Bonding alloy filamentary silver and preparation method thereof

A technology of alloy and silver wire, which is applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., and can solve problems such as technical differences and oxidation of bonding alloy silver wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

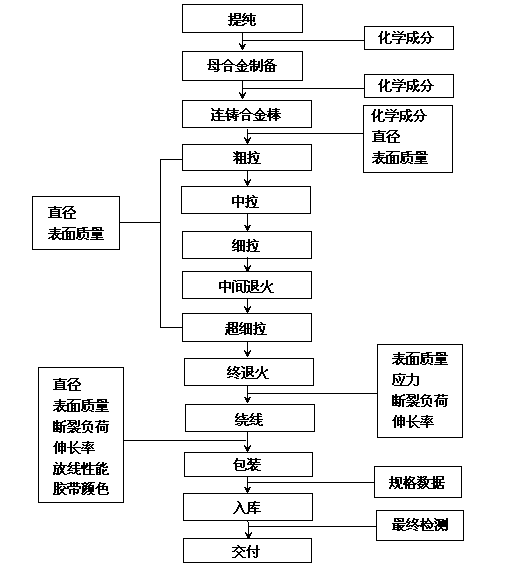

Method used

Image

Examples

Embodiment 1

[0086] The bonding alloy silver wire in this embodiment is composed of metal materials with the following weight ratio: gold (Au) with a purity of 99.999wt% 8wt%, palladium (Pd) with a purity of 99.97wt% 3wt%, commercially available purity It is 99.99% oxygen-free copper (Cu) 200ppm, calcium (Ca) 80ppm, cerium (Ce) 60ppm, beryllium (Be) 8ppm, and the rest is silver (Ag) with a purity of 99.999wt%.

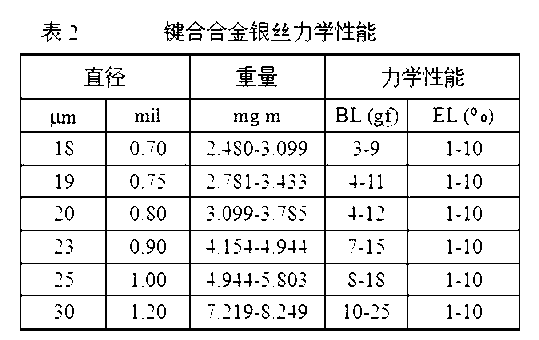

[0087] The product model is KT1, and its mechanical properties are shown in Table 3.

[0088] Its preparation method comprises the following steps:

[0089] 1) Smelting master alloy

[0090] a. The method of smelting Au-Be master alloy is:

[0091] The purity by weight is 99.999wt%, gold 99.20wt%-99.60wt%, and beryllium sheet 0.40wt%-0.80wt%.

[0092] i), Feeding: Put the gold that accounts for 90-95% of the total weight of gold directly into the large crucible in the furnace, and make the rest of the gold into gold foil, wrap the broken beryllium sheets in the gold foil and put...

Embodiment 2

[0126] The difference between this embodiment and embodiment 1 is:

[0127] The bonding alloy silver wire in this embodiment is composed of metal materials in the following weight ratio: gold (Au) with a purity of 99.999wt% 8wt%, palladium (Pd) with a purity of 99.97wt% 3 wt%, calcium (Ca) 80ppm, cerium (Ce) 60ppm, beryllium (Be) 8ppm, and the remaining content is silver (Ag) with a purity of 99.999wt%.

[0128] The operation process is the same as in Example 1, and the product model name is KT3, and its mechanical properties are shown in Table 3.

Embodiment 3

[0130] The difference between this embodiment and embodiment 1 is:

[0131] The bonding alloy silver wire in this embodiment is composed of metal materials in the following weight ratio: gold (Au) with a purity of 99.999wt% 8wt%, palladium (Pd) with a purity of 99.97wt% 3 wt%, calcium (Ca) 80ppm, beryllium (Be) 8ppm, and the remaining content is silver (Ag) with a purity of 99.999wt%.

[0132] The follow-up process is the same as in Example 1. The product model name is KT5, and its mechanical properties are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com