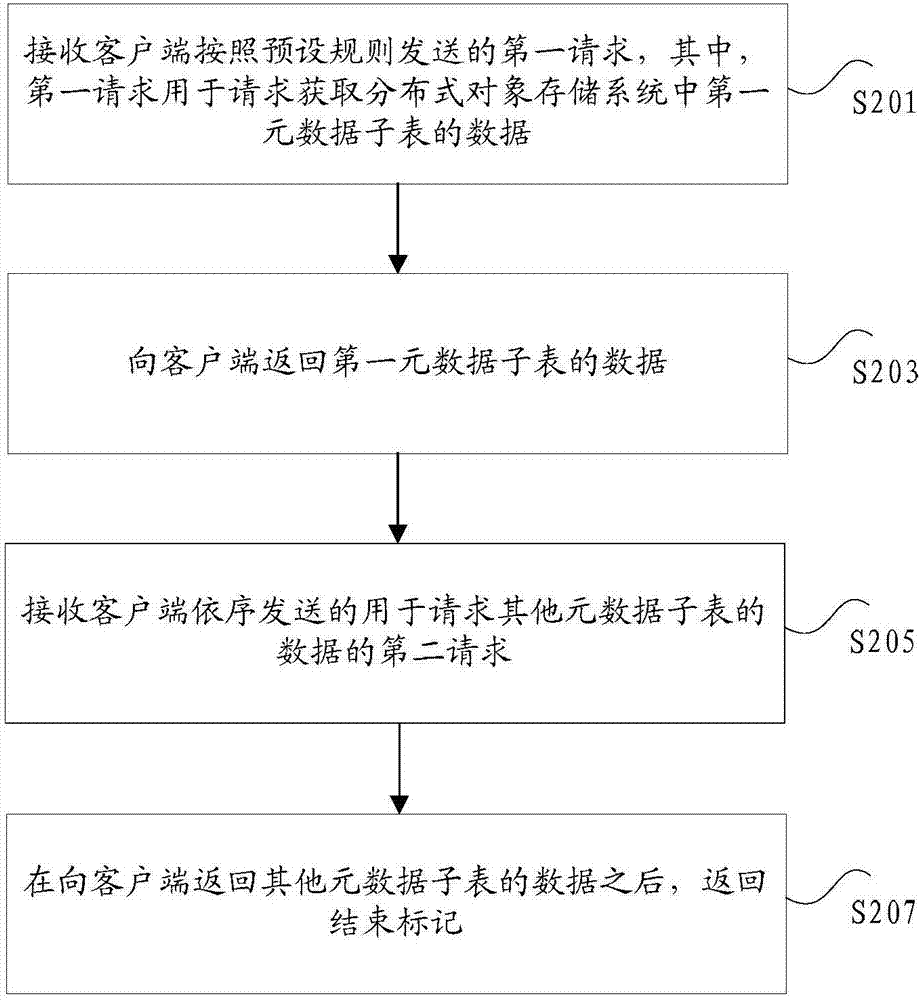

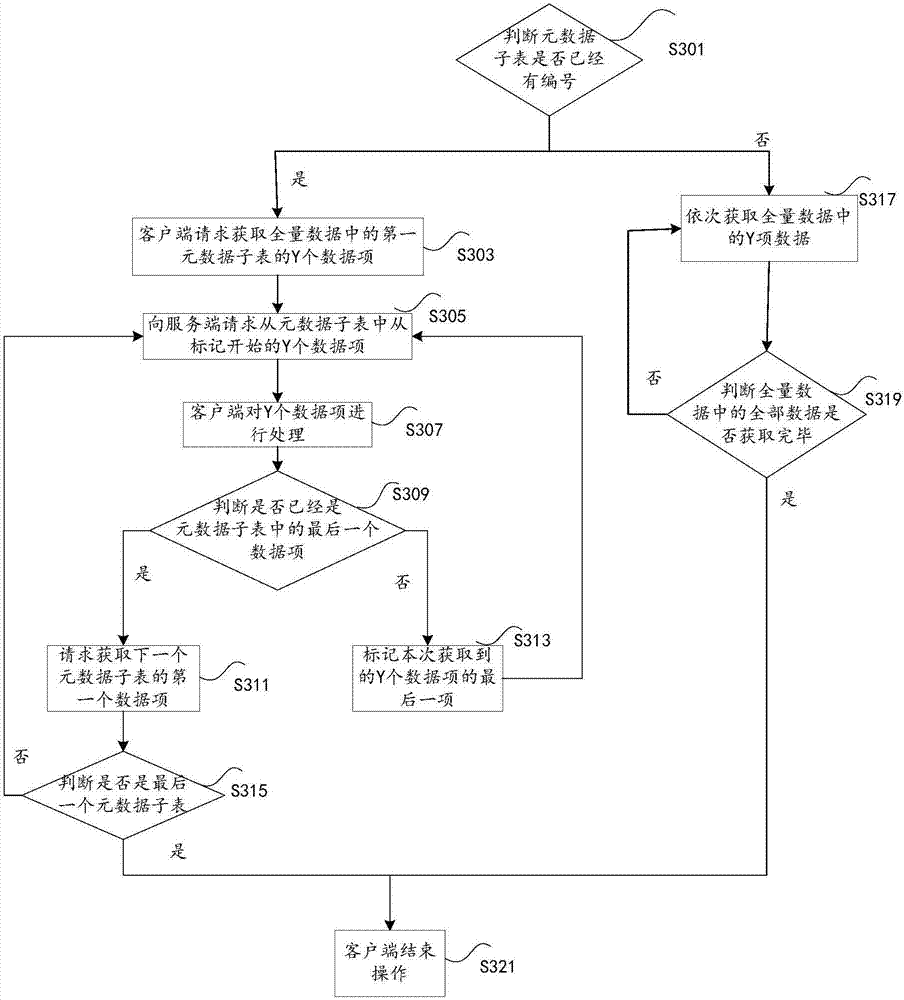

Data acquisition method and system for distributed object storage system

ActiveCN107070987AAvoid sortingSolve technical problems with low resource utilizationTransmissionDistributed objectResource utilization

The invention discloses a data acquisition method and system for a distributed object storage system. The method comprises the following steps: sending a first request to a server according to a preset rule, wherein the first request requests to obtain data of a first metadata sub-table in the distributed object storage system; receiving the data of the first metadata sub-table returned by the server; and sequentially sending a second request for requesting the data of other metadata sub-tables, and receiving the data returned by the server until the server returns an end mark. According to the data acquisition method and system disclosed by the invention, the technical problem of low resource utilization rate during the acquisition of a large amount of data can be solved.

