Sorting device and method

A kind of equipment and first-level technology, applied in the field of sorting equipment, can solve problems such as card bag, hospital clinical treatment work loss, and affect sorting efficiency, and achieve the effect of fast sorting speed, novel structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, specific implementations will now be described in detail with reference to the accompanying drawings.

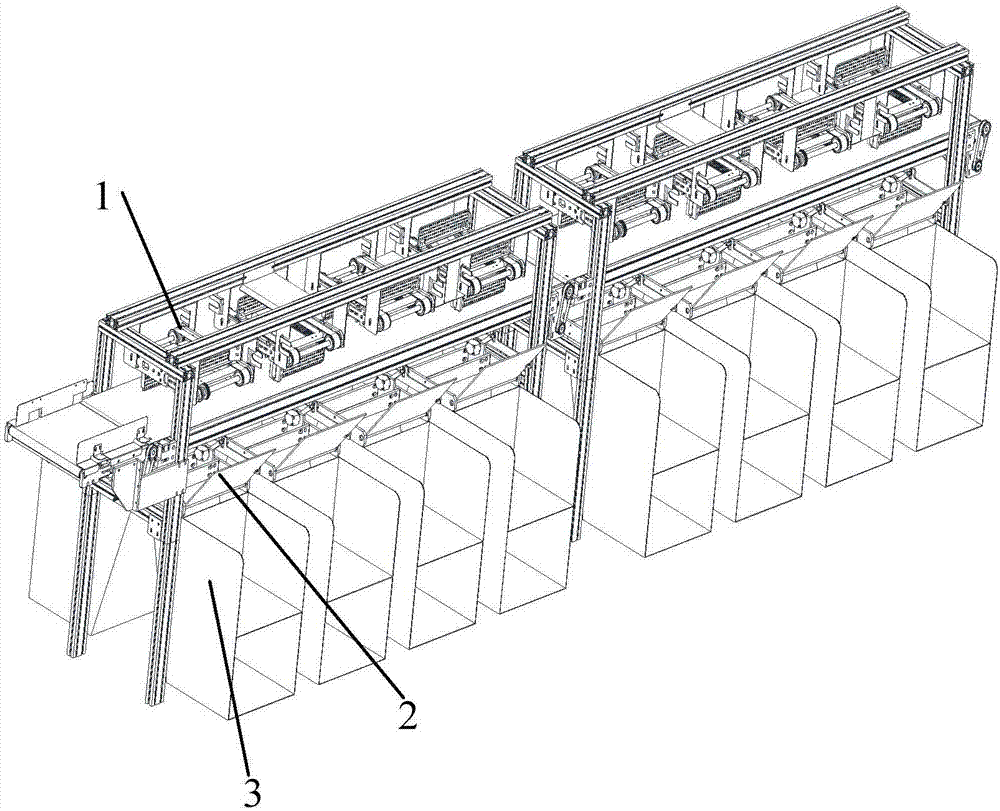

[0032] Such as figure 1 As shown, the sorting equipment includes the primary sorting and conveying unit 1 on the upper layer and the secondary guiding sorting unit 2 connected to it on the lower layer. The primary sorting and conveying unit 1 has two outlet stations on the left and right, The left and right sides of the secondary guide sorting unit 2 are connected with a feed bin unit 3 respectively, and each side feed bin unit is provided with at least two storage positions.

