Guide plate detection separation, turnover and pre-material-cutting device

A sheet metal cutting technology, applied in the direction of stripping device, feeding device, positioning device, etc., can solve problems such as bonding and increasing labor intensity of parts processing, and achieve the effect of reducing labor intensity and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "bottom" and "top "Face", "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

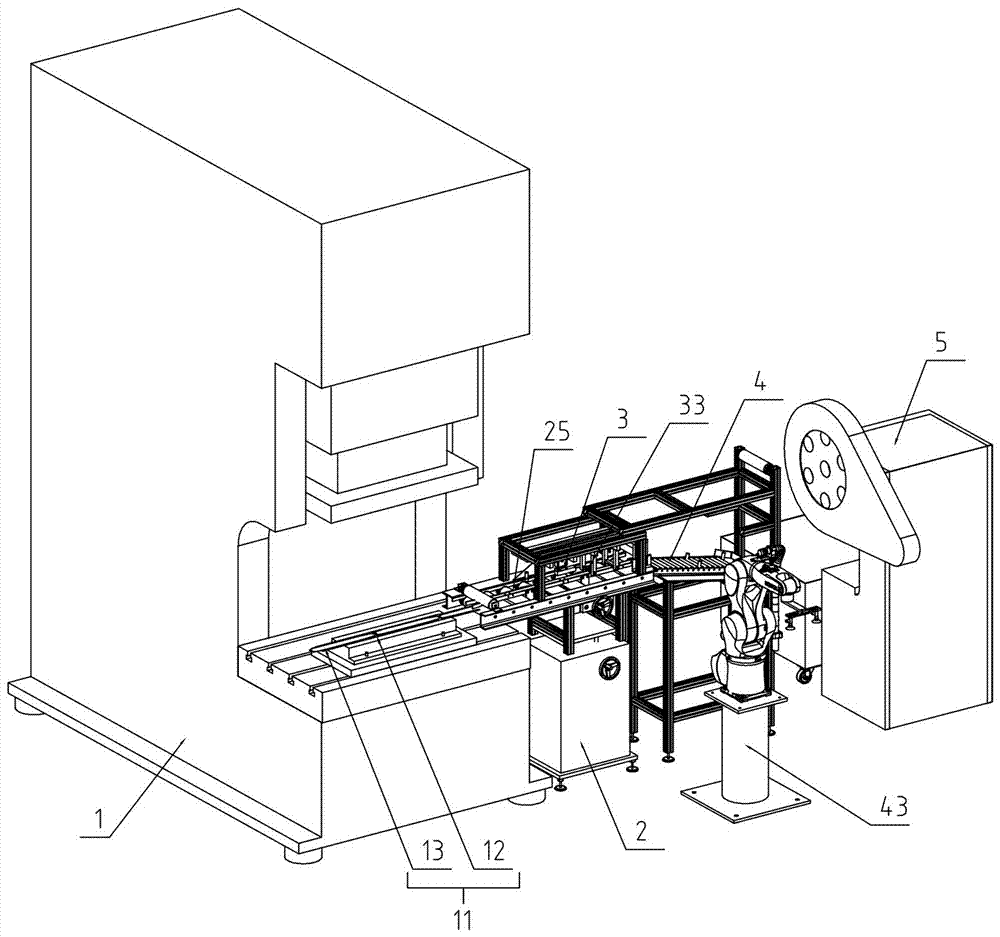

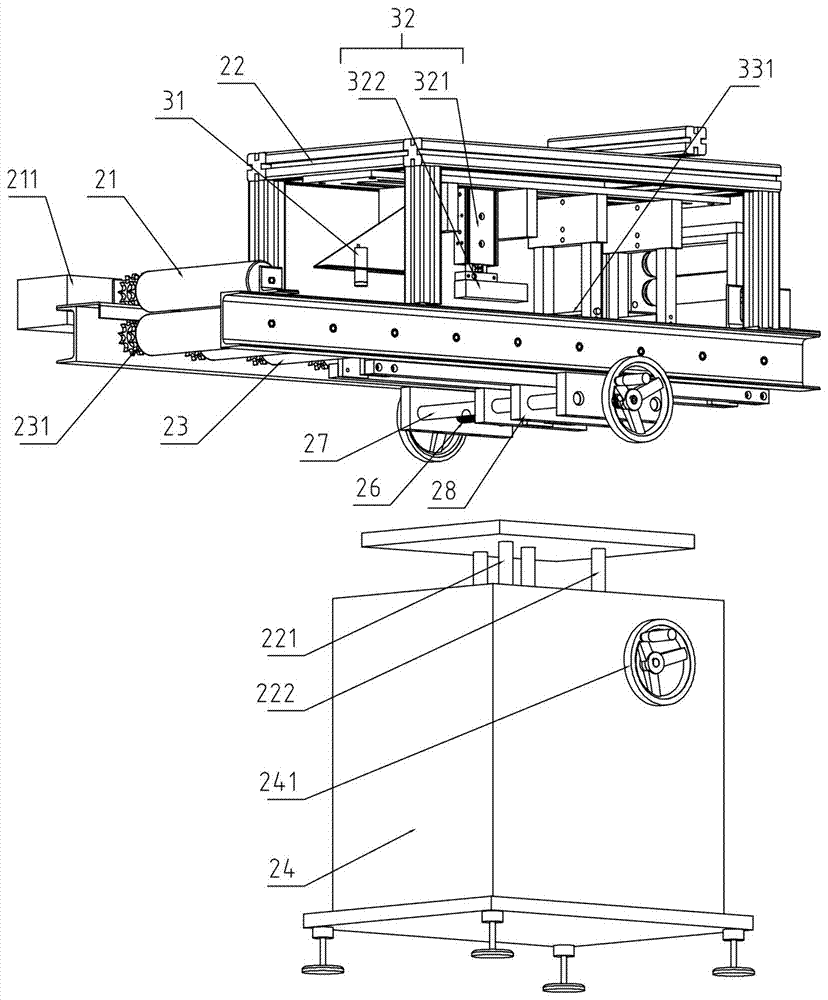

