LED lamp with high power

An LED lamp, high-power technology, applied in the cooling/heating device, lighting and heating equipment, electrical components and other directions of lighting devices, can solve the problems of poor product heat dissipation, not suitable for LED, poor sealing, etc., to increase the light output efficiency , The effect of sealing and protecting the chip and preventing glue from climbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

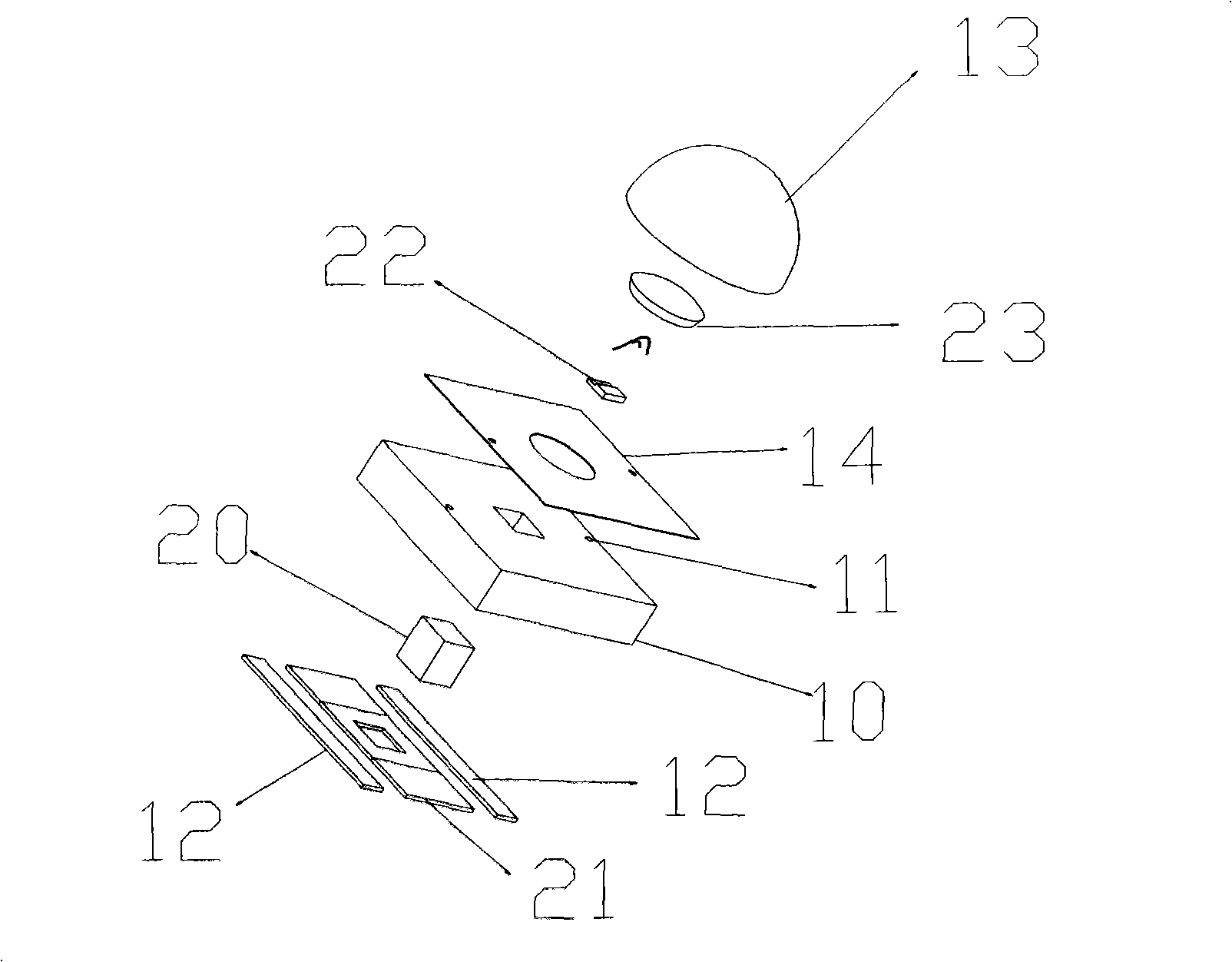

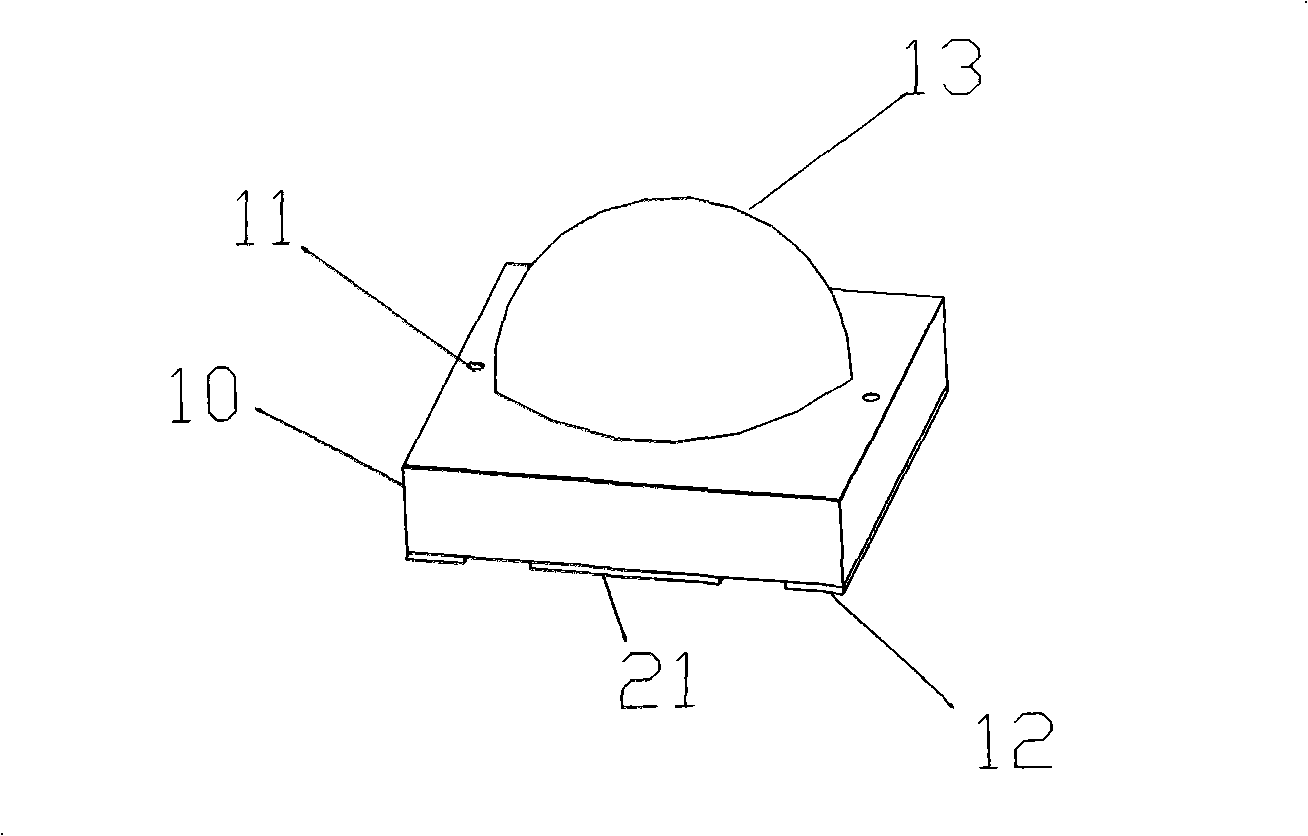

