High-purity Cu bonding wire

A high-purity, lead-in technology, used in electrical components, circuits, electrical solid devices, etc., can solve problems such as excellent hardness, inability to draw circuits, and IC chip cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] [Manufacturing method of copper lead for ball bonding]

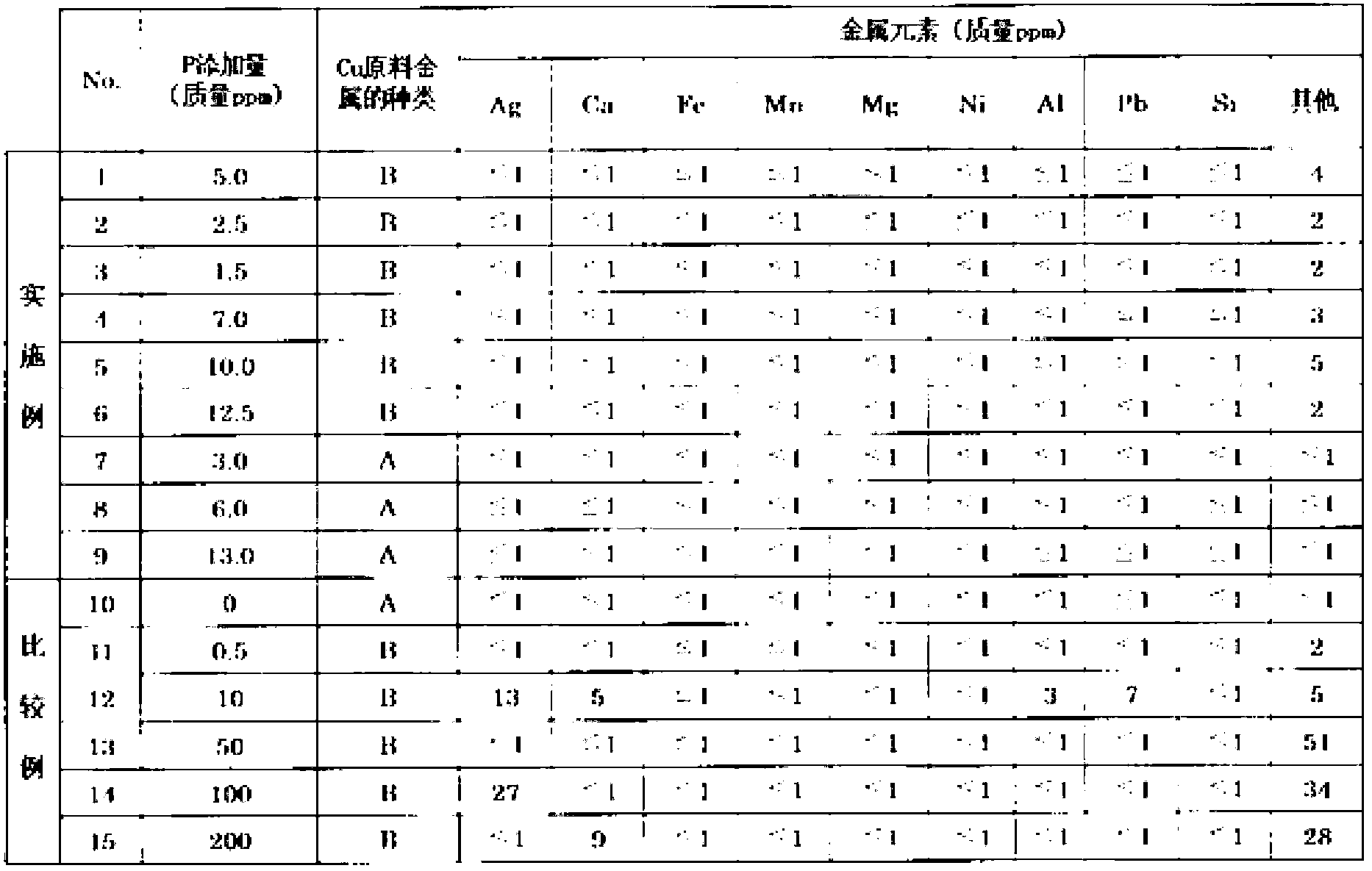

[0045] A method of manufacturing the copper alloy lead for ball bonding according to the present invention will be described. Prepare to add high-purity copper (Cu) metal of 99.9999 mass% or more (as Cu raw material metal [A]) and 99.999 mass% or more of high-purity copper (Cu) metal (as Cu raw material metal [B]) Specimens having copper alloy lead compositions shown in Table 1 containing a predetermined amount of phosphorus (P) were used. Samples with these compositions were processed into soldered leads in the same manner as the method for producing high-purity gold leads. First, a predetermined amount of raw material is melted in a vacuum melting furnace and cast into an ingot. This ingot was rolled with a groove roll and subjected to debonding treatment, antirust treatment, etc., to produce a high-purity copper alloy lead wire with a diameter of 25 μm.

