Spiral arc bevel gear mechanism without relative sliding

A technology of relative sliding and circular arc teeth, which is applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., and can solve problems such as tooth surface wear and plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

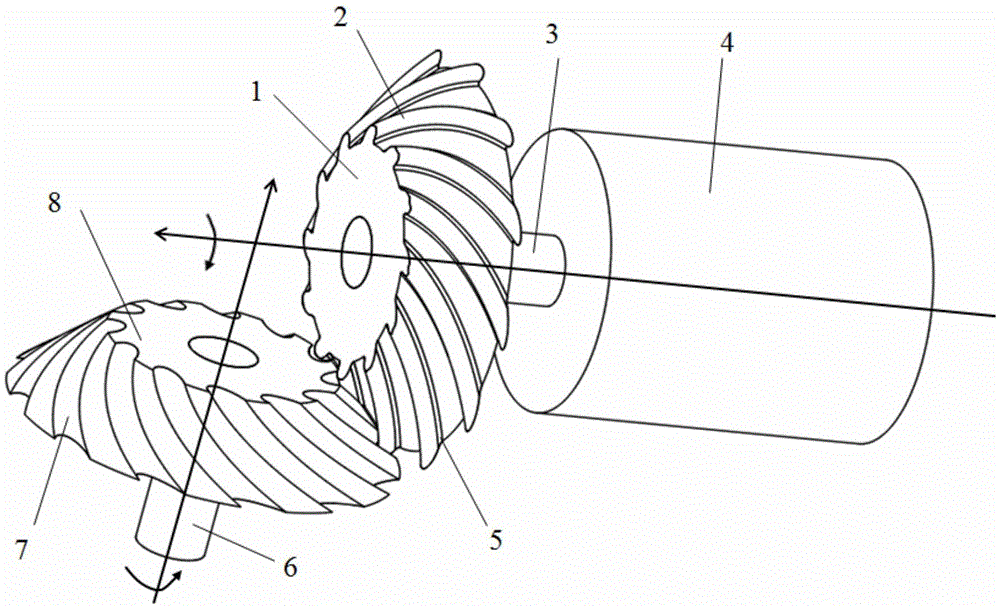

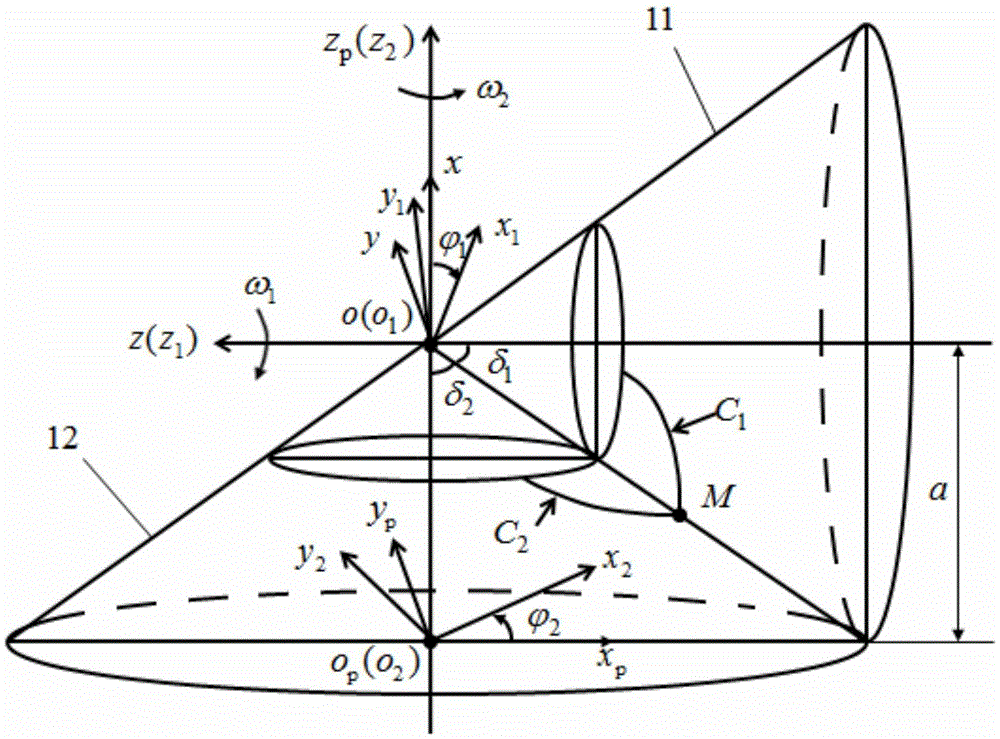

[0053] Embodiment 1: The present invention provides a spiral circular arc bevel gear mechanism without relative sliding, which is applied to the transmission with a transmission ratio of 1 between plane orthogonal axes, and its structure is as follows figure 1 As shown, it includes a small wheel 1 and a large wheel 8. The small wheel 1 and the large wheel 8 form a pair of transmission pairs. The small wheel 1 is connected to the input shaft 3, and the large wheel 8 is connected to the output shaft 6, that is, the large wheel 8 is connected to the output shaft 6 through the output shaft 6. The driven loads are connected; the axes of the small wheel 1 and the big wheel 8 are perpendicular to each other. figure 2 It is a schematic diagram of the spatial coordinate system of the non-relative sliding helical arc bevel gear mechanism of the present invention.