Owner:深圳爱捷云科技有限公司

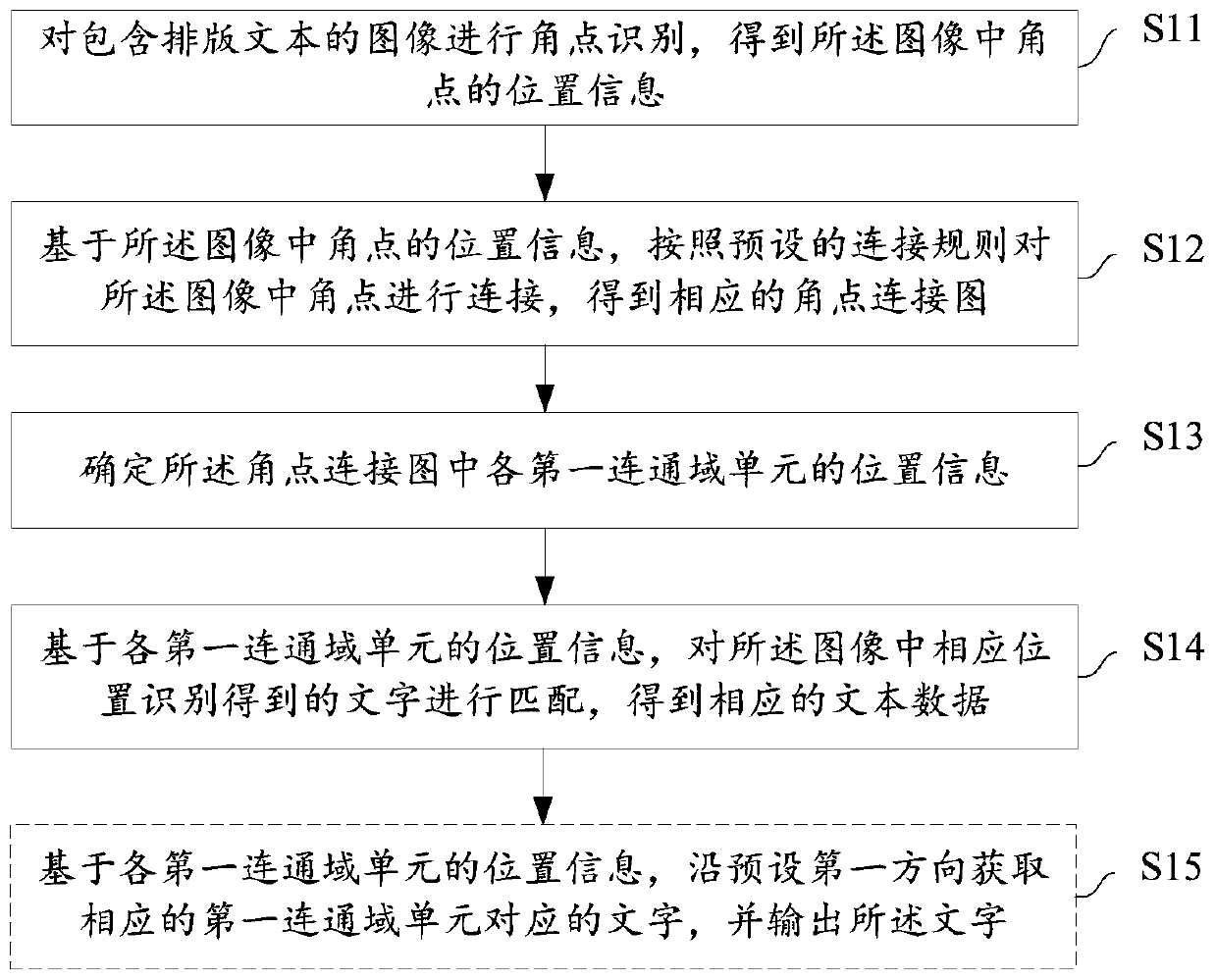

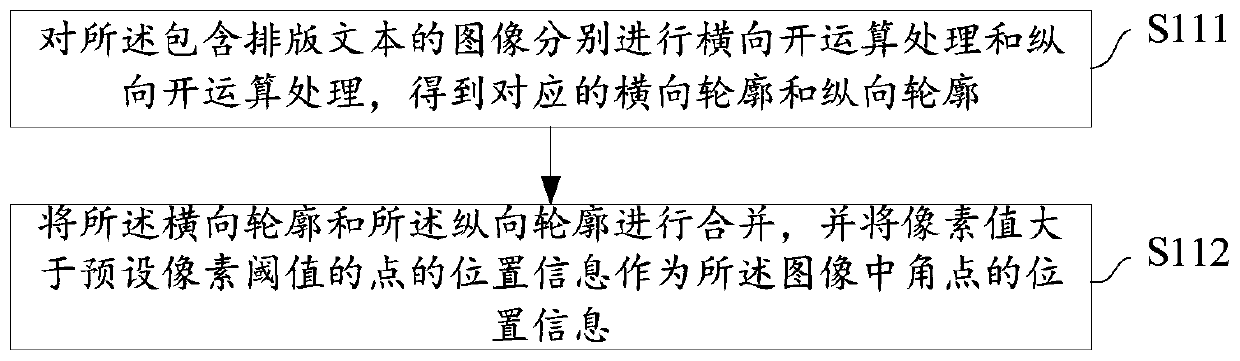

Text processing method and system, data processing equipment and storage medium

PendingCN111027521AImprove readabilityShorten the timeCharacter recognitionComputer graphics (images)Engineering

