Patents

Literature

45results about How to "Avoid sorting errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

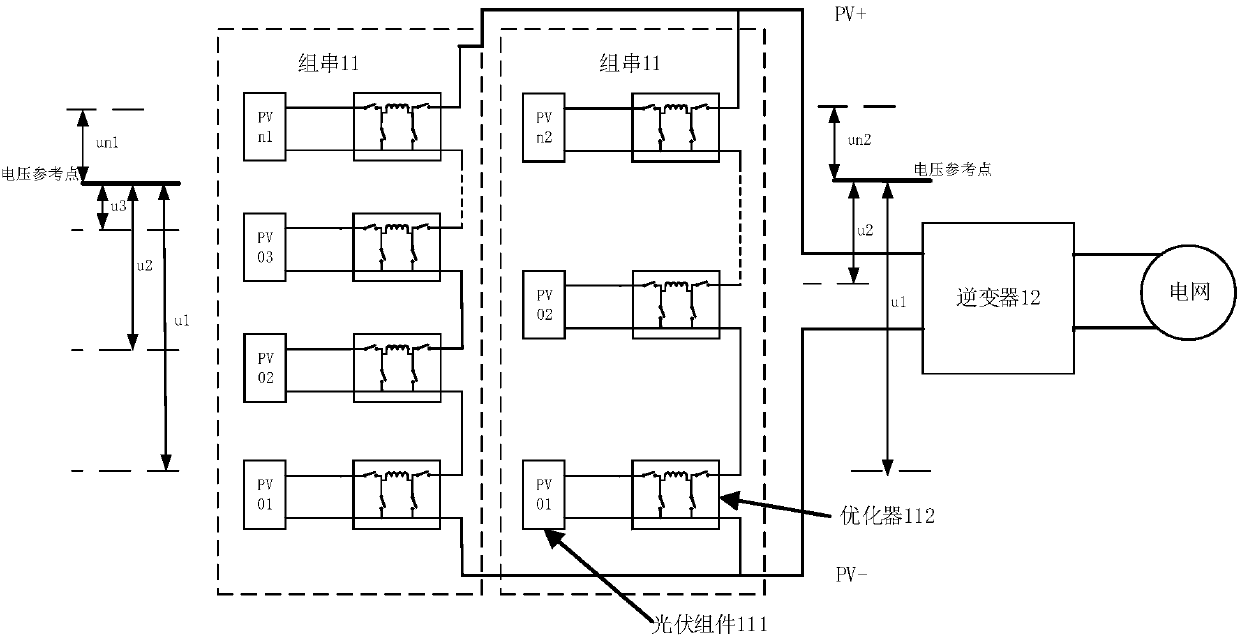

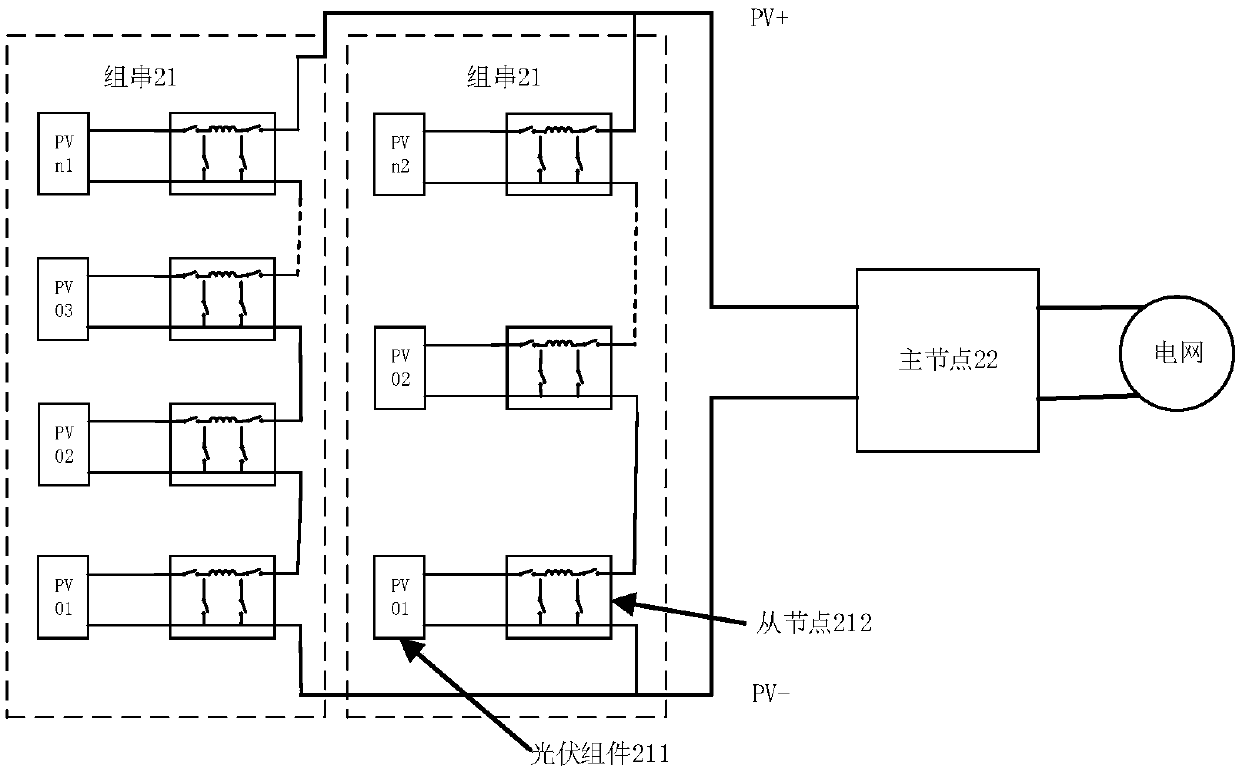

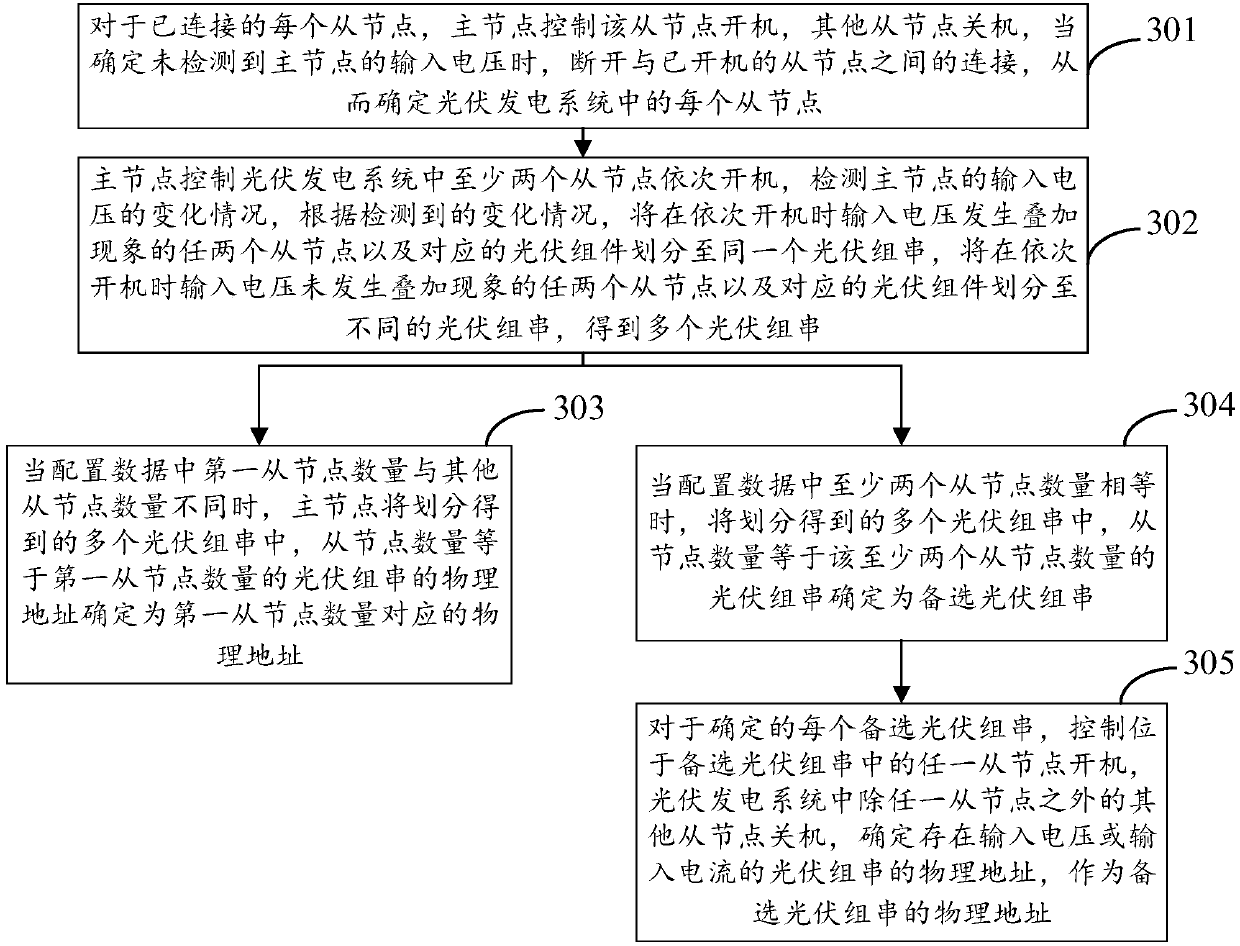

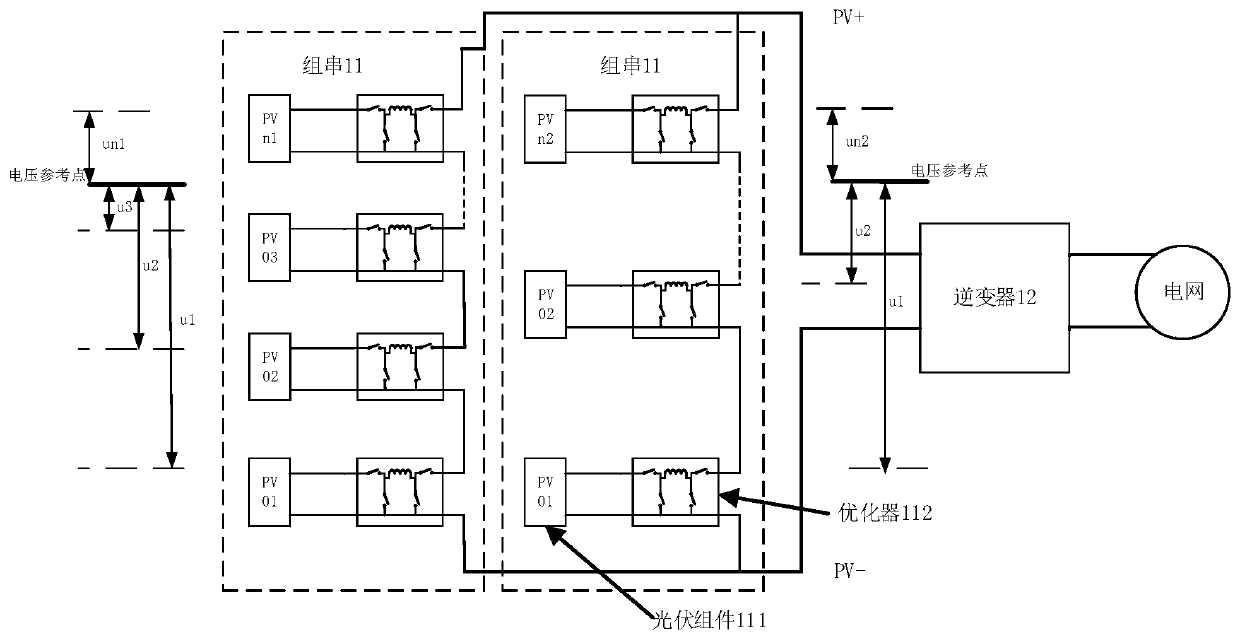

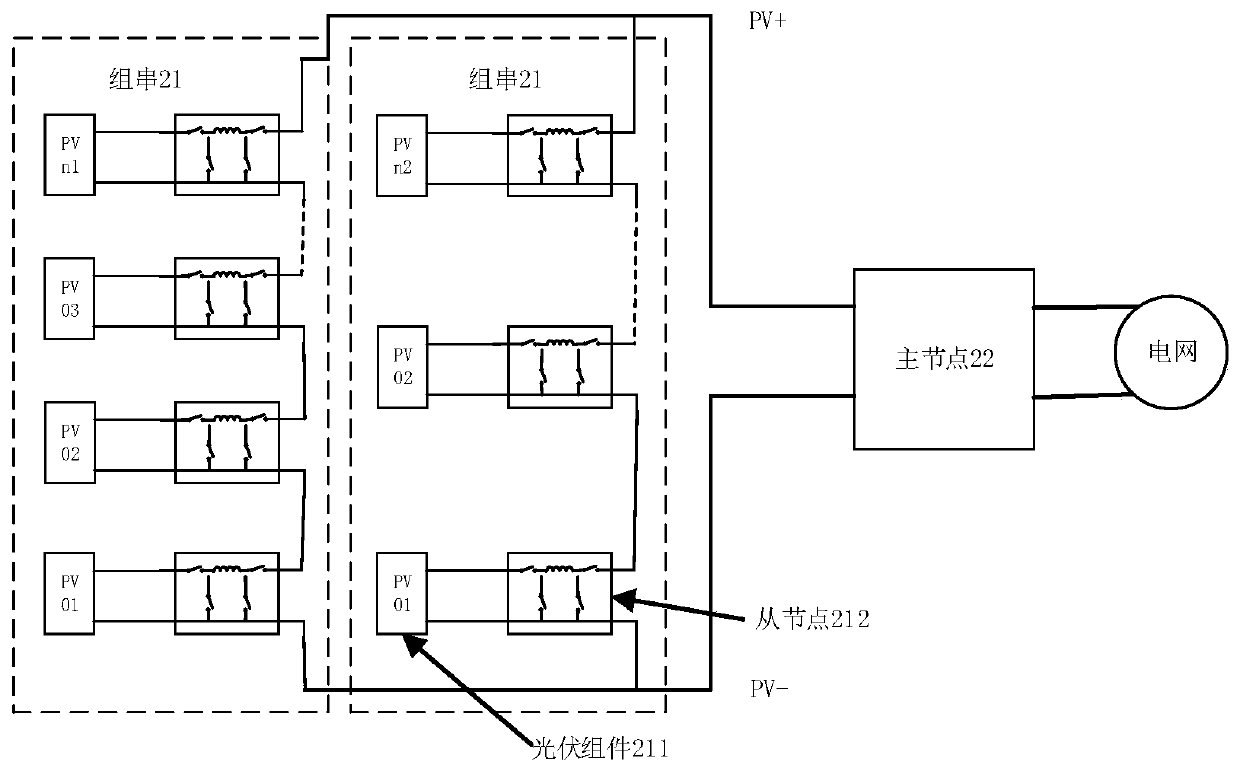

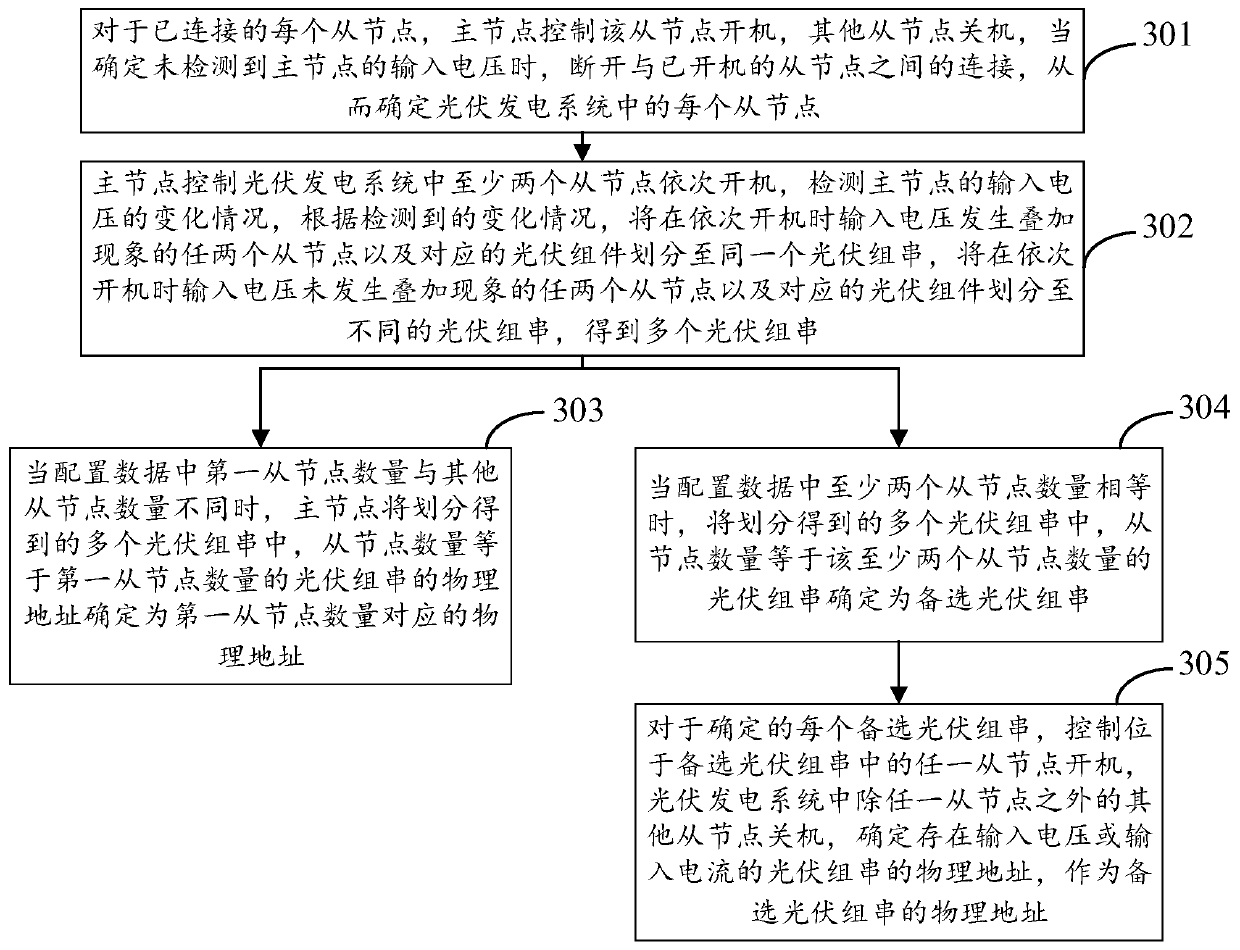

Physical address determination method, device and equipment and storage medium

ActiveCN107769250AAchieve positioningExtended functional scopePhotovoltaic monitoringSingle network parallel feeding arrangementsPhysical addressSystem stability

The invention provides a physical address determination method, device and equipment and a storage medium, and belongs to the field of solar energy. The method comprises the steps of controlling at least two slave nodes to be sequentially started, and detecting a change condition of an input voltage of a main node; dividing a photovoltaic power generation system into a plurality of photovoltaic strings; determining the photovoltaic string of which the number of the slave node is equal to the number of at least two nodes to be an alternative photovoltaic string when at least two slave nodes inconfiguration data are equal in number; and controlling an arbitrary slave node in the alternative photovoltaic string to be started and other slave nodes to be closed with regard to each alternativephotovoltaic string, and determining a physical address of the photovoltaic string with existence of an input voltage or an input current as a physical address of the alternative photovoltaic string.The invention provides a mode for automatically determining the physical address of the photovoltaic string. By the method, the positioning of the photovoltaic string is achieved, the function range of the system is expanded, abnormality can be timely eliminated when an abnormal condition occurs, and the system stability is improved.

