Multi-station stacking device and stacking process thereof

A stacking device, multi-station technology, applied in the directions of transportation and packaging, destacking of objects, stacking of objects, etc. problems such as vehicle efficiency, to achieve the effect of convenient storage and loading, reduce the probability of errors, and facilitate transshipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

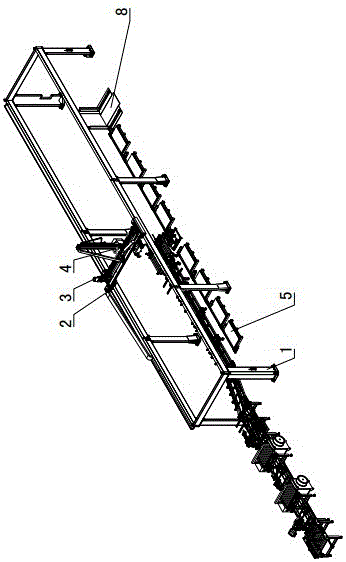

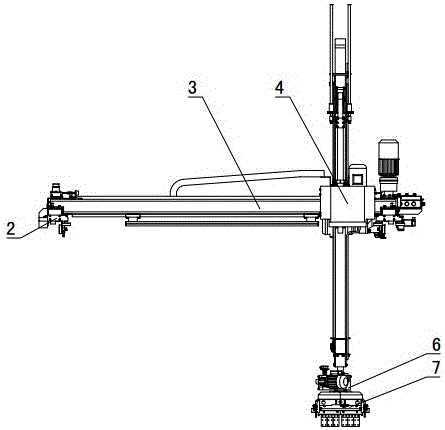

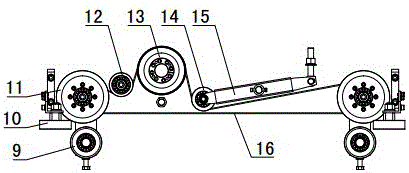

[0043] Figure 1~14 It is the best embodiment of the present invention. Figure 1~14 The present invention will be further explained.

[0044] A multi-station palletizing device includes a frame 1, a walking mechanism, a grasping mechanism 7 and a control device. The walking mechanism is installed on the frame 1, and the grasping mechanism 7 is installed on the walking mechanism. The walking mechanism and the grasping mechanism All are connected to the control device. The lower part of the frame 1 is provided with a pallet library 8 and a plurality of tile libraries 5, which are arranged along the tile conveying direction, and the control device controls the walking mechanism and the grabbing mechanism 7 to grab the pallet library The pallet in 8 is placed in the tile library 5. The rack 1 is also equipped with a tile detection unit. The tile detection unit is used to detect the type of ceramic tile and transmit the signal to the control device. The control device, according to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com