The invention discloses a text processing method and system, data processing equipment and a storage medium, and the method comprises the steps: carrying out corner recognition of an image containinga typesetting text, and obtaining the position information of a corner in the image; based on the position information of the corner points in the image, connecting the corner points in the image according to a preset connection rule to obtain a corresponding corner point connection graph; determining position information of each first connected domain unit in the corner connection graph; and based on the position information of each first connected domain unit, matching the characters obtained by identifying the corresponding positions in the image to obtain corresponding text data. By adopting the scheme, the readability of the text can be improved.

Owner:SHANGHAI XIAOI ROBOT TECH CO LTD

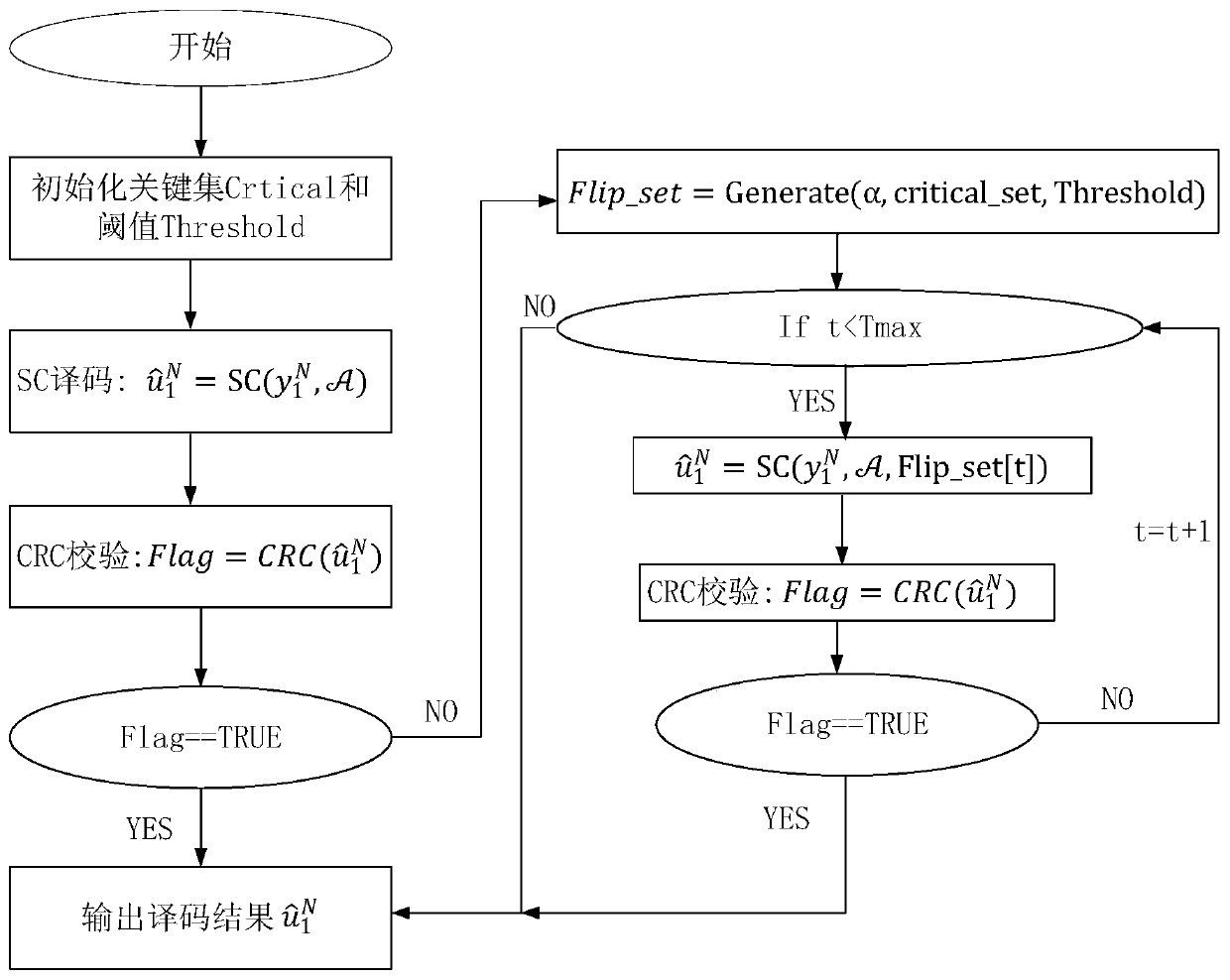

Bit inversion decoding method based on threshold value of polar code

PendingCN110061747ATake advantage ofAvoid sortingError correction/detection using multiple parity bitsCode conversionDecoding methodsRound complexity

The invention provides a bit inversion decoding method based on a threshold value of a polar code, which comprises the following steps: when CRC of a decoding result of an SC algorithm fails, judginga likelihood value in a key set by using the pre-designed threshold value so as to screen out candidate inversion bits; and based on the candidate inversion bit set, sequentially inverting the candidate bits, and performing SC decoding again from the current position until the CRC check is passed or the remaining bits of the inversion set are null. According to the method, the offline channel information is fully utilized, the Gaussian approximation theory is used for calculating the basic threshold value, and then the Monte Carlo method is used for optimizing the parameter k, so that the complexity can be reduced, and meanwhile, the error correction performance of the polarization code can be effectively improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