Owner:HUAWEI DIGITAL POWER TECH CO LTD

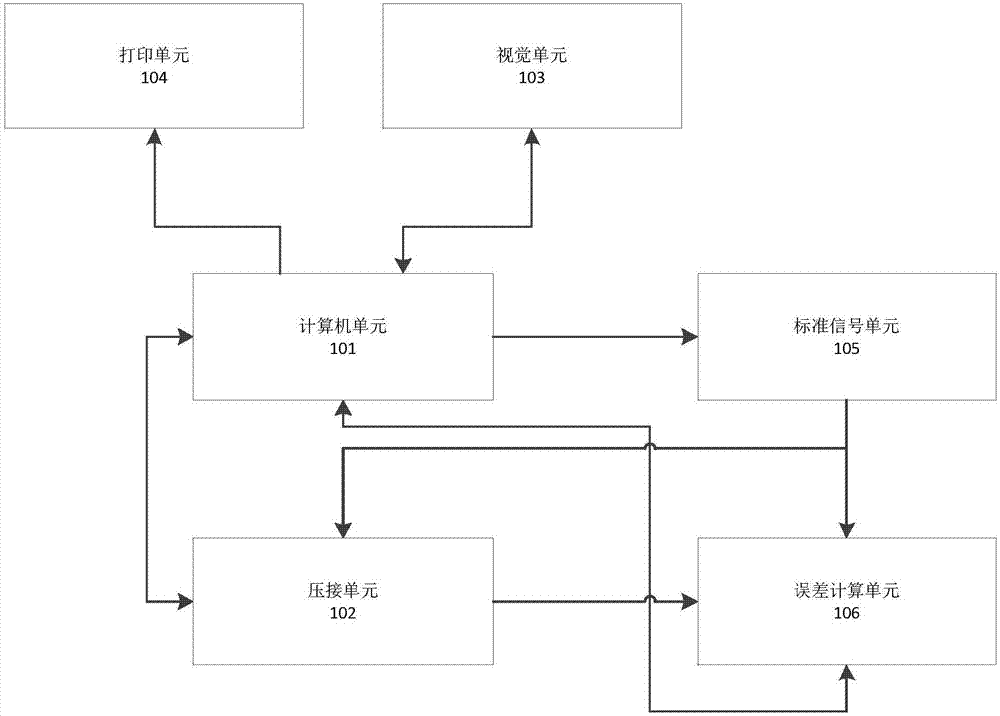

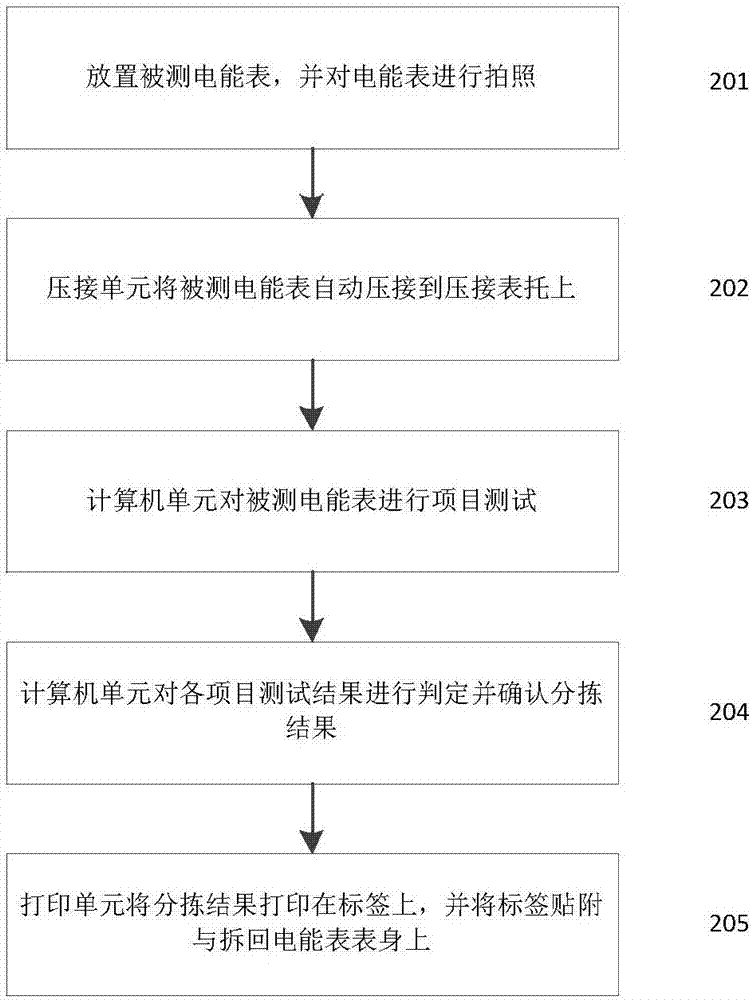

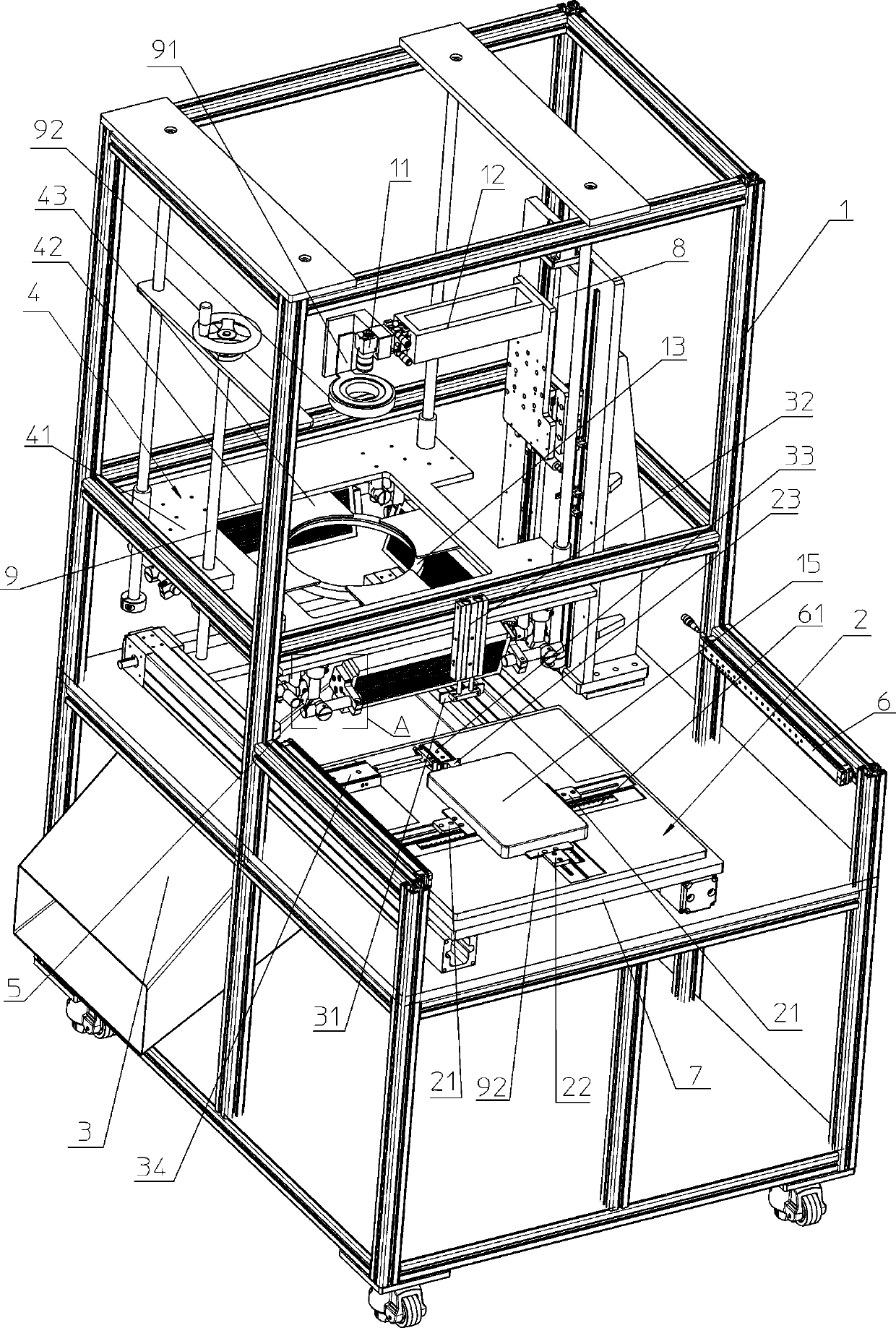

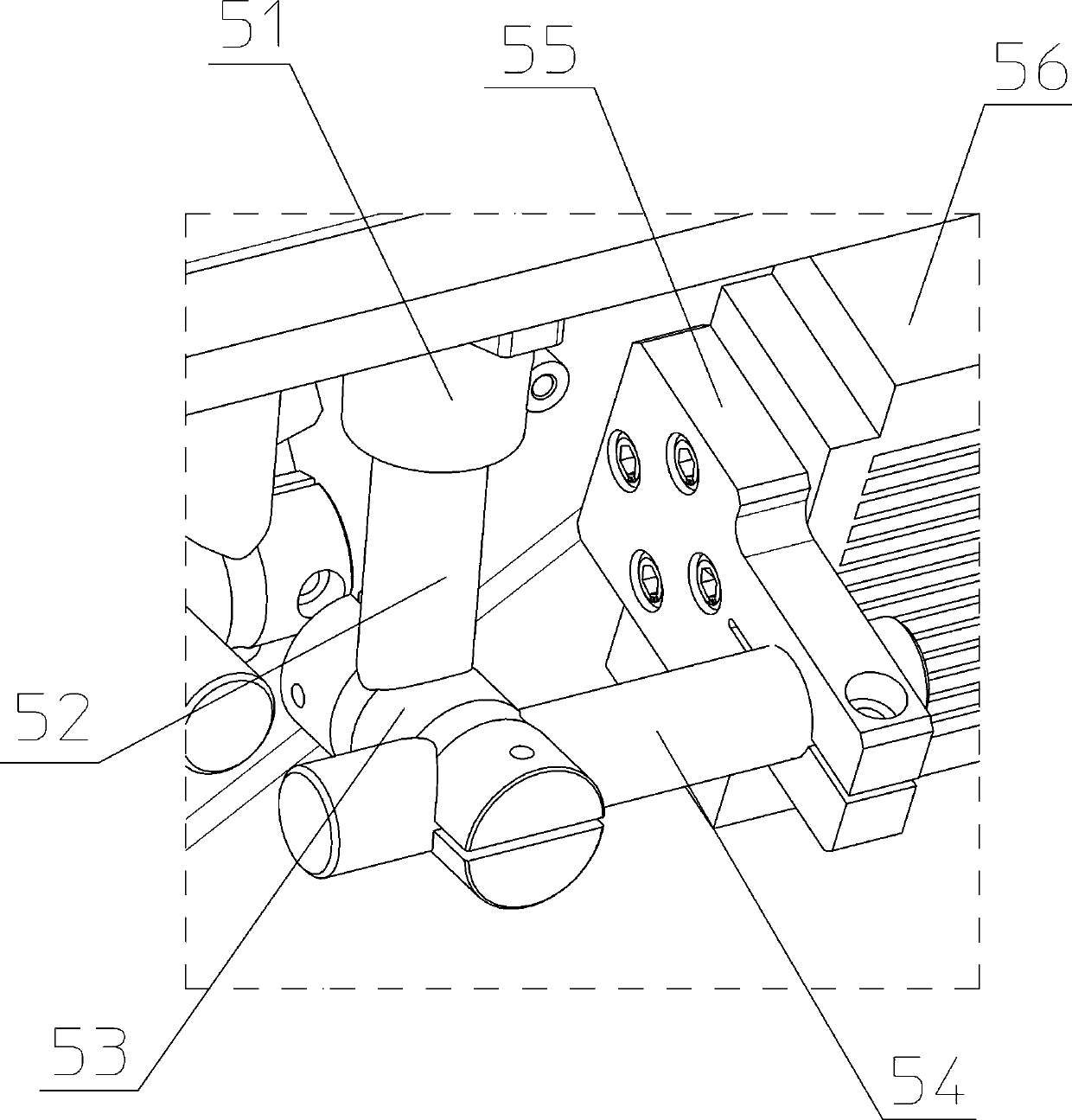

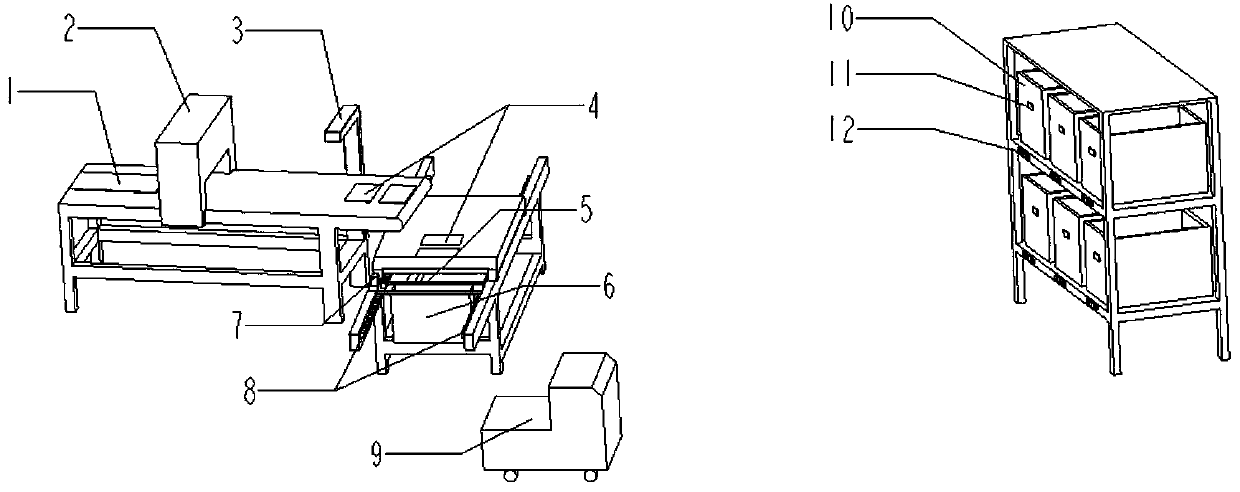

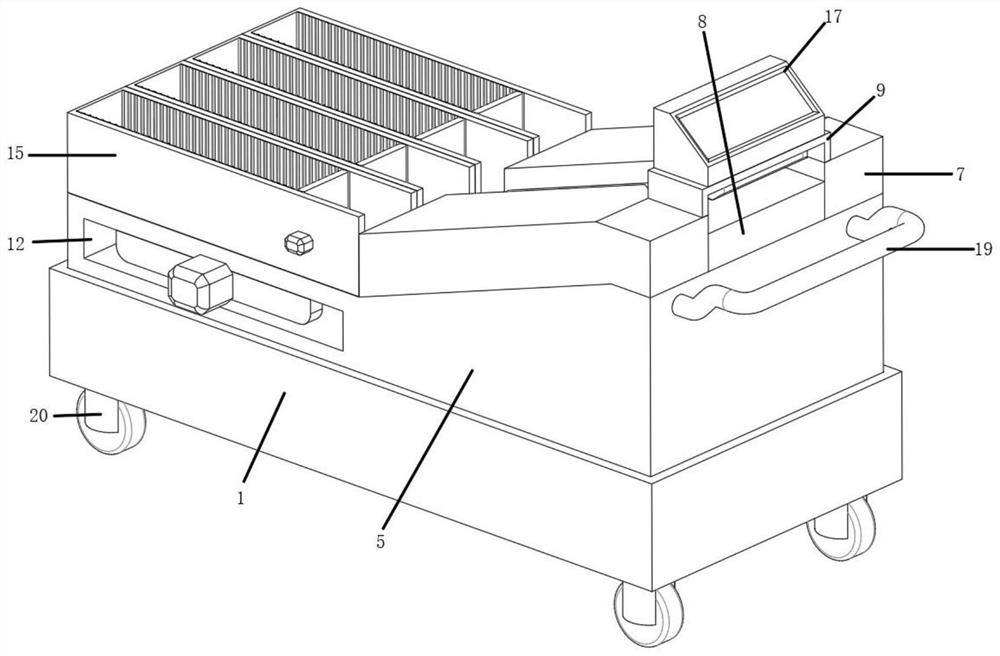

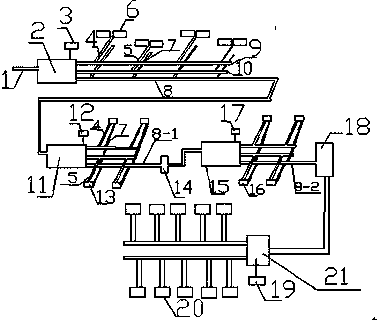

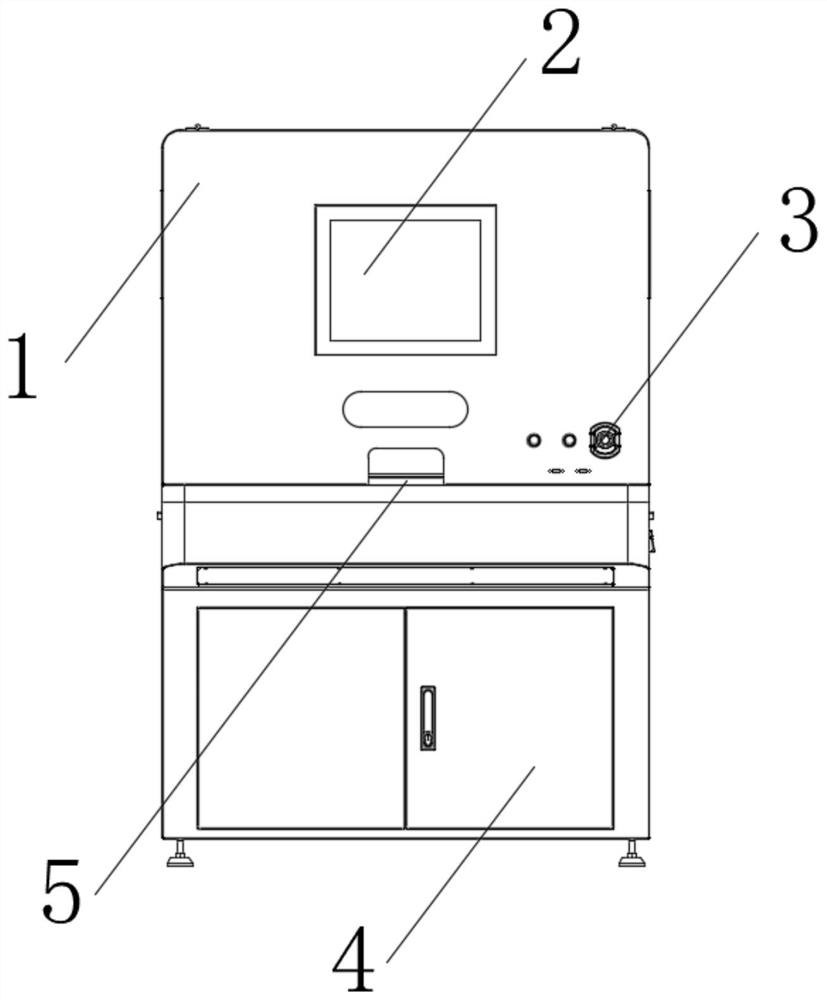

Sorting device and method for power meters taken down and back

InactiveCN107470181AImprove sorting efficiencyHigh sorting accuracyElectrical measurementsSortingElectrical connectionEngineering

The invention discloses a sorting device and method for power meters taken down and back. The sorting device comprises a computer unit, a pressure joint unit, a vision unit, a printing unit, a standard signal unit and an error calculation unit, wherein the computer unit is used for having control over the other units, the pressure joint unit is used for carrying out automatic electrical connection on the different specifications of power meters taken down and back, the vision unit is used for photographing the power meters taken down and back, the printing unit is used for printing the sorting results on labels and attaching the labels on the bodies of the power meters taken down and back, the standard signal unit is used for generating standard signals, and the error calculation unit is used for measuring the errors of the power meters taken down and back. According to the sorting method, the power meters taken down and back are each placed on a pressure joint meter support to be photographed, the pressure joint unit carries out automatic pressure joint on each power meter taken down and back and the pressure joint meter support, the computer unit carries out all item tests on the power meters taken down and back and determines the sorting results, and then the printing unit prints the sorting results on the labels and attaches the labels on the bodies of the power meters taken down and back.

Owner:CHINA ELECTRIC POWER RES INST +1

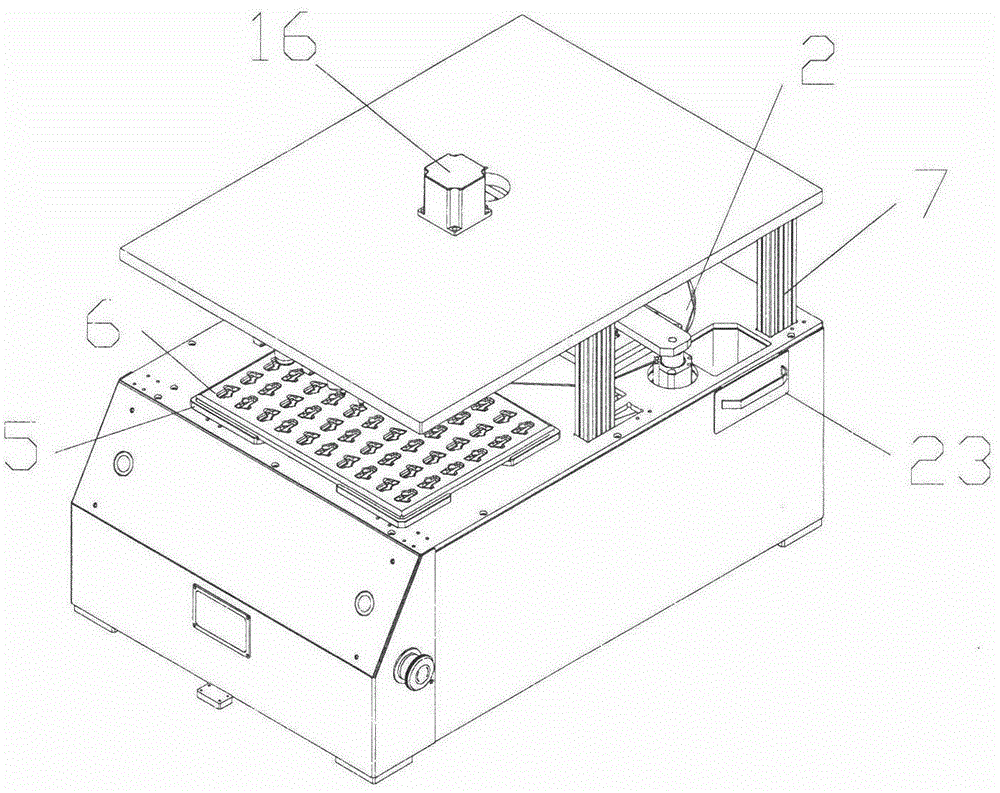

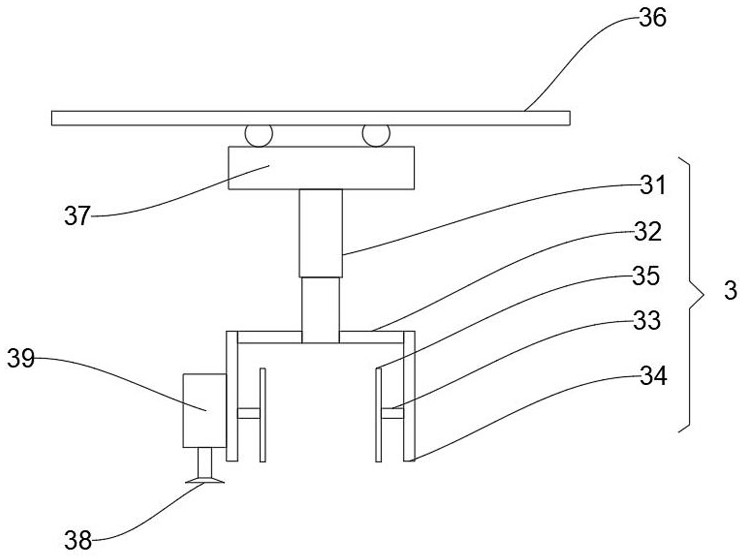

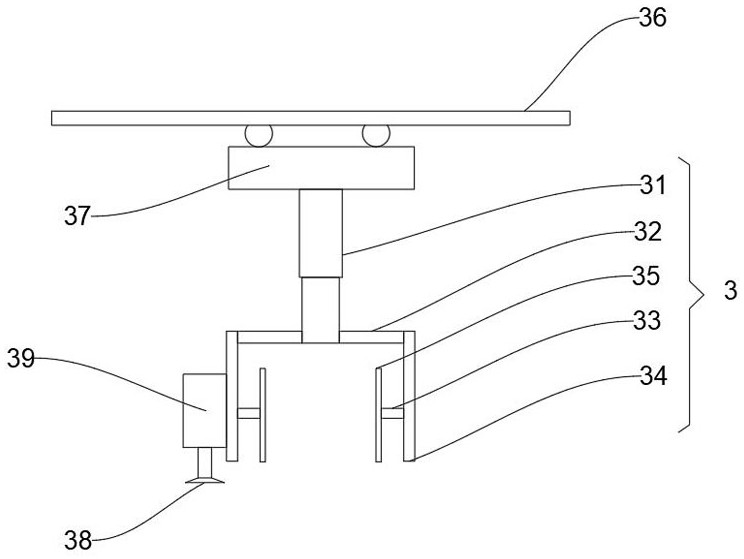

Visual detecting device

ActiveCN109865679AImprove versatilityEasy to replaceOptically investigating flaws/contaminationSortingVisual perceptionComputer science

The invention discloses a visual detecting device. The visual detecting device comprises a rack, and the rack is provided with a camera mounting frame, a light source mounting table, a moving table and a moving table driving device; the moving table is provided with a positioning mechanism which can conduct left-right positioning and rear positioning on workpieces, a front positioning block is arranged on the front part of the moving table, the rack is further provided with a removing device, and the removing device structurally comprises a removing channel, a blocking plate, a blocking platedriving device, a positioning block moving device and an avoidance driving device capable of driving the front positioning block to leave the front parts of the workpieces; after moving downwards, theblocking plate can block on the path where the workpieces on a picture-taking station move rearwards to return to a loading and unloading station; and when the front positioning block leaves the front parts of the workpieces and the moving table drives the workpieces to move rearwards, unqualified workpieces on the moving table can be blocked by the blocking plate to be unable to move rearwards along with the moving table, and thus the unqualified workpieces can slide off the moving table and fall into the removing channel. According to the visual detecting device, the unqualified workpiecescan be automatically removed, and thus sorting error can be prevented.

