An intelligent conveying device for hub processing

A technology of processing intelligence and conveying device, applied in the direction of conveyor objects, transportation and packaging, packaging, etc., can solve the problems of poor product quality stability and uniformity, increased labor cost, low automation level, etc., to achieve stable product quality. , The effect of reducing labor costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

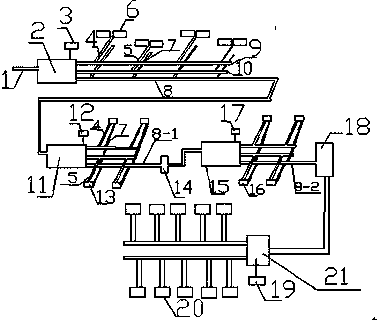

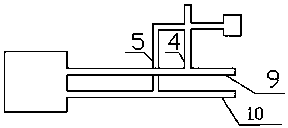

[0020] Such as figure 1 , figure 2 As shown, an intelligent conveying device for wheel hub processing includes: blank collection roller table 1, blank identification device 2, blank identification device 2 is connected with first lower roller table 8, upper roller table 9, middle roller table 10, upper roller table 9. The middle roller table 10 is connected to multiple machine tools 6 through the upper roller table branch line 4 and the middle roller table branch line 5 respectively. 8. The semi-finished product is transported to the semi-finished product identification device 11 through the first lower roller table 8. The blank identification device 2 is provided with a first wheel type distribution control module 3, and the first wheel type distribution control module 3 is connected with the blank identification device 2 and multiple The machine tool 6 is connected, and the first wheel type distribution control module 3 matches the identified blank product model with the p...

Embodiment 2

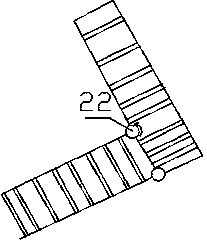

[0022] Such as figure 1 , figure 2 , Figure 4 As shown, the structure of the hub processing intelligent conveying device is basically the same as that of Embodiment 1, the difference is that a moving push rod 23 is provided at the vertical corner where the roller table is connected, and the moving direction of the moving push rod 23 is perpendicular to the roller table The direction of movement, moving the push rod to push the product on the roller table from one roller table to another roller table, this control method can realize the control of the product at the processing end, the product to be processed or tested stays at the vertical corner, when the previous product When the processing or detection is completed, the moving push rod receives the signal and transports the next product to be processed to the processing or detection end.

[0023] To sum up, the use of the wheel hub processing intelligent conveying device of the present invention greatly reduces the labo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com