Film material

A film material and base layer technology, applied in the direction of flexible slender elements, flexible coverings, packaging, etc., can solve the problems of loss of isolated moisture, air, decreased packaging durability, unfavorable content preservation, etc., to achieve good isolation of moisture , prevent slipping, and maintain bright colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

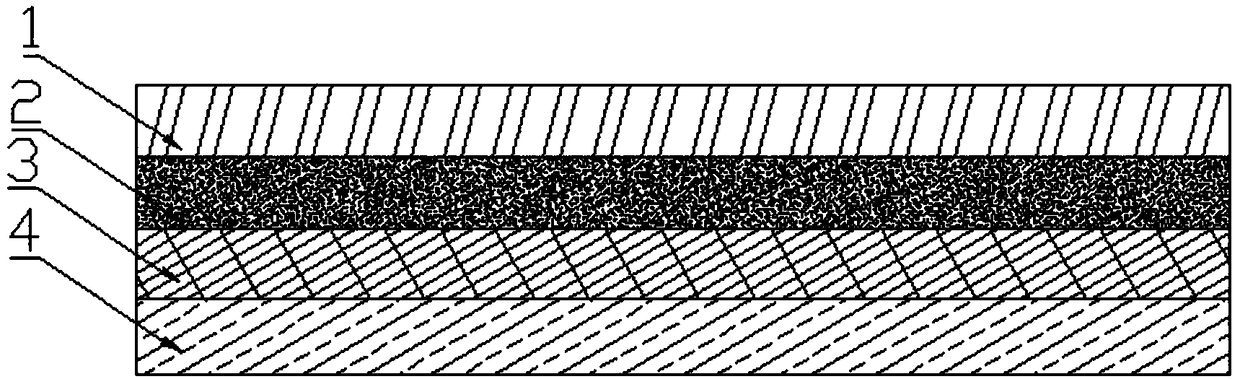

[0018] A film material, comprising a PET base layer with a roughness of 1.0-2.5nm, an LDPE layer covering the base layer in sequence, a blended layer of CPP and PA, and a BOPP layer coated on the blended layer, the thickness of the film material It is 0.01~0.05mm; the tensile modulus of the membrane material is 500-1300MPa. It is suitable for film packaging of most products and has good anti-exposure performance.

Embodiment 2

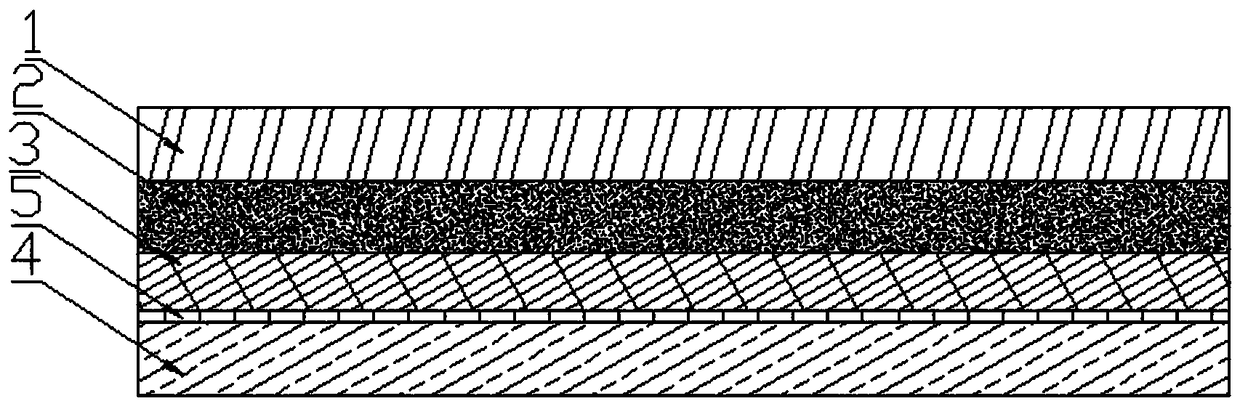

[0020] A film material, comprising a PET base layer with a roughness of 1.2-3.5nm, an ink layer covering the base layer, an LDPE layer, a blended layer of CPP and PA, and a BOPP layer coated on the blended layer, the film The thickness of the material is 0.01~0.05mm; the tensile modulus of the film material is 500-1300MPa, and the adhesion energy is 0.8-1.5mJ. While having good anti-exposure performance, it also has a more effective ability to isolate moisture and air.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com