Owner:高视科技(苏州)股份有限公司

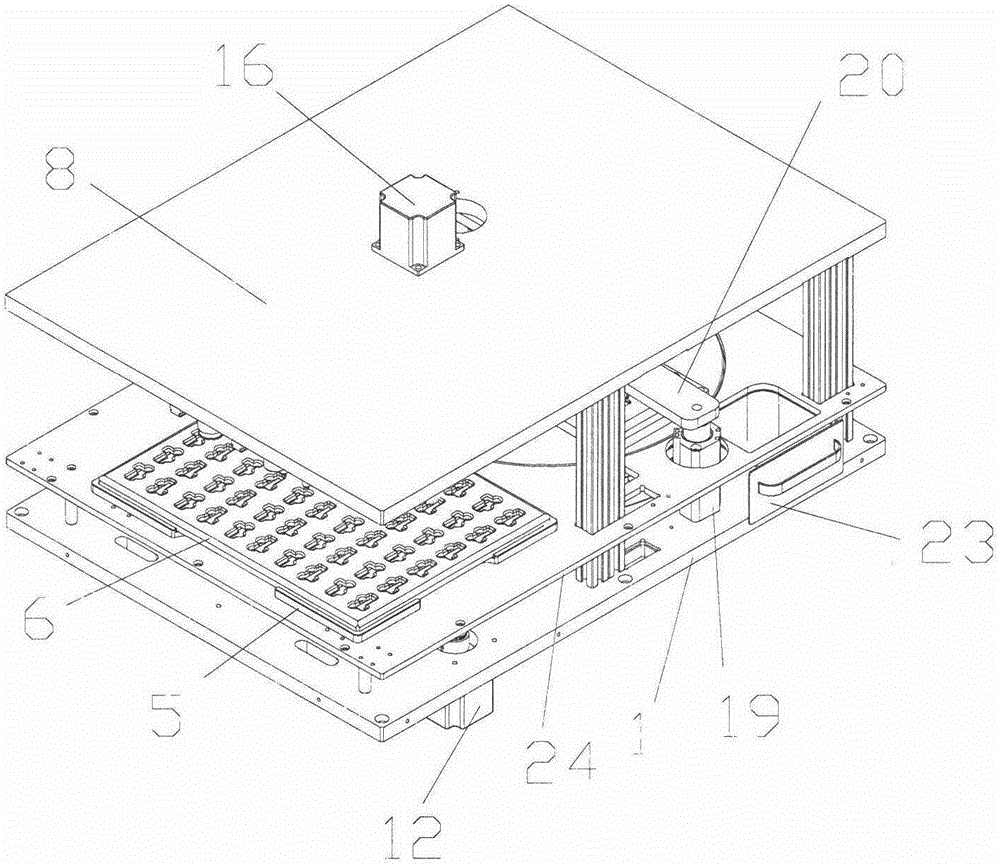

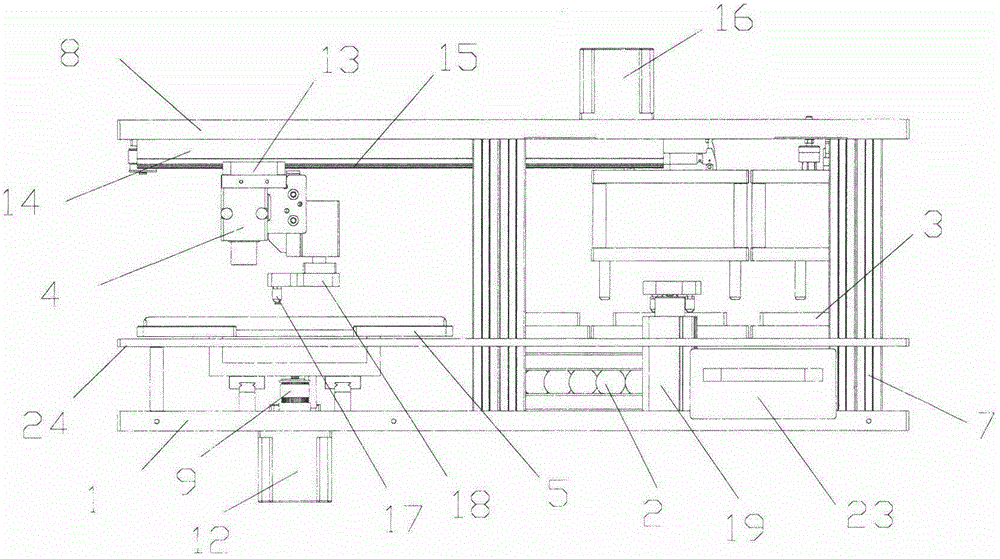

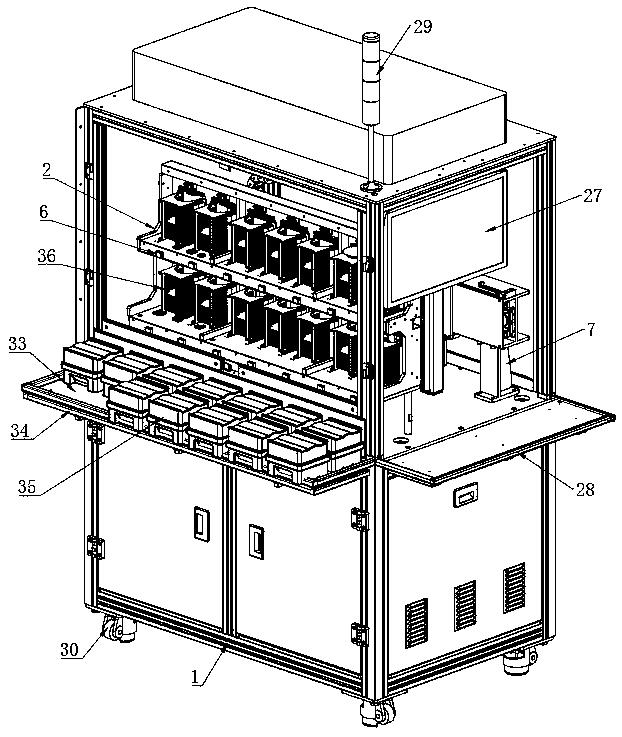

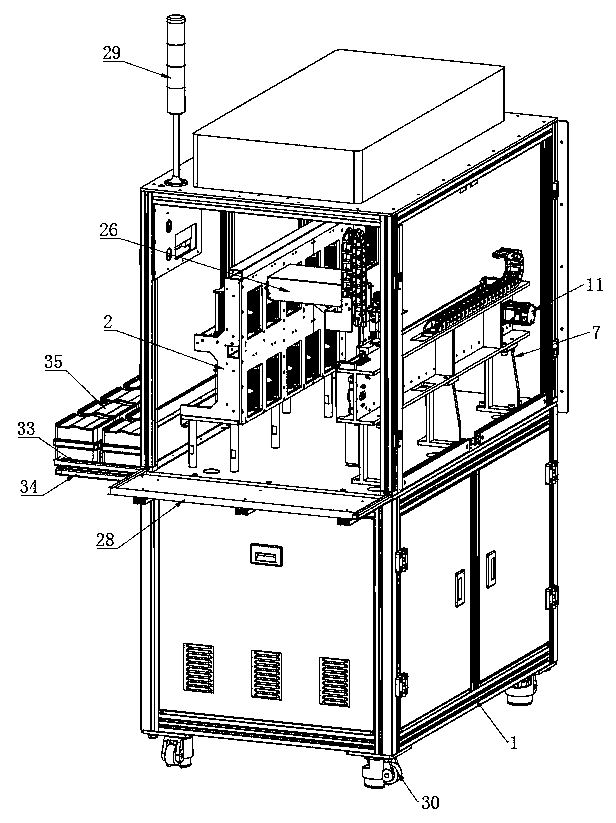

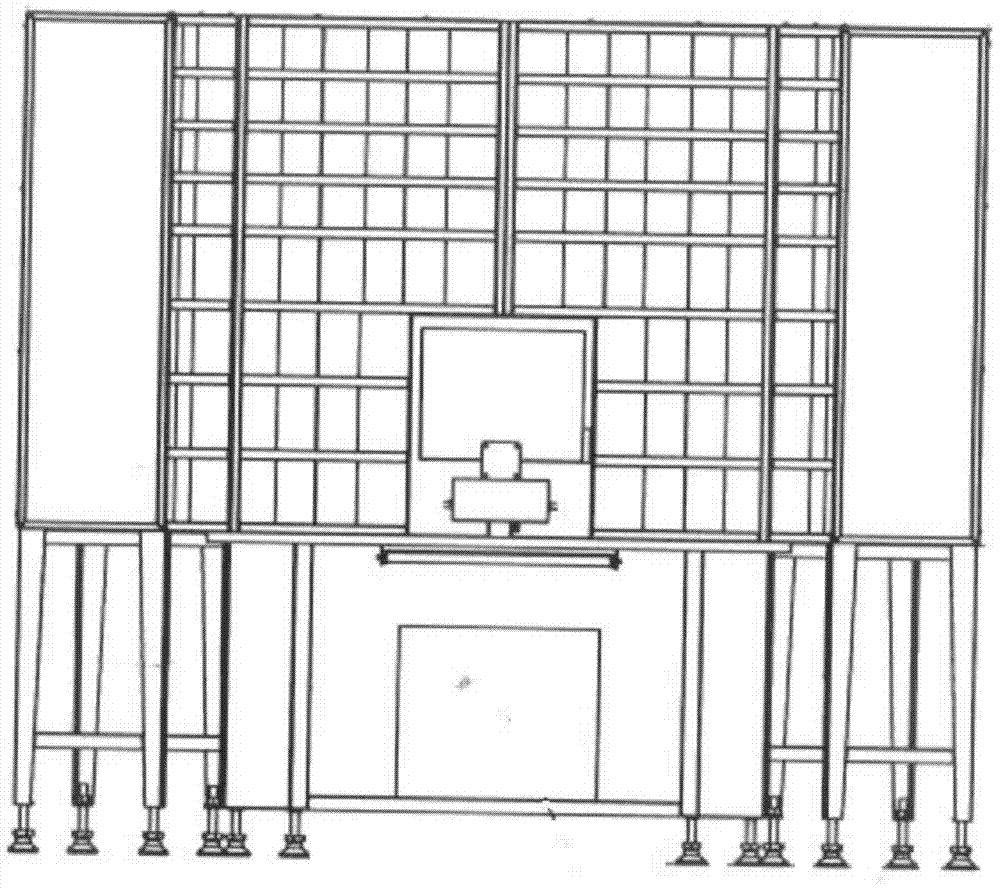

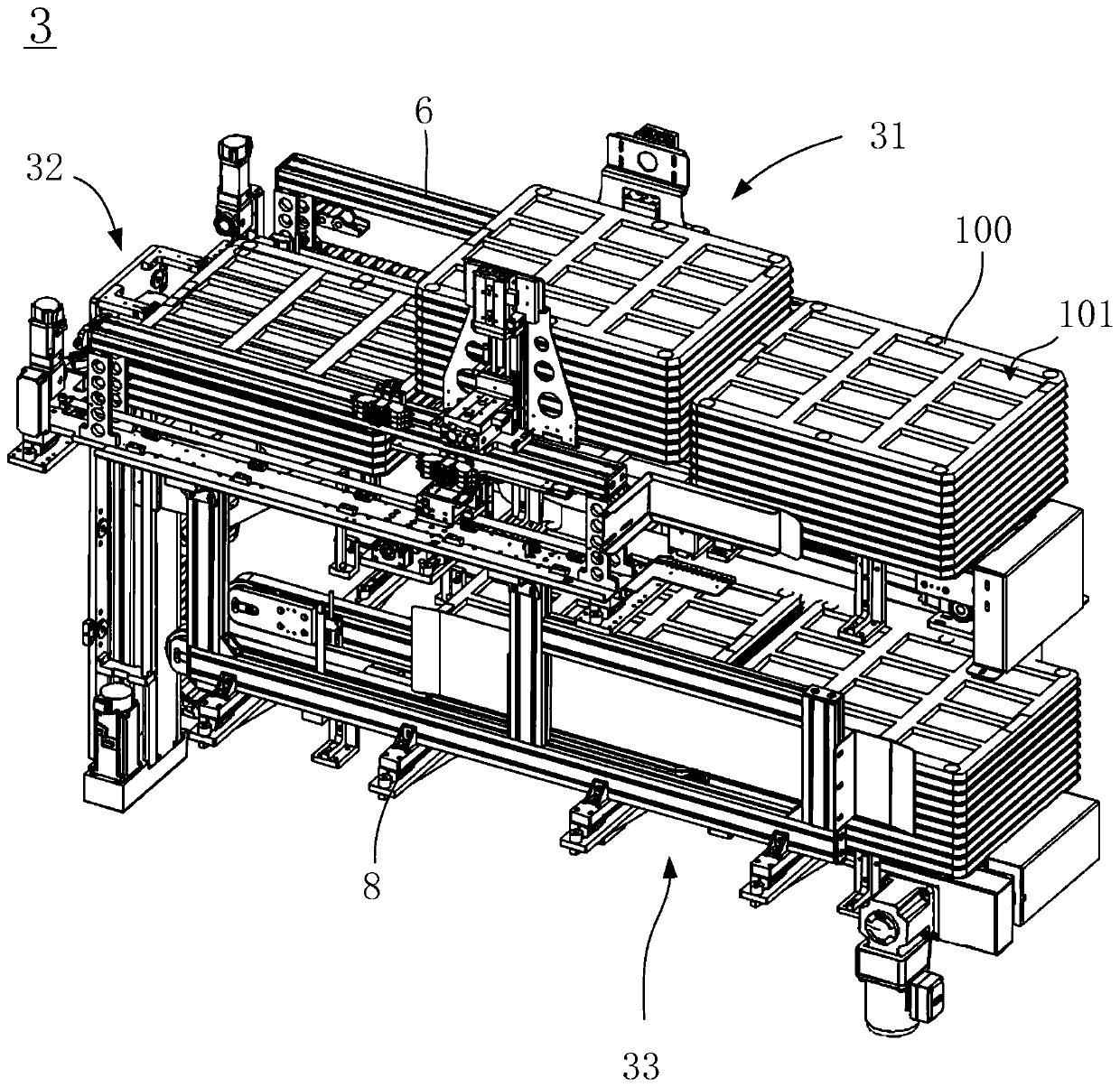

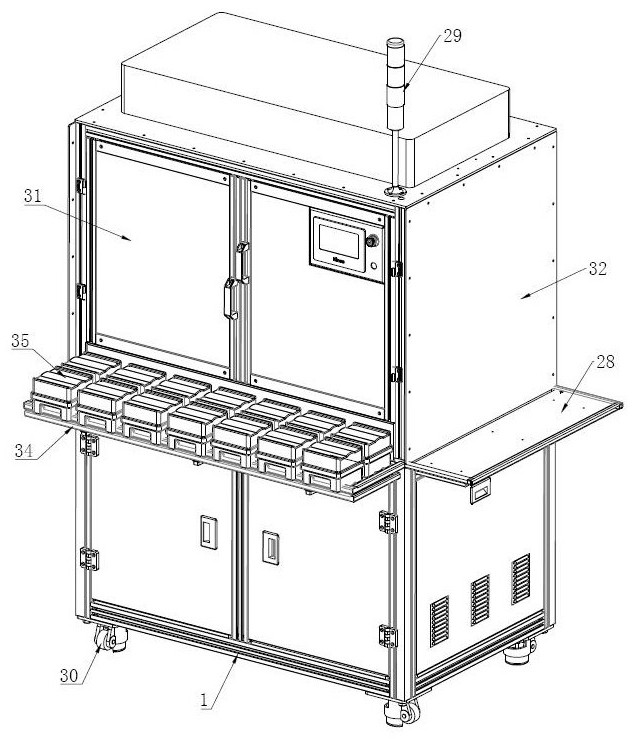

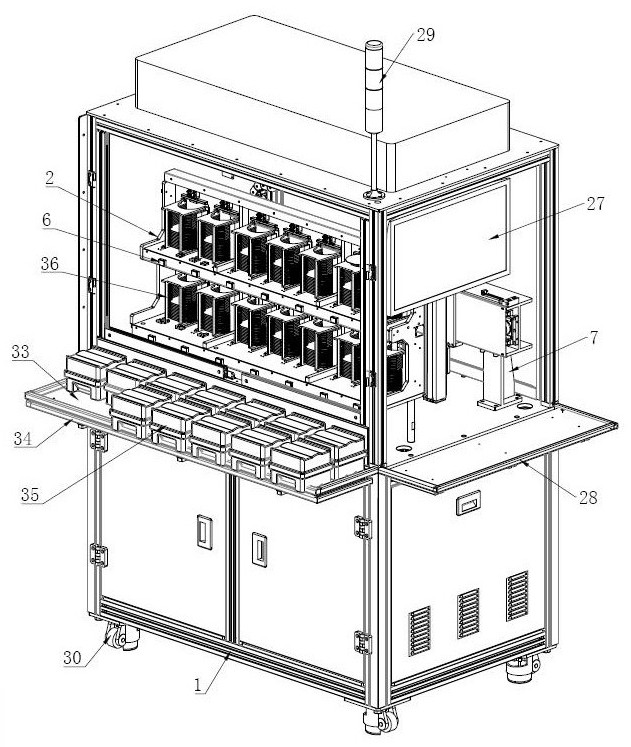

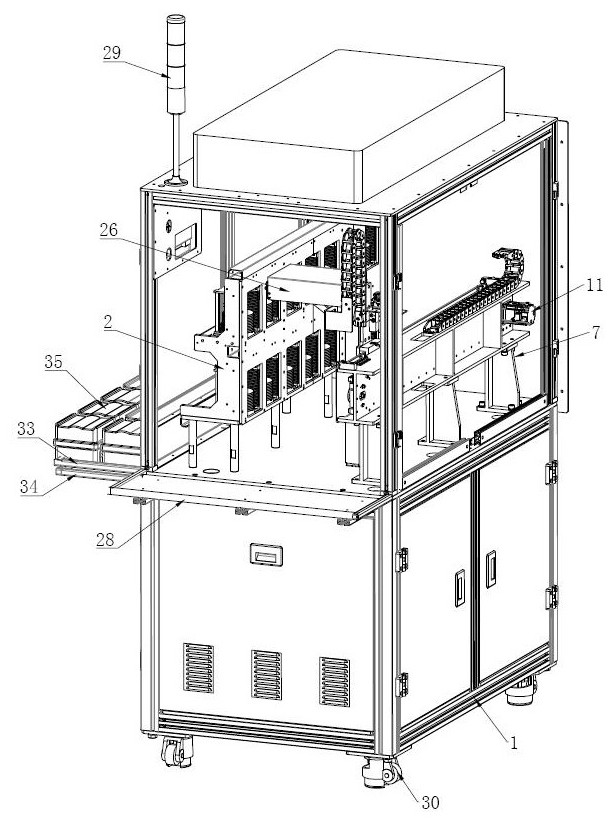

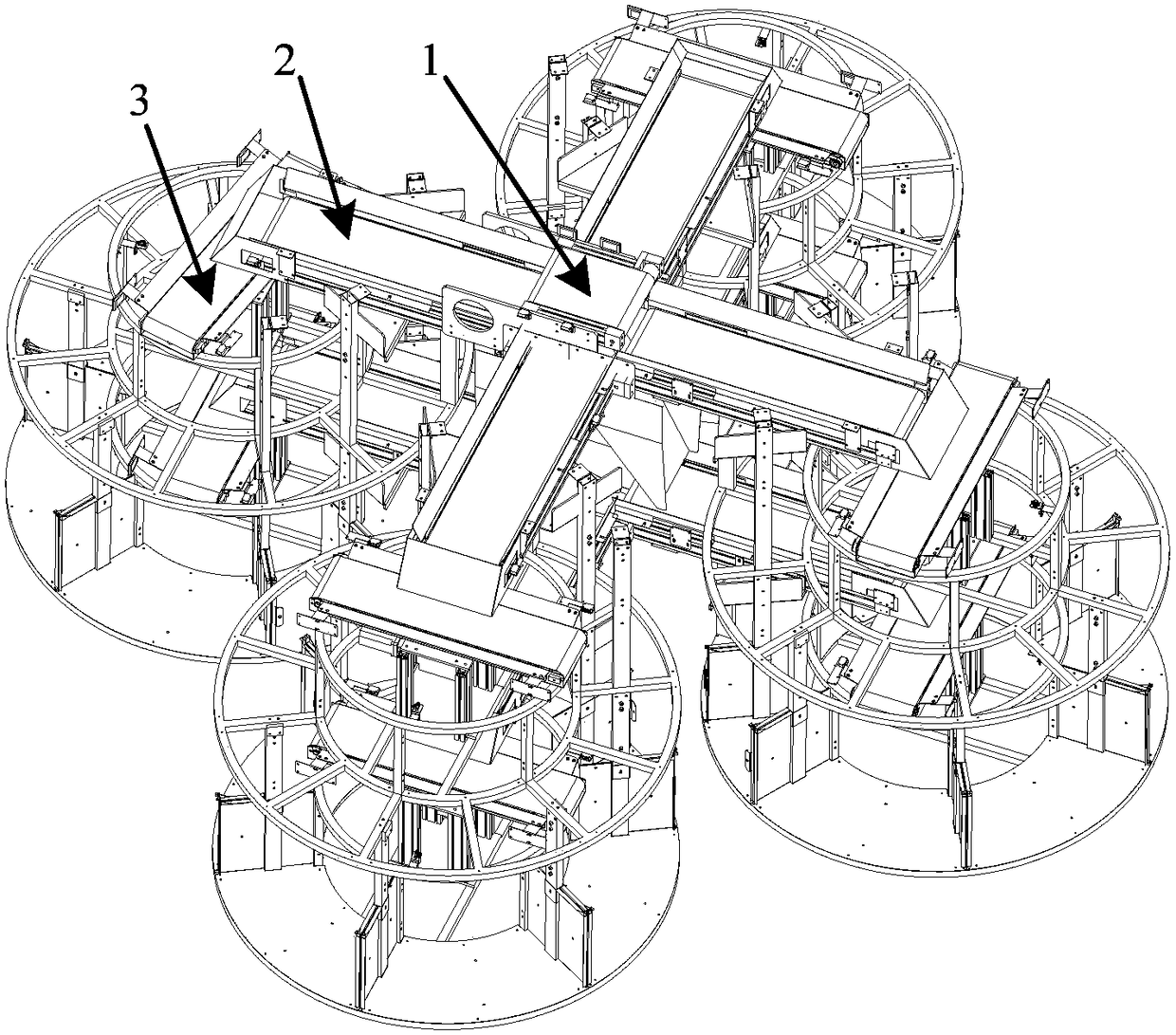

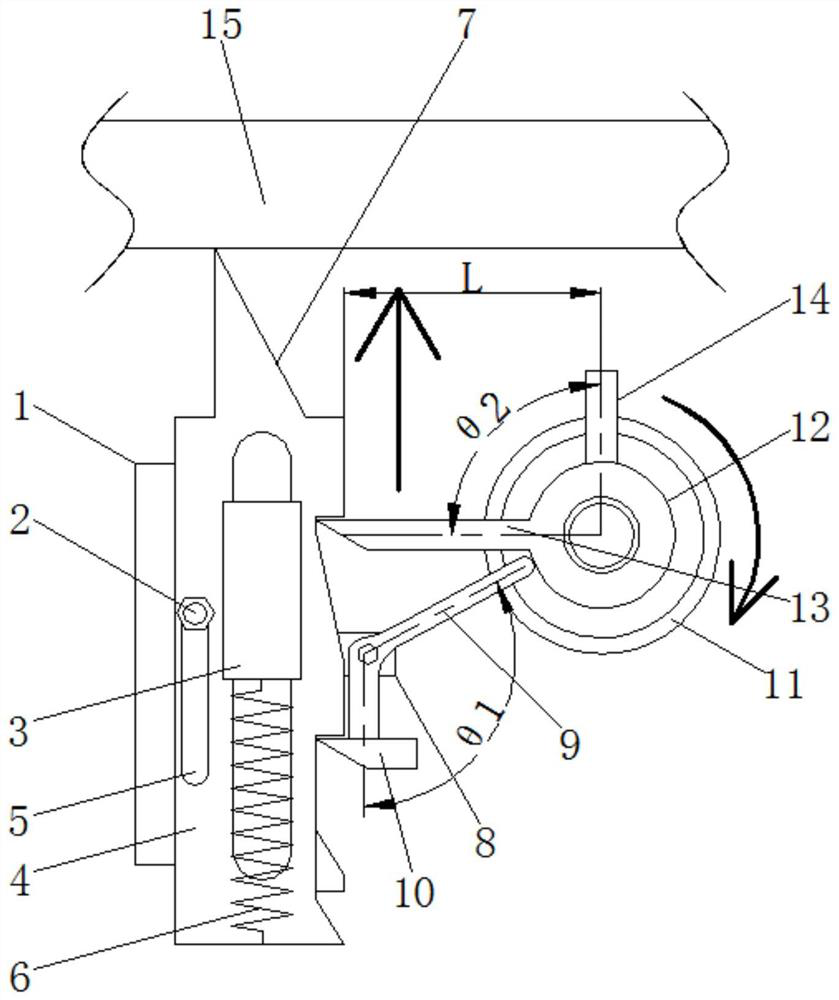

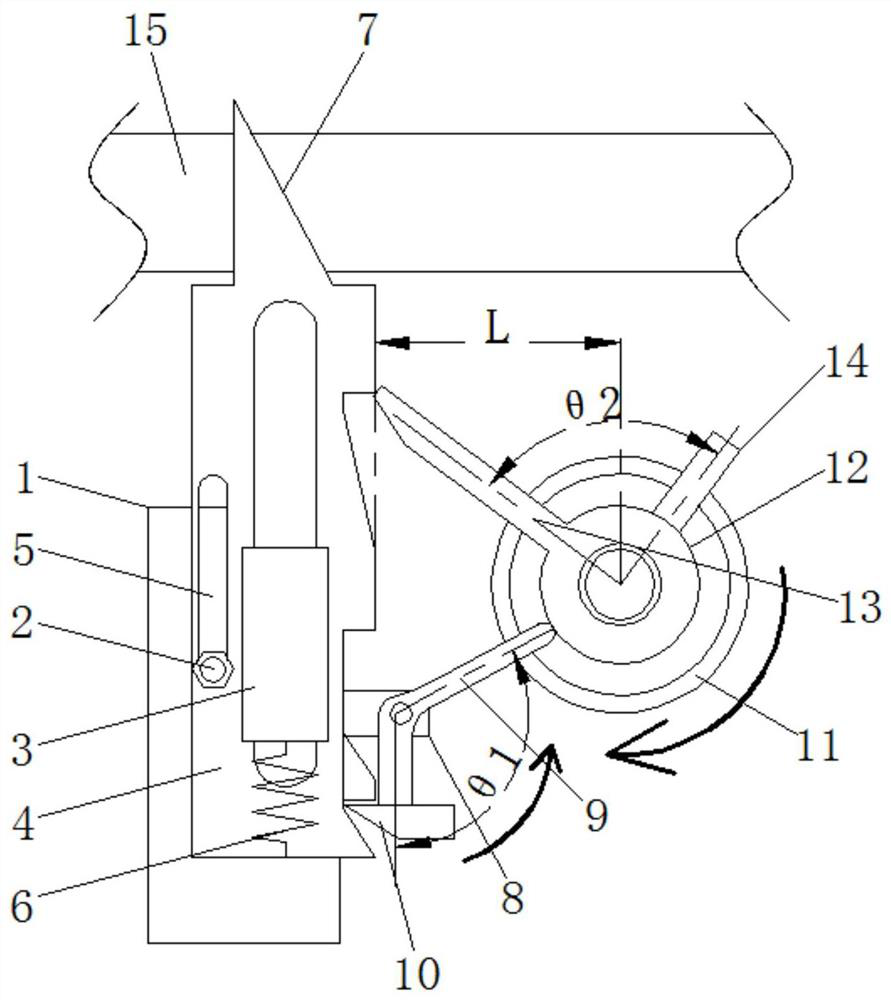

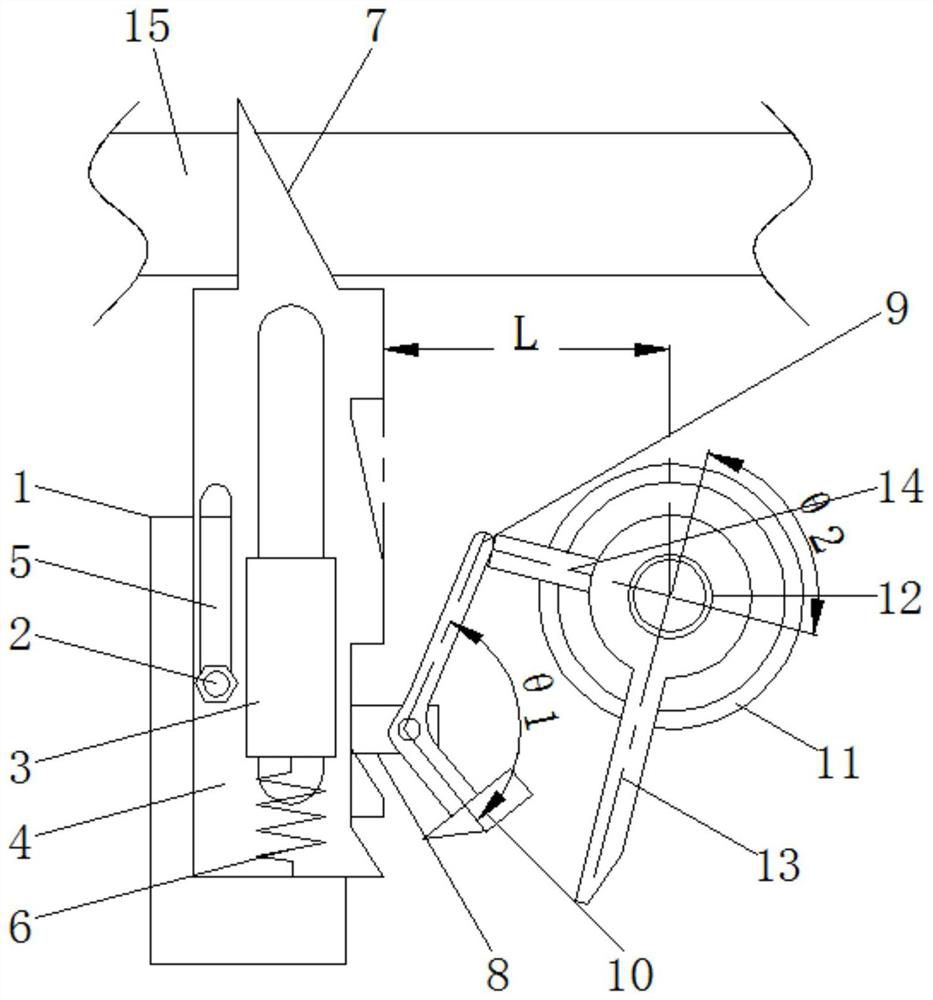

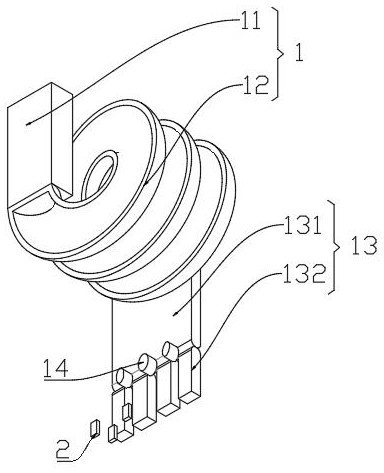

Full-automatic feeding and discharging system

InactiveCN104386290AHigh precisionAvoid sorting errorsPackagingTesting equipmentElectrical and Electronics engineering

The invention discloses a full-automatic feeding and discharging system. The full-automatic feeding and discharging system comprises a workbench, wherein rotating disks are arranged in the center of the workbench; a function testing machine and a camera are further arranged on the workbench; a reclaiming mechanism and a sorting mechanism are further arranged on the workbench; the reclaiming mechanism comprises a support tray, a horizontal moving mechanism and a vertical moving mechanism; the reclaiming mechanism, the function testing machine and the sorting mechanism are uniformly distributed on the peripheries of the rotating disks; product boxes are arranged on the rotating disks respectively. Circuit boards in a material box can be moved from the material box to the product boxes by using the reclaiming mechanism, and are moved close to corresponding detection equipment through carrying of the rotating disks. Unqualified detected circuit boards are sorted by using the sorting mechanism, and qualified circuit boards are placed back through the reclaiming mechanism. A manual operation way is replaced through automatic equipment, and the production efficiency is increased.

Owner:昆山星连达电子有限公司

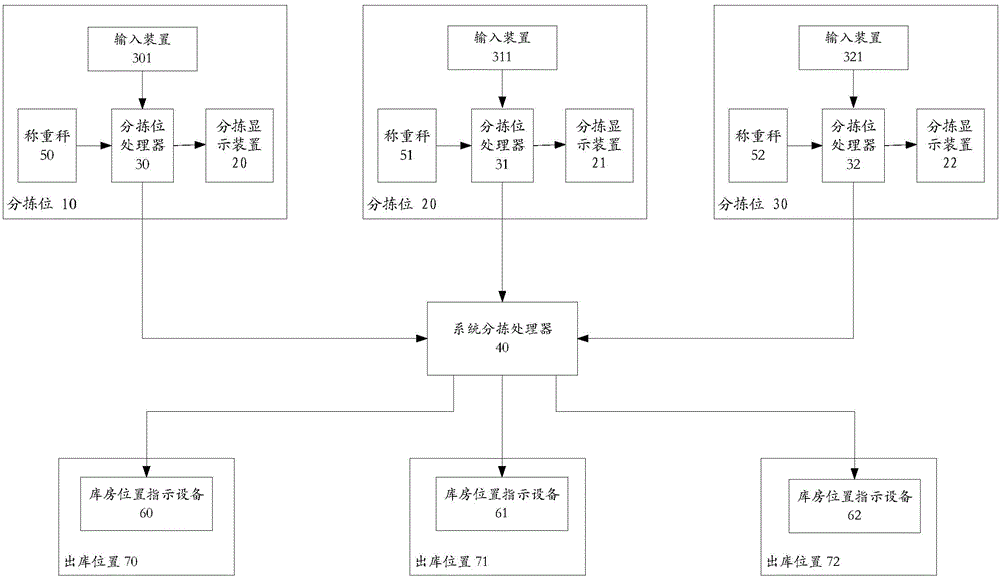

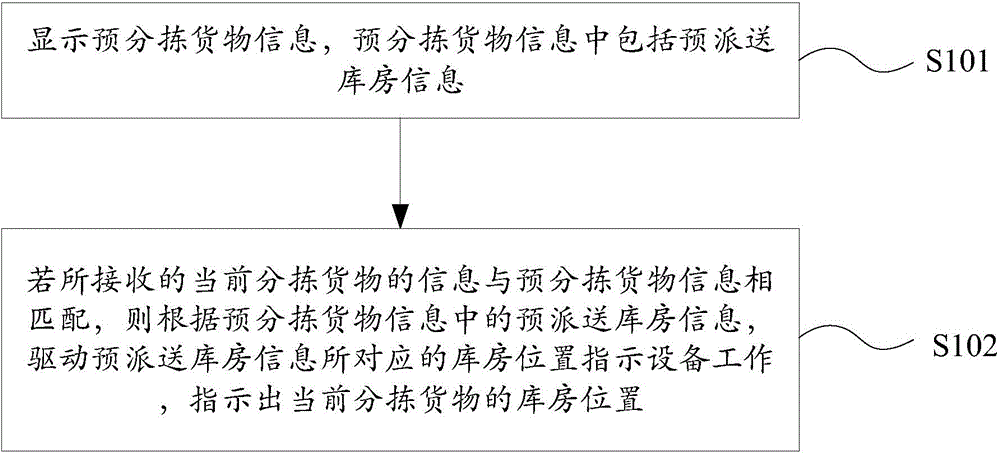

Efficient sorting method and efficient sorting system

The invention relates to an efficient sorting method which comprises the following steps: displaying pre-sorted cargo information comprising pre-delivery warehouse information; if the received current sorted cargo information is matched with the pre-sorted cargo information, driving indicating equipment of a warehouse position corresponding to the pre-delivery warehouse information to work to indicate the warehouse position of the current sorted cargo according to the pre-delivery warehouse information in the pre-sorted cargo information. The problems that the existing sorting process is complicated and has a long period are solved. In the cargo sorting process, a specific indication can be given to an operator, so that the sorting error is prevented and the sorting efficiency is improved. The sorted commodities are photoelectrically indicated, so that the stacking and arrangement process of cargo is shortened. Therefore, the sorting time is shortened, the manual taking step is simplified, the possibility of deterioration of fresh commodities, especially for products of which the quality is greatly influenced by temperature, is reduced, and the timely sorting of cargo is ensured, and thus the logistics period and the transaction validity are improved.