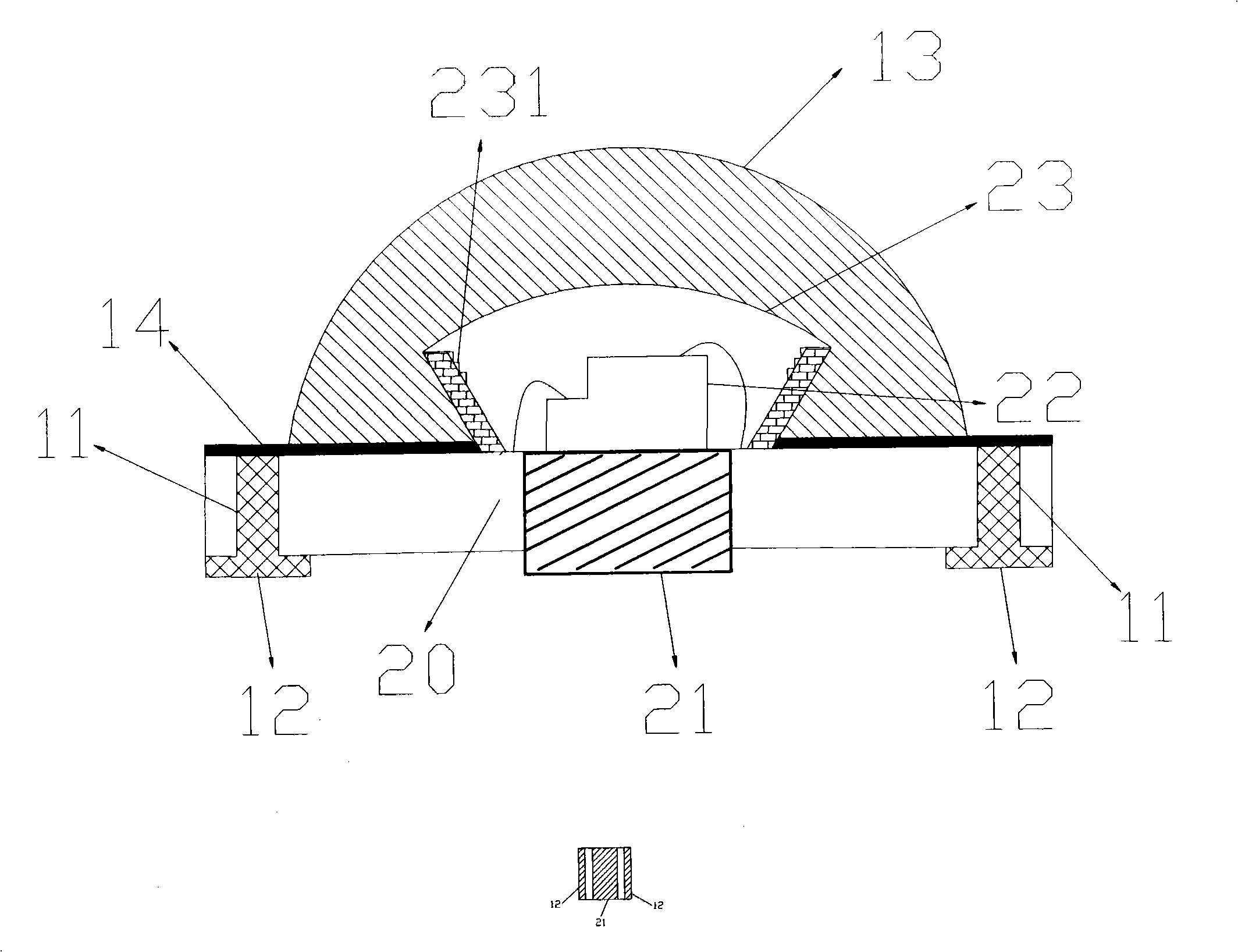

[0024] As shown in the drawings, in an embodiment of a high-power LED lamp of the present invention, it includes a thermally conductive and insulating substrate 10 and a thermally conductive base column 20 that is the same thickness as the substrate 10 and embedded in the substrate 10. The base column 20 is a cuboid, its lower surface is connected to a cooling plate 21, and the upper surface is fixed with a chip 22; the upper surface of the substrate 10 is fixed with a transparent cover 23, and the circuit and electrodes are arranged, and the through hole 11 through which the circuit passes is arranged on the edge, and the bottom of the through hole 11 The conductive electrode sheet 12 is separated from the heat dissipation plate 21 of the base column 20 to separate the heat conduction part from the conduction part, and the lens 13 is encapsulated on the transparent cover 23 of the substrate 10 .

[0025] The transparent cover 23 is an inverted conical shape with a large top an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com