Tray cleaning, drying and storing assembly line

An assembly line and tray technology, applied in drying, sorting, dryers, etc., can solve problems such as increased cleaning costs, inability to automatically identify and sort, and customer complaints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

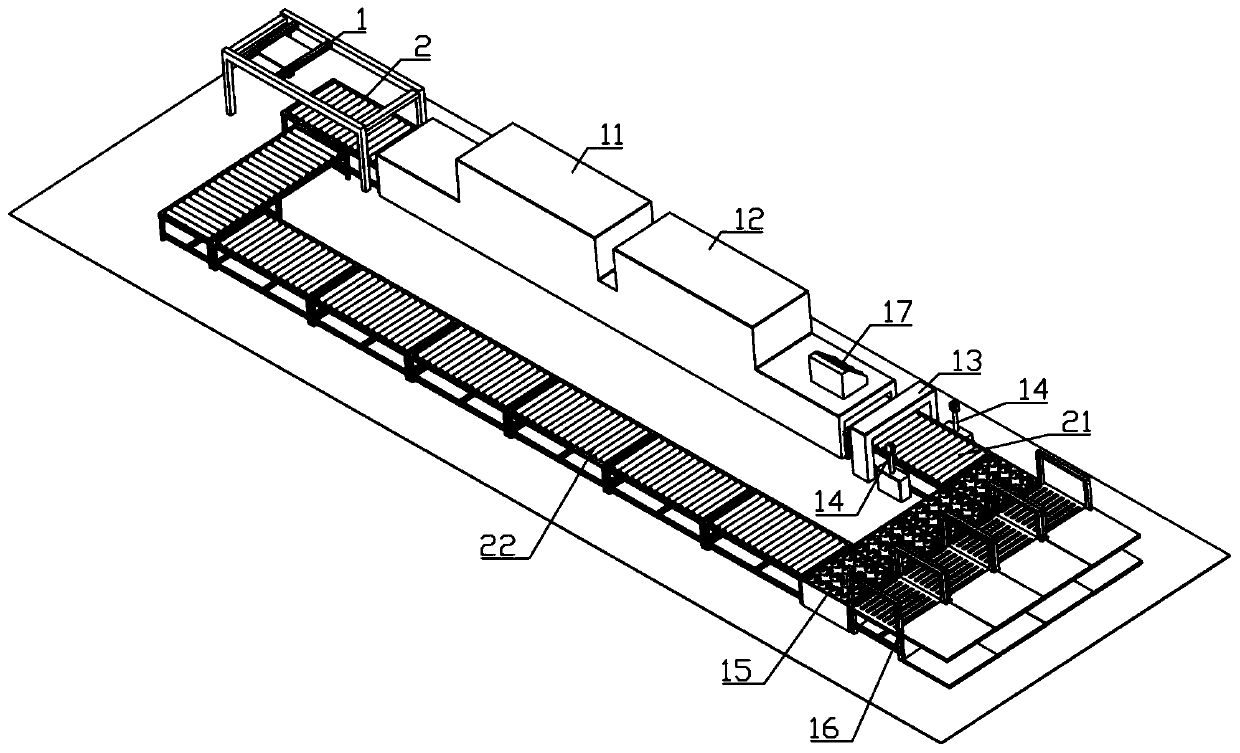

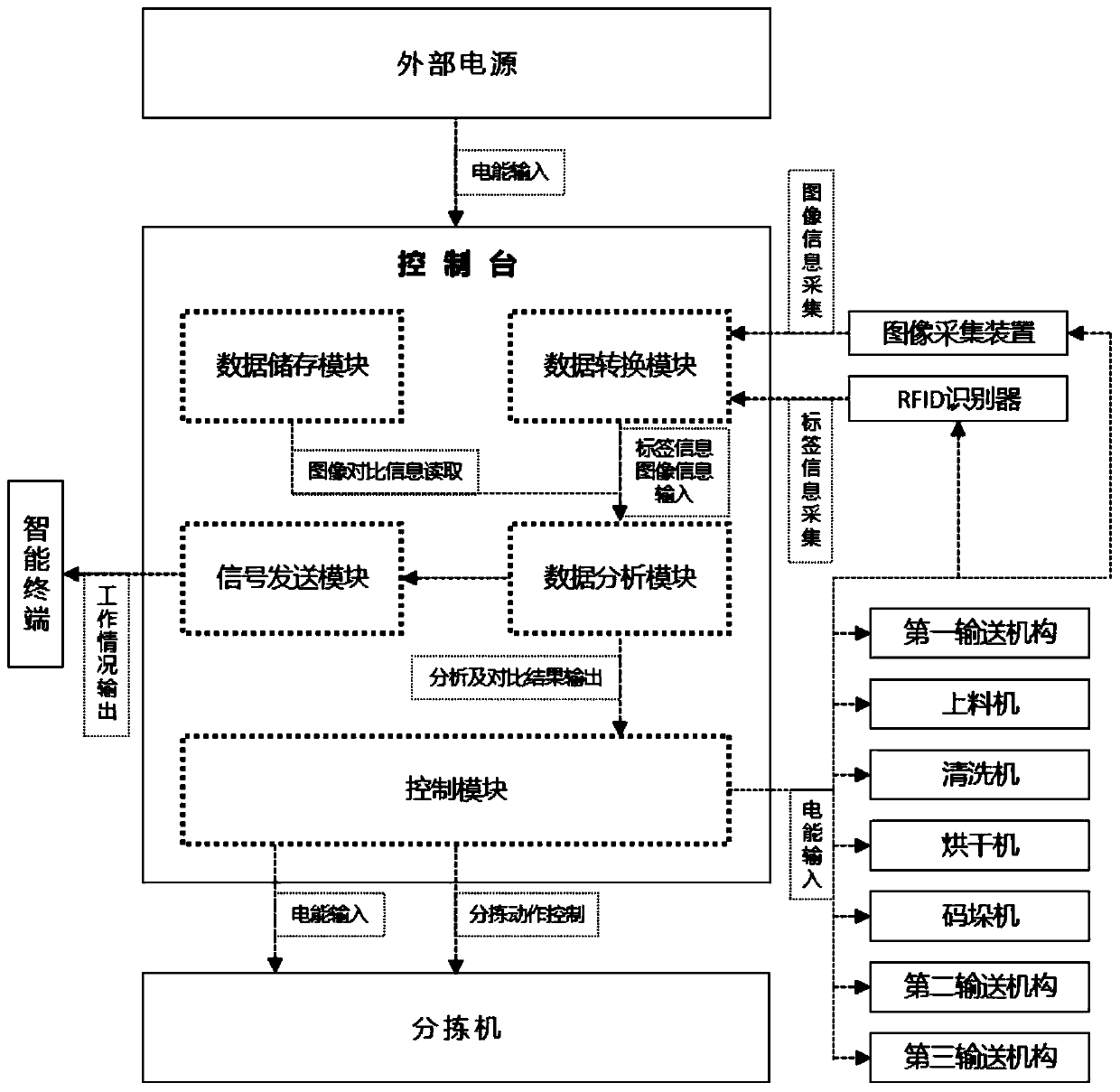

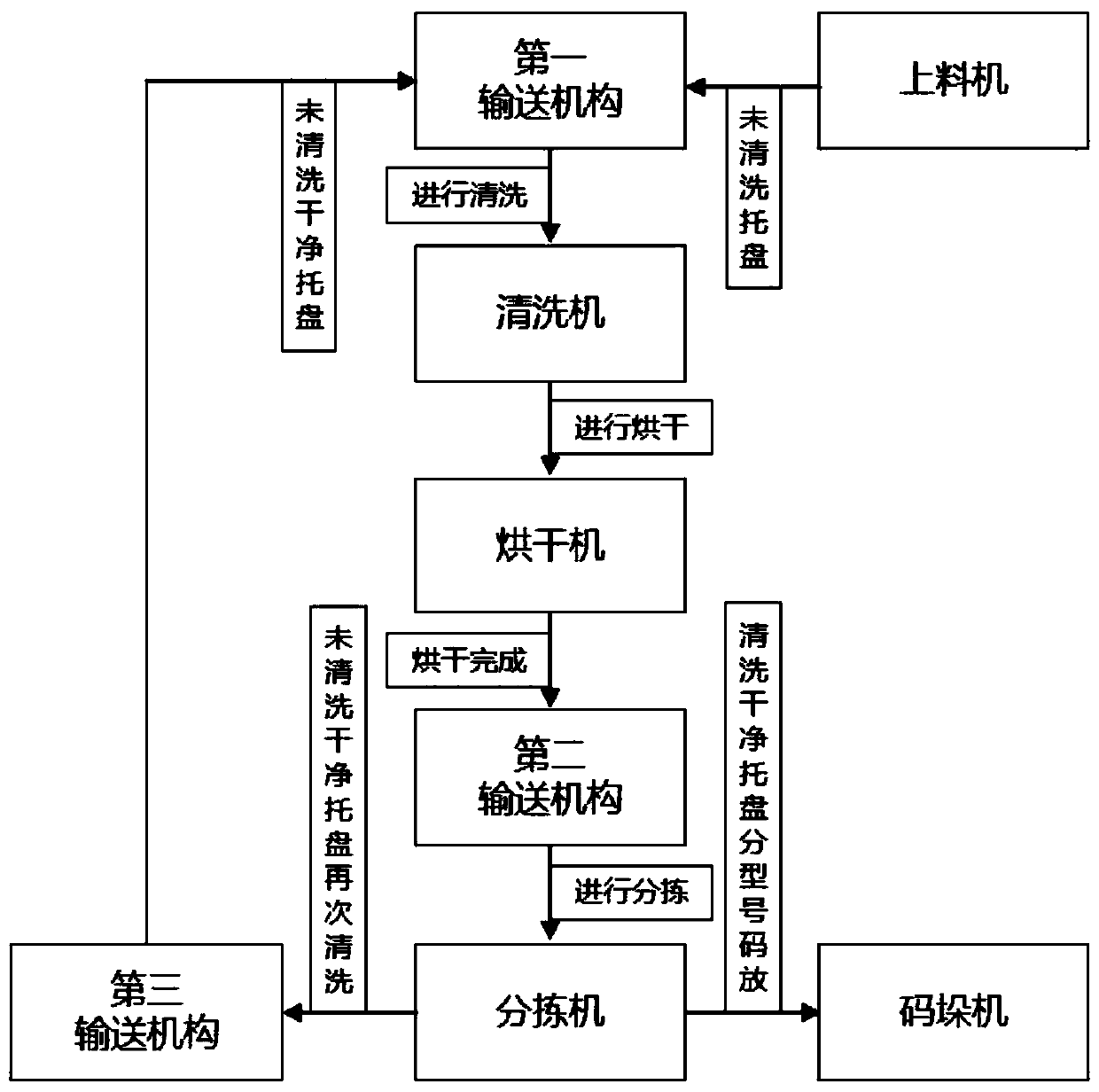

[0025] Such as Figure 1-3 As shown, a pallet cleaning, drying and sorting line of the present invention includes a loading machine 1, a washing machine 11, a drying machine 12, an RFID identifier 13, an image acquisition device 14, a sorting machine 15, and a palletizer 16 And the console 17, the first conveying mechanism 2 is provided between the feeder 1 and the cleaning machine 11, the cleaning machine 11 includes some first movable shower heads and some second movable shower heads, and the dryer 12 includes several first movable shower heads. An air knife and several second air knives, a second conveying mechanism 21 is arranged between the dryer 12 and the sorter 15, and the RFID identifier 13 is arranged on the side of the second conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com