Owner:北京任我在线电子商务有限公司

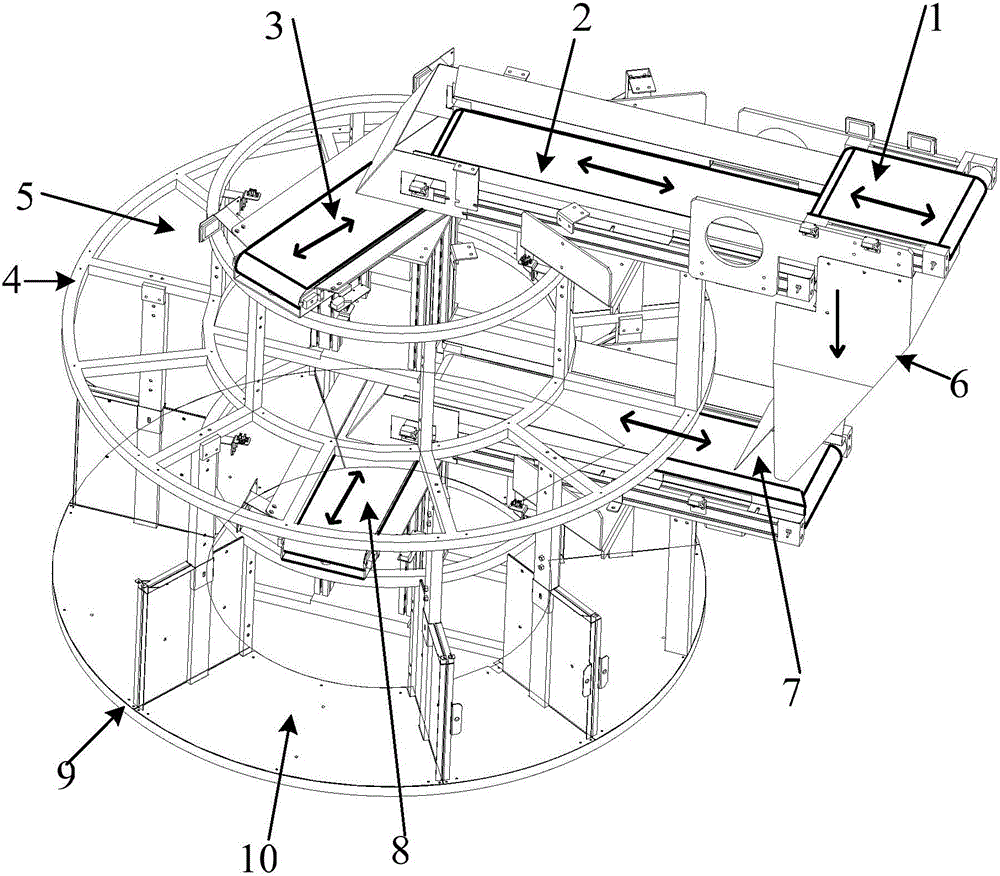

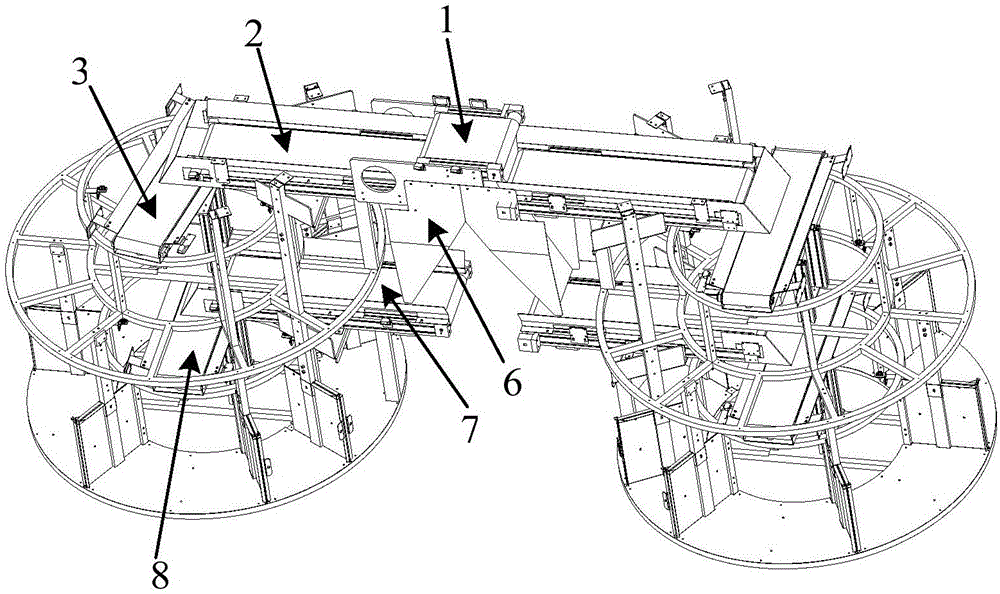

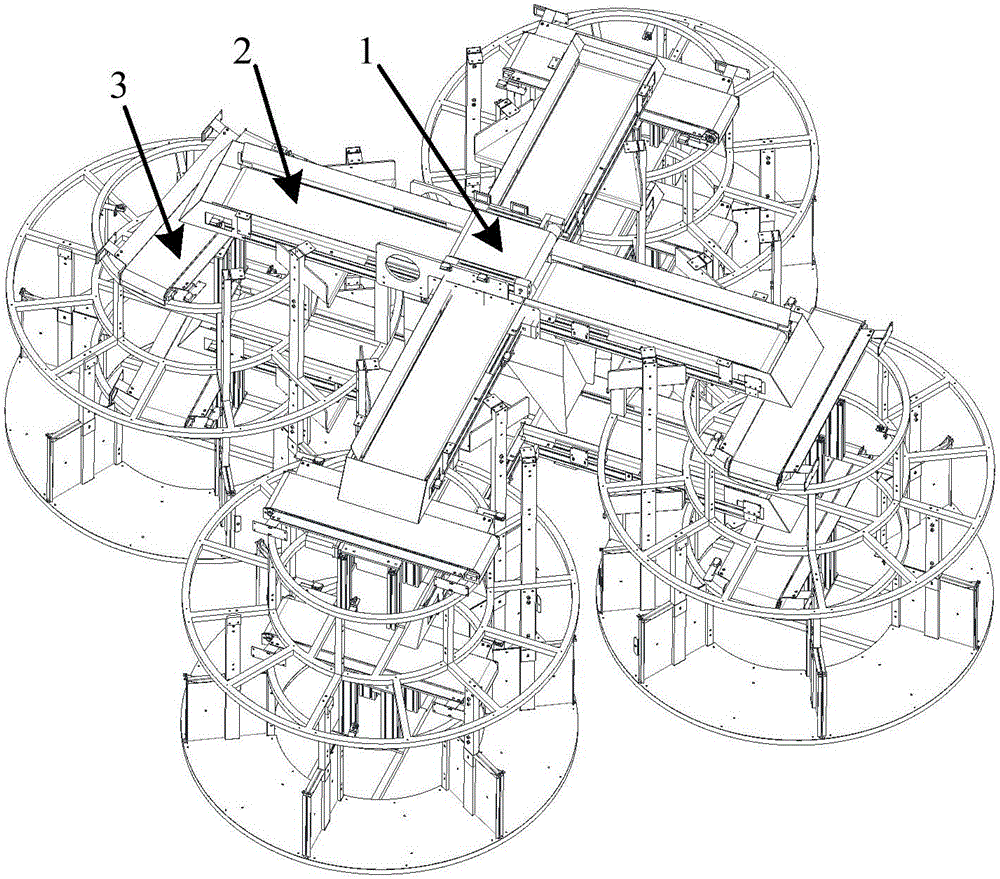

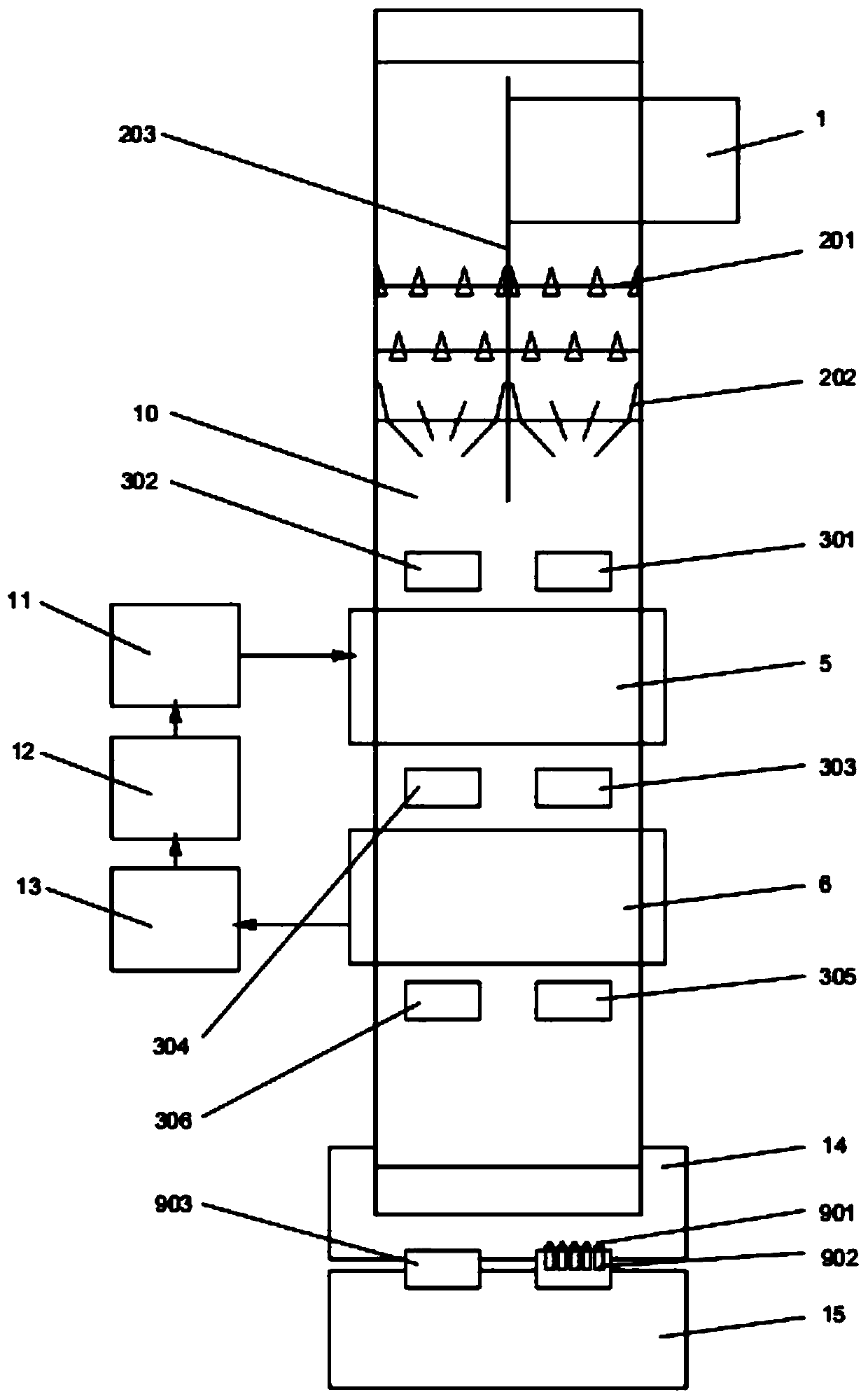

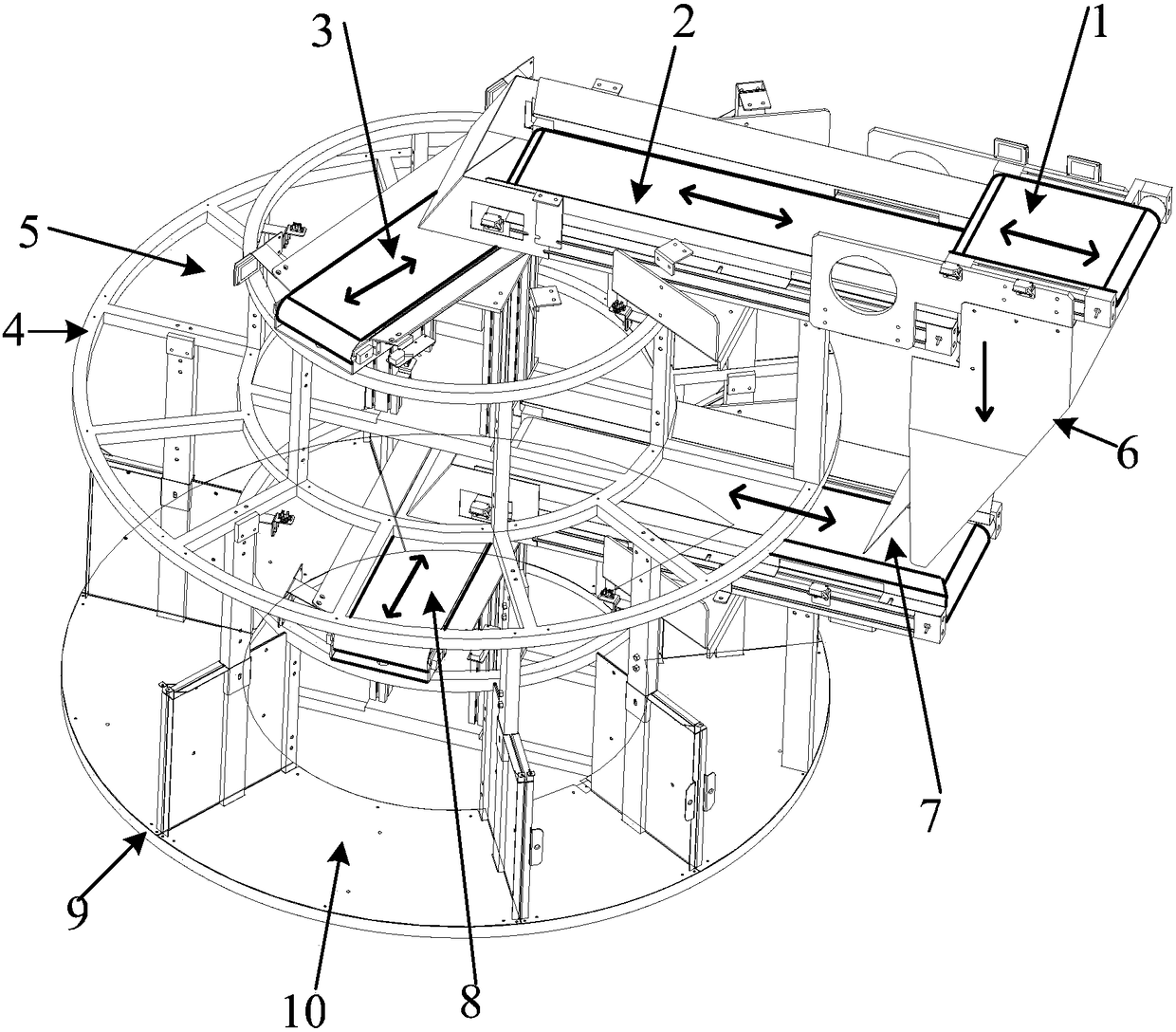

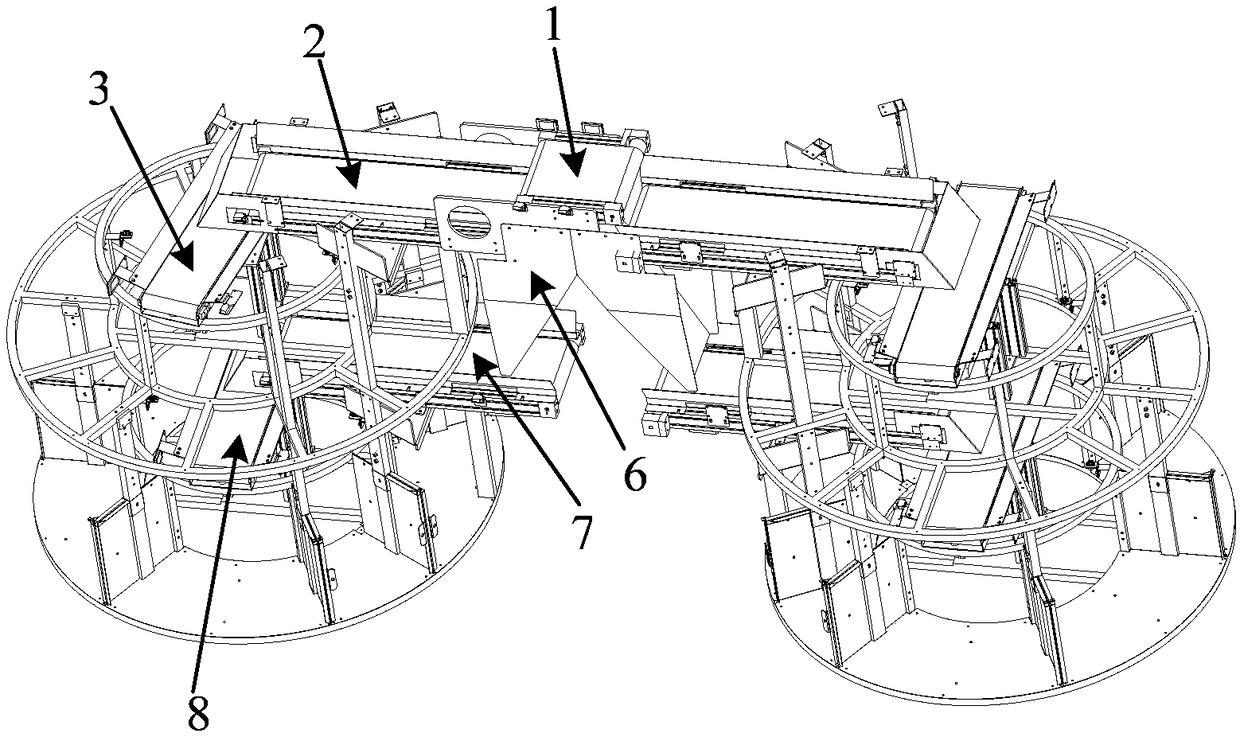

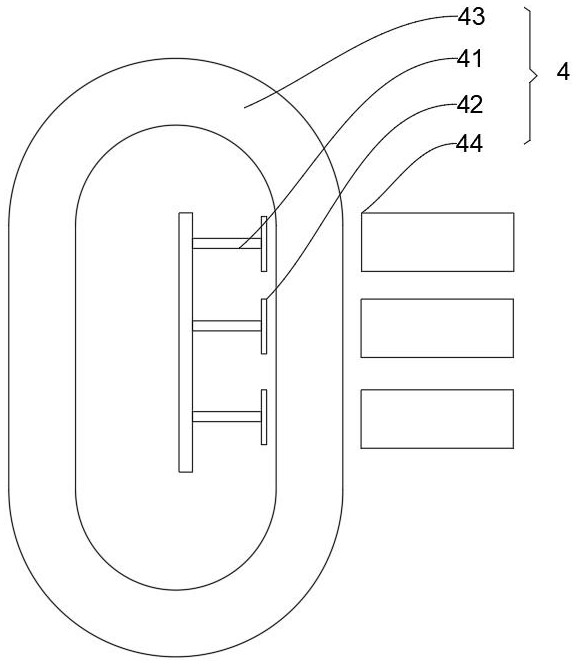

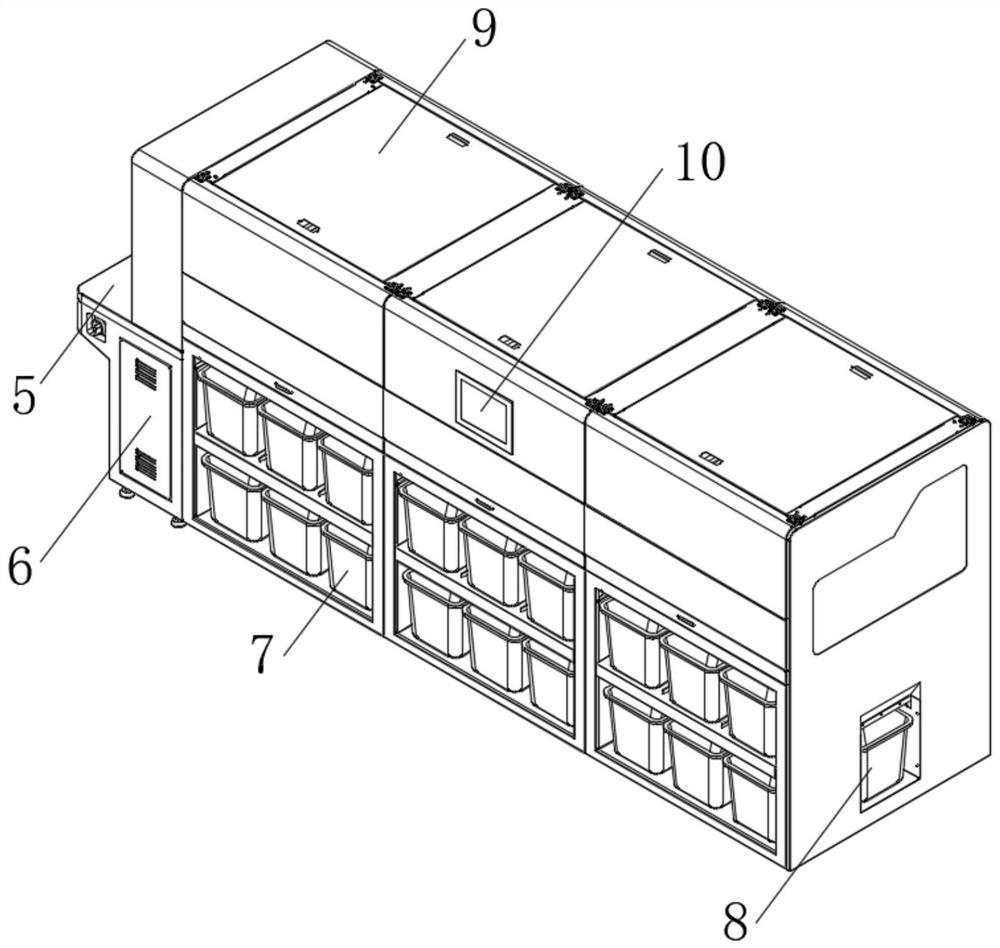

Rotating type static allocation infusion bag intelligent sorting system and method thereof

The invention discloses a rotating type static allocation infusion bag intelligent sorting system and a method. The rotating type static allocation infusion bag intelligent sorting system comprises a primary sorting conveying unit and bins. A discharging port of the primary sorting conveying unit is connected with a secondary sorting conveying unit. A discharging port of the secondary sorting conveying unit is connected with a rotating type sorting conveying unit which is located above the first layer of bins, the first layer of bins are provided with multiple bin spaces in the circumferential direction, and the rotating type sorting conveying unit can rotate in the circumferential direction to enable a discharging port of the rotating type sorting conveying unit to correspond to the needed bin space. The other discharging port of the secondary sorting conveying unit is provided with a linear type sorting conveying unit in a connected manner, a discharging port of the linear type sorting conveying unit is provided with a rotating type sorting conveying unit in a connected manner, the rotating type sorting conveying unit is located above a second layer of bins, the second layer of bins are provided with multiple bin spaces in the circumferential direction, and the rotating type sorting conveying unit can rotate in the circumferential direction to enable a discharging port of the rotating type sorting conveying unit to correspond to the needed bin place. The rotating type static allocation infusion bag intelligent sorting device is high in sorting speed, high in accuracy and capable of achieving automatic sorting and feeding of infusion bags.

Owner:SUZHOU IRON TECH

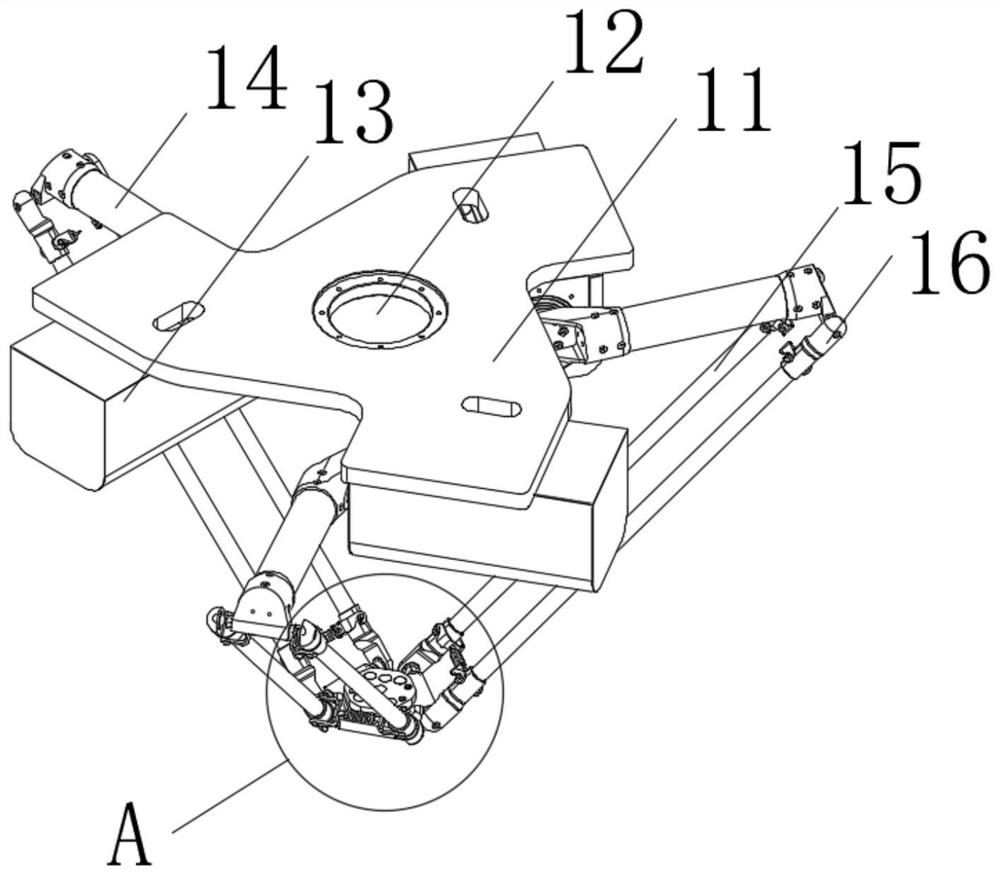

Automatic wafer sorting machine

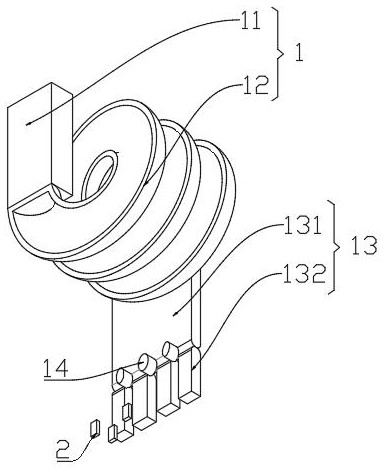

ActiveCN111540703AAccurate placementImprove adsorption capacitySemiconductor/solid-state device manufacturingSortingWaferMachine

The invention belongs to the technical field of wafer production equipment and provides an automatic wafer sorting machine which comprises a rack, a material frame, a wafer taking and placing device and a controller. The material frame is divided into a to-be-sorted area and a sorting completion area, and basket positioning mechanisms corresponding to basket placement positions are arranged on theto-be-sorted area and the sorting completion area respectively; the wafer taking and placing device comprises a mounting frame, an installation plate driven by a first driving device is installed onthe installation frame in the X-axis direction in a sliding mode, an installation base driven by a second driving device is arranged on the installation plate, the installation base slides in the Z-axis direction, a supporting plate driven by a third driving device is installed on the installation base in the Y-axis direction in a sliding mode, and a wafer supporting part is arranged at the tail end of the supporting plate. The controller is respectively connected with the basket positioning mechanisms, the first driving device, the second driving device and the third driving device. Comparedwith traditional manual wafer sorting, the sorting efficiency is greatly improved, sorting errors are effectively avoided, the wafers cannot be scratched, and the substrate numbers of the sorted wafers can be sorted and placed.