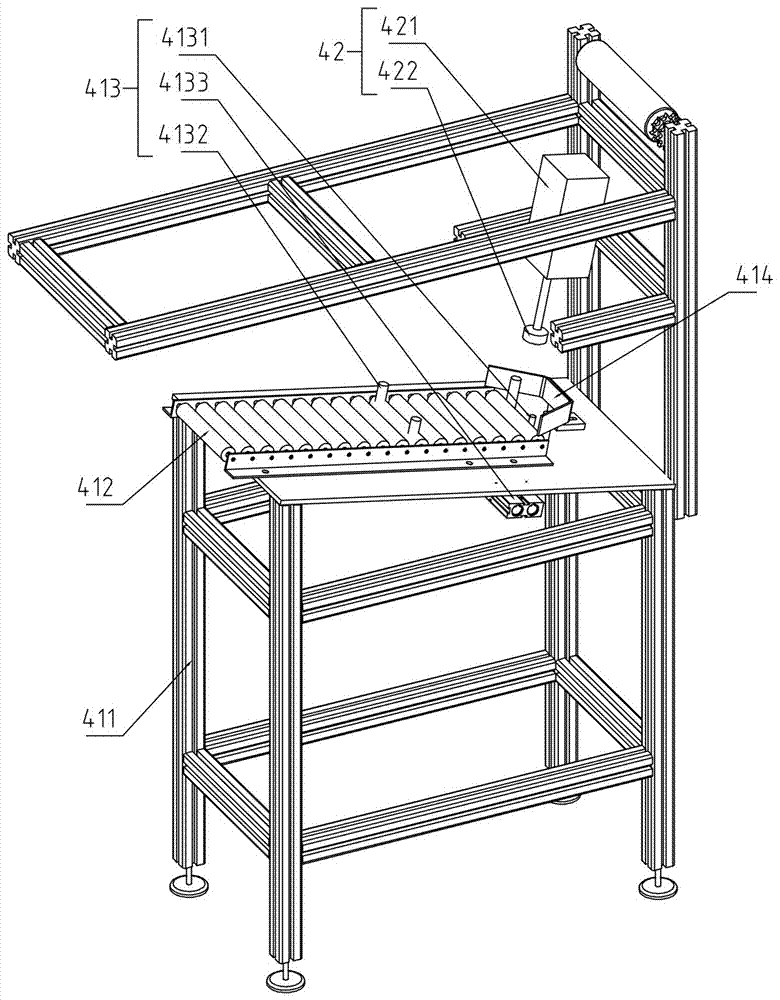

[0019] refer to Figure 1-5 As shown, a device for guide plate detection separation, turning over, and predictive cutting includes a punch 1 and a strip-shaped coil 11 processed by the punch 1. The strip-shaped coil 11 includes a strip-shaped waste 12 and a strip-shaped waste 12. The connected finished sheet material 13 is stamped and formed by the punch press 1 on the strip coil 11 through the upper and lower dies, and the punched finished sheet mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com