Sorting wagon loading state detecting system based on gray scale meters and sorting system

A technology for sorting trolleys and loading status, which is applied in the detection system of sorting trolley loading status and sorting system based on gray scale meter, and can solve the problem of express sorting errors, simultaneous transmission to a sorting trolley, and express delivery not delivered and other issues to achieve the effect of avoiding sorting errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

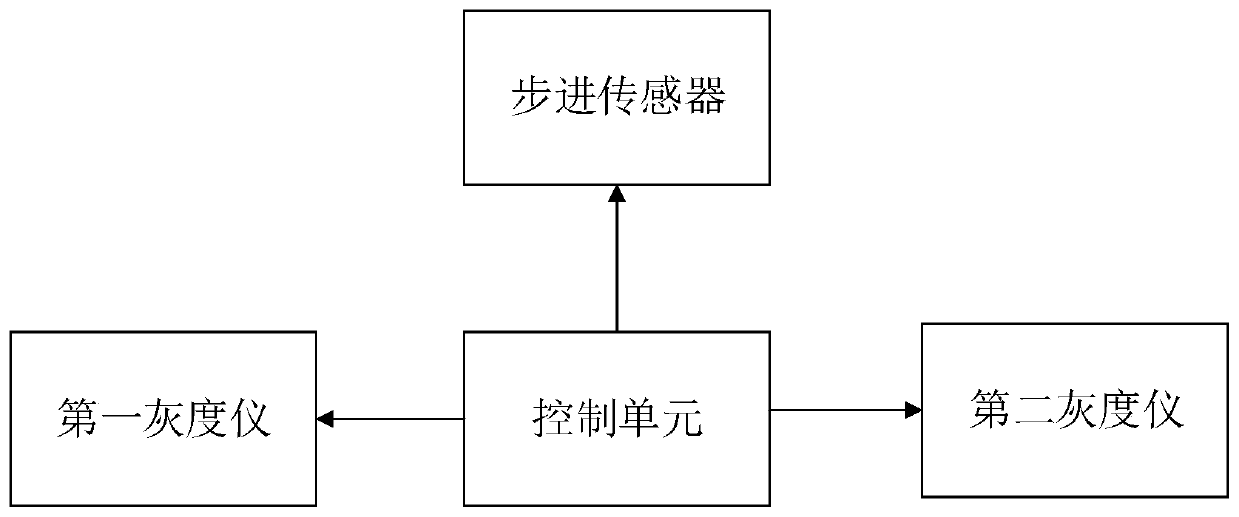

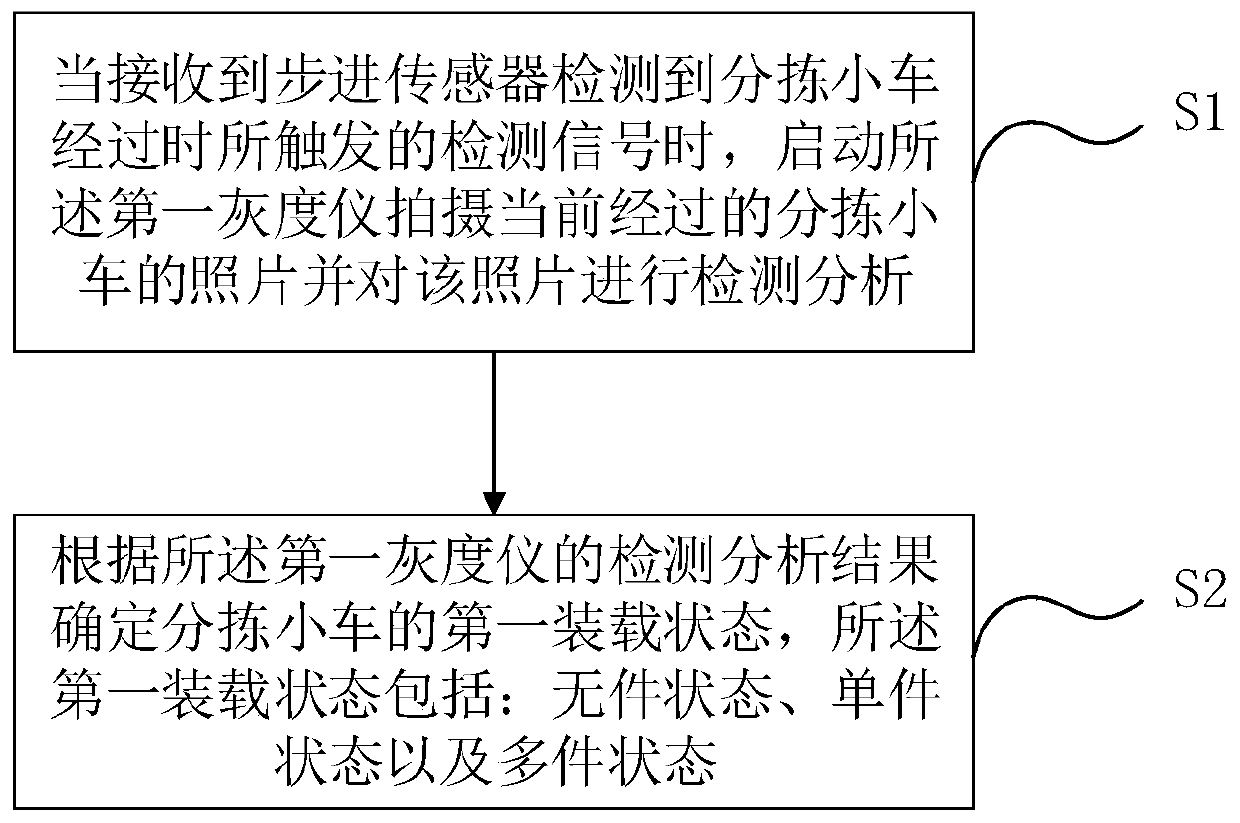

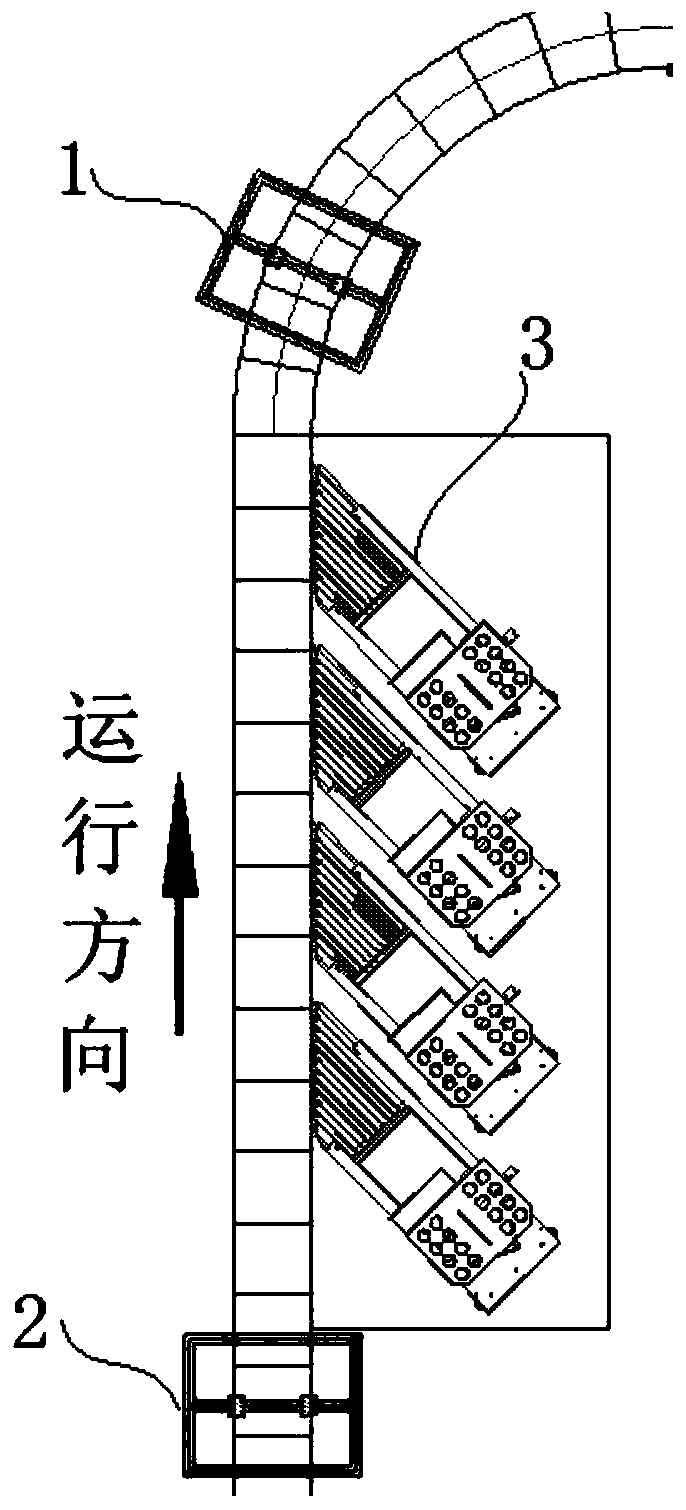

Method used

Image

Examples

Embodiment approach

[0047] As a preferred implementation, the method further includes: marking the sorting trolley whose second loading state is the status of the item as an abnormal sorting trolley so that the express items at the loading entrance will not be loaded onto the sorting trolley . Determine the unloading status of the sorting trolleys according to the second loading status, and mark the sorting trolleys that still have express parcels as abnormal sorting trolleys, so that the sorting system will not continue to upload express parcels to these sorting trolleys when loading on the trolley to avoid sorting errors, and the follow-up staff can process the express items on these sorting trolleys according to the records of the abnormal sorting trolleys.

[0048] As a preferred embodiment, the second loading state also includes the state of the leading zone and the state of the backward zone. The state of the leading zone means that the express on the sorting trolley exceeds the front of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com