Owner:SHANDONG NOVOSHINE OPTOELECTRONICS CO LTD

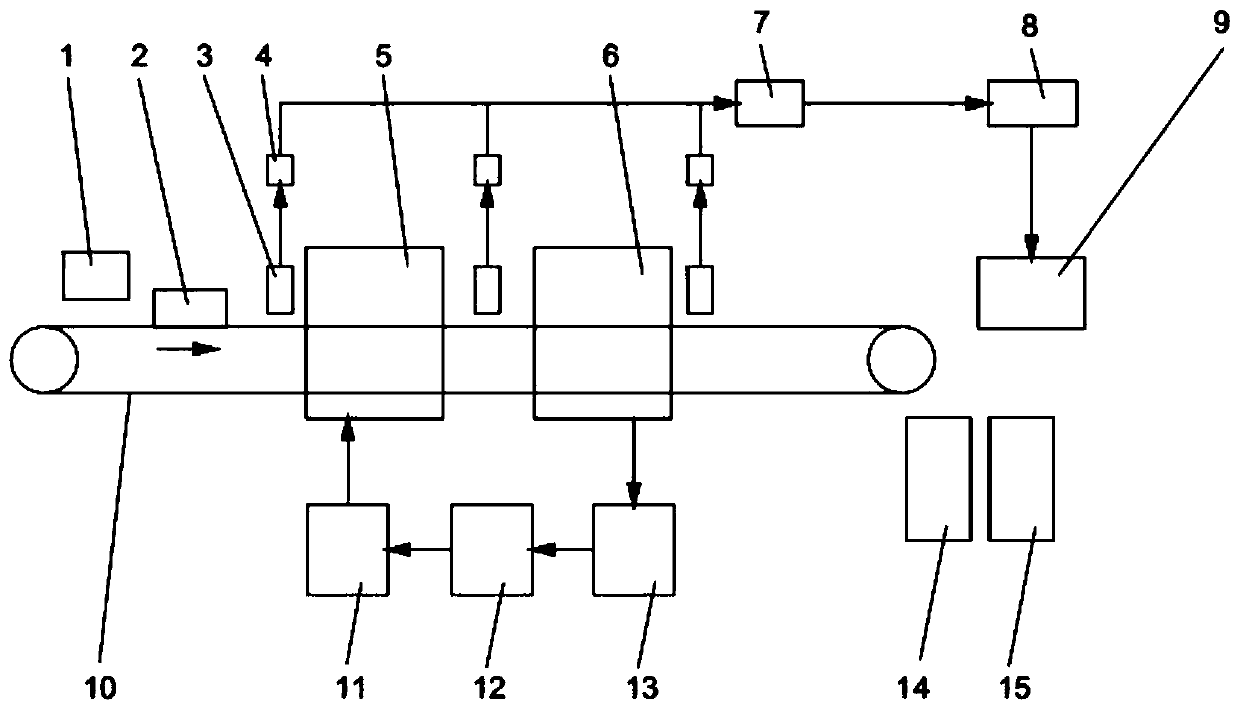

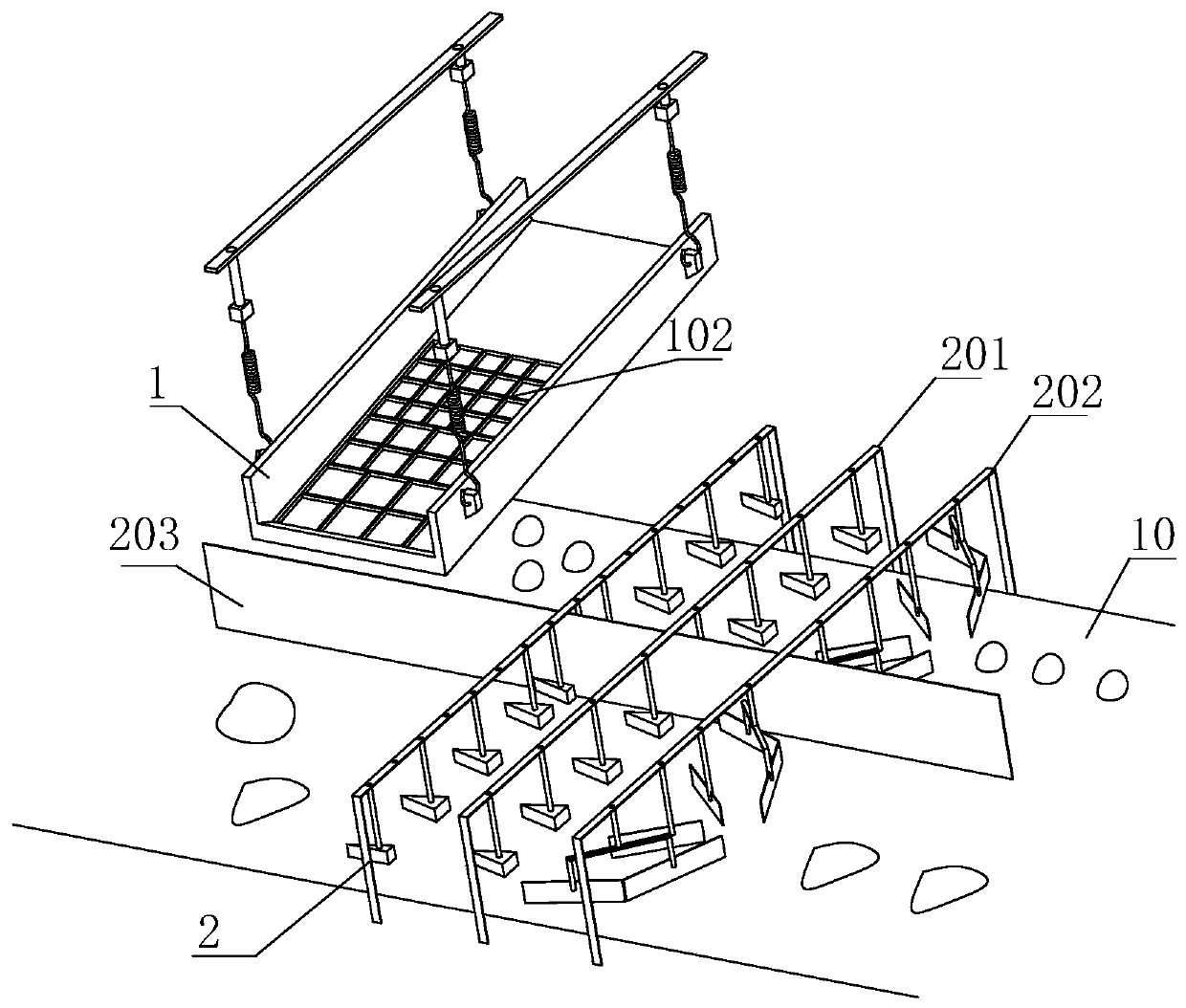

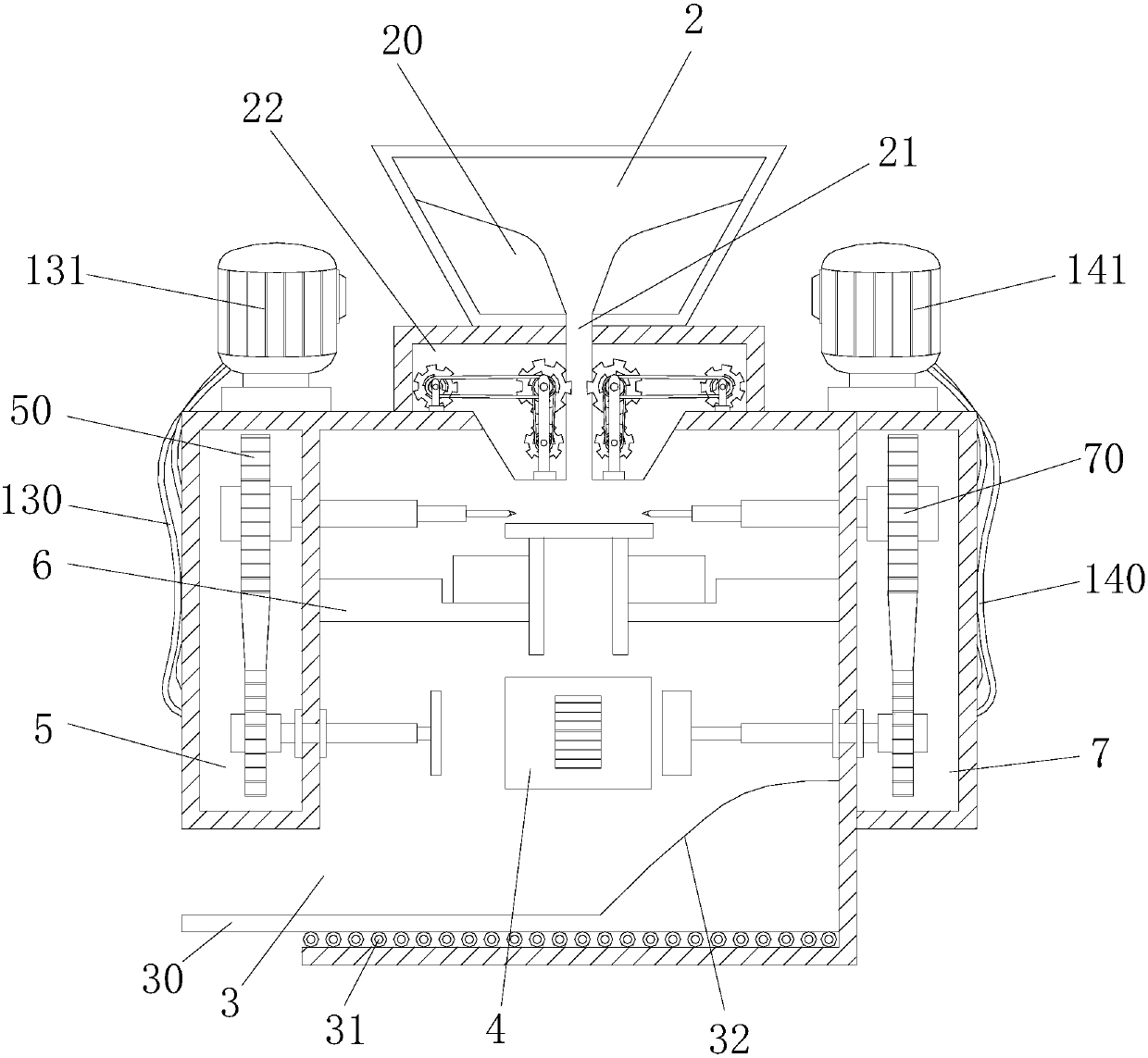

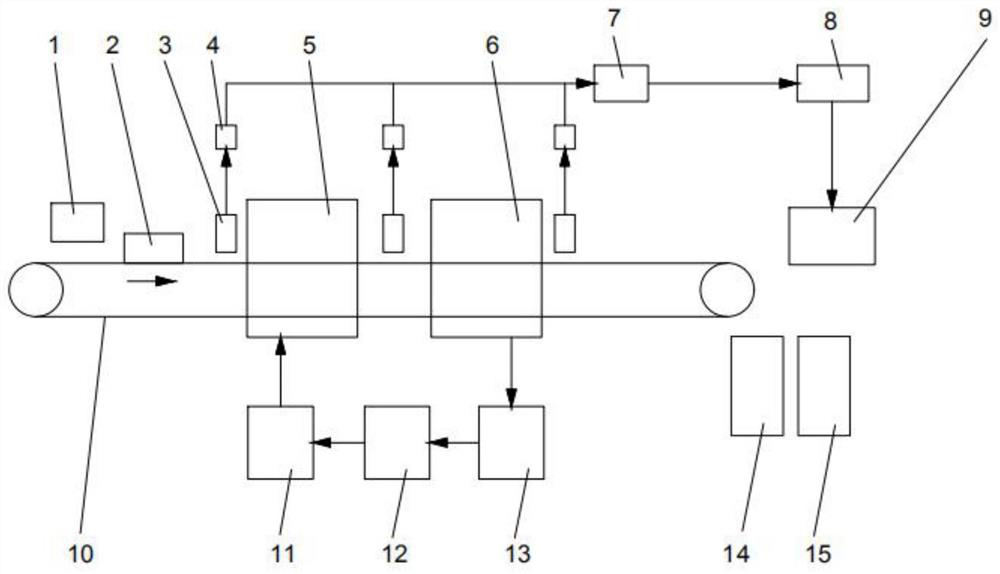

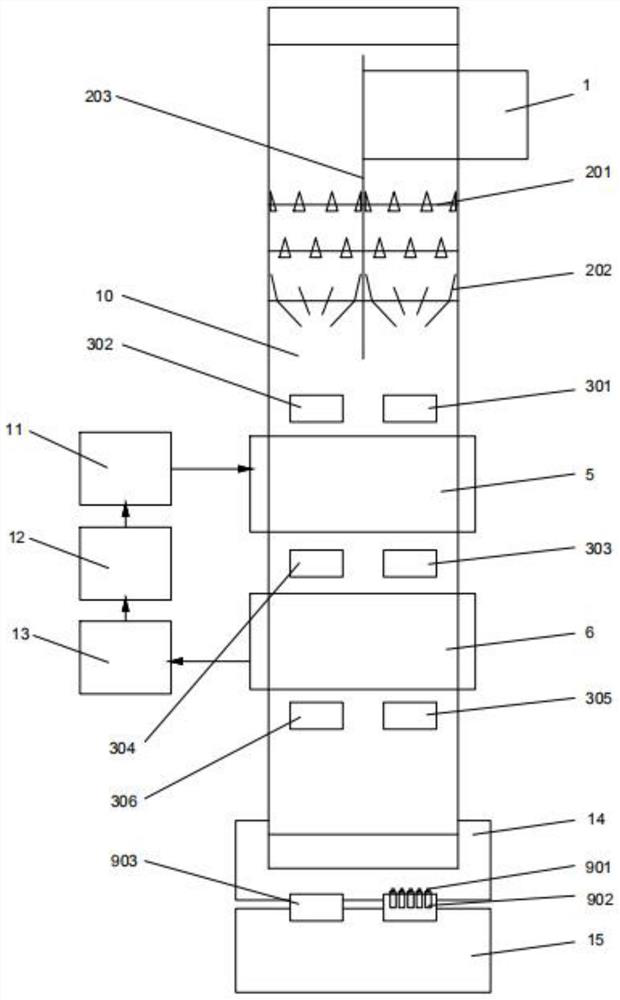

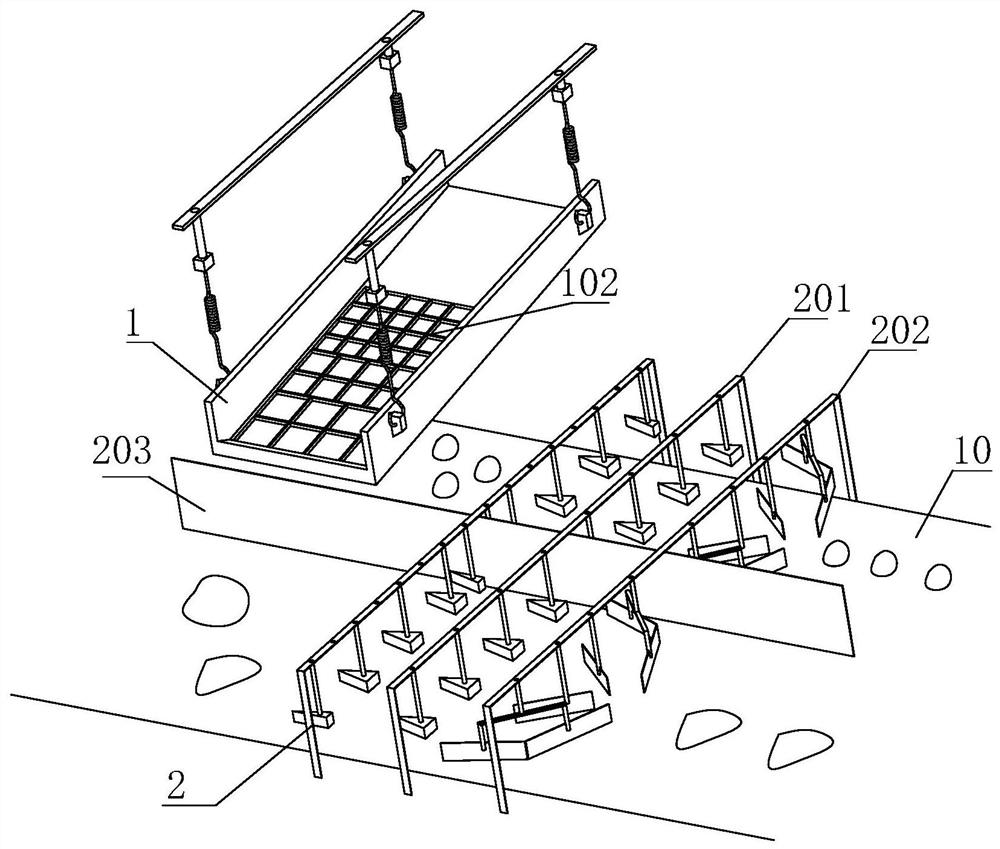

Automatic coal and gangue separation system and method based on temperature changes

The invention relates to the field of automatic separation of coal and gangue, in particular to an automatic coal and gangue separation system and method based on temperature changes. The automatic coal and gangue separation system based on temperature changes comprises a conveying belt, a collection hoper, a feeding device, a queuing device, a detection device, a gas treatment device and a motionexecution device. The feeding device comprises a small suspension-type vibrating screen. The queuing device comprises a lining device, a gathering support and an isolation plate. The detection devicecomprises a thermal infrared temperature sensor, a data acquisition card and a computer. The gas treatment device comprises a gas inflation box, a gas desorption device, a gas collection box, a gas filtering and purification box and a gas pressurizer. According to the automatic coal and gangue separation system and method based on temperature changes, on the basis of the principle that the temperature of coal is increased after the coal absorbs gas and is decreased after the coal desorbs the gas and the temperature of gangue is not changed due to the fact that the gangue does not react with gas, the coal is separated from the gangue, the gangue with the temperature unchanged is separated out and is removed through the motion execution device; and the automatic coal and gangue separation system and method based on temperature changes are high in separation efficiency, capable of separating various types of coal and high in adaptability, and water is not needed.

Owner:ANHUI UNIV OF SCI & TECH

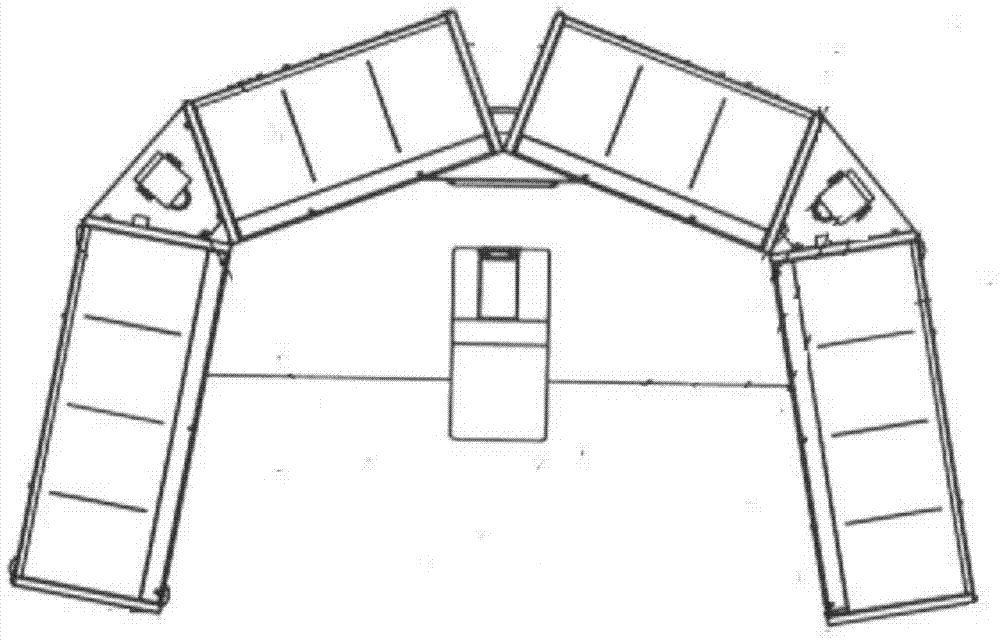

Semi-automatic registered letter sorting method with intelligent reminding and detecting functions and system

The invention relates to a semi-automatic registered letter sorting method with intelligent reminding and detecting functions. The semi-automatic registered letter sorting method is characterized by comprising the following steps: an operator scans a mail barcode, an application program of a scanning terminal finds a logic grid information corresponding to the barcode in a database of an application server according to the barcode, translates the logic grid information into physical grid information after finding the information, and then reminds the operator of placing the mail into one physical grid in a manner of image and / or voice; an entrance of each physical grid is provided with a photoelectric detection device, after the operator scans the mail, the photoelectric detection device corresponding to the physical grid detects the passing of the mail, and then next mail can be scanned. The semi-automatic registered letter sorting method has the advantages that the skill requirement of a registered-letter sorting delivery person is lowered, the posting cost is reduced, the sorting efficiency is improved and the probability of letter delivery errors is greatly reduced.

Owner:SHANGHAI RES INST OF CHINA POST GROUP

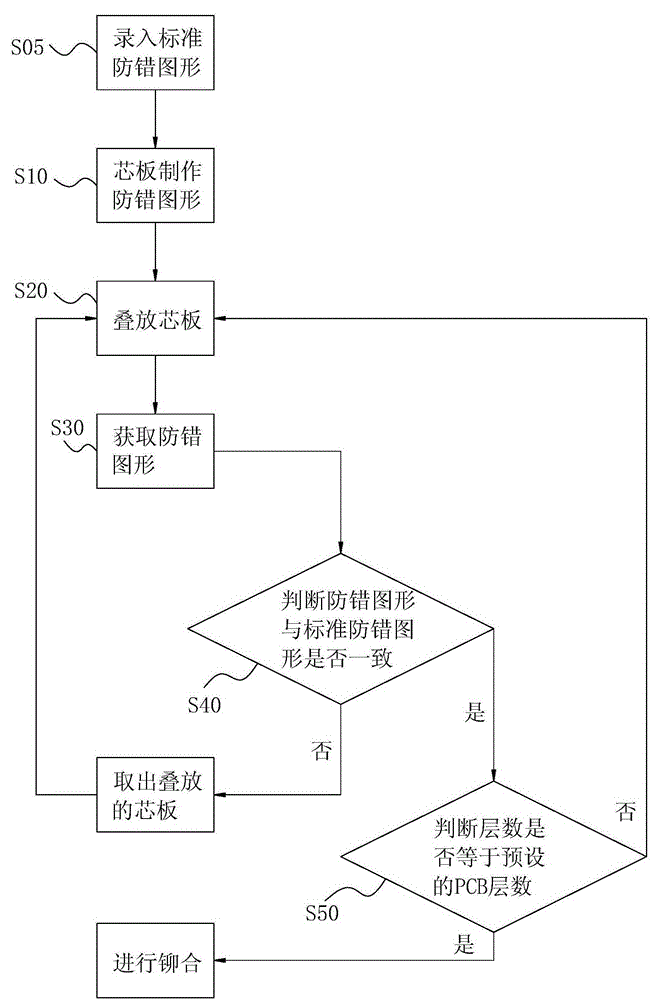

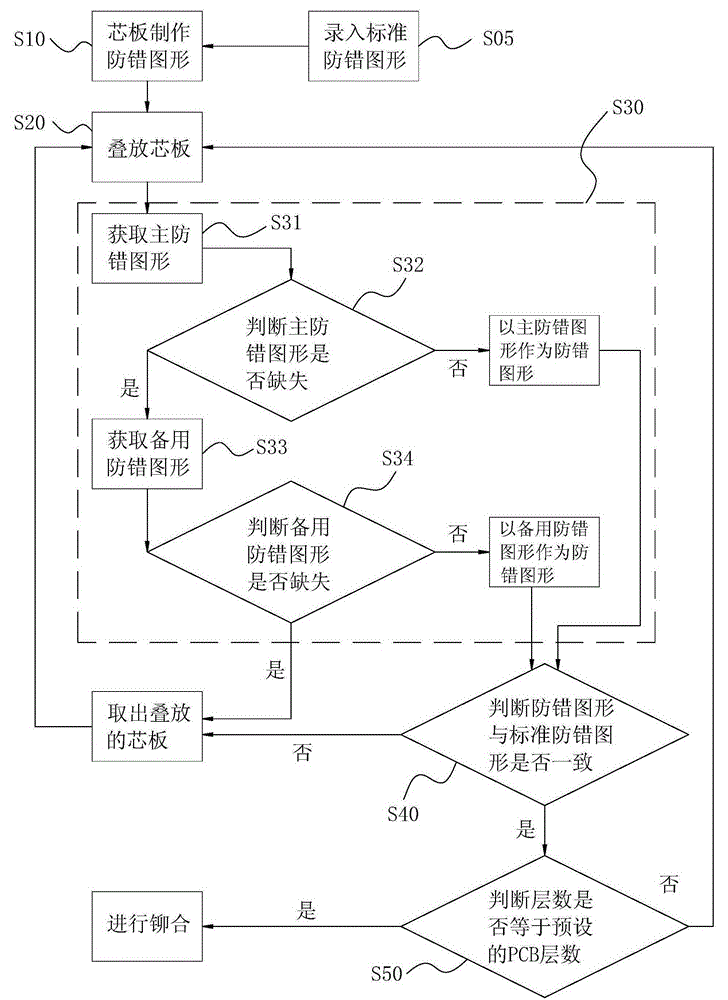

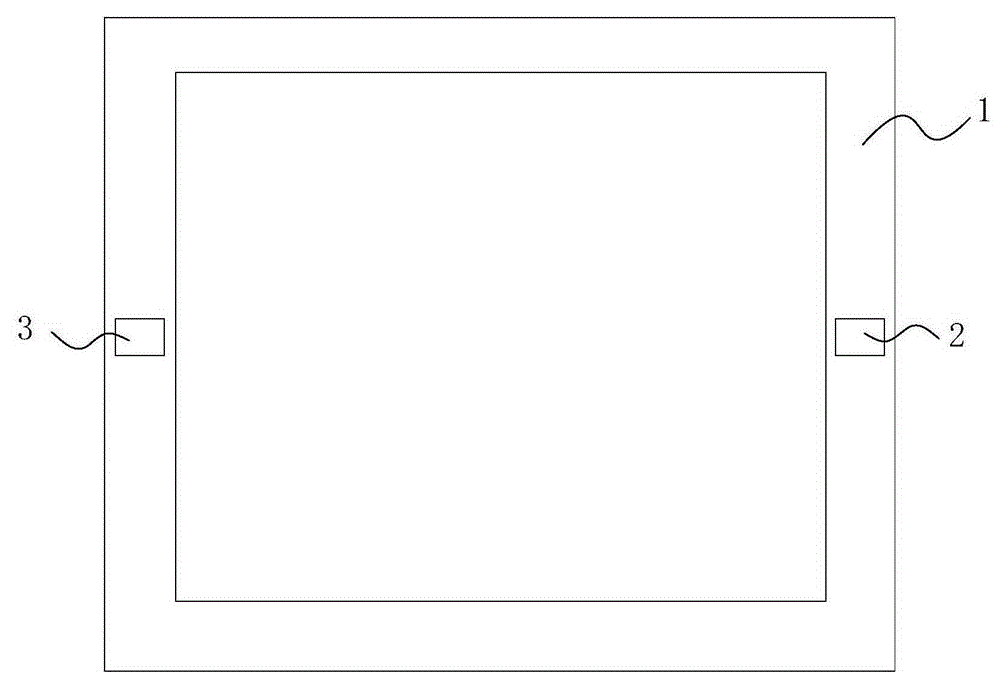

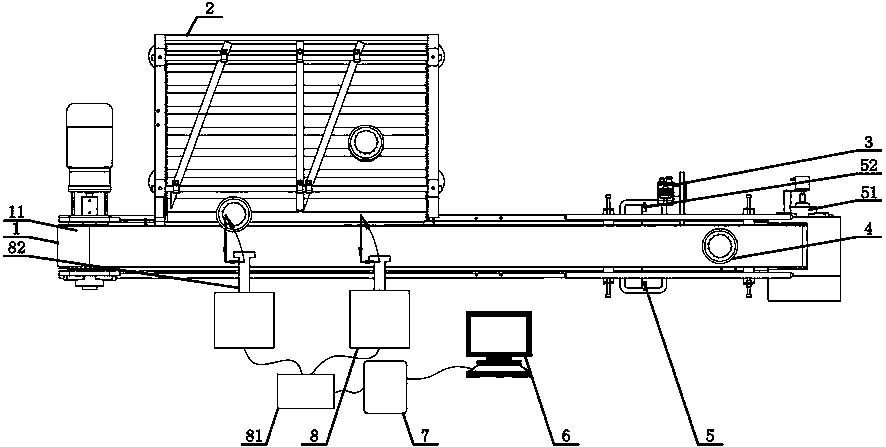

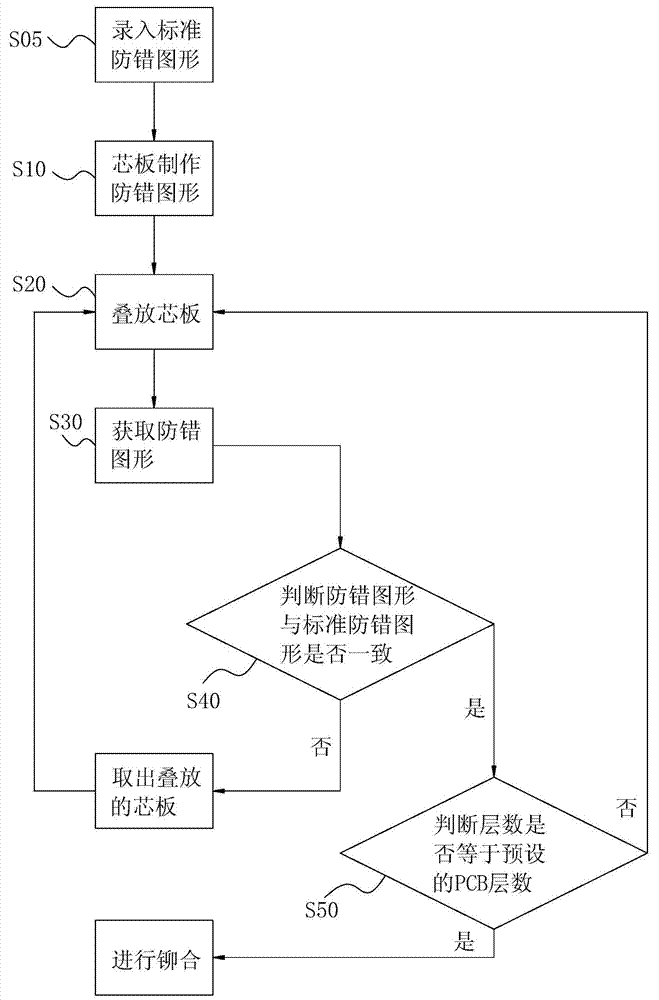

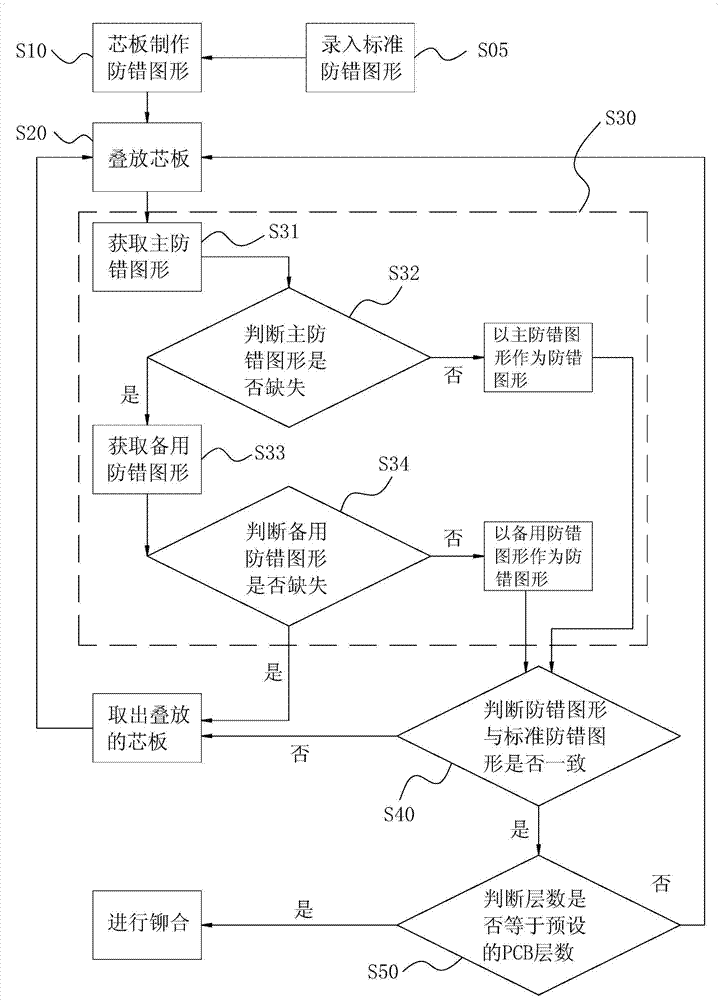

Sorting mistake-proofing method and device for multiple layers of printed circuit board (PCB) lamination

ActiveCN105228377AAvoid scrappingAvoid wastingMultilayer circuit manufactureControl systemEngineering

The invention discloses a sorting mistake-proofing method for multiple layers of printed circuit board (PCB) lamination. The method comprises the following steps: fabricating different mistake-proofing patterns on different levels of core plates; stacking one core plate; obtaining the mistake-proofing pattern on the stacked core plate; judging whether the obtained mistake-proofing pattern is consistent with the corresponding level of standard mistake-proofing pattern in a control system or not, if so, taking out the stacked core plate, and restacking another core plate; if so, judging whether the number of layers of the core plates is equal to the number of layers of PCBs designed in advance or not, if not, stacking the next core plate; and if so, carrying out riveting. The invention further discloses a sorting mistake-proofing device for multiple layers of printed circuit board (PCB) lamination. The correctness of the mistake-proofing pattern on each core plate is judged in the plate stacking process to ensure that various core plates are stacked according to the specified order; according to the method, a riveting operation can be carried out only when the stacking orders of the core plates are all correct; and the core plate with a wrong stacking order is prevented from being riveted and fixed, so that scrapping and waste of the core plate are avoided.