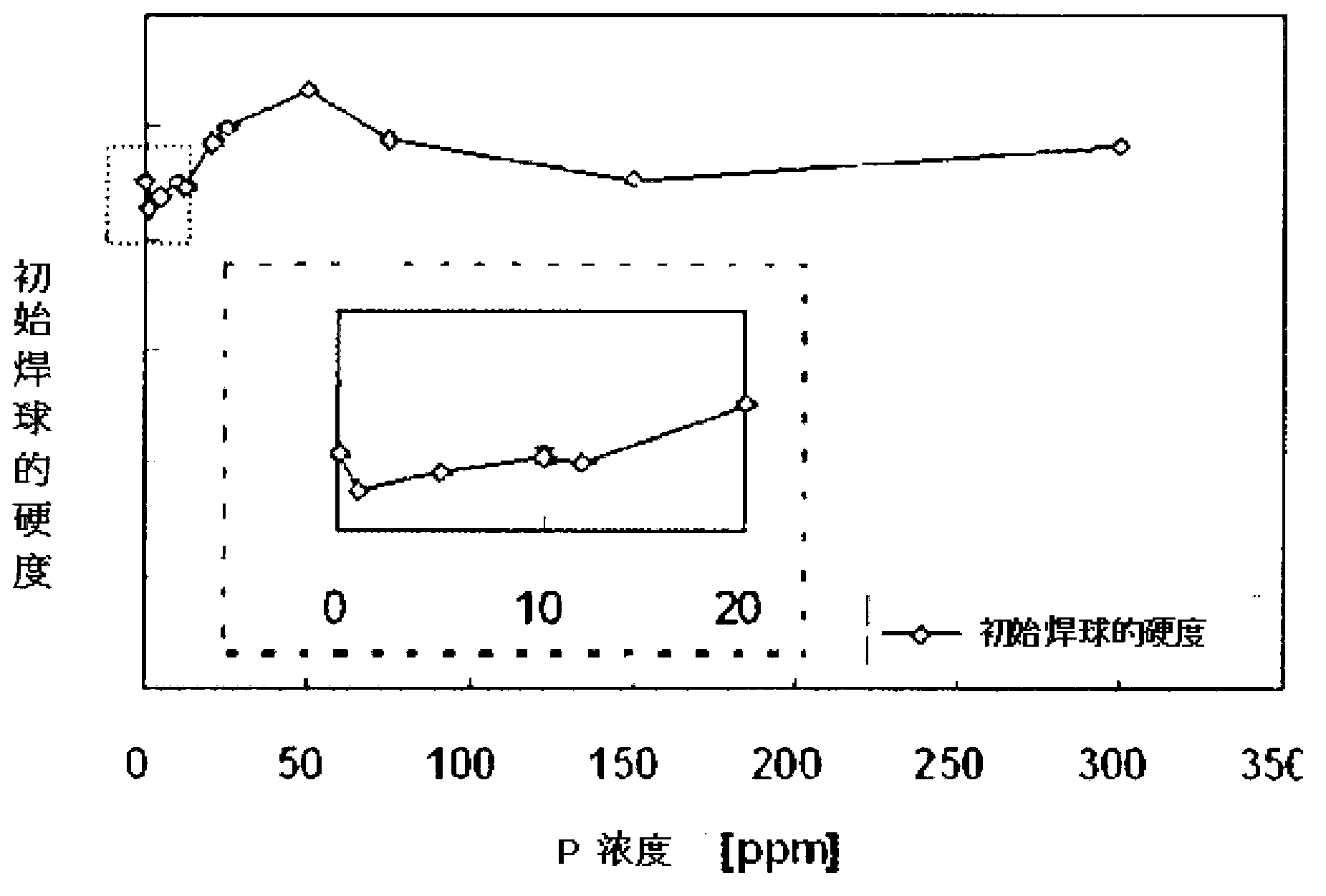

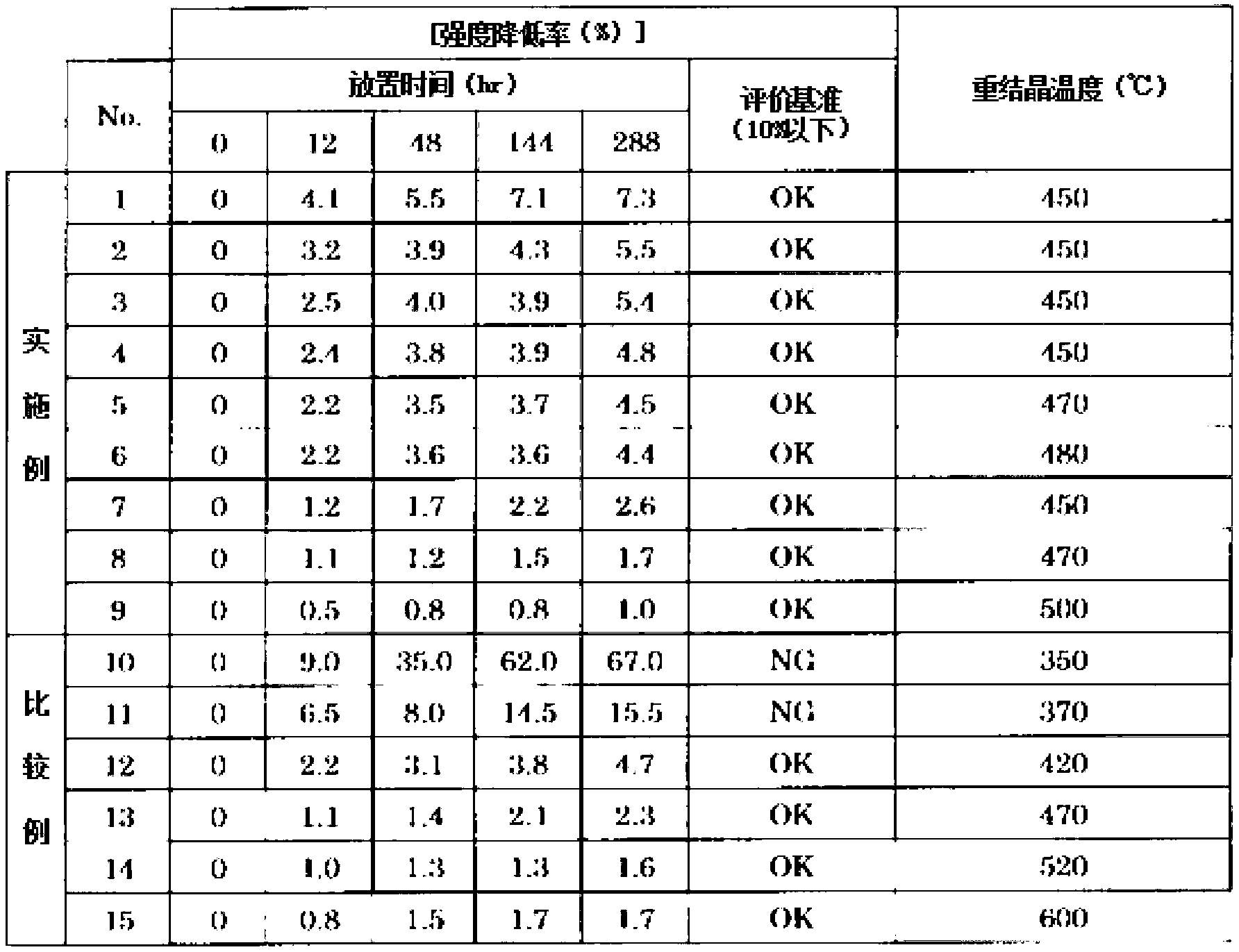

[0046] [Confirmation of aging softening effect]

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com