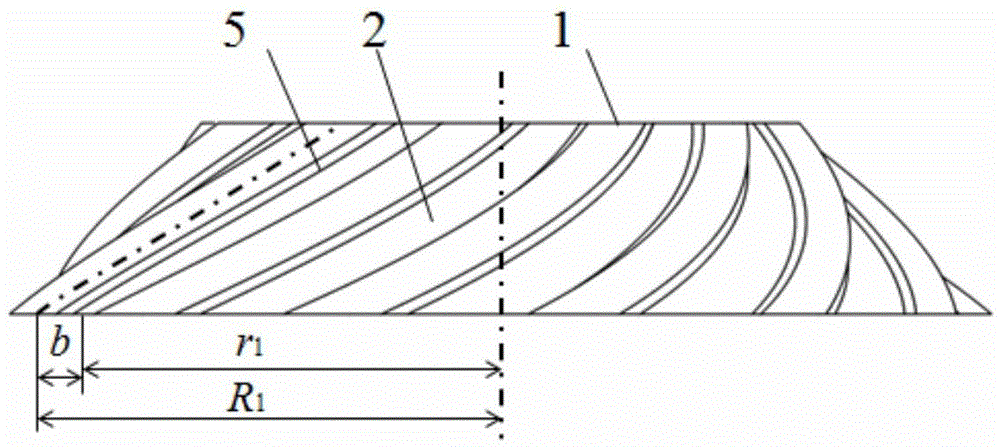

[0054] see figure 1 , 2 , 3, 4, the radius of the large end of the theoretical indexing cone of the small wheel is R 1 ...

Embodiment 2

[0092] Embodiment 2: A spiral circular arc bevel gear mechanism without relative sliding of the present invention is applied to speed-up transmission in a plane orthogonal axis transmission mode. Such as Figure 7 As shown, the large wheel 8 is used to connect the input shaft 3, and the small wheel 1 is connected to the output shaft 6, that is, the small wheel 1 is connected to the driven load through the output shaft 6; the axes of the small wheel 1 and the large wheel 8 are perpendicular to each other. In this embodiment, there are eight spiral arc grooves 7 on the bull wheel 8, and four spiral arc teeth 2 on the small wheel 1. When the input shaft 3 drives the bull wheel 8 to rotate, due to the installation of the bull wheel 8 and the small wheel At 1 o'clock, the spiral arc groove 7 on the big wheel 8 is in mesh with a spiral arc tooth 2 on the small wheel. When the big wheel 8 rotates, the large and small wheels rotate to keep the spiral arc groove and the spiral arc toot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com