Owner:DONGGUAN SHENGYI ELECTRONICS

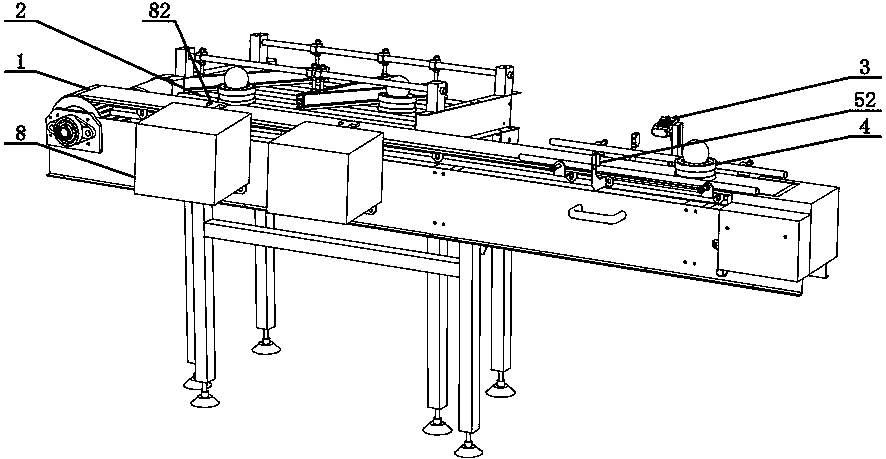

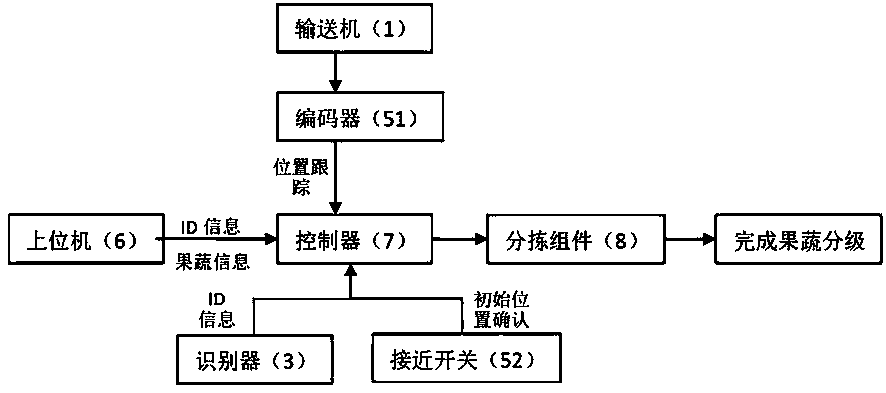

Free conveying type fruit and vegetable sorting device and sorting method thereof

PendingCN109772757AGuaranteed accuracyAffect qualitySortingAgricultural engineeringFruits and vegetables

The invention discloses a free conveying type fruit and vegetable sorting device and a sorting method thereof. The free conveying type fruit and vegetable sorting device comprises a conveyor and a tray. The tray is located on the conveyor. The free conveying type fruit and vegetable sorting device further comprises a recognizer, a distance measuring assembly, a controller, an upper computer, a sorting assembly and a discharging roller way. The recognizer and the distance measuring assembly are arranged on the upstream of the conveyor. The tray is provided with an identification tag. The sorting assembly and the discharging roller way are arranged on the downstream of the conveyor. The sorting method comprises the following steps that firstly, the conveyor conveys the tray; secondly, the upper computer inputs fruit and vegetable ranked data to the controller; thirdly, an initial position of the tray is acquired through a proximity switch, and the recognizer sends the identification information to the controller; fourthly, the controller matches the fruit and vegetable ranked data with the identification information, and the sorting position of the tray is determined; fifthly, an encoder inputs conveying distance into the controller in real time; sixthly, when the tray arrives at a sorting position, the controller controls the sorting assembly (8) to work, and fruit and vegetablesorting is completed. By means of the free conveying type fruit and vegetable sorting device and the sorting method thereof, the fruit and vegetable sorting efficiency is improved, and secondary manual sorting at the later period is avoided.

Owner:浙江德菲洛智能机械制造有限公司

Sorting device

Owner:SUZHOU JINGLAI OPTO CO LTD

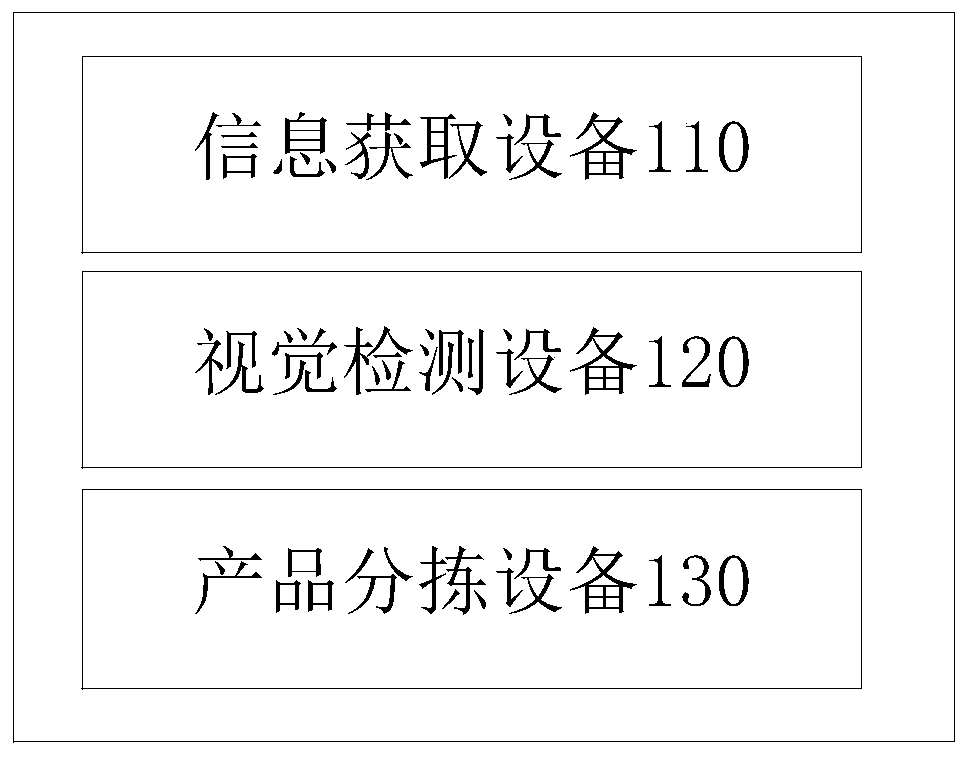

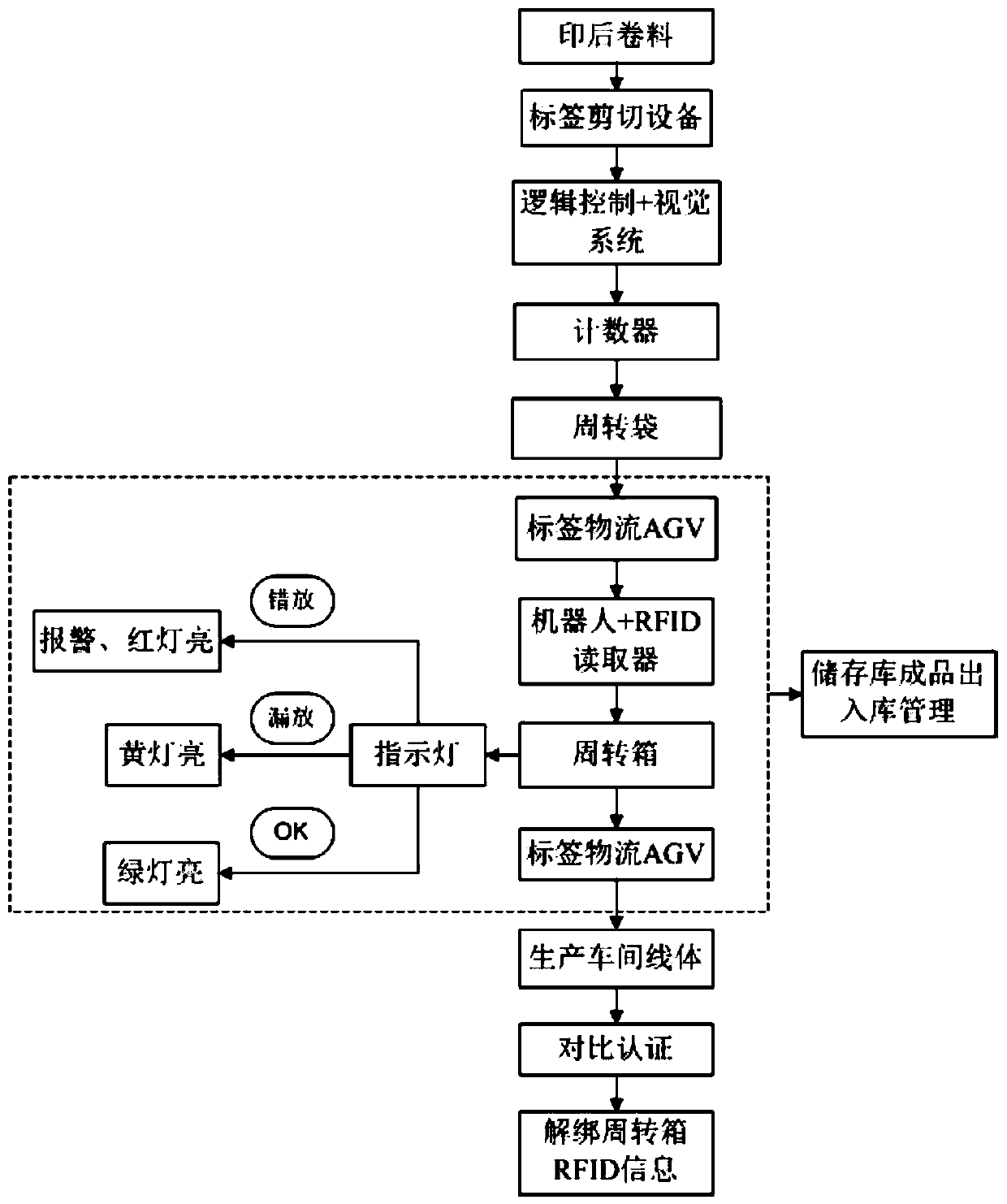

Automatic sorting method and system

ActiveCN110328147AAvoid sorting errorsAvoid mixingCo-operative working arrangementsCharacter and pattern recognitionImage identificationInformation acquisition

The invention provides an automatic sorting method and system. The system comprises an information acquisition device, a vision inspection device and a product sorting device. The information acquisition device is used for acquiring first sub order information, corresponding to a first production line, in a target order, wherein the first sub order information comprises a target order number and aproduct number N corresponding to the first production line; the vision inspection device is used for acquiring image information of first products on the first production line; the product sorting device is used for putting the N first products into a first storage device according to the first sub order information and the image information. According to the automatic sorting method and system,an image identification technology is used for automatic sorting, sorting errors in the sorting process are avoided, manual sorting is not needed, and the sorting speed is increased.

Owner:GREE ELECTRIC APPLIANCES INC

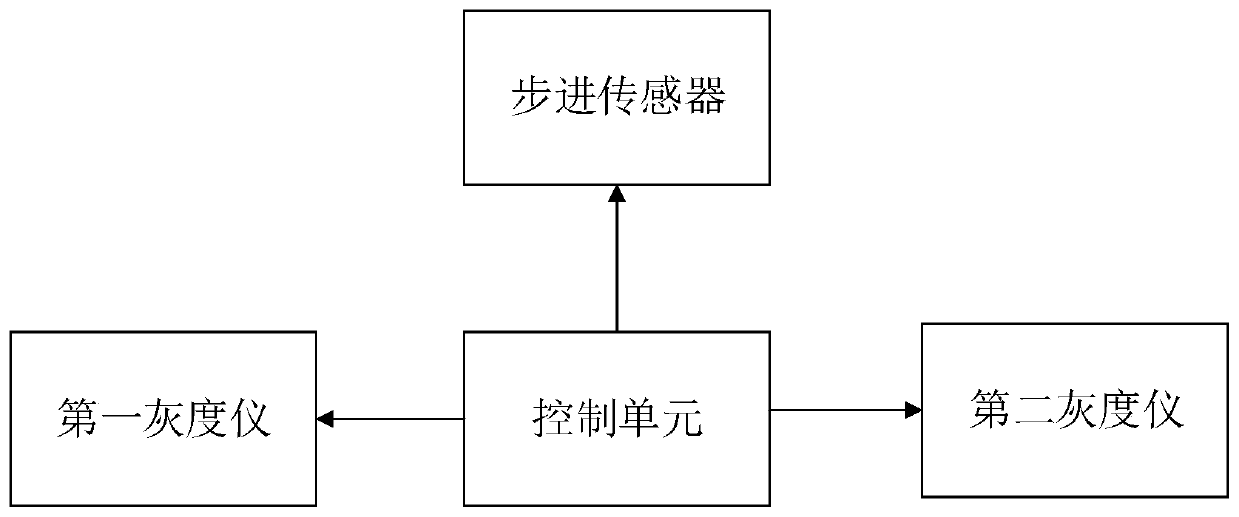

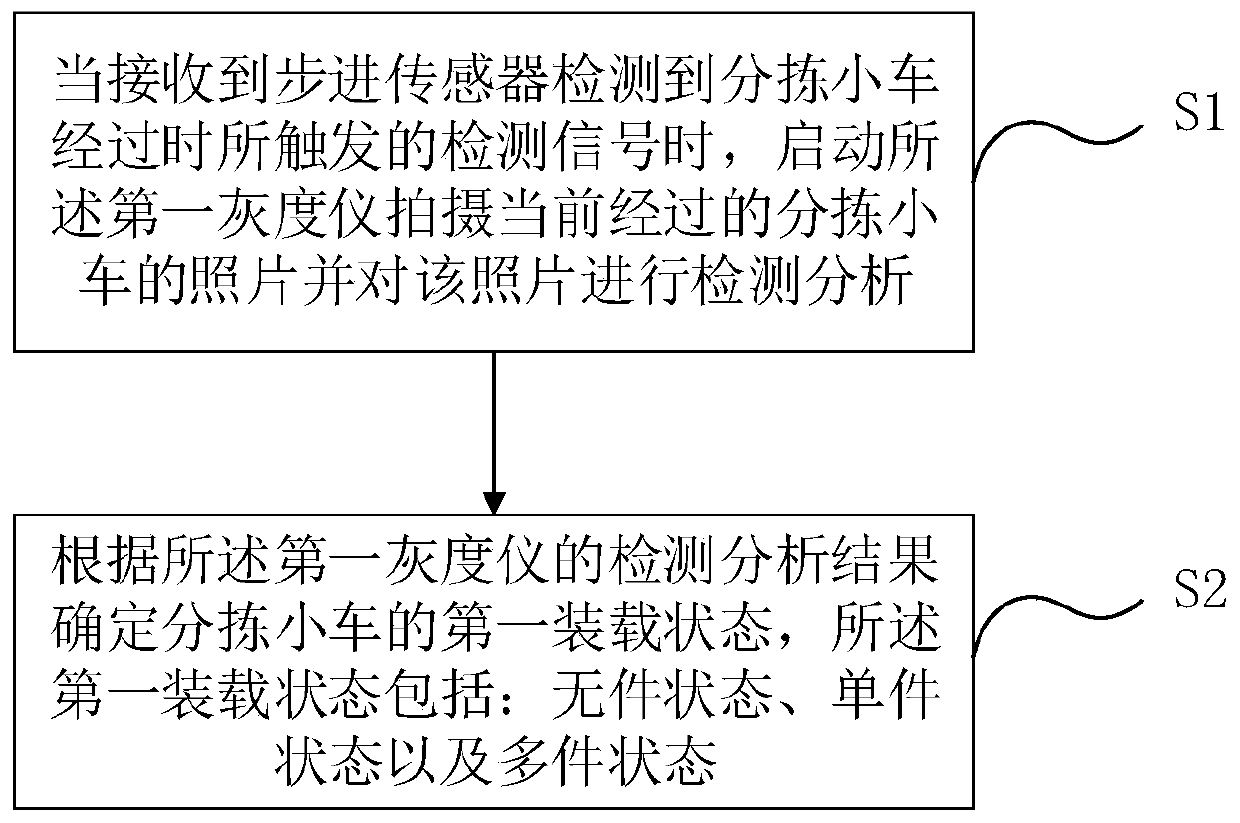

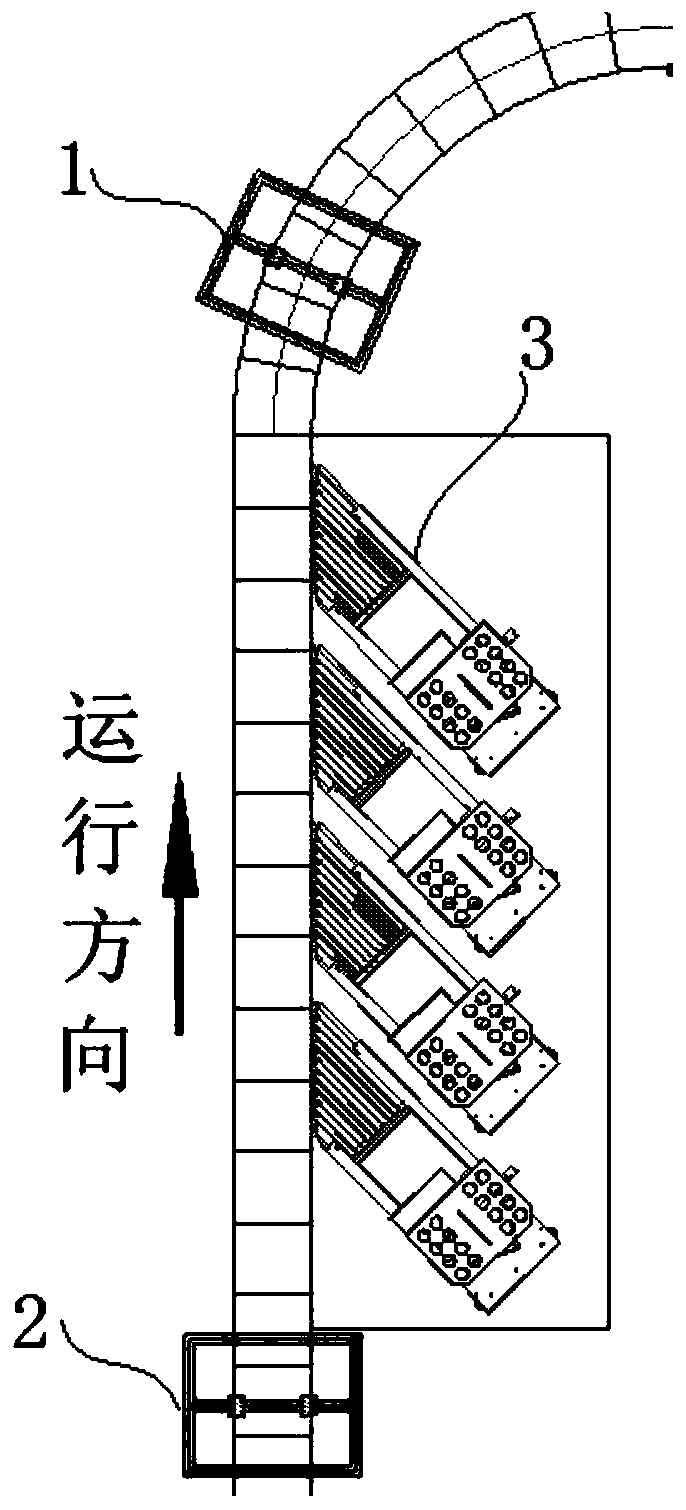

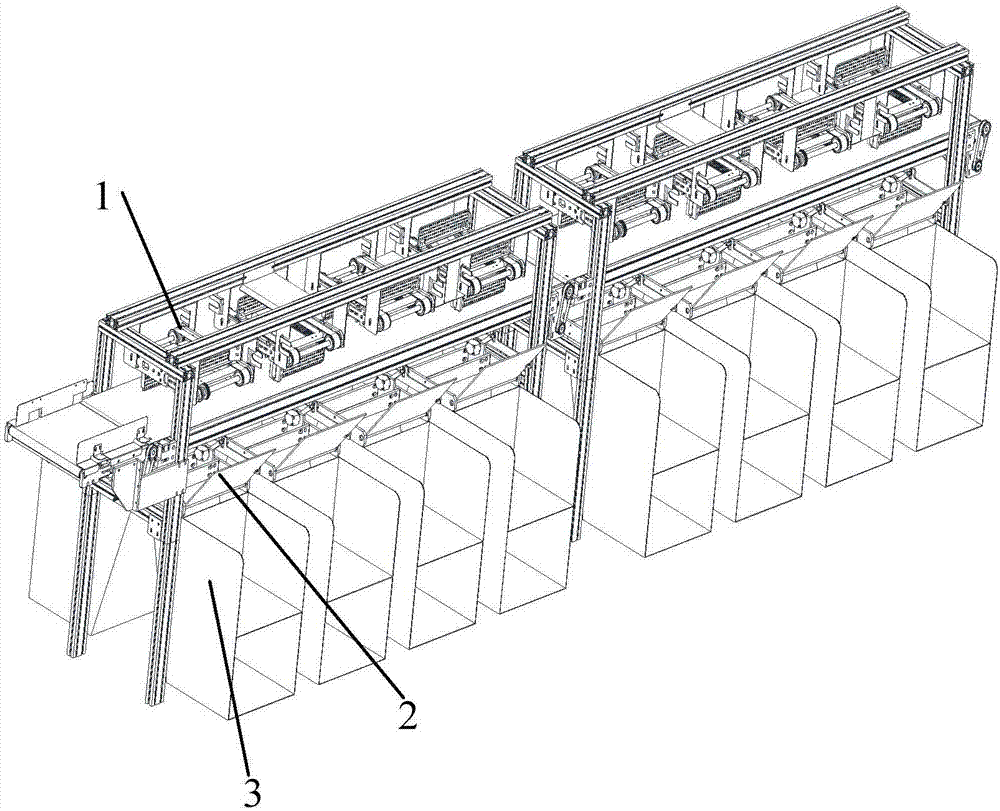

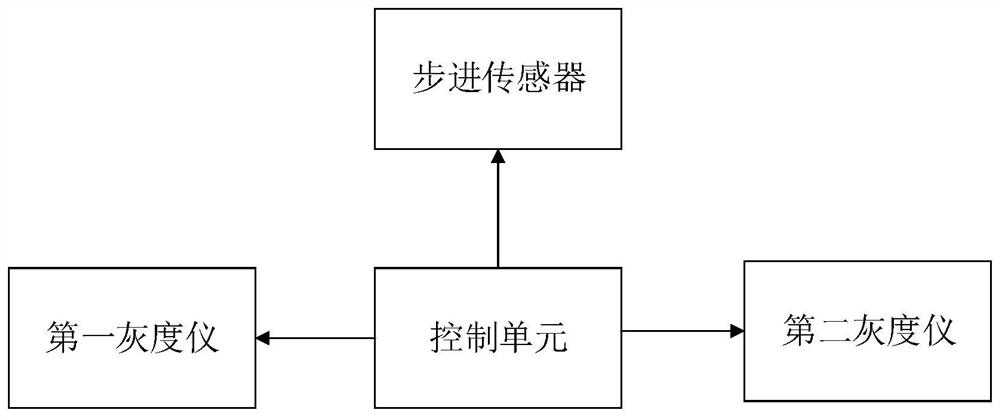

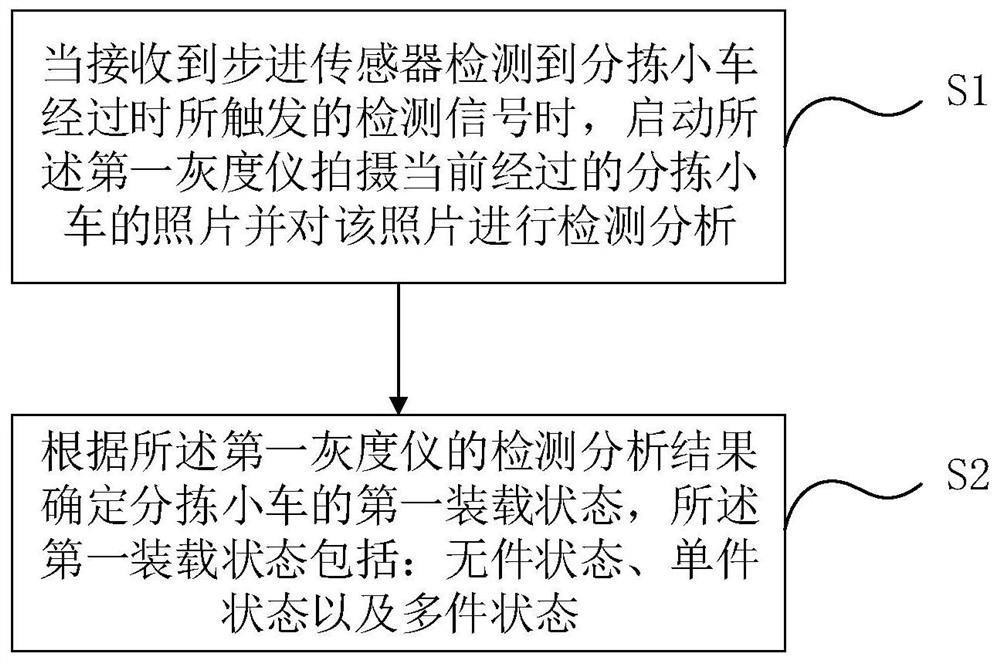

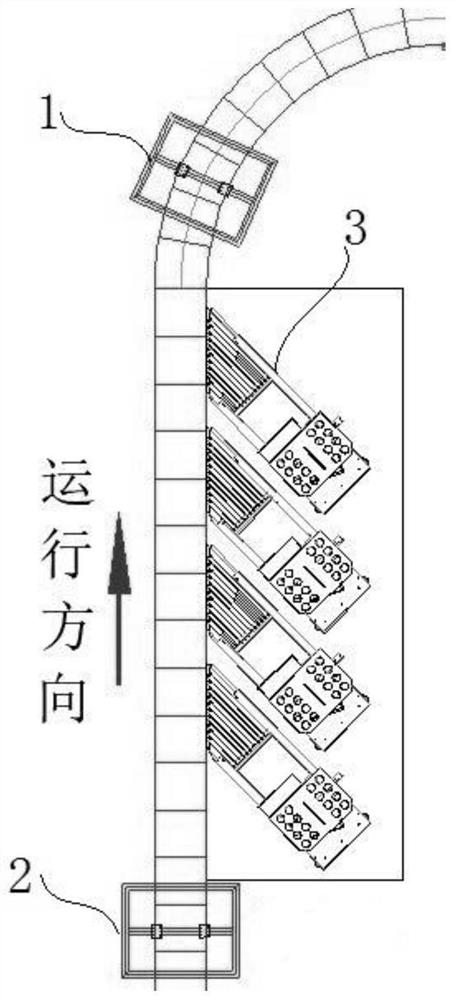

Sorting wagon loading state detecting system based on gray scale meters and sorting system

The invention discloses a sorting wagon loading state detecting system based on gray scale meters and a sorting system. The detecting system comprises a stepping sensor, a first gray scale meter and acontrol unit, wherein the stepping sensor is arranged on a conveying rail of a cross band sorting machine; the first gray scale meter is arranged above the conveying rail, and is located in the advancing direction of a feeding entrance; and the control unit is electrically connected with the stepping sensor and the first gray scale meter. The control unit can execute the method comprising the following steps of: when a detection signal of the stepping sensor is received, starting the first gray scale meter to shoot the photograph of a current passing sorting wagon and performing detecting andanalysis; and according to the detecting and analysis result, determining the first loading state of the sorting wagon. The detecting system disclosed by the invention can detect the loading state ofthe sorting wagon to determine whether a plurality of express items are loaded by the sorting wagon or not, so that the sorting machine can perform special treatment on the sorting wagon loaded withthe express items according to the loading state of the sorting wagon, and sorting mistakes are avoided.

