Fire-resistant paper surface gypsum board and preparation method thereof

A kind of gypsum board, fire-resistant technology, applied in the direction of floors, building components, buildings, etc., can solve the problem that glass fibers are difficult to disperse evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

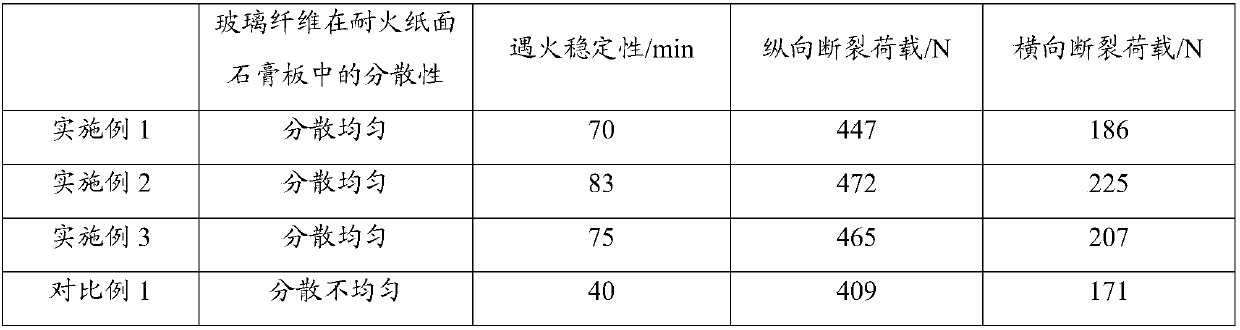

Examples

Embodiment 1

[0023] 1) Weighing 100 parts by weight of gypsum clinker, 0.1 parts by weight of glass fibers with an average monofilament diameter of 10 μm and a length of 12 mm, 0.8 parts by weight of starch and 0.06 parts by weight of foaming agent;

[0024] 2) Add the glass fibers into the water, first stir for 10 minutes with a stirring device with a stirring paddle (the speed of the stirring paddle is 1500r / min), and then disperse it with an ultrasonic device (ultrasonic frequency is 55KHz, ultrasonic power is 0.7kw) for 15 minutes to make the glass Fibers are evenly dispersed in water.

[0025] 3) Add the aqueous solution uniformly dispersed with glass fibers, gypsum clinker, starch, and foaming agent into the mixer and stir fully to prepare a uniform slurry.

[0026] 4) The slurry is continuously poured between two layers of fire-resistant cardboard, and then extruded to obtain a fire-resistant paper-faced gypsum board wet board;

[0027] 5) The wet fire-resistant gypsum board is sol...

Embodiment 2

[0029] 1) Weigh 100 parts by weight of gypsum clinker, 0.3 parts by weight of glass fibers with an average monofilament diameter of 15 μm and a length of 12 mm, 0.8 parts by weight of starch and 0.06 parts by weight of foaming agent;

[0030] 2) Add the glass fibers into the water, first stir for 10 minutes with a stirring device with a stirring paddle (the rotation speed of the stirring paddle is 1000r / min), and then disperse it with an ultrasonic device (ultrasonic frequency is 40KHz, ultrasonic power is 0.6kw) for 10 minutes to make the glass Fibers are evenly dispersed in water.

[0031] 3) Add the aqueous solution uniformly dispersed with glass fibers, gypsum clinker, starch, and foaming agent into the mixer and stir fully to prepare a uniform slurry.

[0032] 4) The slurry is continuously poured between two layers of fire-resistant cardboard, and then extruded to obtain a fire-resistant paper-faced gypsum board wet board;

[0033] 5) The wet fire-resistant gypsum board ...

Embodiment 3

[0035] 1) Weigh 100 parts by weight of gypsum clinker, 0.5 parts by weight of glass fibers with an average monofilament diameter of 20 μm and a length of 12 mm, 0.8 parts by weight of starch and 0.06 parts by weight of foaming agent;

[0036] 2) Add the glass fibers into the water, first stir with a stirring device with a stirring paddle (the speed of the stirring paddle is 500r / min) for 5 minutes, and then disperse it with an ultrasonic device (the ultrasonic frequency is 25KHz, and the ultrasonic power is 0.5kw) for 5 minutes to make the glass Fibers are evenly dispersed in water.

[0037] 3) Add the aqueous solution uniformly dispersed with glass fibers, gypsum clinker, starch, and foaming agent into the mixer and stir fully to prepare a uniform slurry.

[0038] 4) The slurry is continuously poured between two layers of fire-resistant cardboard, and then extruded to obtain a fire-resistant paper-faced gypsum board wet board;

[0039] 5) The wet fire-resistant gypsum board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com