Rubber film separant

A technology of release agent and film, applied in the direction of coating, can solve the problems affecting the use effect, the influence of processing technology, the deposition of effective components, etc., and achieve the effect of good wetting and isolation, preventing dust and glue, and good isolation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

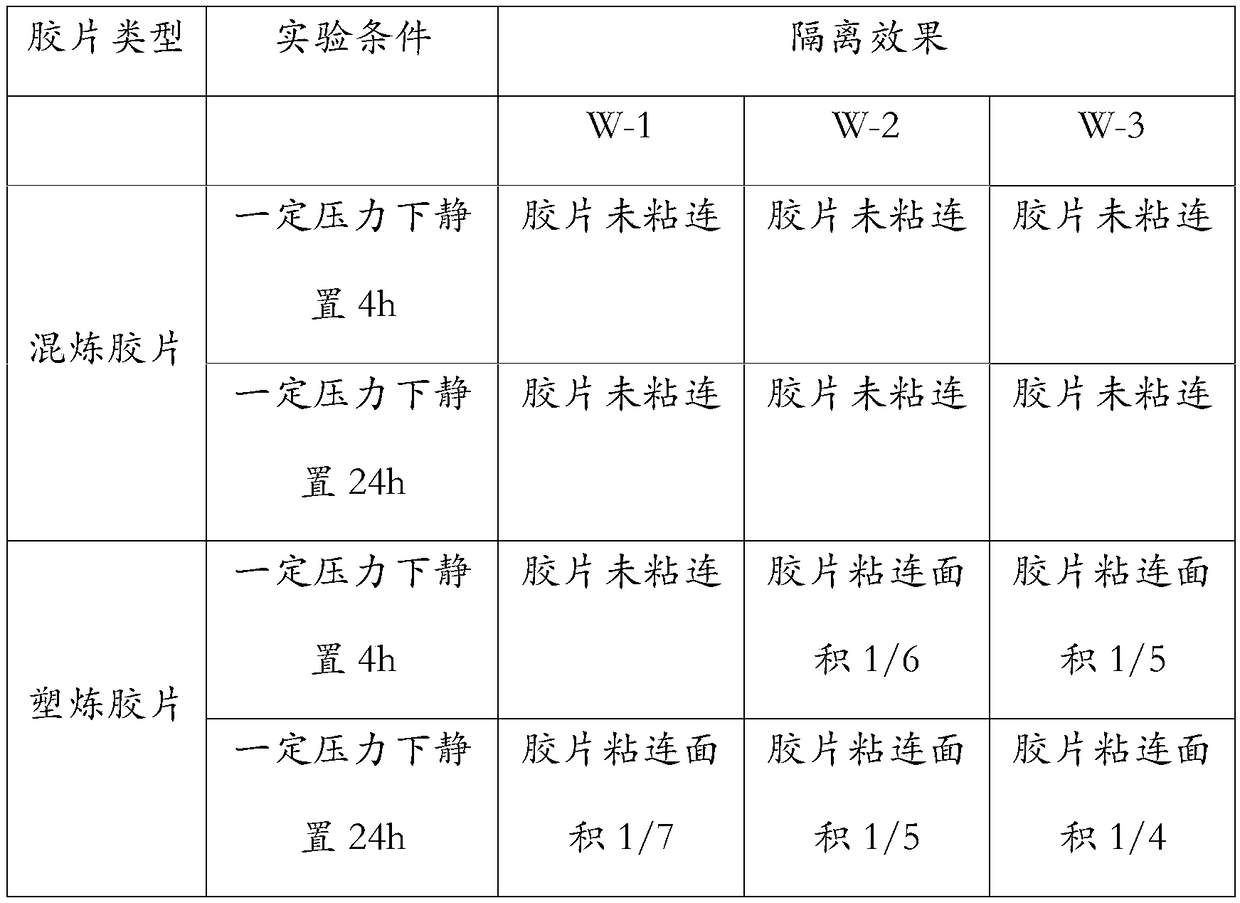

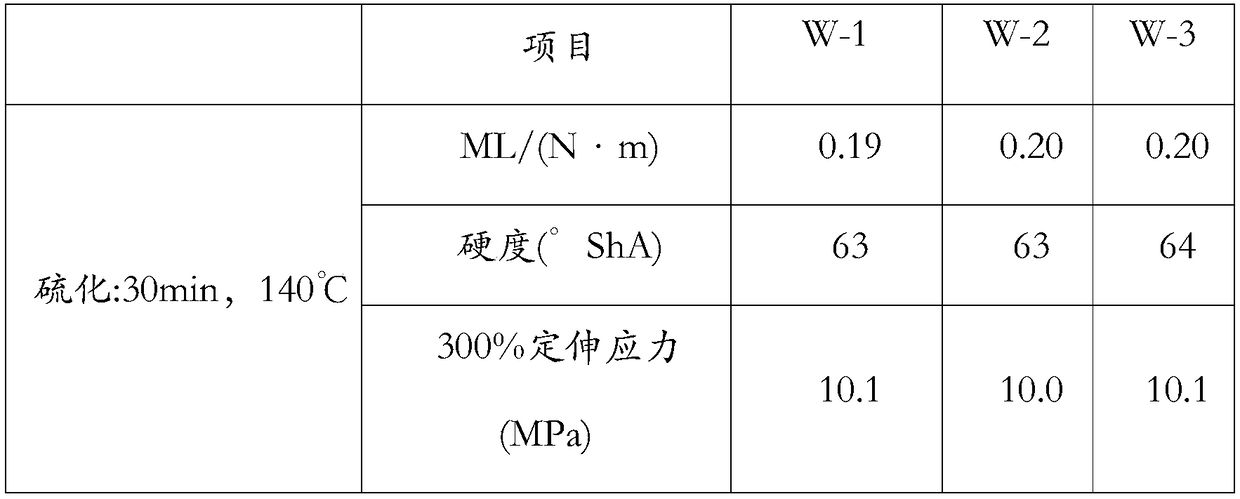

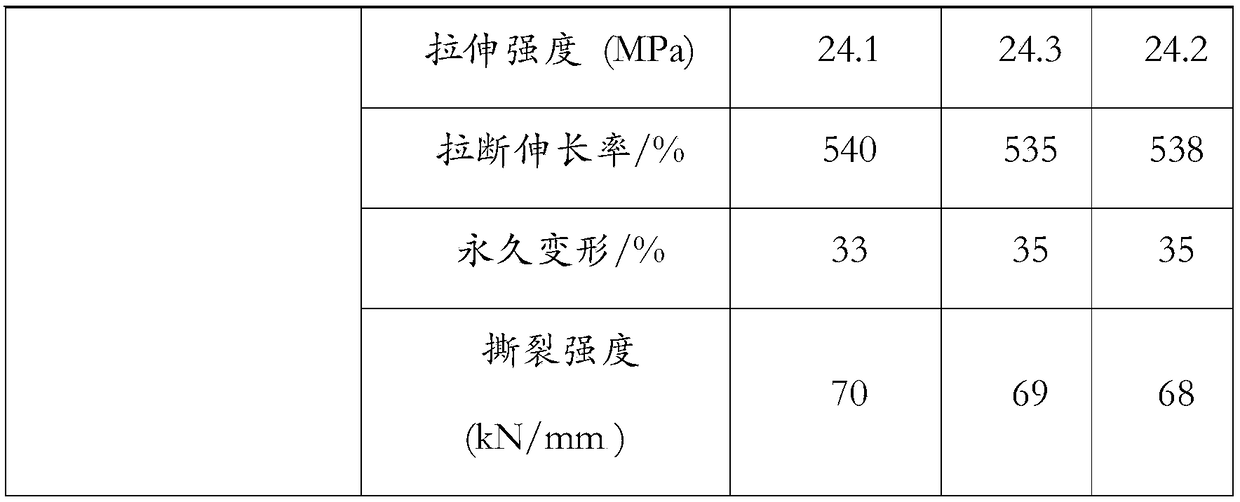

Examples

Embodiment 1

[0021] A film release agent, in terms of mass percentage, comprising the following components: 10-30 parts of fatty acid salt, 5-10 parts of inorganic thickener, 1-5 parts of organic thickener, and 50-75 parts of inorganic filler , wherein the fatty acid salt is one or both of fatty acid calcium, fatty acid zinc, fatty acid magnesium, fatty acid potassium, and fatty acid sodium; the inorganic thickener is organic bentonite, fumed silica, diatomaceous earth, silicon One or both of lithium magnesium acid; the organic thickener is sodium carboxymethyl cellulose, hydroxymethyl cellulose, guar gum, chitosan, polyacrylamide, sodium polyacrylate, polyethylene One, two or more of alcohol; the inorganic filler is one, two or more of talcum powder, double fly powder, pottery clay, kaolin, mica powder, and white bag soil.

Embodiment 2

[0023] A kind of preparation of film release agent:

[0024] 30 parts of fatty acid zinc, 5 parts of organic bentonite, 1.5 parts of sodium carboxymethylcellulose, 1 part of polyvinyl alcohol, and 62.5 parts of inorganic fillers are weighed according to the material ratio, added to a powder mixer, stirred evenly, and weighed for packaging.

Embodiment 3

[0026] A kind of preparation of film release agent:

[0027] 25 parts of fatty acid magnesium, 8 parts of organic bentonite, 1.5 parts of guar gum, and 45.5 parts of inorganic filler are weighed according to the material ratio, added to a powder mixer, stirred evenly, weighed and packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com