Owner:GUANGZHOU GENYE INFORMATION TECH

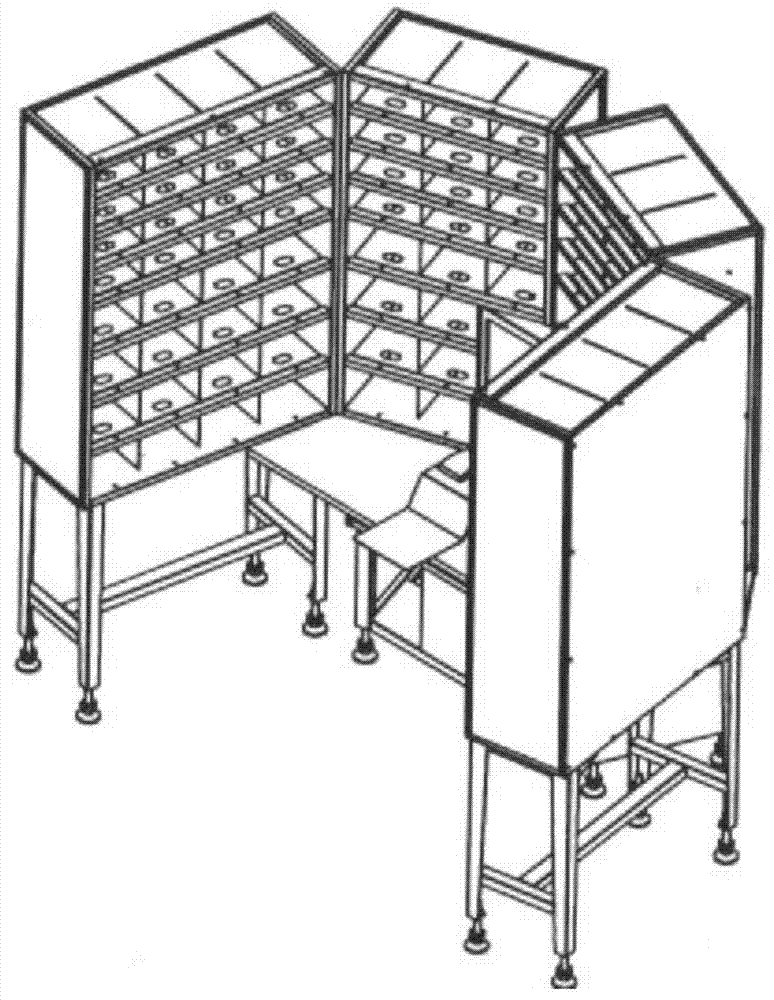

Sorting device and method

The invention discloses a sorting device and method. The sorting device comprises an upper-layer primary sorting conveying unit and a lower-layer secondary guiding sorting unit connected with the primary sorting conveying unit. The primary sorting conveying unit is provided with a left discharging outlet station and a right discharging outlet station. Receiving bin units are arranged on the left and right sides of the secondary guiding sorting unit in a connected mode correspondingly. Each receiving bin unit is provided with two bin positions. The secondary guiding sorting unit comprises a left rotating shaft and a right rotating shaft which are parallelly arranged. The rotating shafts are supported on a front frame part and a rear frame part in a free rotation mode. A guiding plate is fixed to each rotating shaft. A main connecting rod is hinged between the left guiding plate and the right guiding plate. A driving mechanism is in driving connection with the main connecting rod and can drive the left and right guiding plates to swing leftwards and rightwards synchronously. The left and right guiding plates can swing leftwards or rightwards to guide articles sorted out by the primary sorting conveying unit to fall into the corresponding bin positions. The sorting speed is high, the accuracy rate is high, and performance is stable.

Owner:SUZHOU IRON TECH

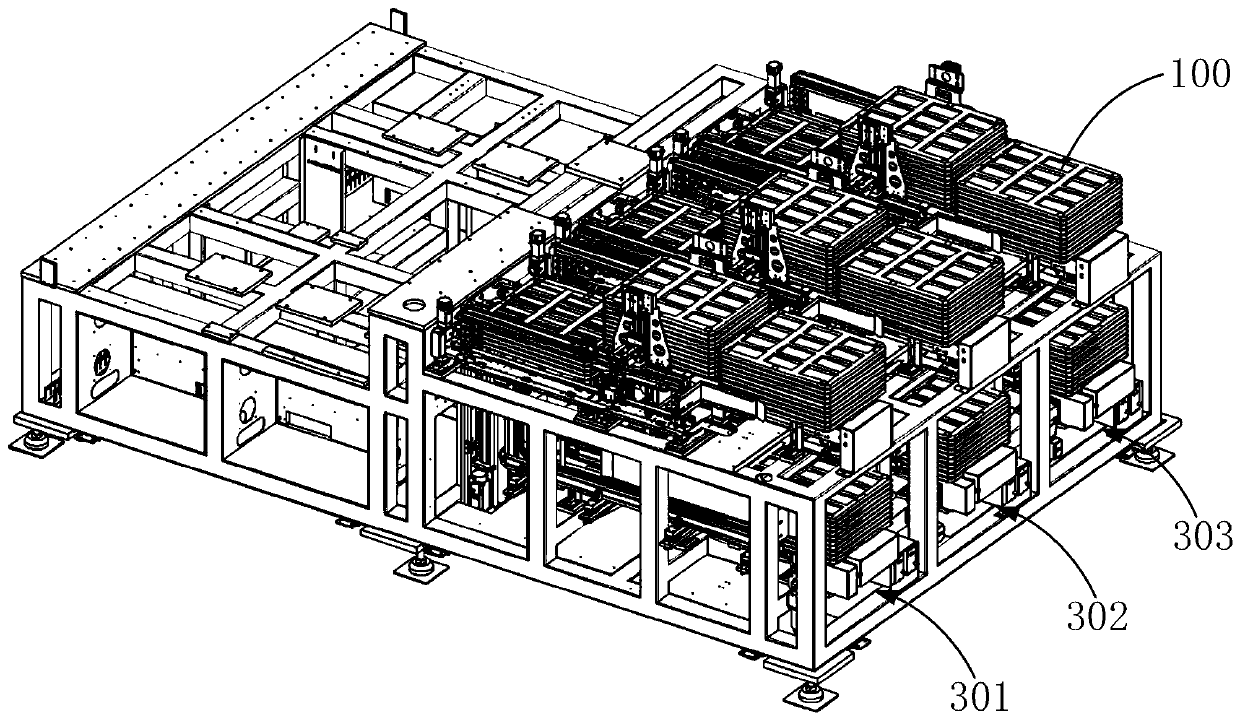

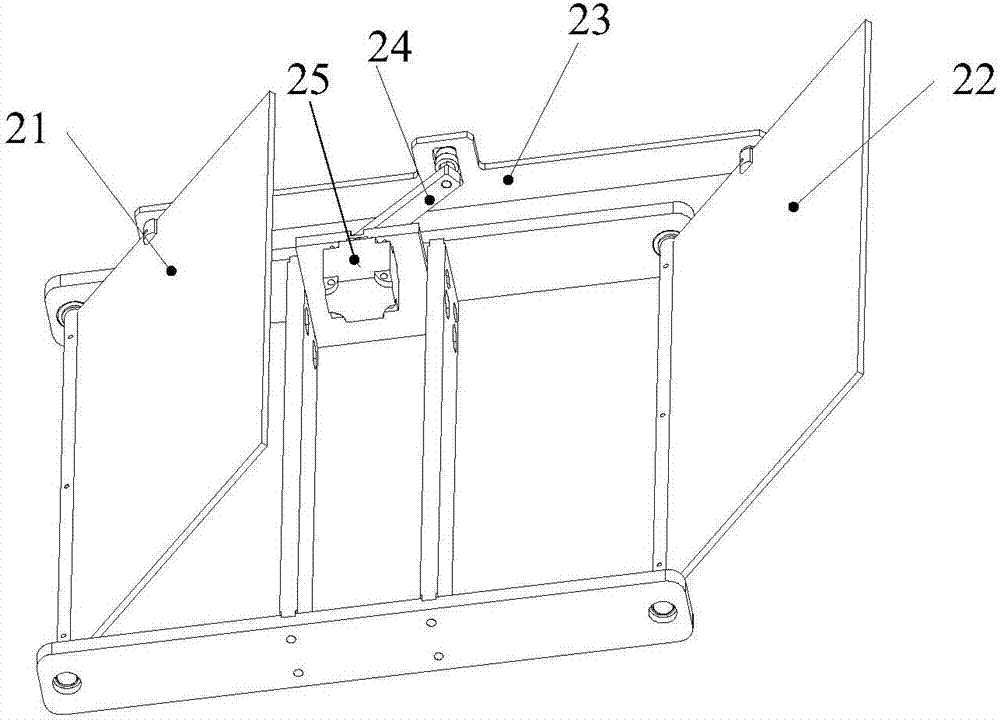

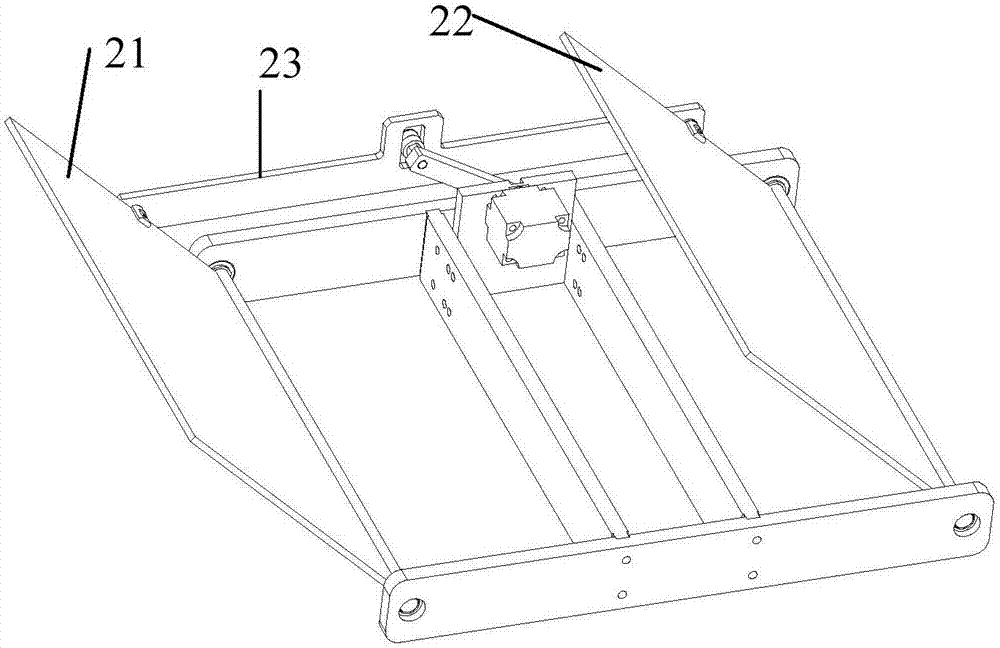

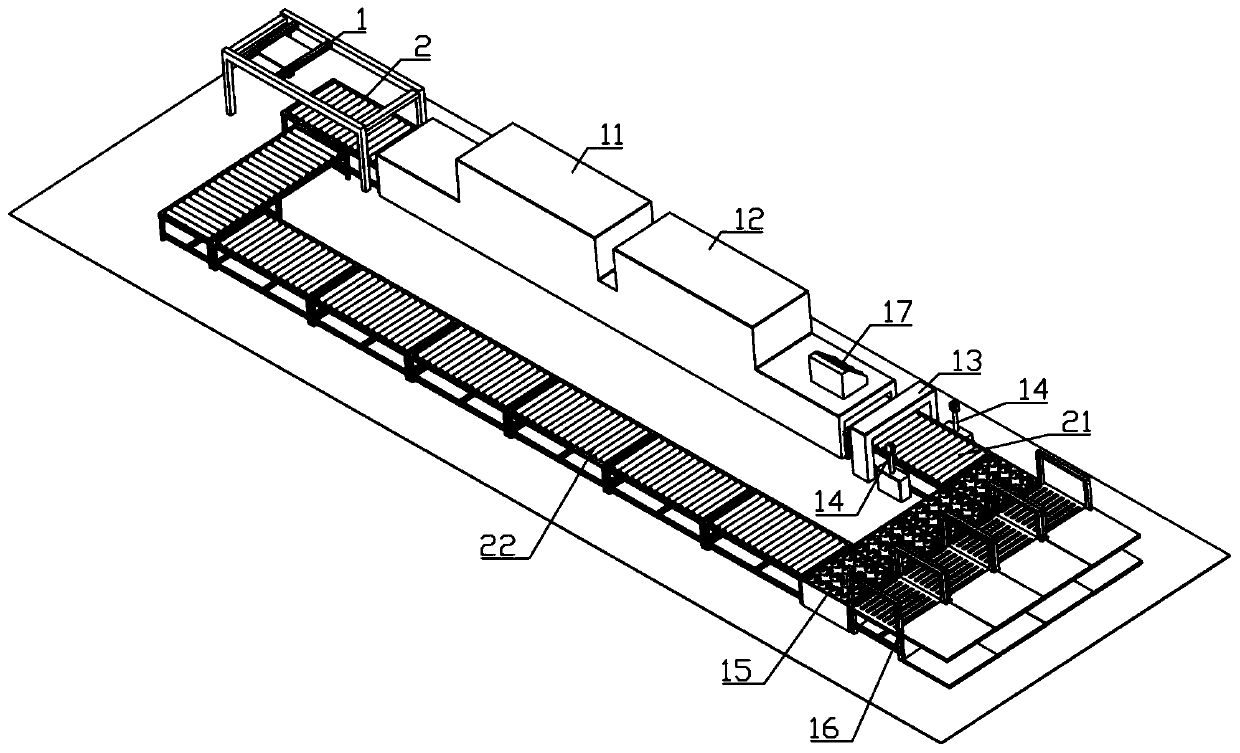

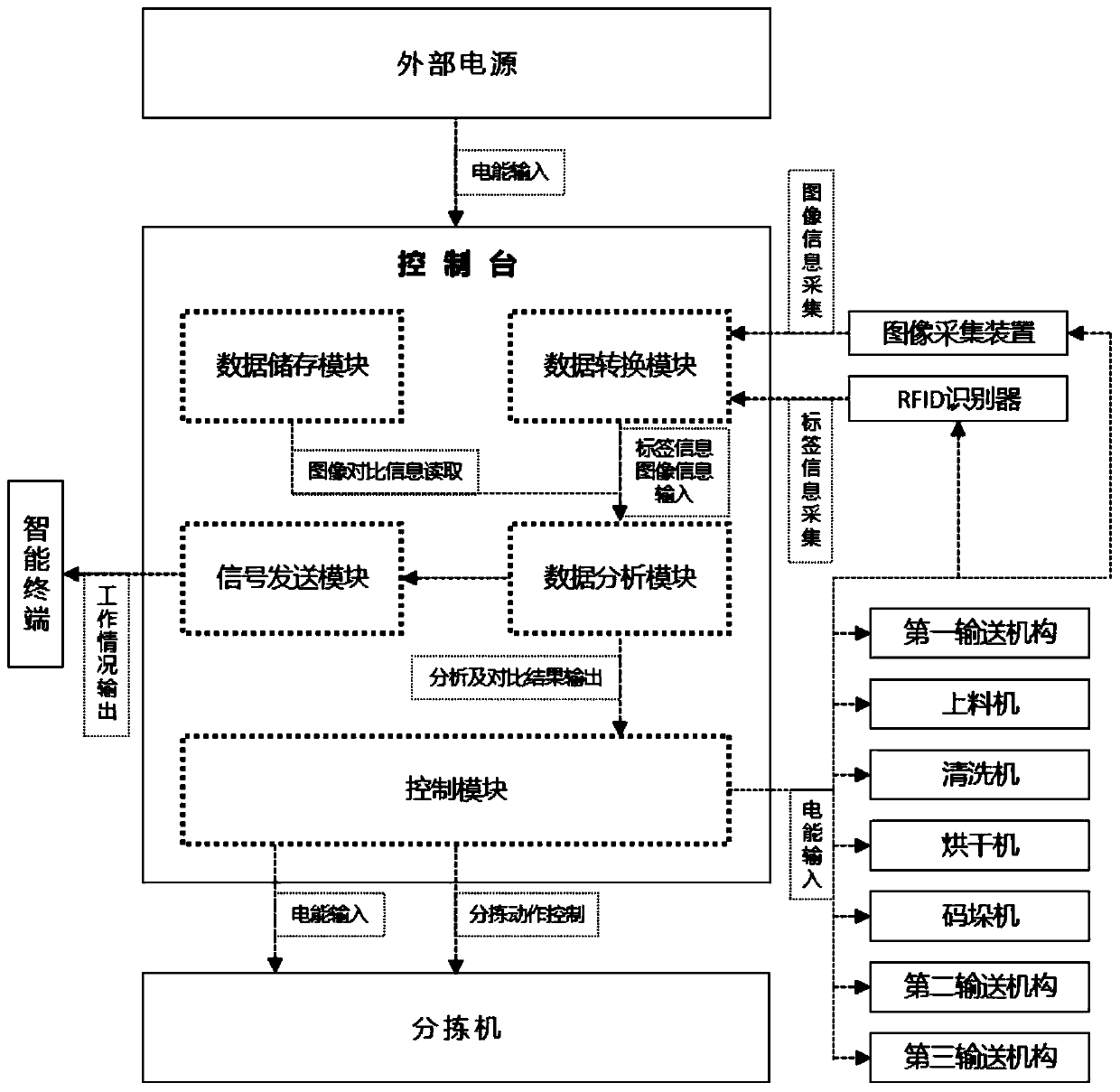

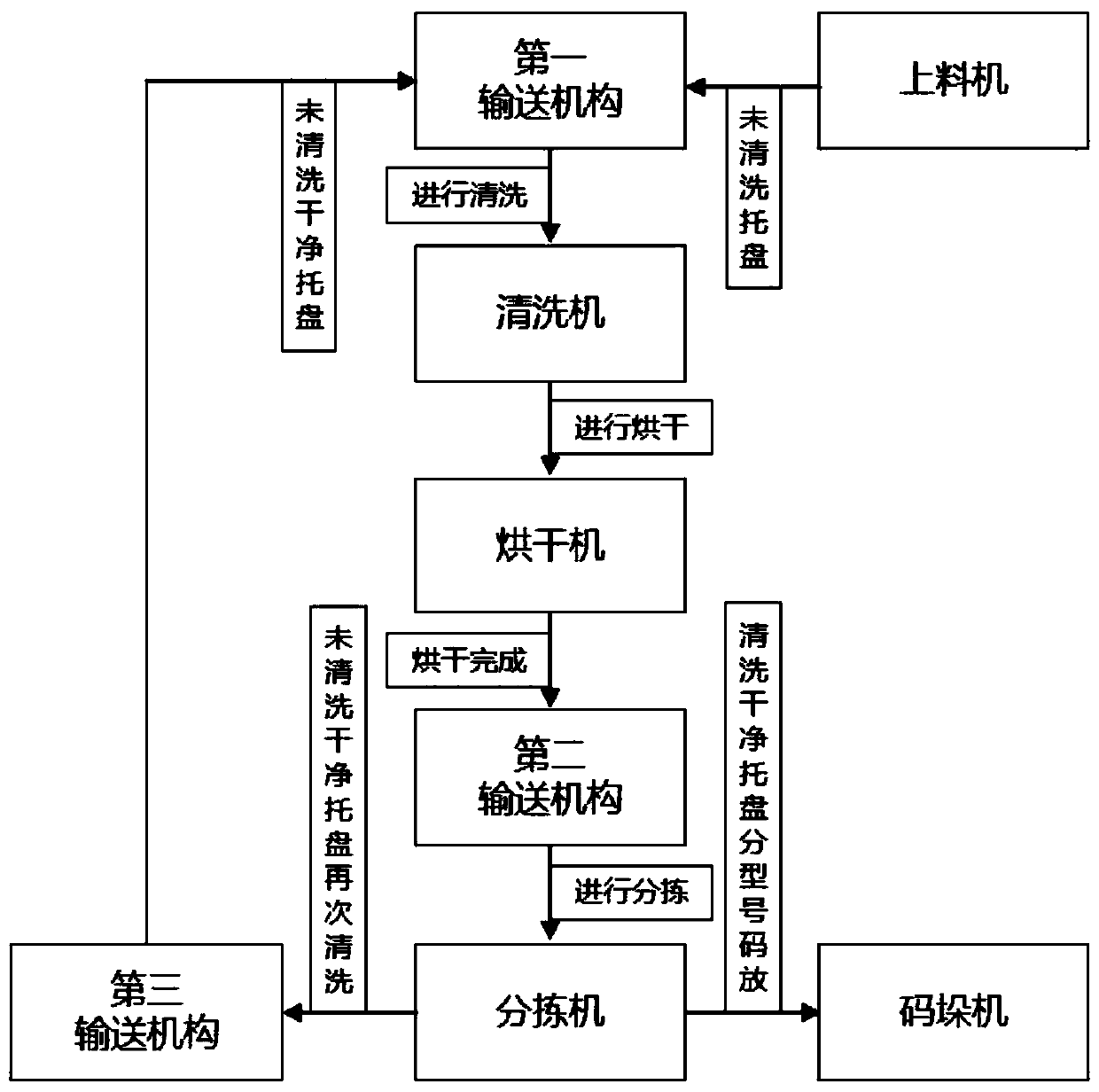

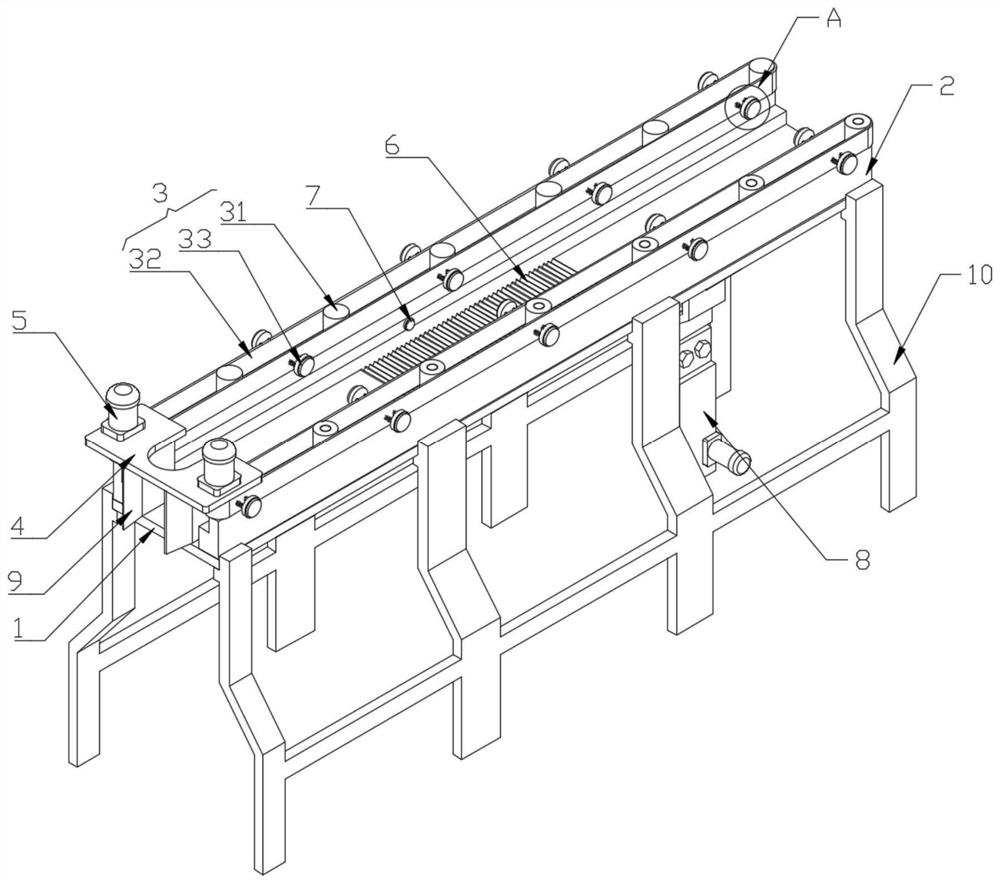

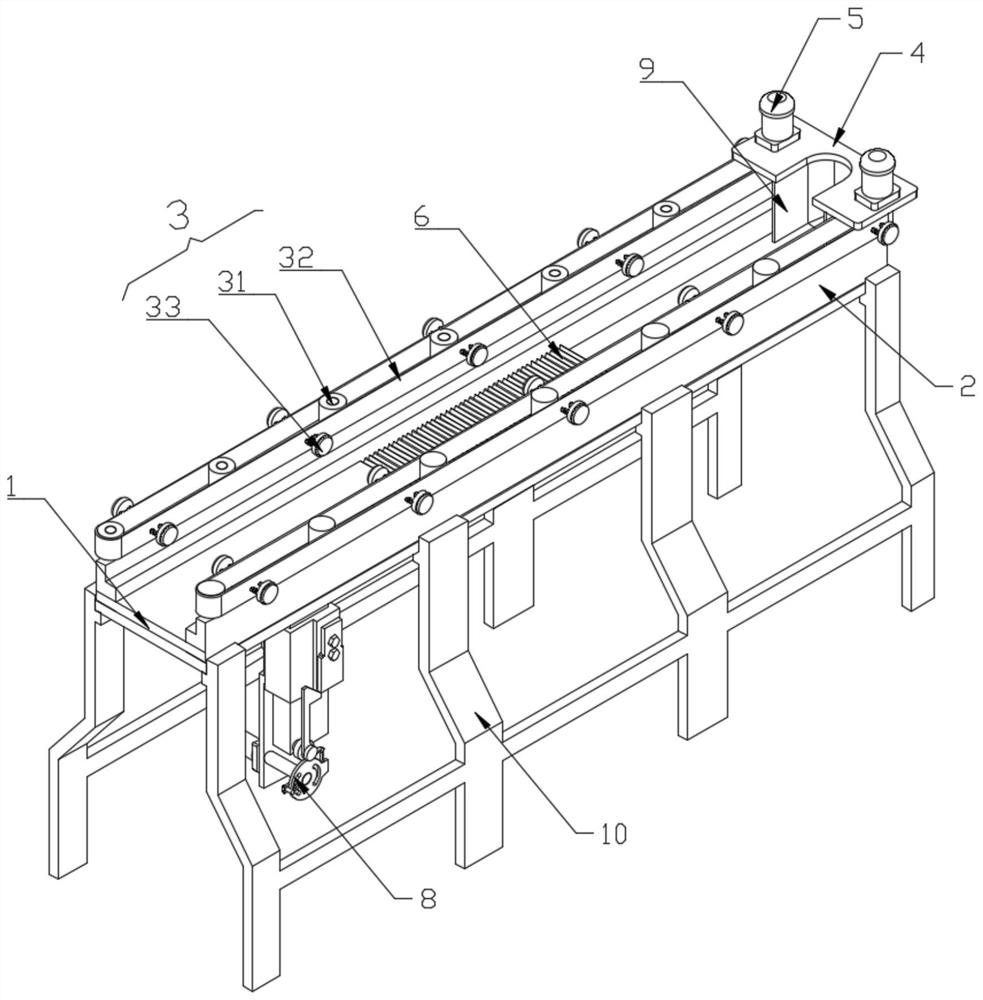

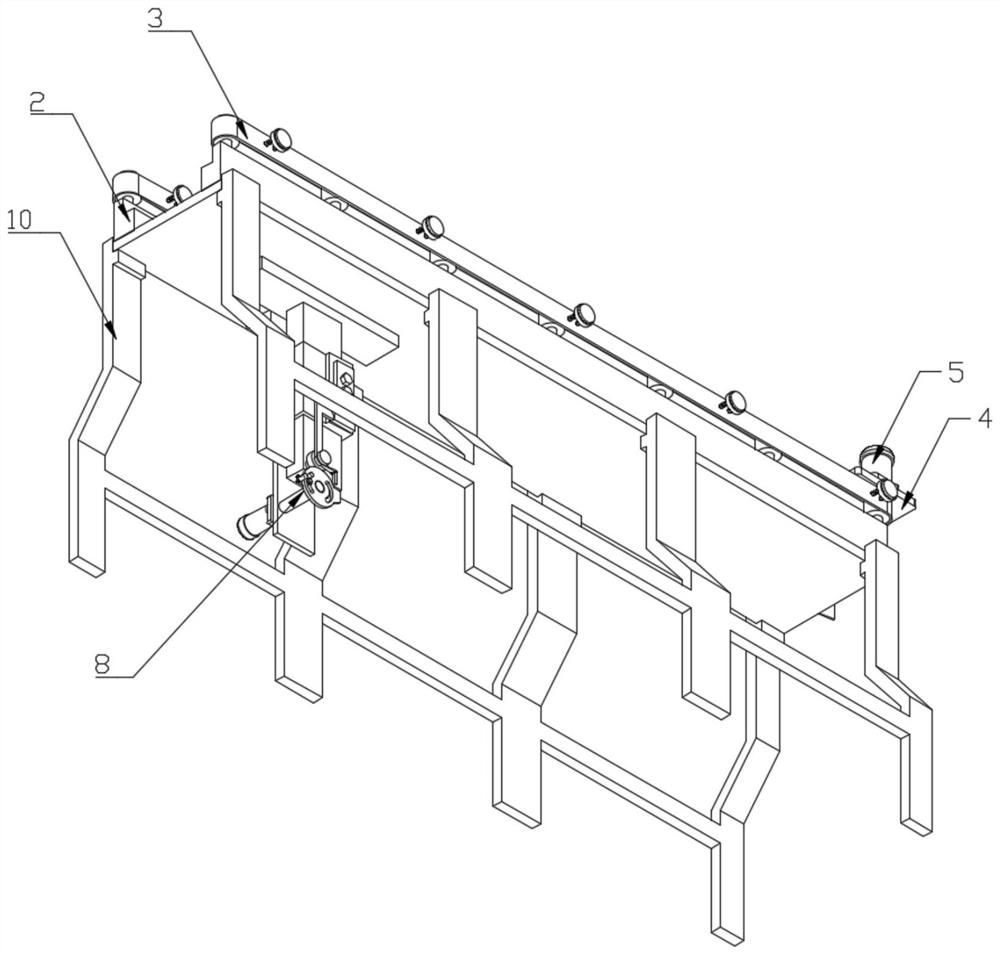

Tray cleaning, drying and storing assembly line

PendingCN111282937AImprove work efficiencyReduce labor costsHollow article cleaningDrying gas arrangementsData transformationPalletizer

The invention belongs to the technical field of tray cleaning, and particularly relates to a tray cleaning, drying and storing assembly line. A feeding machine, a cleaning machine, a drying machine, an RFID recognizer, an image collecting device, a sorting machine, a stacking machine and a control table are included. A first conveying mechanism is arranged between the feeding machine and the cleaning machine. The cleaning machine comprises a plurality of first movable spraying heads and a plurality of second movable spraying heads. The drying machine comprises a plurality of first air knives and a plurality of second air knives. A second conveying mechanism is arranged between the drying machine and the sorting machine. The RFID recognizer is arranged on the side, close to the drying machine, of the second conveying mechanism. The image collecting device comprises two cameras. A third conveying mechanism is arranged between the sorting machine and the first conveying mechanism. The control table comprises a data conversion module, a data analysis module, a data storage module and a control module, the control table is electrically connected with an outer power source, and the datastorage module stores image comparison information.

