A nano-modified aluminum alloy material and its preparation method and energy-saving and environment-friendly power fittings produced therefrom

An aluminum alloy material, nano-modification technology, applied in the field of aluminum matrix composite materials and power fittings preparation, can solve the problems of poor processing performance, limitations, unsuitability for mass production, etc., and achieve damage load enhancement, installation and maintenance. The effect of convenience and large magnetic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of a nano-modified aluminum alloy material, the specific steps are as follows:

[0027] 1) Mix silicon powder and carbon nanotubes with a mass ratio of 7:3 and perform mechanical ball milling. By controlling the ball milling process parameters, the silicon powder and carbon nanotubes are fully mixed to construct a core-shell structure and obtain silicon-coated carbon nanotubes;

[0028] 2) Add the silicon-coated carbon nanotubes obtained in step 1) into the 6005 aluminum alloy matrix for semi-solid stirring, the amount of silicon-coated carbon nanotubes added is 0.25wt%, the stirring temperature is 600°C, the stirring time is 30min, and then the temperature is raised to Cast at 740°C to obtain nano-modified aluminum alloy casting rods.

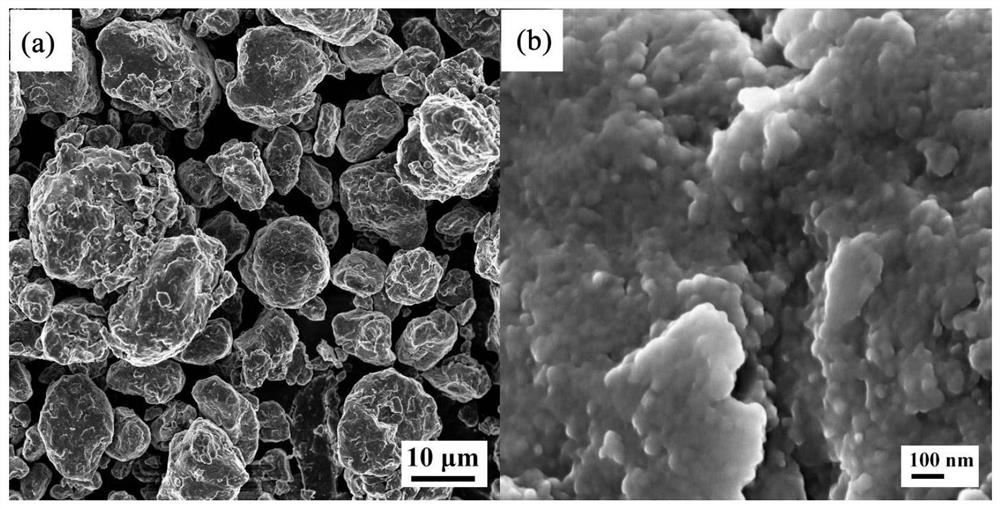

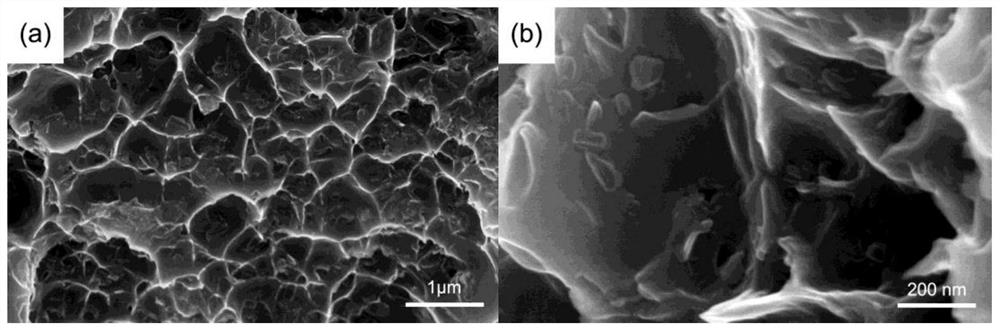

[0029] Such as figure 1 Shown is the SEM photo of silicon-coated carbon nanotubes after ball milling. The mixed powder of carbon nanotubes and silicon powder is repeatedly impacted by the ball milling medium, and h...

Embodiment 2

[0032] A preparation method of a nano-modified aluminum alloy material, the preparation method is similar to that of Example 1, except that the mass ratio of silicon powder to carbon nanotubes is 7:6.

[0033] Performance tests were performed on the nano-modified aluminum alloy material prepared in this example, and the test results are shown in Table 1.

Embodiment 3

[0035] A preparation method of a nano-modified aluminum alloy material, the preparation method is similar to that of Example 1, except that the mass ratio of silicon powder to carbon nanotubes is 14:3.

[0036] Performance tests were performed on the nano-modified aluminum alloy material prepared in this example, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com