Anchor rope total length anchoring method for coal mine soft rock roadway

A full-length anchoring and soft rock technology, which is applied in mining equipment, earthwork drilling, bolt installation, etc., can solve the problems of not significantly improving the bearing capacity of surrounding rock, small breaking load of anchor cables, and weak active support. , to improve the bearing capacity of the surrounding rock, control the deformation of the surrounding rock, and simplify the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0020] The anchor cable full-length anchoring method used for soft rock roadways in coal mines of the present invention:

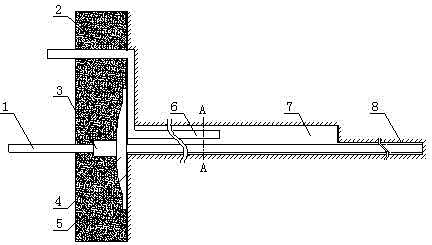

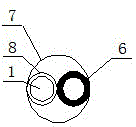

[0021] a. Construction drilling in the excavation working face of the soft rock roadway, first construct the grouting drilling 7 with a diameter of 42mm and a depth of 1000mm, and then continue inward along the bottom of the grouting drilling 7 with a diameter of 24mm and a depth of 1 8000mm anchor cable drilling 8;

[0022] b. Install the anchor cable 1 in the drilled hole according to the conventional existing technology, first send the anchoring agent into the drilled hole, then insert the anchor cable to stir the anchoring agent, and perform end anchoring;

[0023] c. After the end of the anchor cable is anchored, place a Z-shaped grouting pipe 6 at the grouting drilling hole. The middle section of the Z-shaped grouting pipe 6 is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com