Owner:江苏乐橘云盘科技有限公司

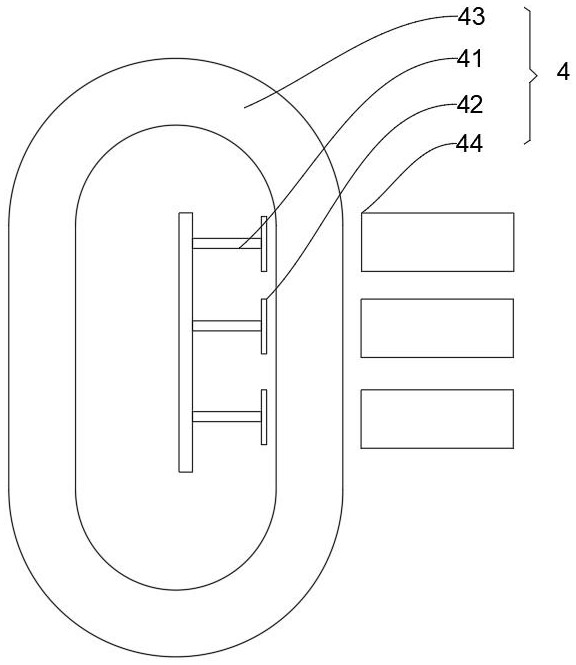

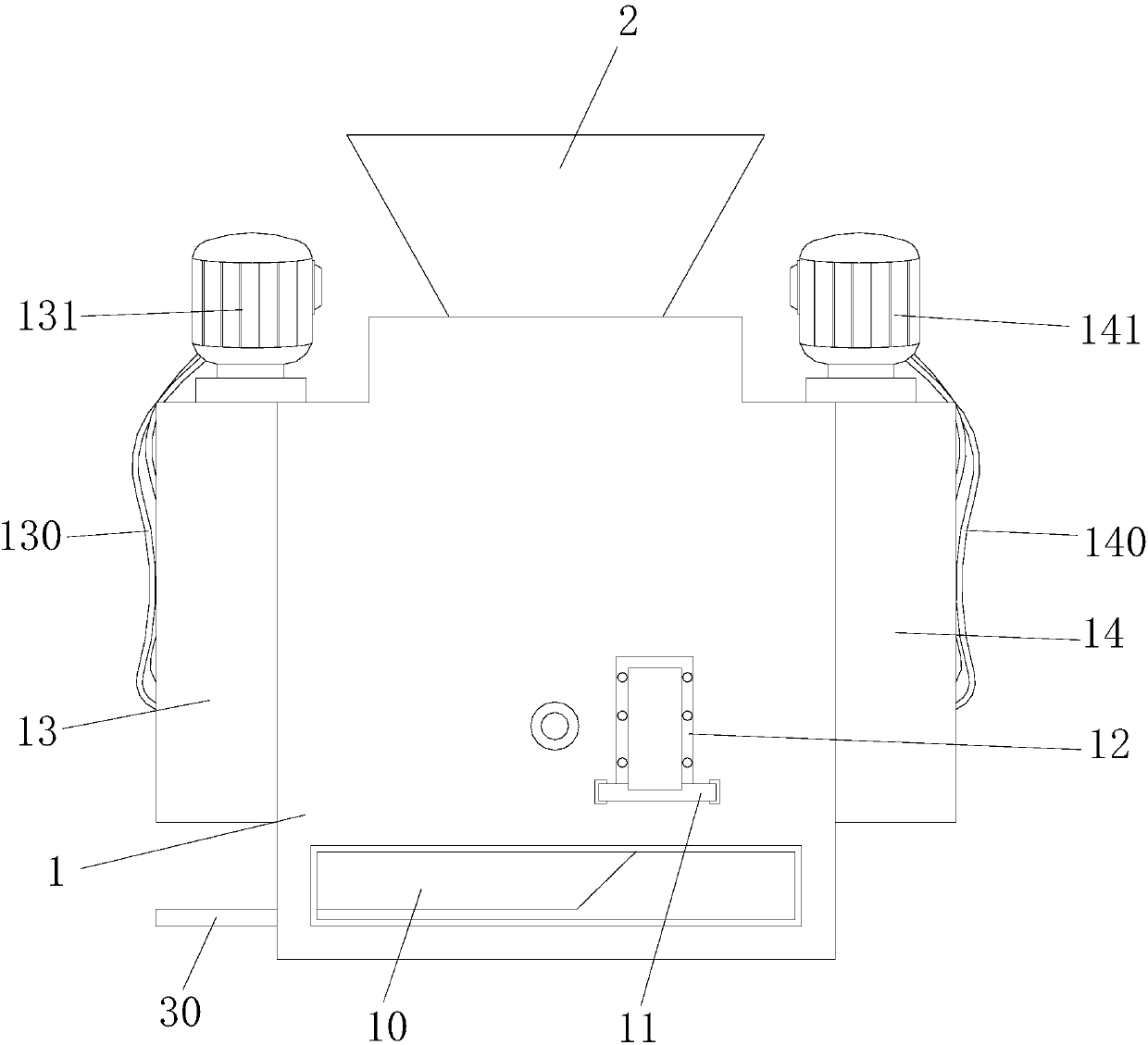

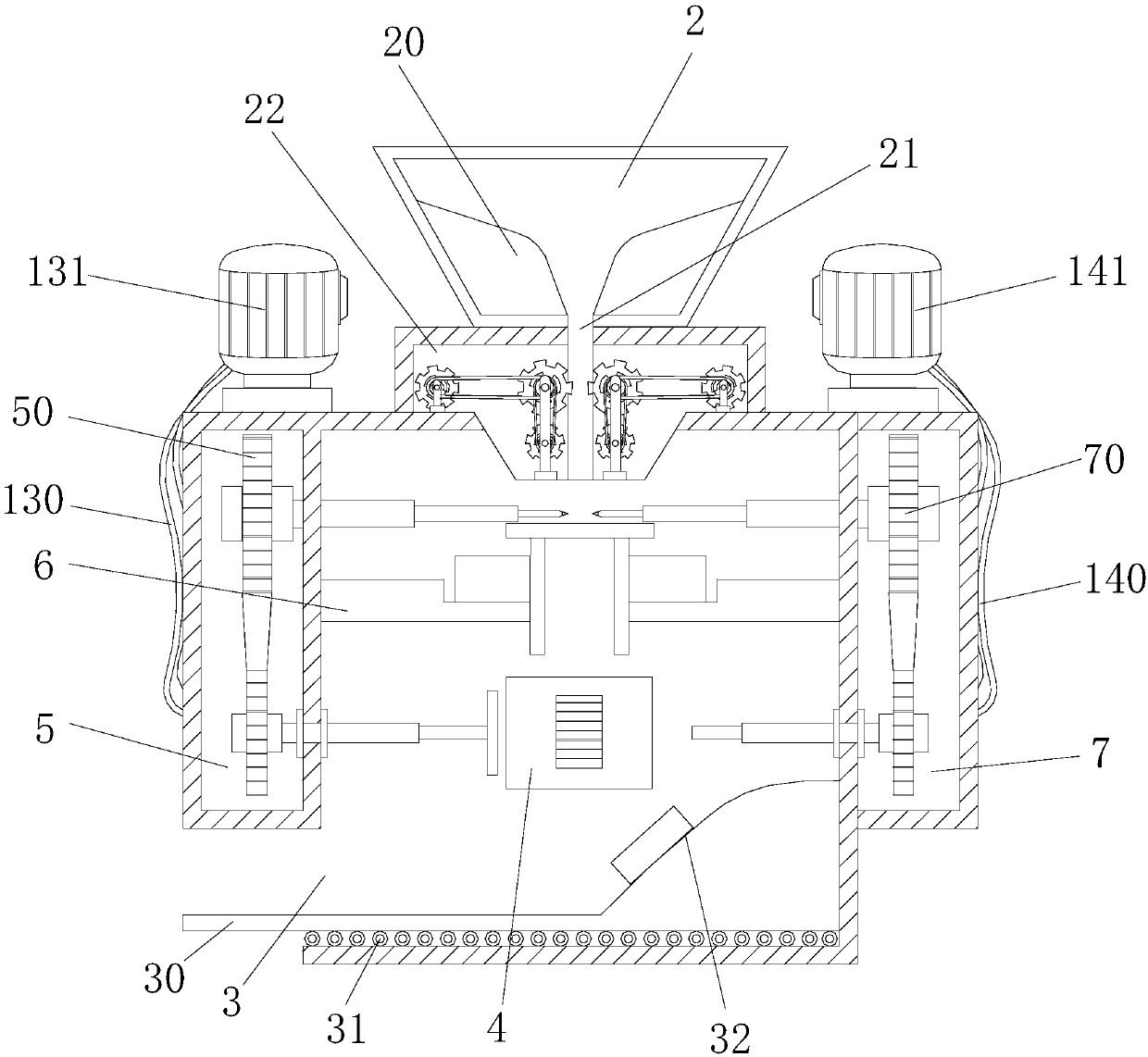

Gear packaging, conveying and sorting device

ActiveCN113714108AReduce manual labor intensityAvoid sorting errorsGradingSynchronous motorGear wheel

The invention discloses a gear packaging, conveying and sorting device, and relates to the technical field of gear sorting equipment. When the gear packaging, conveying and sorting device is used, firstly, gears to be sorted are placed in a U-shaped groove in a mounting plate one by one, the two sides of each gear are clamped by gear fixing pieces, a synchronous motor drives a conveying belt to rotate through a transmission wheel, and under driving of the conveying belt, the gear moves towards one end, when the gear moves to the position above a tooth-shaped groove, the gear sinks and is meshed with the tooth-shaped groove under the action of the weight of the gear, then the gear rotates in the tooth-shaped groove, and if the detected gear has blind teeth, the gear generates an upward jumping action in the rotating process. According to the gear packaging, conveying and sorting device, therefore, sorting of unqualified gears is achieved, manual picking is not needed, the labor intensity of workers is greatly reduced, and the problem of sorting errors caused by visual fatigue of the workers can be avoided.

Owner:JIANGSU AIRSHIP GEAR

A wafer automatic sorting machine

ActiveCN111540703BQuality is not affectedAvoid scratchesSemiconductor/solid-state device manufacturingSortingWaferMechanical engineering

The invention belongs to the technical field of wafer production equipment and provides an automatic wafer sorting machine, which includes a frame, a material rack, a wafer pick-and-place device and a controller; the material rack is divided into an area to be sorted and a sorting completed area area, and are respectively equipped with a flower basket positioning mechanism corresponding to the placement position of the flower basket; the wafer pick-and-place device includes a mounting frame, and a mounting plate driven by the first driving device is installed on the mounting frame slidingly along the X-axis direction. The mounting seat driven by the second driving device and sliding along the Z-axis direction, the supporting plate driven by the third driving device is slidably installed on the mounting seat along the Y-axis direction, and the end of the supporting plate has a wafer holding part; the controller respectively It is connected with the flower basket positioning mechanism, the first driving device, the second driving device and the third driving device. Compared with the traditional artificial wafer sorting, the present invention not only greatly improves the sorting efficiency, effectively avoids sorting errors, does not cause scratches to the wafers, and can sort and place the substrate numbers of the sorted wafers.

Owner:SHANDONG NOVOSHINE OPTOELECTRONICS CO LTD

Book sorting device and using method thereof

PendingCN111822389AControl sliding speedAvoid sorting errorsSortingSoftware engineeringMechanical engineering

Owner:LIUPANSHUI NORMAL UNIV

Rotary Static Infusion Bag Intelligent Sorting System and Method

The invention discloses a rotating type static allocation infusion bag intelligent sorting system and a method. The rotating type static allocation infusion bag intelligent sorting system comprises a primary sorting conveying unit and bins. A discharging port of the primary sorting conveying unit is connected with a secondary sorting conveying unit. A discharging port of the secondary sorting conveying unit is connected with a rotating type sorting conveying unit which is located above the first layer of bins, the first layer of bins are provided with multiple bin spaces in the circumferential direction, and the rotating type sorting conveying unit can rotate in the circumferential direction to enable a discharging port of the rotating type sorting conveying unit to correspond to the needed bin space. The other discharging port of the secondary sorting conveying unit is provided with a linear type sorting conveying unit in a connected manner, a discharging port of the linear type sorting conveying unit is provided with a rotating type sorting conveying unit in a connected manner, the rotating type sorting conveying unit is located above a second layer of bins, the second layer of bins are provided with multiple bin spaces in the circumferential direction, and the rotating type sorting conveying unit can rotate in the circumferential direction to enable a discharging port of the rotating type sorting conveying unit to correspond to the needed bin place. The rotating type static allocation infusion bag intelligent sorting device is high in sorting speed, high in accuracy and capable of achieving automatic sorting and feeding of infusion bags.

Owner:SUZHOU IRON TECH

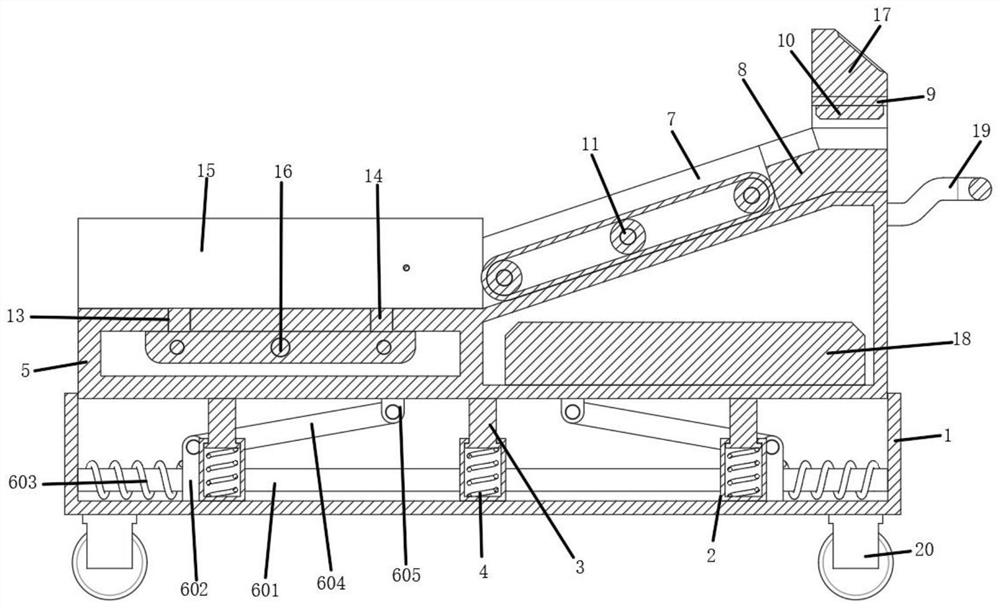

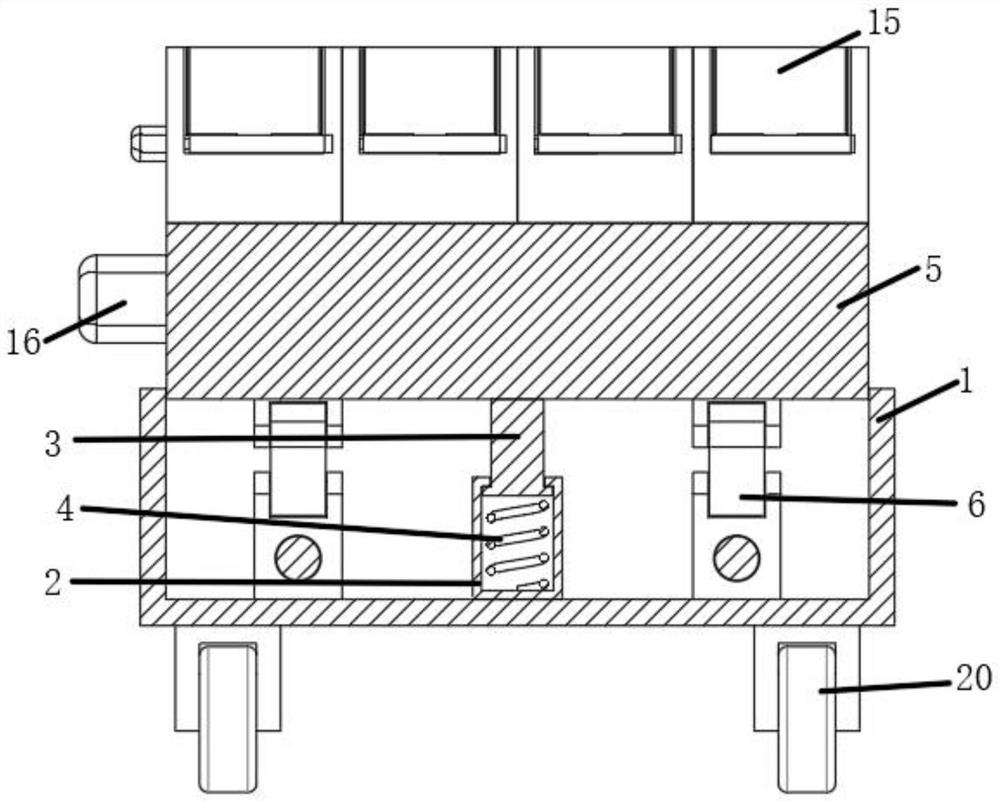

Intermittent transportation mechanism for freight logistics transportation and carrying

InactiveCN112110173AHigh precisionAvoid failureConveyor partsLogistics managementControl engineering

The invention relates to the technical field of freight logistics, and discloses an intermittent transportation mechanism for freight logistics transportation carrying. The mechanism comprises a baseand a fixed disc, wherein a positioning block is fixedly mounted on the front surface of the base, a limiting block is fixedly mounted on the front surface of the base, a movable plate is connected tothe outer side of the limiting block in a sleeving manner, and a positioning groove is formed in the front surface of the movable plate, a reset spring is fixedly mounted at the bottom of the limiting block, a baffle is fixedly mounted on the top of the movable plate, and a fixing plate is fixedly mounted on the outer side of the base. According to the intermittent transportation mechanism for freight logistics transportation and carrying, sorting errors caused by inaccurate detection due to stacking of articles are avoided, the article sorting precision is improved, meanwhile, the sorting work efficiency is greatly improved. Machine faults caused by the fact that a plurality of articles need to be processed by a machine in a subsequent process within a short time as the transportation interval time of the articles is not controlled are avoided, the frequency of machine faults is greatly reduced, and the income of an operator is further increased.

Owner:广州胜宇达货运代理有限公司

Logistics sorting device and method

The invention relates to a logistics sorting device. The sorting device a transportation assembly, two recognition assemblies, an overturning assembly, a sorting assembly and multiple delivery assemblies, the recognition assemblies are arranged above the transportation assembly, the overturning assembly is arranged between the two recognition assemblies, the sorting assembly is arranged at the tail end of the transportation assembly, the sorting assembly is provided with a plurality of outlets, and each outlet of the sorting assembly is provided with one delivery assembly. The overturning assembly is arranged to overturn express parcels, feature objects attached to the surfaces of the express parcels can be prevented from being blocked by the express parcels, and the sorting efficiency is improved.

Owner:南通长盈电子科技有限公司

Color pen packing lifting machine

The invention discloses a color pen packing lifting machine. The color pen packing lifting machine structurally comprises a lifting machine body, a falling device, a discharging mechanism, a packing mechanism, a first transmission mechanism, a direction correcting mechanism and a second transmission mechanism. The discharging mechanism is provided with a sending plate, conveying rollers and a bottom guiding plate. The packing mechanism is provided with a pen falling opening, fixing shafts and pen embedding grooves. The direction correcting mechanism is provided with a fixing bearing plate, a correcting plate and a limiting groove. A second transmission gear set is provided with a second transmission large gear, a second convoy belt, a second transmission pinion, a second transmission supporting rod, a packing plate, a second transmission correcting rod and a second correcting rod head. When the color pen packing lifting machine is used, color pens can be automatically sorted, correctedin direction and packed, the trouble of manual sorting is reduced, mistakes such as the sorting mistake, the incorrect direction or pen cap missing are avoided, the time and manpower are saved, meanwhile, the packing speed rate is also increased, and the error rate is decreased.

Owner:浙江珠龙包装科技股份有限公司

A sorting and error-proofing method and device for multi-layer PCB stacked boards

ActiveCN105228377BAvoid scrappingAvoid wastingMultilayer circuit manufactureControl systemEngineering

The invention discloses a sorting mistake-proofing method for multiple layers of printed circuit board (PCB) lamination. The method comprises the following steps: fabricating different mistake-proofing patterns on different levels of core plates; stacking one core plate; obtaining the mistake-proofing pattern on the stacked core plate; judging whether the obtained mistake-proofing pattern is consistent with the corresponding level of standard mistake-proofing pattern in a control system or not, if so, taking out the stacked core plate, and restacking another core plate; if so, judging whether the number of layers of the core plates is equal to the number of layers of PCBs designed in advance or not, if not, stacking the next core plate; and if so, carrying out riveting. The invention further discloses a sorting mistake-proofing device for multiple layers of printed circuit board (PCB) lamination. The correctness of the mistake-proofing pattern on each core plate is judged in the plate stacking process to ensure that various core plates are stacked according to the specified order; according to the method, a riveting operation can be carried out only when the stacking orders of the core plates are all correct; and the core plate with a wrong stacking order is prevented from being riveted and fixed, so that scrapping and waste of the core plate are avoided.

Owner:DONGGUAN SHENGYI ELECTRONICS

A logistics sorting device and method

Owner:南通长盈电子科技有限公司

A sorting trolley loading state detection system and sorting system based on a grayscale meter

The invention discloses a sorting car loading state detection system and a sorting system based on a gray scale meter. The detection system includes: a step sensor, a first gray scale meter and a control unit; On the conveying track of the machine, the first grayscale meter is set above the conveying track and is located in the forward direction of the upper part inlet. The control unit is electrically connected with the step sensor and the first grayscale meter respectively. The control unit can perform the following methods: when When receiving the detection signal from the step sensor, start the first grayscale meter to take pictures of the currently passing sorting trolley and perform detection and analysis; determine the first loading state of the sorting trolley according to the detection and analysis results. The detection system can detect the loading status of the sorting trolley and determine whether there are multiple express shipments in the sorting trolley, so that the sorter can perform special processing on the sorting trolley with multiple express parcels according to the loading status of the sorting trolley. Avoid sorting errors.

Owner:GUANGZHOU GENYE INFORMATION TECH

Method, device, equipment and storage medium for determining physical address

ActiveCN107769250BAchieve positioningExtended functional scopePhotovoltaic monitoringSingle network parallel feeding arrangementsPhysical addressSystem stability

Owner:HUAWEI DIGITAL POWER TECH CO LTD

An intelligent conveying device for hub processing

ActiveCN107187648BReduce labor costsAvoid sorting errorsPackaging automatic controlConveyor partsMachiningBranch line

The invention discloses an intelligent conveying device for wheel hubs. The intelligent conveying device for the wheel hubs comprises a workblank collecting roller way and a workblank identifying device, wherein the workblank indentifying device is connected with a lower roller way, an upper roller way and a middle roller way; the upper roller way and the middle roller way are connected with a plurality of machining and detecting devices through upper-roller-way branch lines and middle-roller-way branch lines correspondingly; and after being machined and detected, the wheel hubs are conveyed to the lower roller way through lower-roller-way branch lines, and a lower track achieves wheel hub conveying between upper and lower machining ends. Through using of the new intelligent conveying device for the wheel hubs, the labor cost of a factory is reduced greatly, the production efficiency is enhanced greatly, the whole production process is completed automatically, the quality of produced products is stable, and the uniformity is good.

Owner:BINZHOU DAISEN WHEEL TECH CO LTD

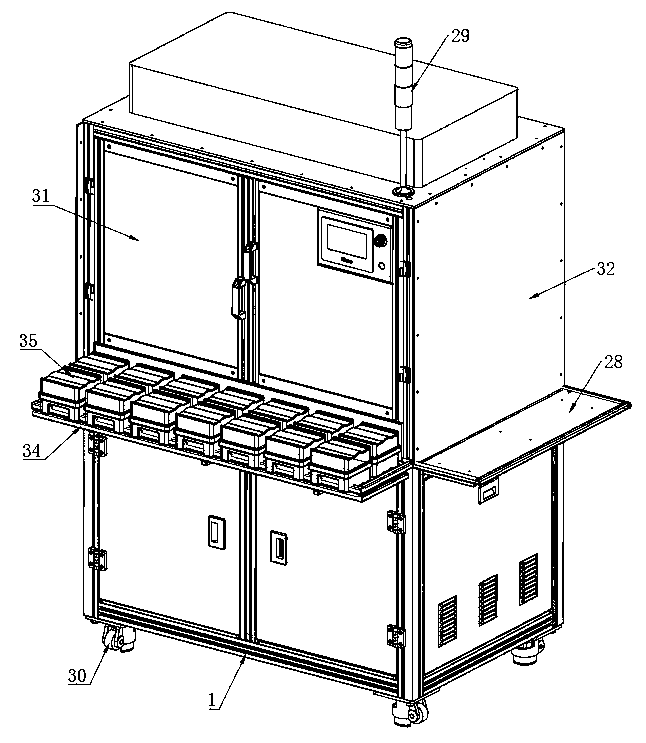

Infusion bag sorting equipment

The invention discloses infusion bag sorting equipment. The equipment comprises a main machine frame, wherein a front display screen is embedded into the front face of the main machine frame, a feeding belt is arranged in the middle of the surface of the main machine frame, a side face monitoring screen is arranged on the side face of the main machine frame, a clamping jaw cover plate is fixedly bolted to the bottom of an inner cavity of the main machine frame, bearing barrels are arranged at the bottom of the main machine frame and located at the two sides of the feeding belt in parallel, anda tail end leakage-proof barrel is arranged at the tail end of the feeding belt and located on the bottom face of the inner cavity of the main machine frame. According to the equipment, the monitoring display screen is arranged on the side face of the equipment, the action of the equipment can be controlled according to a real-time situation, a sorting error of the equipment is avoided, and the sorting accuracy of the whole equipment is improved; an assembly line is adopted for automatic sorting, sorting of infusion bags by a large amount of manpower is avoided, the overall infusion bag sorting efficiency is improved, and manpower cost is lowered; and by adopting multi-barrel multi-area sorting, the infusion bags in different inpatient areas can be sorted synchronously.

Owner:上海贝林尔智能系统有限公司

A system and method for automatically sorting coal and gangue based on temperature changes

The invention relates to the field of automatic separation of coal and gangue, in particular to an automatic coal and gangue separation system and method based on temperature changes. The automatic coal and gangue separation system based on temperature changes comprises a conveying belt, a collection hoper, a feeding device, a queuing device, a detection device, a gas treatment device and a motionexecution device. The feeding device comprises a small suspension-type vibrating screen. The queuing device comprises a lining device, a gathering support and an isolation plate. The detection devicecomprises a thermal infrared temperature sensor, a data acquisition card and a computer. The gas treatment device comprises a gas inflation box, a gas desorption device, a gas collection box, a gas filtering and purification box and a gas pressurizer. According to the automatic coal and gangue separation system and method based on temperature changes, on the basis of the principle that the temperature of coal is increased after the coal absorbs gas and is decreased after the coal desorbs the gas and the temperature of gangue is not changed due to the fact that the gangue does not react with gas, the coal is separated from the gangue, the gangue with the temperature unchanged is separated out and is removed through the motion execution device; and the automatic coal and gangue separation system and method based on temperature changes are high in separation efficiency, capable of separating various types of coal and high in adaptability, and water is not needed.

Owner:ANHUI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com