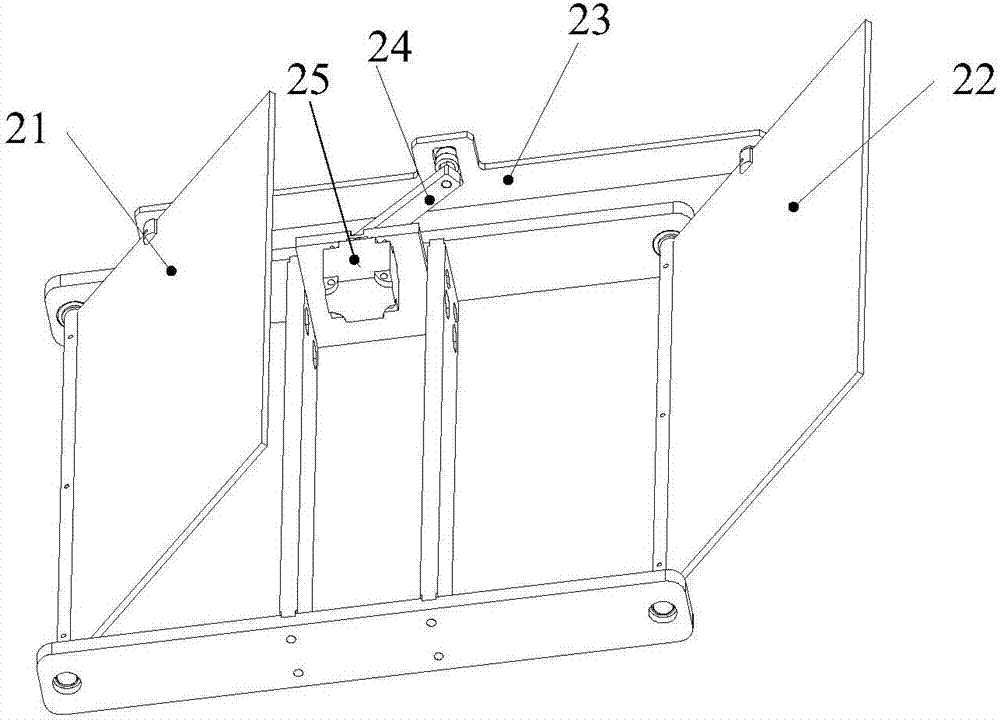

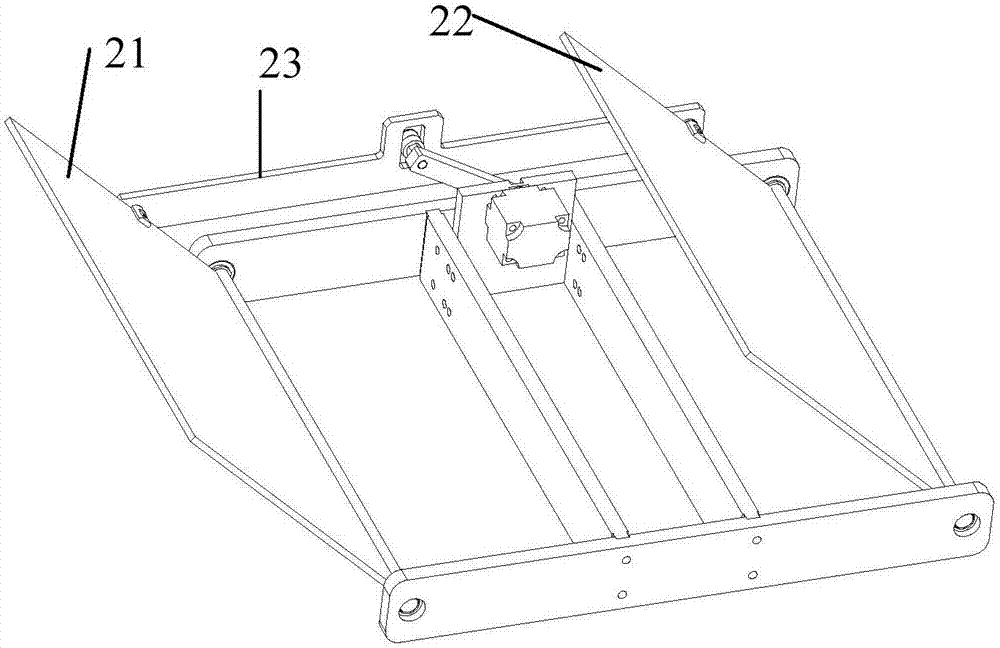

[0033] Such as Figure 2~3 As shown, the secondary guide sorting unit 2 includes two left and right rotating shafts arranged in parallel, the rotating shafts are freely rotatably supported on the front and rear frame parts, and a guide plate is fixed on each rotating shaft, betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com