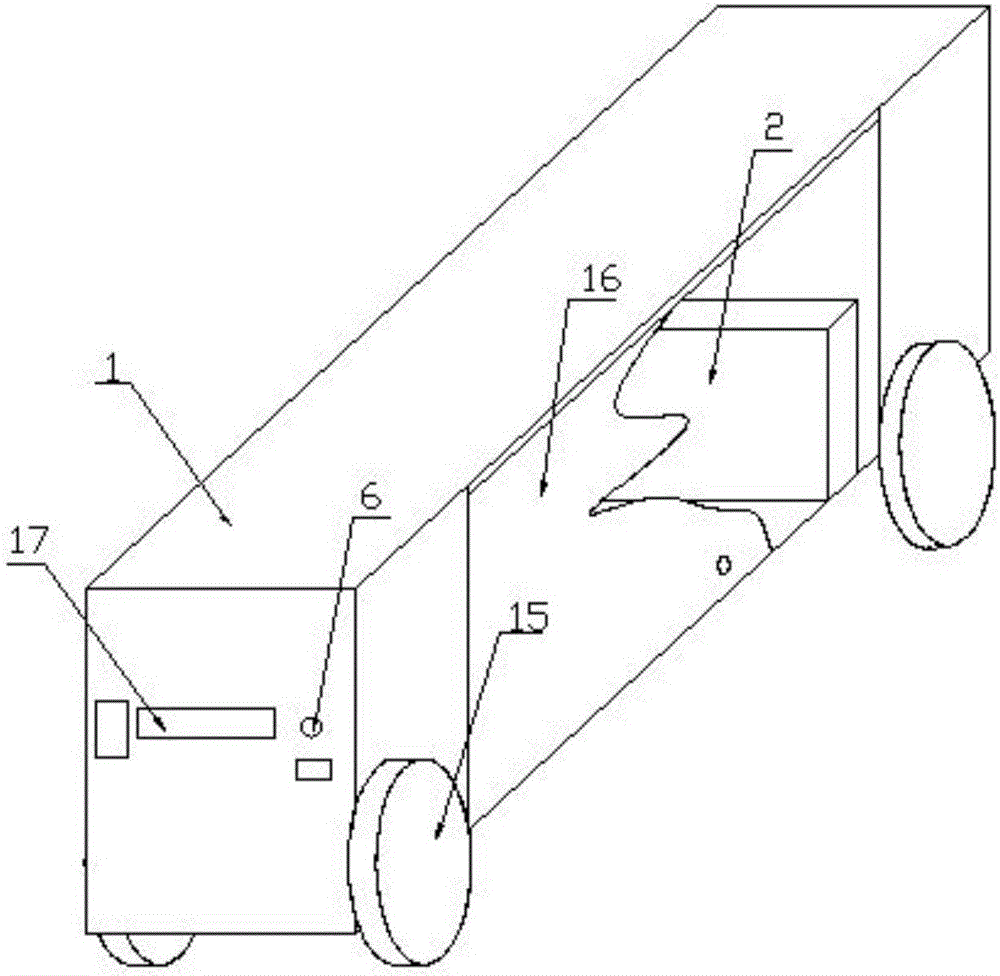

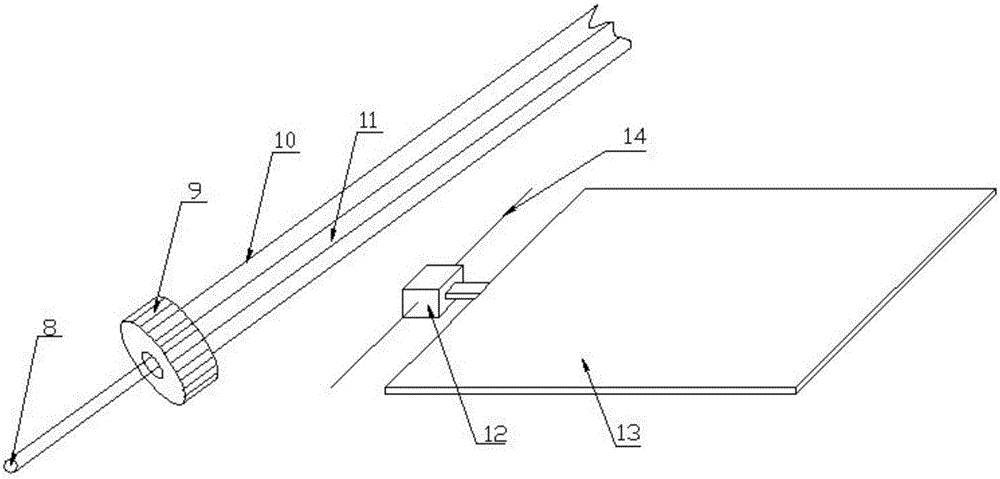

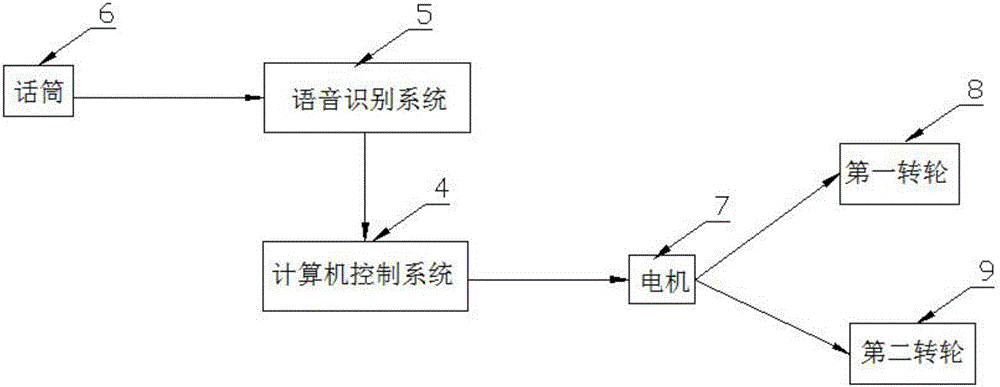

Practical post box capable of automatically classifying

InactiveCN106510418AImplement classificationAvoid sortingDwelling equipmentKitchen equipmentComputer control systemMechanical components

