Full-automatic feeding and discharging system

A fully automatic technology for loading and unloading, applied in packaging and other directions, can solve the problems of missed detection of circuit boards, low efficiency, damaged circuit boards, etc., achieve high accuracy, avoid sorting errors, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

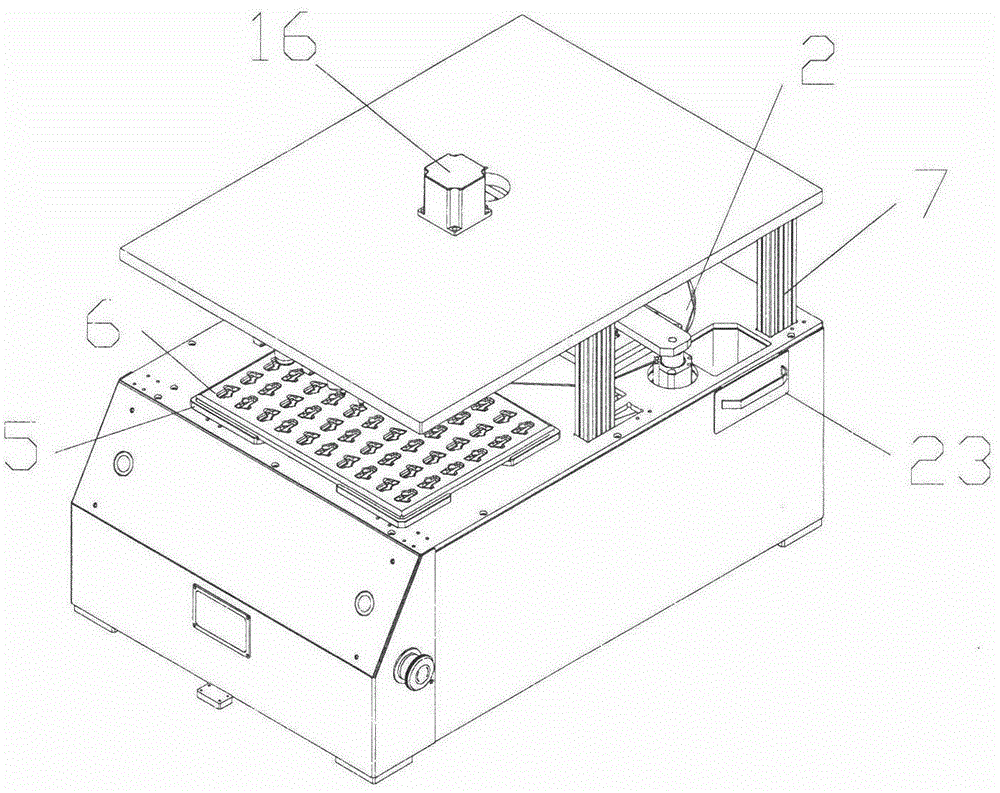

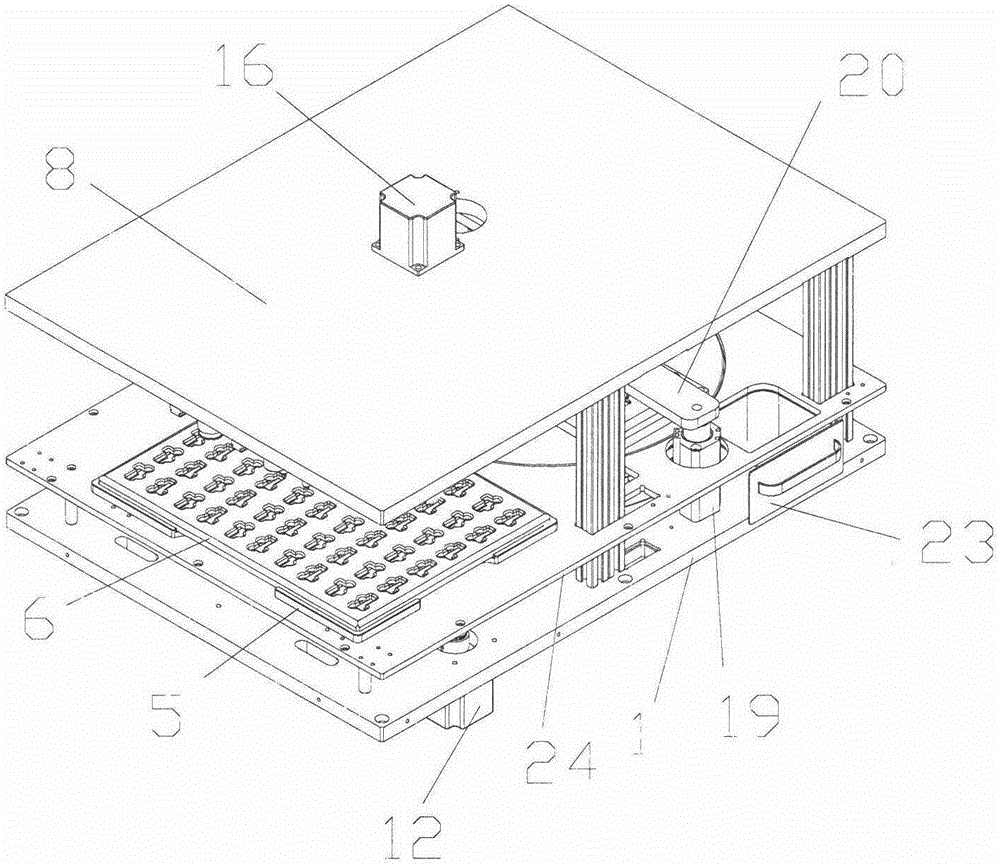

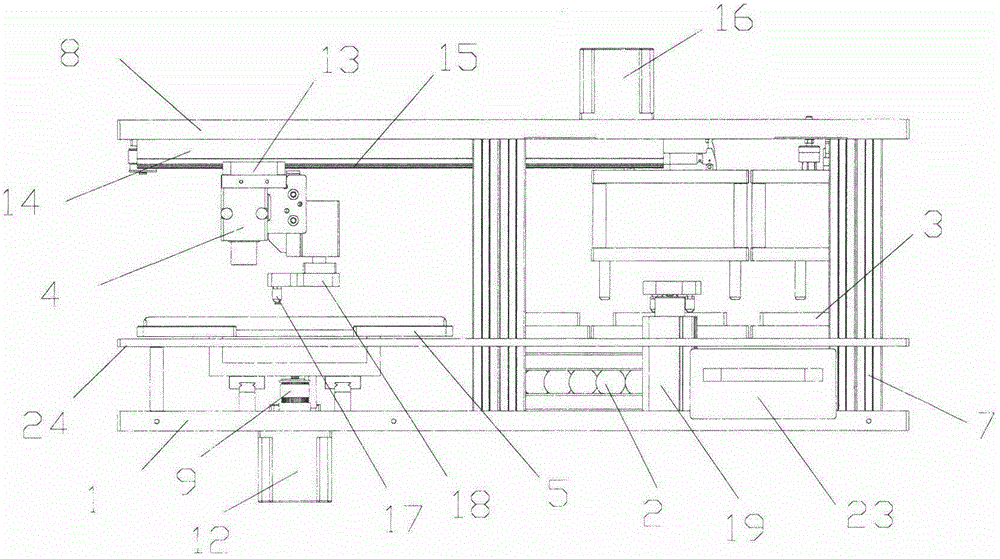

[0027] A fully automatic loading and unloading system, including a workbench, such as figure 1 As shown, a turntable 2 is installed in the center of the workbench, please combine image 3 with Figure 4 , a function testing machine 3, a camera 4, a material retrieving mechanism and a sorting mechanism are provided on the periphery of the turntable 2, and the functional testing machine 3, the material retrieving mechanism and the sorting mechanism are fixed on the workbench superior.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com