Gear packaging, conveying and sorting device

A sorting device and gear technology, applied in classification, solid separation, chemical instruments and methods, etc., can solve the problems of blind gears, low efficiency of manual sorting, high labor intensity, etc., to achieve easy removal and avoid sorting errors , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

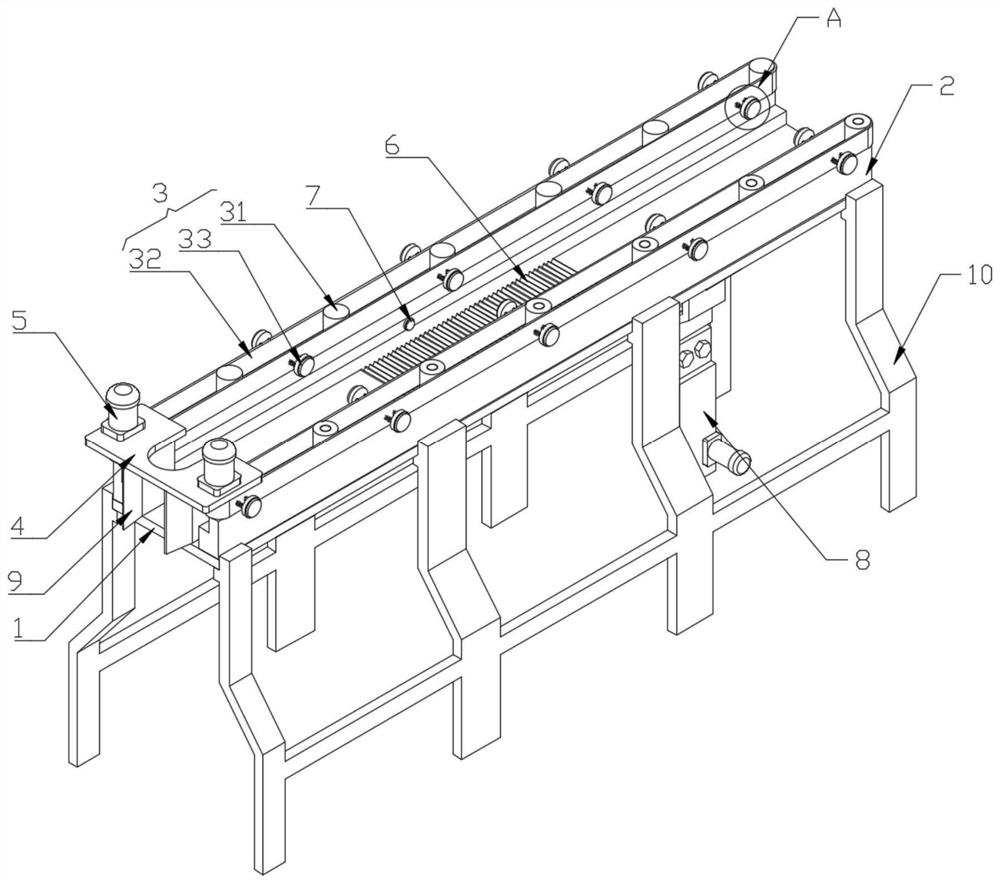

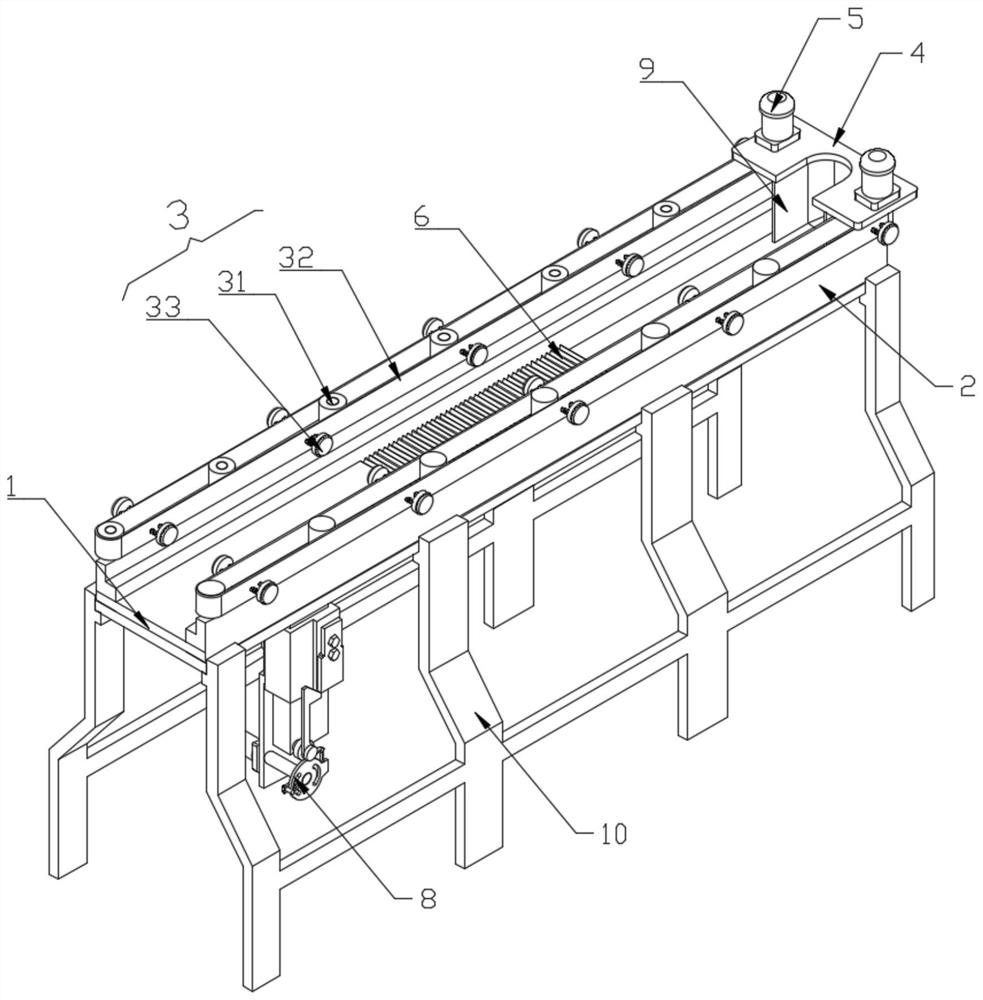

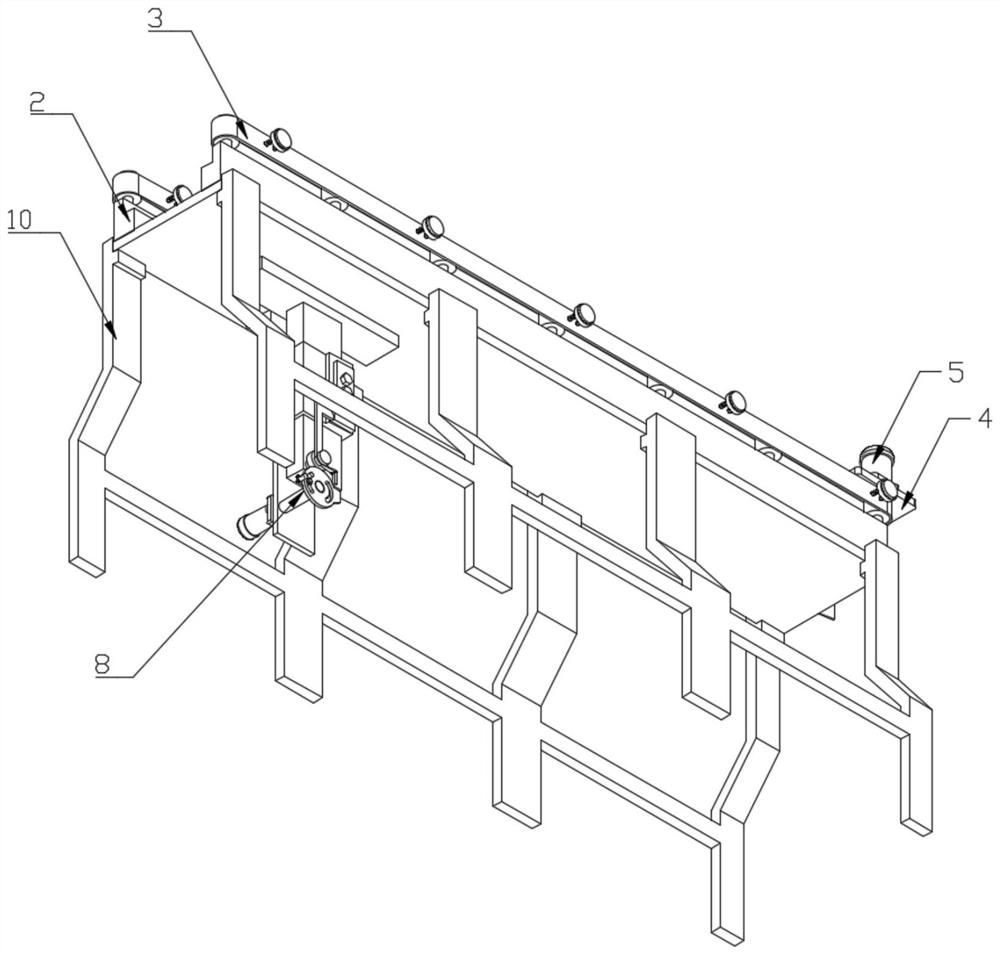

[0037] Please refer to Figure 1 to Figure 9 As shown, it has shown the specific structure of a preferred embodiment of the present invention, a gear packaging conveying and sorting device, including a workbench 1, and the two sides above the workbench 1 are fixedly installed with mounting seats 2; A gear clamping transmission assembly 3 is provided above each of the mounting seats 2; a toothed groove 6 is provided at the middle position of the top of the workbench 1; an opening groove 11 is provided on one side of the toothed groove 6 ; The gear sorting ejection assembly 8 is arranged directly below the opening groove 11; the gear sorting ejection assembly 8;

[0038]The gear sorting ejection assembly 8 includes a jacking block 81, the jacking block 81 is movably connected inside the opening groove 11, and a driving rod 82 is fixed below the jacking block 81; the lower end of the driving rod 82 Socketed in the fixed shell 83 and flexibly connected, the lower end of the drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com