The invention discloses a practical post box capable of automatically classifying, which comprises a box body and a letter box in the box body. A button is arranged on an outer shell of the box body and is connected with a computer control system; the computer control system is arranged in the box body and is connected with a microphone through a voice recognition system; the microphone is arranged at one side of the button; the computer control system is electrically connected with a motor; the motor is electrically connected with a first rotary wheel and a second rotary wheel; a concentric circle is arranged in the middle of the second rotary wheel; a rotary rod is embedded in the concentric circle; a sliding chute is arranged on the rotary rod; a movable slide block is arranged in the sliding chute and is fixedly connected with a wood plate; a steel wire penetrates through the slide block so as to sleeve on the first rotary wheel, and is in an annular shape; the rotary wheels sleeves on two ends of the steel wire; and the first rotary wheel drives the other rotary wheel on the steel wire to rotate. According to the practical post box capable of automatically classifying provided by the invention, the computer control system is utilized to be combined with a mechanical component, so that letters can be classified, and deliverers are prevented from classifying the letters; and the arranged voice recognition system can recognize voices of people.

Owner:董锦涛

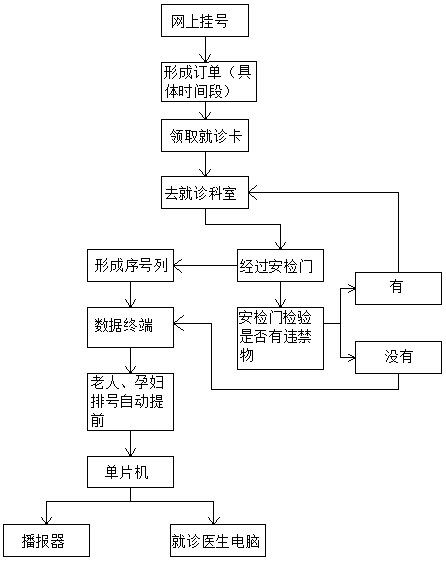

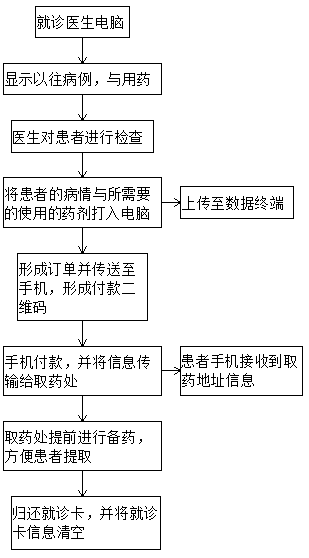

Intelligent hospital outpatient clinic system optimization system and safety scanning system

PendingCN111430015AAvoid carryingAvoid disputesDrug and medicationsOptical detectionPatient needCard reader

Embodiments of the invention disclose an intelligent hospital outpatient clinic system optimization system and a safety scanning system. The invention particularly relates to the field of medical care. A method includes following steps: firstly, a patient makes a registration on network, and the system schedules a probable date and time plan according to the number of registered patients; at the specific date and time, the patient goes to the hospital and acquires the patient card, and then finds out the department that the patient needs to visit, and swipes the card on a card reader for queuing; at the same time, the patient and the accompany personal pass through a safety-check door for detection, if a prohibited object is found, the system makes an alarm. By means of the safety-check door, the patient and the accompany personal are scanned for inspection, so that dangerous objects can be rejected, thereby preventing the dispute between the doctors and patients and protecting the life safety of the doctors. The card reader is set on the door of the departments, so that the patients can queue for visiting the doctors, so that a problem of queuing during the registration is avoided, and a problem that some patients make the registration too early and the time of visiting the department is long. The system can improve the visiting efficiency and prevents jumping a queue of the patients.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com